A Bottleneck Analysis of Robotics and Automation in the Coca-Cola Production Line †

Abstract

1. Introduction

2. Methodology

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ajenblit, D.A. Applying Genetics Algorithms to the U-shaped Assembly Line Balancing Problem. In Proceeding of the IEEE Conference of Evolutionary Computation, Anchorage, AK, USA, 4–9 May 1998; pp. 96–101. [Google Scholar]

- Yin, X.; Pan, L. Direct adaptive robust tracking control for 6 DOF industrial robot with enhanced accuracy. ISA Trans. 2018, 72, 178–184. [Google Scholar] [CrossRef] [PubMed]

- Heizer, J.; Barry, R. Production and Operation Management; Allyn and Bacon Inc.: Boston, MA, USA, 1988. [Google Scholar]

- Ribeiro, J.; Lima, R.; Eckhardt, T.; Paiva, S. Robotic Process Automation and Artificial Intelligence in Industry 4.0—A Literature review. Procedia Comput. Sci. 2021, 181, 51–58. [Google Scholar] [CrossRef]

- International Labour Office. Introduction to Work Study, 3rd ed.; ILO Press: Geneva, Switzerland, 1979. [Google Scholar]

- Goldratt, E.M. The Goal, 4th ed.; The North River Press Publishing Corporation: Great Barrington, MA, USA, 2014. [Google Scholar]

- Rout, A.; BBVL, D.; Biswal, B.B.; Mahanta, G.B. Optimal trajectory planning of industrial robot for improving positional accuracy. Ind. Robot. Int. J. Robot. Res. Appl. 2021, 48, 71–83. [Google Scholar] [CrossRef]

- Rout, A.; Mahanta, G.B.; Gunji, B.; Deepak BB, V.L.; Biswal, B.B. Kinematic and dynamic optimal trajectory planning of industrial robot using multi-objective ant lion optimizer. In Advances in Mechanical Engineering: Select Proceedings of ICRIDME 2018; Springer: Singapore, 2020; pp. 1475–1486. [Google Scholar]

- Mohamed, A.; Ben, J.; Muduli, K. Implementation of Autonomous Maintenance and Its Effect on MTBF, MTTR, and Reliability of a Critical Machine in a Beer Processing Plant. In Applications of Computational Methods in Manufacturing and Product Design; Springer: Singapore, 2023; pp. 511–521. [Google Scholar]

- Oyekola, P.; Oyewo, T.; Oyekola, A.; Mohamed, A. Arduino based smart home security system. IJITEE 2019, 8, 2880–2884. [Google Scholar] [CrossRef]

| Process | Description |

|---|---|

| Preforms are loaded onto the rinser, and the process starts. |

| The PET preforms are heated to 180 and blown using 40 bar air pressure. The bottle takes the shape of the mold casing. |

| All caps are checked for defects and ovality before being sent to the filler. |

| The mixer processes CO2 + Syrup from the syrup room, chills it to 2 °C, and sends it to the filler for filling. |

| Bottles from the blow mold oven are filled and capped by injecting beverage through a filling nozzle at high pressure. |

| After the bottles are capped, their levels and capping quality are checked using an X-ray camera. Products with lower levels or faulty caps are rejected automatically. |

| The bottles are coded for manufacturing or expiry dates. |

| The bottles are labeled with the trademark label. |

| The bottles are separated into 4-by-6 blocks and wrapped with the shrink film wrapper. |

| The tunnel heats the film and shrinks it at 180 °C. The packs are ready to be palletized. |

| The machine sorts the cases into layers and stack each layer on the pallets. |

| The pallet products are wrapped and sealed as finished goods. |

| Manually driven forklift is used for transportation to storage. End of the line. |

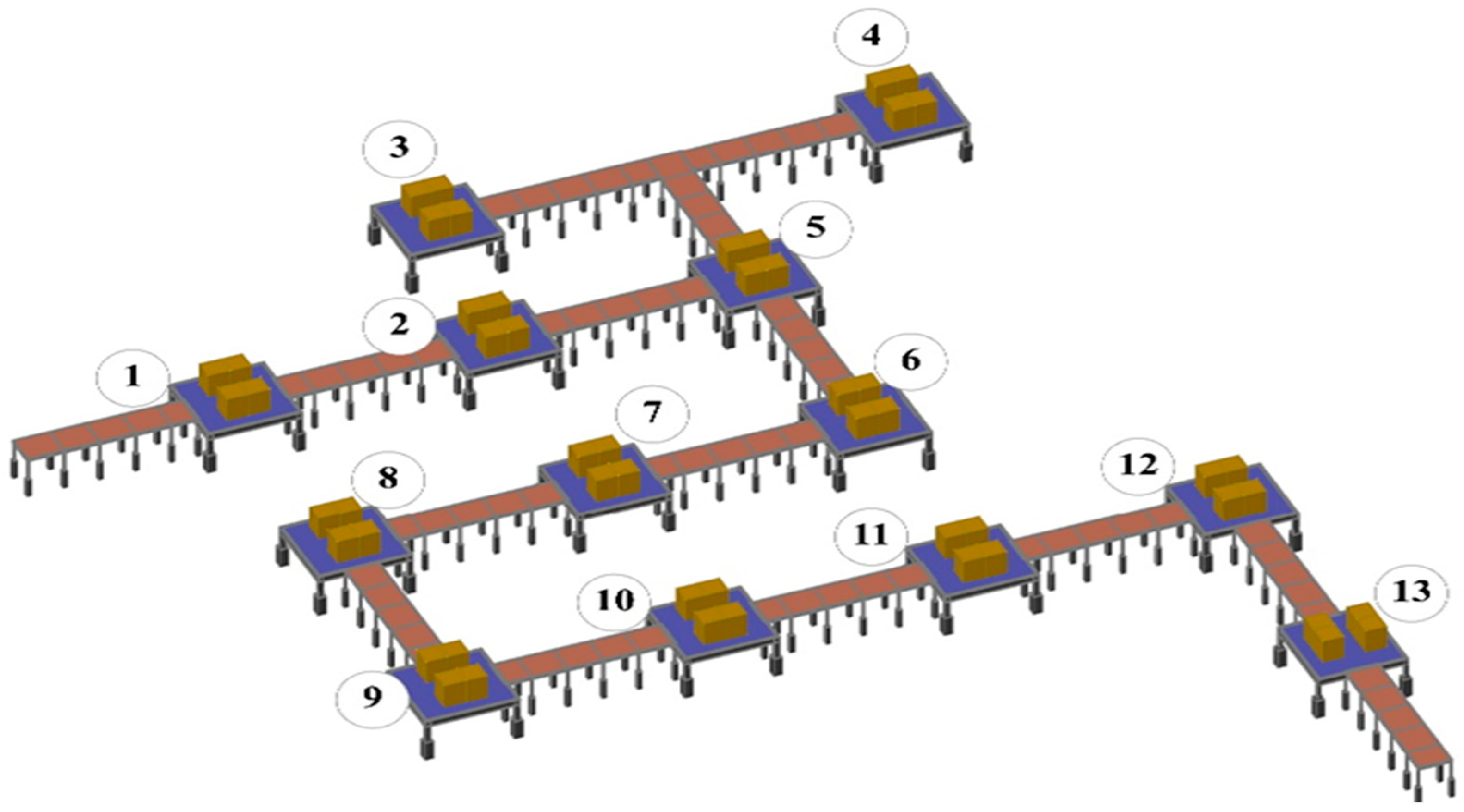

| Operation | Description | Station | No. of Servers | Workload of Station, Sec/Bottle | Convey/Move Sec/Bottle |

|---|---|---|---|---|---|

| Loading | Loading preformed bottles onto conveyor | 01 | 02 | 005 | Start |

| Rinsing | Rinsing each preformed bottle | 01 | 02 | 005 | 030 |

| Blow molding | Blowing the preformed bottles into desired shapes in the mold | 02 | 50 | 060 | 030 |

| Filling | Filling and capping happen in the same station | 03 | 50 | 060 | 030 |

| Fill level inspection | Inspection of the fill level and capping quality | 04 | 01 | 001 | 020 |

| Date coding | Printing of manufacturing date and expiry date | 05 | 01 | 002 | 015 |

| Labeling | Labelling with trademarked labels | 06 | 01 | 030 | 010 |

| Packing | Packing of the bottles into packs/cartons | 07 | 01 | 120 | 120 |

| Palletizing | Sorting of the cartons/packs onto pallets | 08 | 01 | 300 | 420 |

| Stretch wrapping | Wrapping of the pallets | 09 | 01 | 120 | 180 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mai, M.; Kunar, S.; Mohamed, A. A Bottleneck Analysis of Robotics and Automation in the Coca-Cola Production Line. Eng. Proc. 2024, 66, 22. https://doi.org/10.3390/engproc2024066022

Mai M, Kunar S, Mohamed A. A Bottleneck Analysis of Robotics and Automation in the Coca-Cola Production Line. Engineering Proceedings. 2024; 66(1):22. https://doi.org/10.3390/engproc2024066022

Chicago/Turabian StyleMai, Malachi, Sandip Kunar, and Aezeden Mohamed. 2024. "A Bottleneck Analysis of Robotics and Automation in the Coca-Cola Production Line" Engineering Proceedings 66, no. 1: 22. https://doi.org/10.3390/engproc2024066022

APA StyleMai, M., Kunar, S., & Mohamed, A. (2024). A Bottleneck Analysis of Robotics and Automation in the Coca-Cola Production Line. Engineering Proceedings, 66(1), 22. https://doi.org/10.3390/engproc2024066022