A Python-Based Tool for Real-Time Reverse Osmosis Data Normalization in Desalination Applications †

Abstract

1. Introduction

2. RO Modeling and Simulation

3. Python Tool Development

3.1. Normalized Permeate Flow

- Here, Qpn represents the normalized permeate flow, Qpo is the operating permeate flow, NDPr is the reference driving pressure, NDPo is the operating net driving pressure, TCFr is the reference temperature correction factor, and TCFo is the operating temperature correction factor.

3.2. Normalized Differential Pressure

- Here, DPn represents the normalized differential pressure, DPo is the operating differential pressure, Qfo is the operating feed flow, Qco is the operating concentrate flow, Qfr is the reference feed flow, and Qcr is the reference concentrate flow.

3.3. Normalized Salt Passage

- Here, SPn represents the normalized salt passage, Cfo is the operating feed salinity, Cfr is the reference feed salinity, Cfo_avg is the operating log mean feed salinity, and Cfr_avg is the reference log mean feed salinity.

4. Results

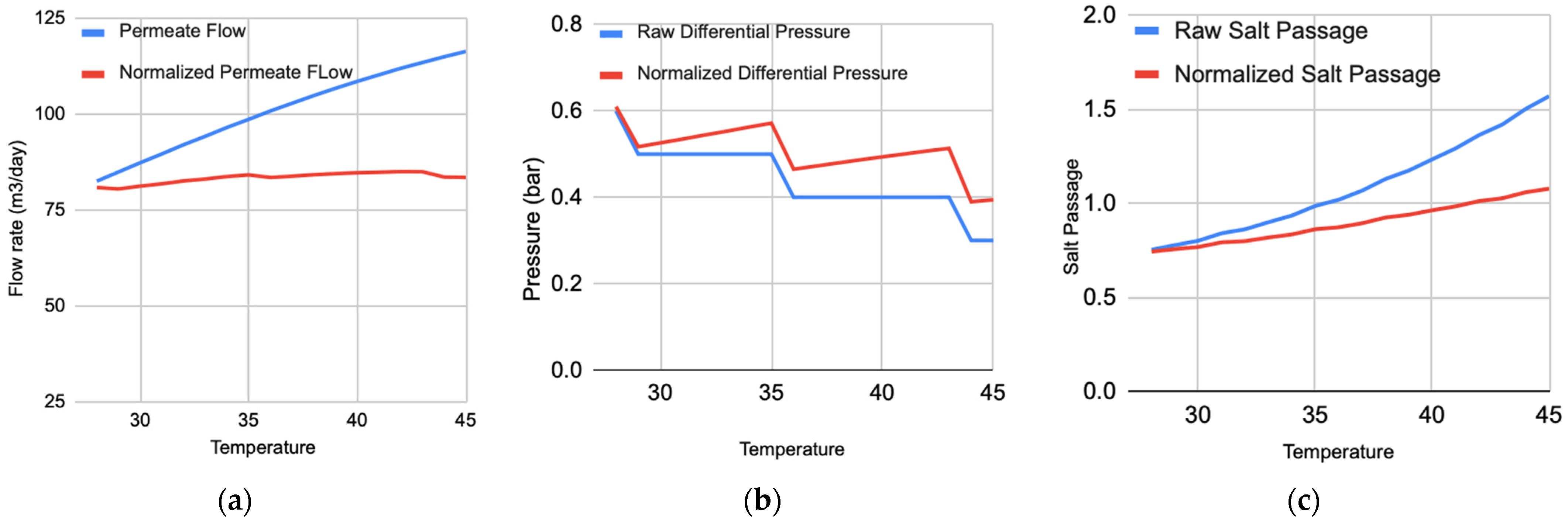

4.1. Case 1: Feed Temperature Variations

4.2. Case 2: Feed TDS Variations

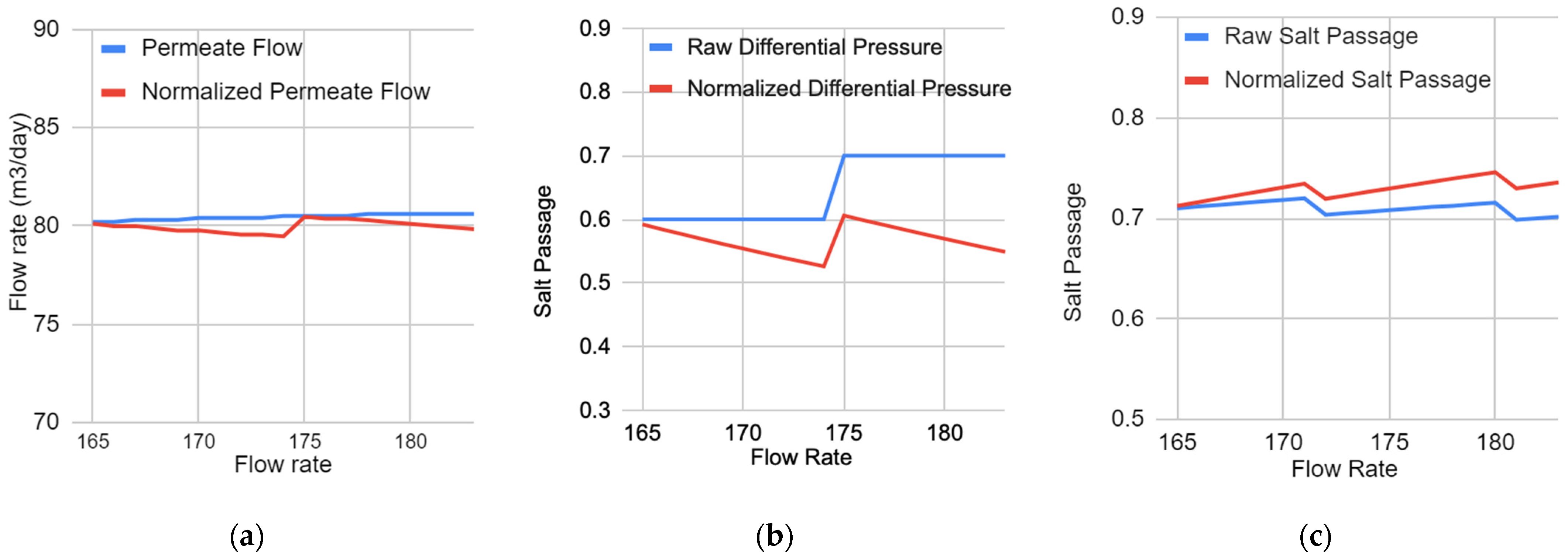

4.3. Case 3: Feed Flow Variations

4.4. Case 4: Flow Factor Variations

5. Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kucera, J. Reverse Osmosis Industrial Applications and Processes, 1st ed.; Scrivener Publishing: Salem, MA, USA, 2010; pp. 3–4. [Google Scholar]

- Dupont. Available online: https://www.dupont.com/water/resources/design-software.html (accessed on 1 April 2024).

| Cases | Feed Flow (m3/Day) | Feed Temperature (°C) | Feed TDS (mg/L) | Feed Pressure (bar) | Flow Factor |

|---|---|---|---|---|---|

| Case 1 | 162–183 | 25 | 1978 | 6 | 1 |

| Case 2 | 162 | 25–45 | 1978 | 6 | 1 |

| Case 3 | 162 | 25 | 1978–2181 | 6 | 1 |

| Case 4 | 241 | 25 | 1978 | 2–10 | 1 |

| Case 5 | 162 | 25 | 1978 | 6 | 0.6–1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Prasad, N.; Maheshwari, A.; Pandian, G.K.; Prasad, V. A Python-Based Tool for Real-Time Reverse Osmosis Data Normalization in Desalination Applications. Eng. Proc. 2024, 69, 98. https://doi.org/10.3390/engproc2024069098

Prasad N, Maheshwari A, Pandian GK, Prasad V. A Python-Based Tool for Real-Time Reverse Osmosis Data Normalization in Desalination Applications. Engineering Proceedings. 2024; 69(1):98. https://doi.org/10.3390/engproc2024069098

Chicago/Turabian StylePrasad, Nitin, Abhilasha Maheshwari, Ganesh Kumar Pandian, and Vijaysai Prasad. 2024. "A Python-Based Tool for Real-Time Reverse Osmosis Data Normalization in Desalination Applications" Engineering Proceedings 69, no. 1: 98. https://doi.org/10.3390/engproc2024069098

APA StylePrasad, N., Maheshwari, A., Pandian, G. K., & Prasad, V. (2024). A Python-Based Tool for Real-Time Reverse Osmosis Data Normalization in Desalination Applications. Engineering Proceedings, 69(1), 98. https://doi.org/10.3390/engproc2024069098