Abstract

The implementation of Industry 4.0 can be a challenge for SMEs as often the existing equipment cannot be simply replaced or data cannot be easily extracted from existing equipment. A system that automatically records downtime with minimal operator interaction can be beneficial by giving a clear picture of how a manufacturing process is running, along with providing information on duration, frequency and reasons for stoppages. When this information is available, further analysis can be performed to identify the main reasons for downtime and identify which sections of the production line are more prone to stopping; therefore, corrective actions can be put in place to reduce this. Off-the-shelf IoT equipment was used to develop this system, which reads the status from the signal towers of the line. These data were recorded in an SQL database and an interactive user interface was developed so that downtime codes could be assigned to stoppages and downtime data could be presented in different ways. This case study has shown that a small investment in IoT can make a huge improvement on the ability to monitor and analyse the downtime of a machining line for an SME.

1. Introduction

The Internet of Things (IoT) is an emerging paradigm that enables the communication between electronic devices and sensors through the internet in order to facilitate our lives. IoT uses smart devices and internet to provide innovative solutions to various challenges and issues related to various business, governmental and public/private industries across the world [1]. Industry 4.0 forms a new industrial production method by linking machines and people for a faster exchange of information, supported by web technology and intelligent systems [2]. The implementation of Industry 4.0 can be a challenge for Small and Medium sized Enterprises SMEs as often the existing equipment cannot be simply replaced or data cannot be easily extracted from the existing equipment. A system that automatically records downtime with minimal operator interaction is very beneficial by giving a clear picture of how a manufacturing process is running, along with providing data on duration, frequency and reasons for stoppages. When this information is available, further analysis can be run to identify the main reasons for downtime and identify which sections of the production line are more prone to stopping, and corrective actions can therefore be put in place to reduce these issues.

According to McKinsey’s survey of 130 firm representatives from various industries in China, although Chinese manufacturers have great enthusiasm and expectations for Industry 4.0, they have more doubts about implementing specific strategies. Only 57% of Chinese companies are fully prepared for Industry 4.0, far lower than the United States (71%) and Germany (68%). Among them, state-owned enterprises are the most conservative, while private enterprises are bolder: only 44% of state-owned enterprises claim to be ready, while as high as 68% of private enterprises claim the same. The doubts of Chinese manufacturers in digital transformation are likely to come from immature strategies. Although 43% of Chinese companies said that they have formulated a macro-level change strategy, only 9% of the companies can really specify a clear division of responsibilities, compared with 33% in the United States, 35% in Germany, and 21% in Japan [3].

An area of manufacturing which is not widely noted as an area to improve efficiency is downtime. Machine downtime results in both the loss of time as well as an increase in company spending. OneServe estimated that downtime costs British manufacturers GBP 180bn per year [4]. Downtime can be attributed to two main areas: planned and unplanned.

2. Methods

The first difficulty in capturing downtime data from existing machines was deciding how to determine when the machine was running. The production line used for this study consisted of multiple CNCs, washers, leak tests and assembly equipment not supplied by the same manufacturer. A common means to indicate whether the machine is running on most industrial equipment is the use of signal towers, typically consisting of a stacked red, amber and green lights, which are fixed to the top of the machine; green generally indicates when the machine is running and red indicates when the machine had stopped.

As all machines in the studied production line have signal towers, as shown in Figure 1, it was possible to use these to determine when the machine was running. In order to capture the machine’s working status, a variety of Brainboxes [5], remote Input /Output devices, were used. To both capture and process the data, a Brainboxes BB-400 Industrial Edge Controller was used along with five ED-516 ethernet to 16 digital inputs. The production line is split into three zones, with ten signal towers in Zone 1, three signal towers in Zone 2 and six signal towers in Zone 3.

Figure 1.

Image showing a typical signal tower [6].

The BB-400 has 8 digital inputs which can read two signal towers and the ED-516 has 16 digital inputs which can read four signal towers. Therefore, one BB-400 and two ED-516 devices were needed for Zone 1 (10 signal towers), one ED-516 for Zone 2 (3 signal towers) and two ED-516 devices for Zone 3 (6 signal towers). The BB-400 is preloaded with Node-RED, a programming tool for wiring together hardware devices, APIs and online services in new and interesting ways. It provides a browser-based editor that makes it easy to wire together flows using the wide range of nodes in the palette that can be deployed to its runtime in a single click [7]. Node-RED was used to create a ‘flow’ which reads the input signals from the signal towers and writes the status to a SQL database.

2.1. Signal Tower Light States

From the machine, there are three light states (0, off; 1, on; and 2, flashing) which the Node-RED flow was programmed to identify. Each zone has one signal tower that gives the overall status for that zone, which has four indication lights: red, amber, green and white. The remaining signal towers for each zone only have three indication lights: red, amber and green.

2.2. Conditions

Certain conditions coming from the signal towers were filtered and ignored so that only relevant information was written into the database. For the CNC machines, often during a tool change, the signal tower lights would flash for a few seconds, indicating a tool change; however, this information was not needed. In order to reduce the number of recorded light changes, the status was filtered to ignore any state change with a duration of less than two minutes. In addition, the trigger for data to be written to the SQL database was when the green light changed states.

2.3. Data Input

The Node-RED software (v0.20.5) writes the signal tower status into the database along with a timestamp. The zone indication has 4 characters, one for each light, red, amber, green and white (RAGW), with the other zones having 3 characters each (RAG) as shown in Table 1.

Table 1.

Signal Tower Status Information.

2.4. Interactive User Interface

Visualization software was needed to show this information and permit the operators to assign downtime codes to the appropriate machine whenever it stopped. Blazor [8] was used to develop an interactive web app, which could be accessed from multiple platforms on and off the shopfloor. The operator logs in to this web app to assign a downtime code against each stoppage.

3. Case Study

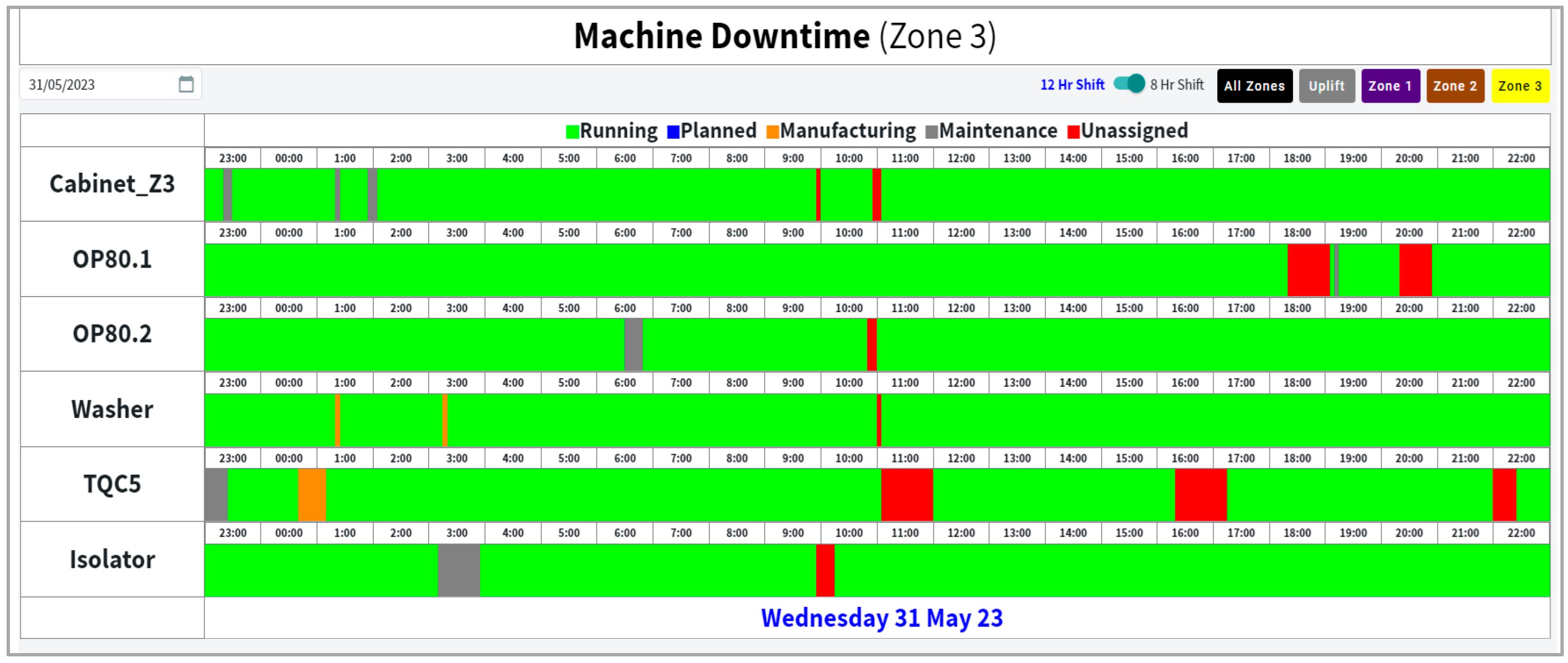

After the installation of the downtime system, all stoppages were automatically recorded against that specific machine. In order for the operator to clear the stoppage, they have to assign a downtime code from an available list that is relevant to that machine; therefore, relevant downtime codes were recorded. To display this downtime information in a clear format, selection can be made for the whole line or by specific zones using a timeline chart indicating when the machine was running/had stopped (colour coded by downtime type, planned, manufacturing or maintenance). From this plot, frequency and duration of stoppages could be easily viewed (Figure 2).

Figure 2.

Image showing timeline chart for Zone 3.

4. Conclusions

This case study has shown that a small investment in IoT can result in a huge improvement on the ability to monitor and analyse the downtime of a machining production line for an SME.

Author Contributions

Conceptualization, D.S. and A.L.; methodology, D.S., A.L. and A.J.; software, A.L. and A.J.; validation, D.S., A.L. and A.J.; formal analysis, A.L.; investigation, A.L.; resources, D.S. and A.L.; data curation, A.L.; writing—original draft preparation, A.L.; writing—review and editing, D.S. and A.J.; visualization, A.L.; supervision, D.S.; project administration, D.S. and A.L.; funding acquisition, D.S. and A.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Invest NI, grant number 1911/13179868.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Restrictions apply to the availability of these data. Data were obtained from Ryobi, Inc. and are available at d.soban@qub.ac.uk with the permission of Ryobi, Inc.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Sfar, A.R.; Zied, C.; Challal, Y. A systematic and cognitive vision for IoT security: A case study of military live simulation and security challenges. In Proceedings of the 2017 International Conference on Smart, Monitored and Controlled Cities (SM2C), Sfax, Tunisia, 17–19 February 2017. [Google Scholar]

- Rauch, E.; Linder, C.; Dallasega, P. Anthropocentric perspective of production before and within Industry 4.0. Comput. Ind. Eng. 2020, 139, 105644. [Google Scholar] [CrossRef]

- Mckinsey.com. China’s Industry 4.0 Road. 2018. Available online: https://www.mckinsey.com.cn/%E4%B8%AD%E5%9B%BD%E5%B7%A5%E4%B8%9A4-0%E4%B9%8B%E8%B7%AF/ (accessed on 1 June 2023).

- Williamson, J. Downtime Costs UK Manufacturers £180bn a Year. The Manufacturer. 2017. Available online: https://www.themanufacturer.com/articles/machine-downtime-costs-uk-manufacturers-180bn-year/ (accessed on 1 June 2023).

- Brainboxes Website. 2023. Available online: https://www.brainboxes.com/ (accessed on 1 June 2023).

- RS PRO Red/Green/Amber Signal Tower, 24 V ac/dc. 2023. Available online: https://uk.rs-online.com/web/p/signal-towers/1902868 (accessed on 1 June 2023).

- Node-RED Website. 2023. Available online: https://nodered.org/ (accessed on 1 June 2023).

- Blazor Website. 2023. Available online: https://dotnet.microsoft.com/en-us/apps/aspnet/web-apps/blazor (accessed on 1 June 2023).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).