The relationship between the intensity vectors of the electric field

and the electric displacement

is established through the mathematical expression connecting these two fundamental quantities in the study of electromagnetism. This expression serves as a crucial link in understanding the behavior of electromagnetic fields and their interactions in various physical systems:

Finally, it is crucial to recognize within the domain of electromagnetism that the electric displacement vector D assumes a pivotal role in upholding Gauss’s theorem, especially in situations devoid of unbound electric charges, thereby underscoring its importance in insulating substances characterized by distinct electrical characteristics. The electric displacement vector D is essential in understanding the behavior of electric fields in materials with no free charges, thus highlighting its significance in the study of dielectric properties and their impact on electromagnetic phenomena:

2.2.1. Linear Piezoelectricity

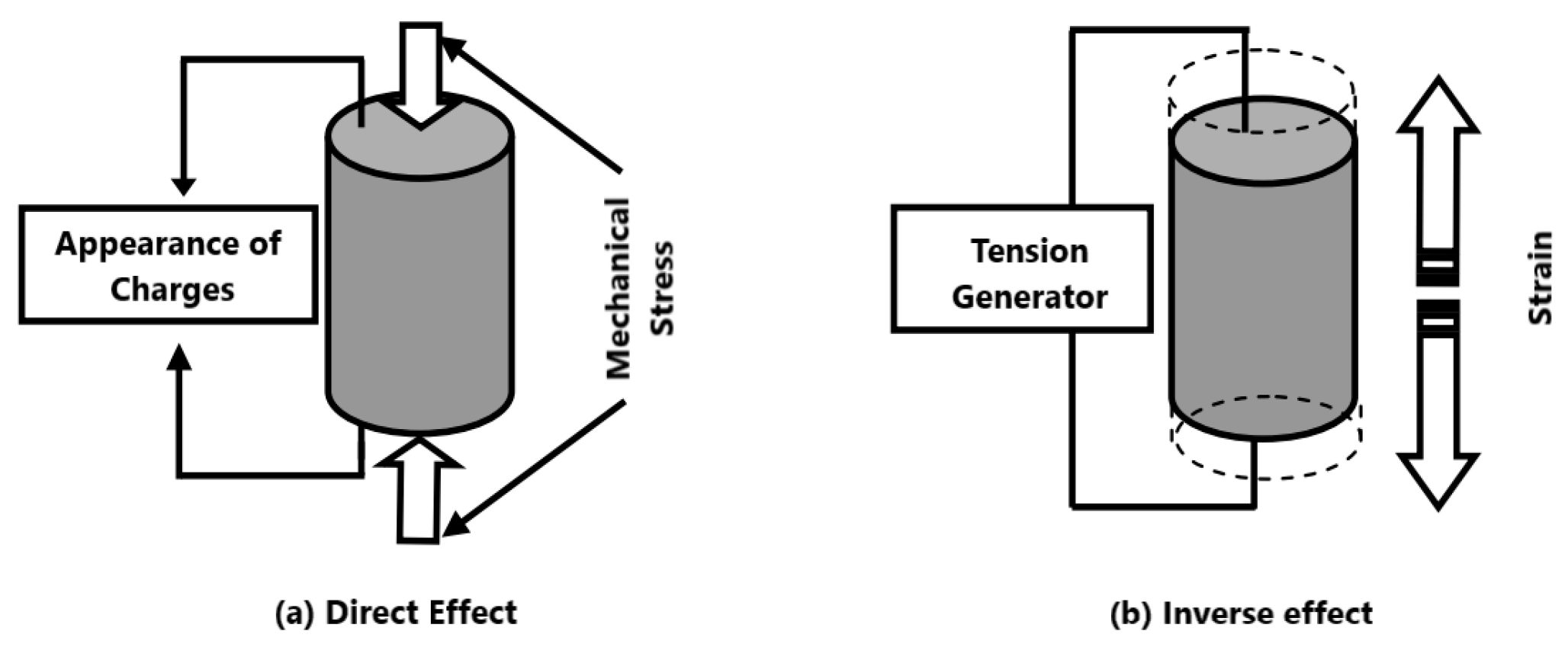

Piezoelectricity emerges as a consequence of the intricate interplay between the electrical energy and mechanical energy inherent in a material, showcasing a fascinating coupling phenomenon. In instances where the pyroelectric effect can be deemed insignificant, the piezoelectric equations effectively establish a profound correlation between a mechanical variable, such as deformation ε or stress σ, and an electrical variable, be it electric induction D or electric field E. These equations serve as pivotal tools in comprehending and characterizing the complex behavior exhibited by piezoelectric materials, shedding light on their unique response to external stimuli. The exploration of these relationships not only enhances our fundamental understanding of piezoelectricity but also paves the way for innovative applications in diverse fields such as sensors, actuators, and energy harvesting devices [

5].

and

are representative of the variables used in the mathematical formulations of stress and strain tensors, which are essential concepts in the study of materials and their mechanical properties, providing a detailed understanding of how materials deform under various conditions and loads. On the other hand,

and

symbolize the quantities associated with the induction and electric field vectors, crucial in the field of electromagnetism and electromechanical systems, playing a fundamental role in the analysis and design of electrical circuits, devices, and machines.

The elastic constants, piezoelectric constants, and dielectric constants, denoted as , , and respectively, are fundamental properties of materials that are quantified under specific conditions: the elastic constants are measured at a constant electric field E, the piezoelectric constants are determined under constant deformations, and the dielectric constants are evaluated at constant electric field strengths.

A more concise representation using matrix notation is possible by condensing the indices

or

into

or

, following the prescribed conventions outlined in

Table 1. This method allows for a more streamlined and efficient way of presenting complex mathematical relationships within the matrix framework.

The constitutive equations, which are fundamental in describing the relationships between different physical properties of materials, can be reformulated and expressed in a more concise and structured manner, allowing for a clearer and more systematic representation of the underlying principles governing the behavior of the system:

2.2.2. General Formalism and Piezoelectric Coefficients

Concerning piezoelectric substances, owing to their anisotropic nature, their attributes are commonly delineated using tensors, which are mathematical entities that comprehensively depict their properties in various orientations and conditions.

The piezoelectric constants (d, e, g, and h) are commonly arranged in matrices with six columns and three rows. Upon transposition, these matrices are represented with a superscript t. Other quantities denoted by superscripts often indicate specific conditions such as constancy or nullity. For example, SE denotes the compliance coefficient under constant or null field conditions, offering valuable insights into the material’s behavior under particular circumstances.

Assuming a voltage denoted by V is applied across two electrodes that are positioned on surfaces perpendicular to the material’s spontaneous polarization, this action leads to a deformation that results in expansion or contraction along direction 3 (A) and directions 1 and 2 (B). In cases where the polarization voltage V is applied to electrodes located on surfaces perpendicular to axis 1, which is also perpendicular to the axis of spontaneous polarization, the deformation experienced by the piezoelectric material will be characterized by shear stresses and strains, indicating a different type of response compared to the previous scenario [

6].

2.2.3. Mode of Deformation

Due to the anisotropy inherent in piezoelectric materials, their deformation occurs preferentially in a specific direction when subjected to an electric field . Understanding the properties of these materials necessitates identifying these preferred directions to comprehend their behavior fully. The characterization of piezoelectric properties relies on a standardized system of symbols and notations, which serves as a common language for researchers and engineers in the field.

Typically, a piezoelectric ceramic is denoted by a trihedron (O, x1, x2, x3) for reference and analysis. As a convention, there is a tendency to interchange the direction with the polarization direction, often associating them with axis 3 or Oz for simplicity and ease of communication among professionals.

To achieve the desired deformation in piezoelectric materials, a potential difference is applied across the faces perpendicular to axis 3. The application of an electric field aligned with the Oz axis results in three distinct deformation modes, as illustrated in

Figure 2 of the relevant literature. The coupling modes, crucial for understanding material behavior, are specified by a pair of numerical values: the first representing the direction of the electric field applied, and the second indicating the axis along which deformation occurs [

7].

By comprehensively studying these coupling modes and understanding the relationship between applied fields and resulting deformations, researchers can gain insights into the intricate behavior of piezoelectric materials under different conditions. The ability to control and manipulate these deformation modes is essential for various technological applications, such as sensors, actuators, and transducers, where precise and efficient conversion between electrical and mechanical energy is crucial.

Moreover, the systematic analysis of piezoelectric properties and their corresponding symbols and notations enables a unified approach towards studying and utilizing these materials across different disciplines and industries. This standardized system fosters collaboration and knowledge-sharing among experts, facilitating advancements in the development of innovative technologies and applications leveraging piezoelectric effects.

In conclusion, the identification and understanding of directional preferences in piezoelectric materials, as well as the systematic representation of their properties through standardized symbols and notations, are fundamental for advancing research and applications in this field. By delving into the specifics of coupling modes and deformation behaviors, researchers can unlock the full potential of piezoelectric materials for a wide range of technological advancements and innovations [

8].

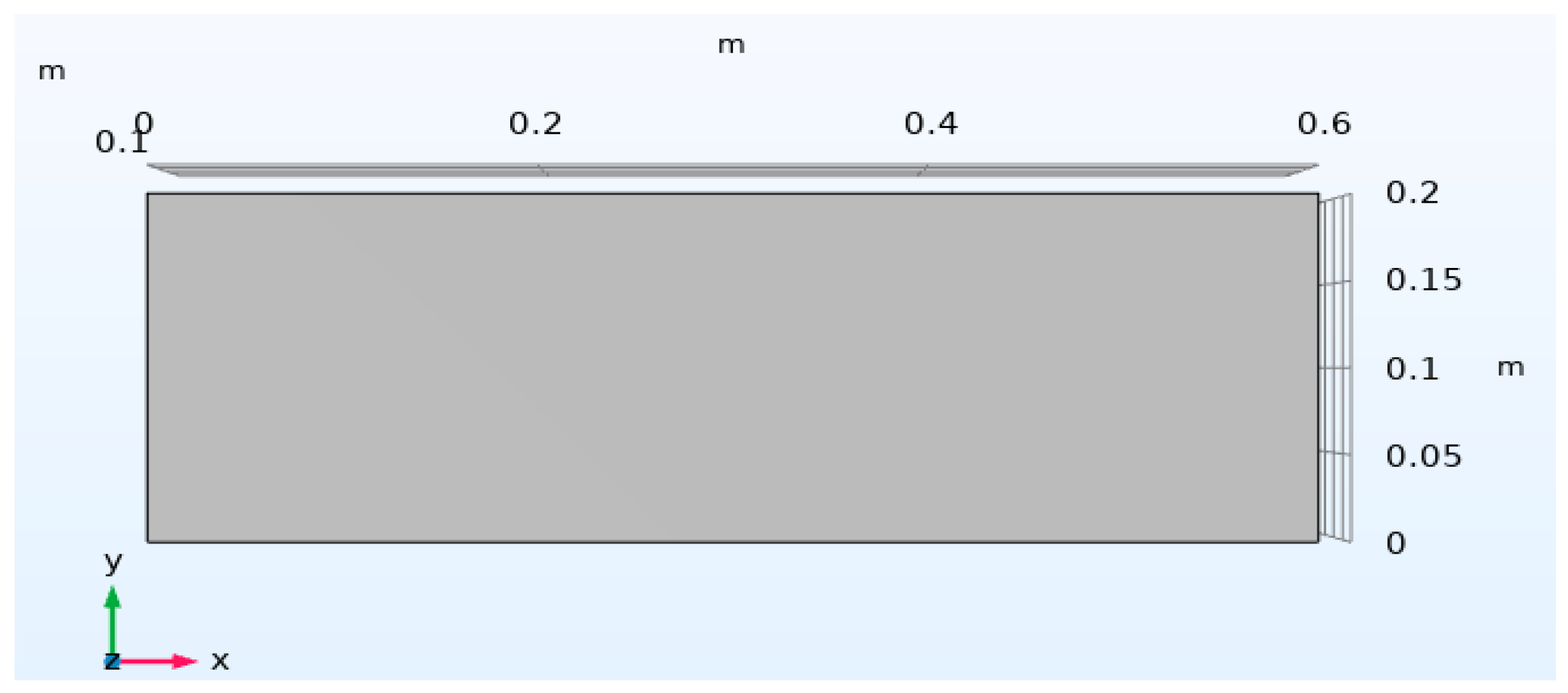

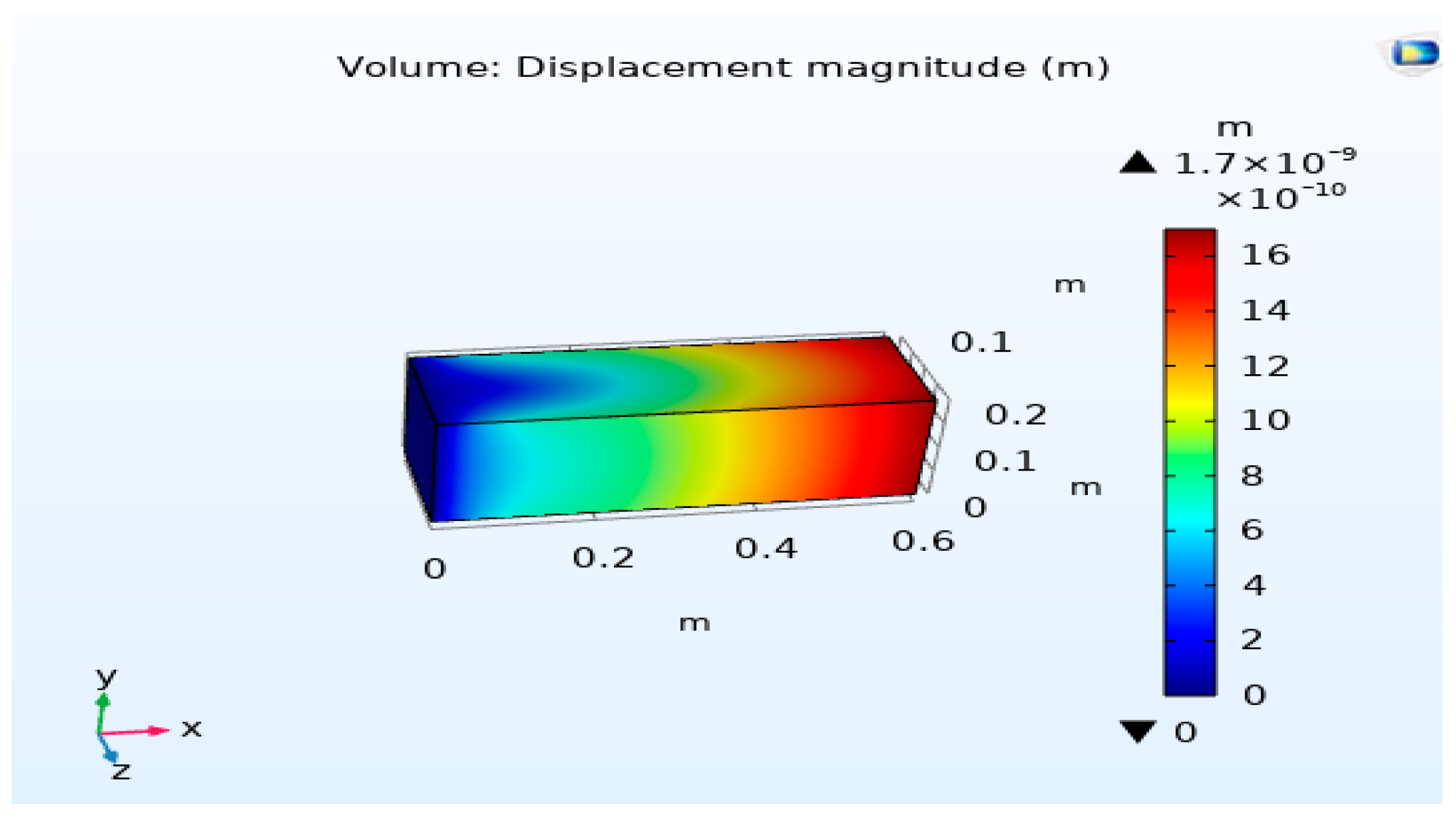

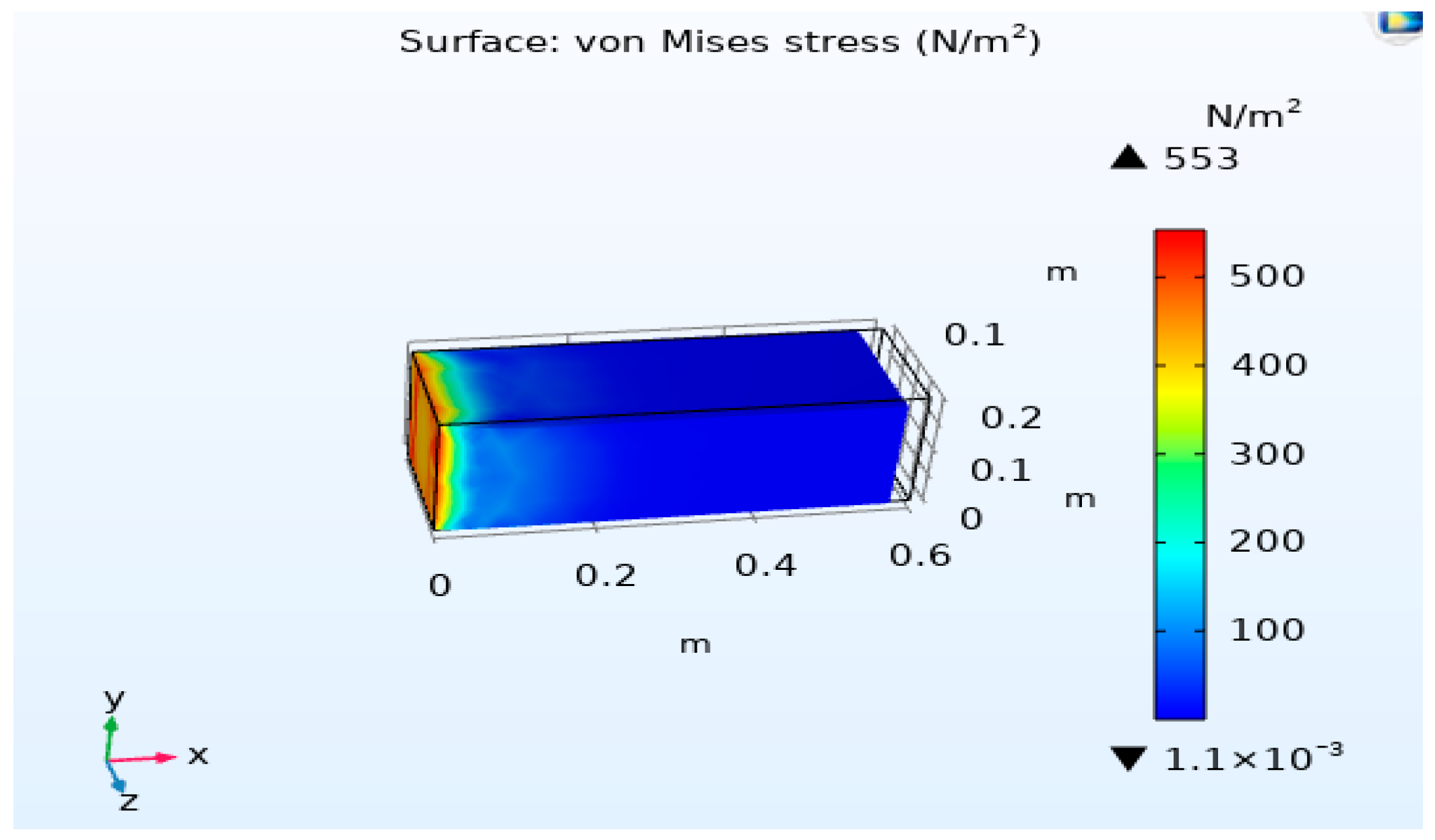

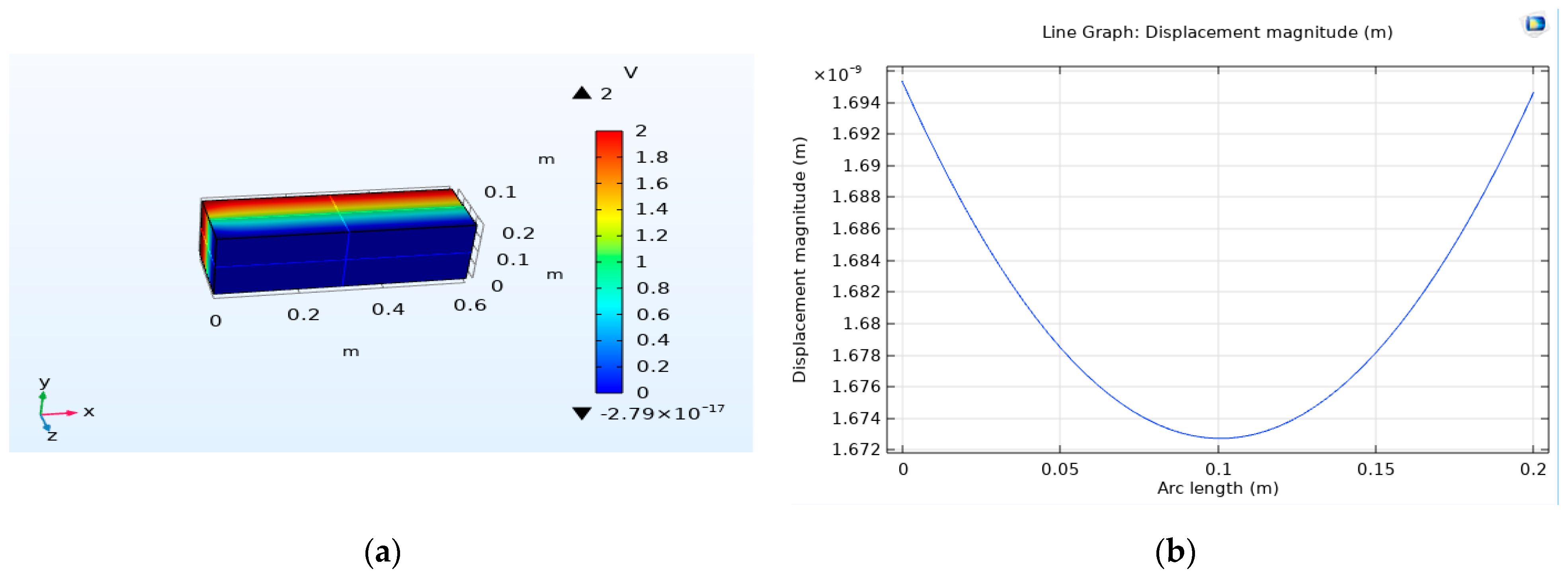

For the purpose of investigating the reverse impact of piezoelectricity, a numerical simulation is conducted on a beam made of PZT piezoelectric material with an opposite polarity configuration. Upon the application of an electric voltage in a transverse manner to the thickness of the beam, the internal deformations occurring within the two layers of piezoelectric material generate control forces that result in the bending of the piezoelectric beams. This process is crucial for understanding the behavior of piezoelectric materials under specific conditions and can have significant implications for various applications. The detailed geometry of the system under consideration is visually represented in

Figure 3, providing a visual aid for comprehending the experimental setup and configuration.

The specific material chosen for this investigative study is a type of piezoelectric ceramic known as PZT-5H, renowned for its unique properties and suitability for such applications. In this experimental setup, the beam is subjected to a unit voltage denoted as V, which is precisely applied to the terminals of the electrodes connected to the piezoelectric material. This controlled application of voltage allows for the precise manipulation of the piezoelectric beam and facilitates the observation of its behavior under varying conditions and electrical stimuli. Such detailed analyses are essential for advancing our understanding of piezoelectric materials and their applications in diverse fields ranging from engineering to biomedical sciences. The utilization of numerical simulations in this context enables researchers to explore the complex interactions and responses exhibited by piezoelectric materials, paving the way for innovative technological developments and scientific discoveries in the realm of materials science and engineering.