Abstract

In previous work, a small electric furnace with a capacity of 3.5 kg of liquid copper, capable of reaching temperatures up to 1200 °C, and with nominal power input of 2.1 or 6.2 kW at 230 V was designed and constructed. The purpose of this furnace was to melt metals for casting replicas of historical weapons, tools, and jewellery from the Bronze Age. The theoretical operating parameters, such as electric energy consumption and the time required to melt the batch of metal, were derived from the design calculations. This study focuses on the experimental determination of the furnace’s operating parameters. Experiments were conducted to determine surface heat losses from the furnace, as well as electric energy consumption and the time required to melt aluminium and copper batches of various quantities during cold starts and continuous furnace operation. The data from these experiments were subsequently analysed to determine the thermal efficiency of the furnace and the cost of energy consumed for melting a batch under given conditions. The experimental results indicate that the furnace does not reach a steady state regarding heat transfer within the time required for melting a batch during cold starts. As a result, the surface heat losses are lower than initially calculated in the theoretical analysis. This leads to shorter required melting times, lower energy consumption, and lower energy costs for the batch compared to design values.

1. Introduction

One of the authors (M.Č.) dedicates a fair part of his free time to historical re-enactment, which includes, among many other activities, crafting of various costumes and replicas of the early Bronze Age. In order to create bronze replicas from this time period, it is necessary to be able to melt and cast said metal.

For this purpose, various furnace designs may be employed. Historically, solid fuel furnaces were used [1]. Initially, a temporarily converted blacksmithing furnace was used, which is a variation of this design. However, this design had problems with achieving the required temperature and long melting times. This prompted a dedicated metal melting furnace build. A properly designed solid fuel furnace would have been possible, but other options were considered as well. One of the design options is a gas fired furnace, which is cheap, simple to build and portable, but has lower energy efficiency due to heat loss in flue gas [2]. Another option is an electric furnace, which is somewhat more complex to build, but offers the best energy efficiency and the possibility of operating indoors.

Therefore, an electric furnace was designed and constructed [3]. The goal of this work is to experimentally determine the operating parameters of the furnace, such as melting time and energy consumption.

2. Materials and Methods

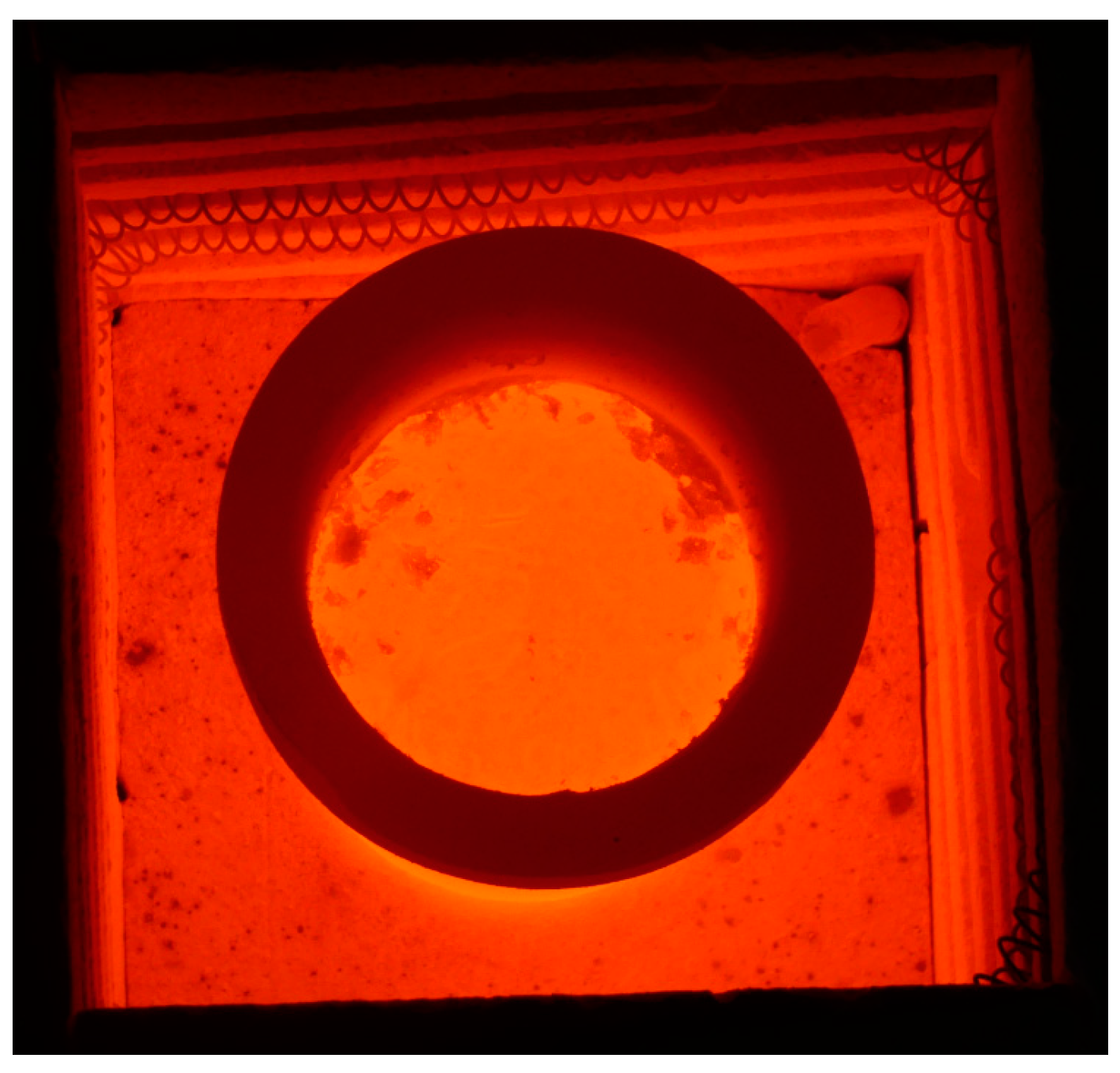

The furnace is built from JM 23 insulating firebricks [4], which displayed the best thermal and mechanical properties out of available materials, with a steel shell around the brick structure. The heating coils are made from Kanthal A1 [5] wire with a thickness of 0.7 mm. The coils are set in grooves carved into the bricks. In order for the furnace to be able to operate on almost any electrical network, it was decided that the maximum current in the coils would be 9 A, which corresponds to a power rating of 2.1 kW (or 6.2 kW for a three-phase configuration) at room temperature. The temperature in the furnace is regulated using a PID regulation unit, containing a REX C-100 FK07 V*AN (RKC Instrument Inc., Tokyo, Japan) temperature controller, which regulates the output power of the furnace using solid-state relays. The temperature inside the furnace is measured using a K-type thermocouple. The inside of the furnace during operation is shown in Figure 1.

Figure 1.

Inside of the furnace during operation.

In an electric furnace, surface heat losses represent the only type of heat losses. Assuming steady state heat transfer conditions, where the temperature inside and on the outside surface of the furnace is constant, several operational parameters of the furnace were determined in the design phase.

Three experiments were conducted in order to determine the operational parameters of the furnace. The first experiment was aimed at determining the steady state losses, while the other two observed real operation of the furnace. The results of the experiments were then compared with theoretical values, which were determined using the same methodology used in the design phase.

The temperature was shown on the display of the PID regulation unit. The power consumption was measured using the A30-BM030-L (BEMKO Sp. z o.o., Jawczyce, Poland) electricity meter. The data were collected using a time-lapse function on a camera, with a picture being taken every 30 s.

2.1. Steady State Heat Losses

Assuming steady state, heat flow from the furnace to the outside environment is given by Equations (1)–(3) [6].

where: Q—heat flow from the furnace to the outside environment, Alm—logarithmic mean of the inside and outside surface area of the furnace, λ—thermal conductivity of the bricks, th—temperature inside the furnace, tw—temperature of the outside surface of the furnace, Aw—outside surface area of the furnace, α—coefficient of heat transfer through convection and radiation, and ta—ambient temperature.

Q = Alm·λ/d·(th − tw),

Q = Aw·α·(tw − ta),

α = 9.77 + 0.07·(tw − ta),

These equations were solved using the solver in MS Excel. Thermal efficiency was the ratio of apparent power (power rating minus heat losses) and power rating.

If steady state is reached, it may be assumed that the electrical energy input is equal to the heat losses. This was the basis of the experiment, where the electricity consumption was measured. The measurement was carried out during both the heat-up and steady state phases of operation. The surface temperature of the furnace was measured using the Powerfix PTSI 9 A1 (Kompernass Handels GmbH, Bochum, Germany) infrared thermometer.

Steady state was assumed once the measured power consumption curve was linear (R2 > 0.9995). The power consumption, and therefore heat losses were represented by the slope of the regression curve. The thermal efficiency of the furnace was determined and the resulting parameters compared with theoretical values.

2.2. Consecutive Aluminium Casting

In order to determine the operational parameters of the furnace during continuous operation, a series of five batches of beverage can aluminium alloy were molten and cast.

The energy required to melt a batch of aluminium from a cold start of the furnace was determined as the sum of the energy required to heat (and melt) the bricks, crucible and aluminium batch to the steady state temperature, whereas the ideal energy input was the amount of heat necessary for the heating and melting of the aluminium batch alone. The real energy used (if proper handling of the furnace is employed) lies somewhere between these two theoretical values, based on how close the furnace is to reaching the steady state of heat transfer.

The cold start and ideal time required to melt a batch of aluminium was determined as the energy required divided by the power of the furnace at operating temperature.

For the experiment itself, the inside temperature as well as electricity consumption was monitored as described in Section 2, during a continuous operation of the furnace. The time of each casting was marked.

The resulting data were used to determine real energy and time necessary to cast each batch using the marked casting time. Furnace efficiency was determined as the ratio of ideal energy required to real energy used. The cost of each batch was determined using the cost of electricity [7]. Additionally, parameters for casting at steady state were determined using apparent power from Section 2.1 to determine real time required.

2.3. Copper Melting

In order to create bronze, it is first necessary to melt copper with a melting point of 1084 °C [8]. Then, the desired amount of tin is added. The resulting bronze has a melting point lower by roughly 100 °C than the melting point of copper, based on the desired composition [9], which means that the melting point of copper is the highest temperature that is required for the operation of the furnace.

The calculation and experiment were carried out in almost the same way as described in Section 2.2, but using copper sourced from cables and a single batch. The crucible was filled fully with material before starting the measurement and once the copper was molten, the furnace lid was opened and additional material was added.

3. Results and Discussion

3.1. Steady State Heat Losses

The resulting real energy parameters as well as the theoretical energy parameters determined by the calculation are shown in Table 1.

Table 1.

Results of steady state experiment.

The observed heat losses were lower than anticipated. Therefore, the thermal efficiency was higher. It is important to note that the experimentally estimated wall temperature represents an average, where in reality the areas of the furnace that contained coils inside were close to the theoretical value, whereas the rest of the surface area of the furnace was slightly cooler, causing lower than anticipated heat losses.

3.2. Consecutive Aluminium Casting

The results of consecutive aluminium casting experiment are shown in Table 2.

Table 2.

Results of consecutive aluminium casting.

As can be seen, the energy and time required to melt a batch of aluminium generally decreases as the furnace approaches the steady state. Comparing this performance with industrial scale, natural gas fired counterparts, which show specific consumption of 0.35 kWh/kg of processed aluminium [10], we can see that the furnace is definitely less energy efficient. However, considering the small scale of the furnace, the resulting energy efficiency is satisfying.

3.3. Copper Melting

The results of the copper batch melting experiment are presented in Table 3.

Table 3.

Results of the copper melting experiment.

In this experiment, the energy consumption was higher in comparison with the aluminium casting, due to multiple copper additions with an increased internal furnace temperature, leading to higher losses when opening the lid of the furnace. Nevertheless, this was still lower than the theoretical energy required for a full cold start. The cost of energy for processing material in this furnace is acceptable since it is rather low compared to the price of the material itself and when considering the small quantities used.

4. Conclusions

The operational parameters of an electric furnace were experimentally determined, showing that the real operation of the furnace displays a shorter melting time, and lower energy consumption and cost than initially anticipated during the design phase of the project. Therefore, the determined operational parameters are satisfying, considering the small scale of the furnace as well as the relative simplicity of construction and operation. Thus, the furnace is acceptable for small-scale production needs and therefore its construction and operation trials can be considered successful. In further work, the performance of the furnace with three-phase configuration and possibly 400 V heating coils will be investigated.

Author Contributions

Conceptualisation, M.Č. and M.V.; methodology, M.Č.; software, T.K.; formal analysis, T.K.; investigation, M.Č.; resources, T.K.; data curation, M.Č.; writing—original draft preparation, M.Č.; writing—review and editing, M.V. and T.K.; visualisation, M.Č.; supervision, M.V.; project administration, M.V.; funding acquisition, M.V. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Slovak Research and Development Agency, Grant No. APVV-18-0134 and APVV-19-0170.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All data obtained by calculations are presented in the contribution.

Conflicts of Interest

The authors declare no conflicts of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

References

- Asmus, B. A natural draft furnace for bronze casting. In Metallurgy and Civilisation: Eurasia and Beyond; Archetype: London, UK, 2009; ISBN 1234 5678 9 1011. Available online: https://www.researchgate.net/publication/299536984_A_natural_draft_furnace_for_bronze_casting/stats (accessed on 28 June 2023).

- Propane Fueled Furnace. Available online: https://uk.vevor.com/melting-furnace-c_11137/vevor-6kg-gas-metal-melting-furnace-propane-forge-copper-silver-crucible-w-tong-p_010233051192 (accessed on 29 August 2023).

- Čižmár, M.; Variny, M. Dizajn elektrickej pece pre odlievanie historických replík z doby bronzovej. In Chémia a Technológie Pre Život, 24. Celoslovenská Študentská Vedecká Konferencia S Medzinárodnou Účasťou; Reháková, M., Oravec, J., Eds.; SCHK: Bratislava, Slovakia, 2022; pp. 233–234. ISBN 978-80-8208-083-7. Available online: https://www.uiam.sk/~oravec/svk/e_zbornik_svk_2022.pdf (accessed on 30 August 2023).

- JM® Insulating Firebrick Series. Available online: https://www.morganthermalceramics.com/media/9428/jm-ifb-series_eng.pdf (accessed on 24 August 2023).

- Kanthal® A-1. Available online: https://www.kanthal.com/en/products/material-datasheets/wire/resistance-heating-wire-and-resistance-wire/kanthal-a-1/ (accessed on 24 August 2023).

- Bafrnec, M.; Báleš, V.; Langfelder, I.; Longauer, J. Chemické Inžinierstvo I; Malé Centrum: Bratislava, Slovakia, 1999. [Google Scholar]

- ZSE Integrated Price of Electricity for Households. Available online: https://www.zse.sk/documents/14391116/Cennik_integrovany_domacnosti_EE_01012023.pdf (accessed on 24 August 2023).

- Valigura, D.; Gracza, T.; Lásiková, A.; Mašlejová, A.; Papánková, B.; Šima, J.; Špirková, K.; Tatarko, M. Chemické Tabuľky; SCHK: Bratislava, Slovakia, 2018; ISBN 978-80-227-3565-0. [Google Scholar]

- Turner-Walker, G. A Practical Guide to the Care and Conservation of Metals; Council for Cultural Affairs: Taipei, Taiwan, 2008; ISBN 978-986-01-7298-0.

- Dzurňák, R.; Varga, A.; Jablonský, G.; Variny, M.; Atyafi, R.; Lukáč, L.; Pástor, M.; Kizek, J. Influence of Air Infiltration on Combustion Process Changes in a Rotary Tilting Furnace. Processes 2020, 8, 1292. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).