Abstract

This research aimed to determine the effect of modified kepok banana starch substitution on the texture (hardness, adhesiveness, cohesiveness, and gumminess) and caramel sponge color with four different modified starch substitution percentages. This research is experimental research with RAL (Completely Randomized Design). The research results show that the values of hardness for caramel sponge cake were 27.48 N, 26.89 N, 26.86 N, and 16.66 N. The values of adhesiveness were 0.38 Nmm, 0.14 Nmm, 0.63 Nmm, and 1.21 Nmm. The cohesiveness values for the caramel cake were 0.34, 0.43, 0.40, 0.31. The values of gumminess were 9.85 N, 11.90 N, 11.02 N, 5.20 N. The L values for caramel cake were 26.61, 25.92, 32.00, and 32.31. The a values for caramel cake were 7.22, 8.83, 8.34, and 6.73, whereas the b values were 15.17, 13.64, 14.84, and 11.56. This research demonstrates that there is an effect of modified kepok banana starch substitution on the texture profile of hardness and on the L value of caramel cake color.

1. Introduction

Caramel cake, also called cake caramel or ant nest cake, is a cake that is liked by many people. There are several unique characteristics of caramel cake: it is fluffy, round in shape, has a soft texture, has a cavity resembling an ant's nest, has a distinctive caramel aroma, and tastes sweet [1]. The diversity of types of food processing in Indonesia that use wheat flour as raw material increases the demand for wheat flour.

There are many ways to reduce the use of wheat flour as a raw food material, one of which is by using substituted local food ingredients as raw materials for making various foods. The potential of local kepok banana ingredients in Indonesia opens up opportunities for processing the product into functional food. Functional food is a food product that has benefits for consumer health. One such functional food ingredient being developed is resistant starch [2]. Resistant starch contains prebiotics and provides the feeling of fullness for a long time, which is beneficial for people who are on a diet [3]. Functional food based on resistant starch is needed by the body because it has several benefits, such as reducing the glycemic index of food, acting as a prebiotic, and reducing the risk of obesity, diabetes, colon cancer, coronary heart disease, and stroke [4].

The resistant starch content in kepok bananas can be increased through a physical modification process, such as the autoclaving-cooling method. Resistant starch levels increase with starch modification treatment. Resistant starch is a starch fraction that is resistant to break down by the enzyme α-amylase. This makes it difficult for starch to be broken down into glucose, but it can still be fermented by colonic microbes in the digestive tract [5].

Besides kepok bananas, other local food ingredients, such cassava, can be used to produce functional food. Cassava can be modified and processed into mocaf flour (Modified Cassava Flour). Mocaf flour is processed from cassava via fermentation [6]. Mocaf flour is similar to wheat flour, with characteristics such as being soft, white in color, having no cassava aroma, and containing a lot of starch. Therefore, it can be used as a substitute for wheat flour by 30–100% [7]. Mocaf flour can be used as an alternative food ingredient to replace wheat flour, playing an important role in improving the texture of food products [8].

Texture is an indicator of physical quality which has an important role in food acceptance [9]. Similarly, color is an important attribute in assessing a food ingredient which determines product quality and is first assessed visually [10]. Texture is one of the parameters that can influence the quality of a food product. Texture is related to the hardness of a food, especially in products such as bread and biscuits [11]. Color is one of the determining factors of quality and visually influences the acceptance of a food by the public or consumers [10].

Based on this description, this research aimed to determine the effect of substituting modified kepok banana starch and mocaf flour on the texture and color of mocaf flour caramel sponge cake.

2. Material and Methods

This research was experimental, utilizing a research design; known as RAL (Completely Randomized Design). The percentages of modified kepok banana starch substitution used were 0%, 20%, 40%, and 60%. Each treatment was repeated twice, and the analysis was also repeated twice. This research was conducted between October 2022 and–January 2023. Mocaf flour caramel sponge cake was made at the Food Science Laboratory, Faculty of Health Sciences, Muhammadiyah University of Surakarta. Testing of the texture and color of the caramel cake was conducted at the Food and Agricultural Products Technology Laboratory, Faculty of Agricultural Technology, Gajah Mada University.

2.1. Tools and Materials

The ingredients used to make mocaf flour caramel sponge cake included mocaf flour, modified kepok banana starch, sugar, sweetened condensed milk, margarin, baking powder, baking soda, eggs, and water. The equipment used to make caramel sponge cake included scales, liters, pans, stoves, mixers, spoons, baking sheets, teflon, spatulas, an oven and baking paper.

2.2. Procedure for Making Kepok Banana Starch

The process of making kepok banana starch began with peeling the raw green skin of kepok bananas. The bananas were, then cut in to pieces approximately 1 × 1 cm in size and soaked in water for 5 min. The kepok bananas were sliced and weighed before being crushed into a mush using a blender. Water was added to achieve a ratio of 1:3 (w/v) for blending. The resulting mixture was filtered to separate the starch from the dregs using a filter cloth. The weight of the dregs was measured and water was added to the dregs at ratio of 1:1 (w/v). The mixture needed and filtered again, with filtered water added twice until the results appeared clear. The filtered mixture settled for about 12 h. The sediment was then dried a cabinet dryer at a temperature of aproximately 60 °C for approximately 12 h until the starch texture cracked. Finally, the dried sediment was ground and sieved an 80 mesh sieve [12].

2.3. Procedure for Modification of Kepok Banana Starch

The modification of kepok banana starch was conducted by conditioning the starch to a water content of 20%. The starch was then packaged with HDPE plastic and stabilized in a refrigerator at a temperature 4 °C for 12 h to ensure that the water spread evenly over the starch. The starch was heated using an autoclave at a temperature of 121 °C for 15 min, The starch was cooled at room temperature for 1 h to prevent further gelatinization, cooled at 4 °C for 24 h, dried in an oven at 50 °C for 4 h, ground, and finally sieved using an 80 mesh sieve [13].

2.4. Procedure for Processing Caramel Cake

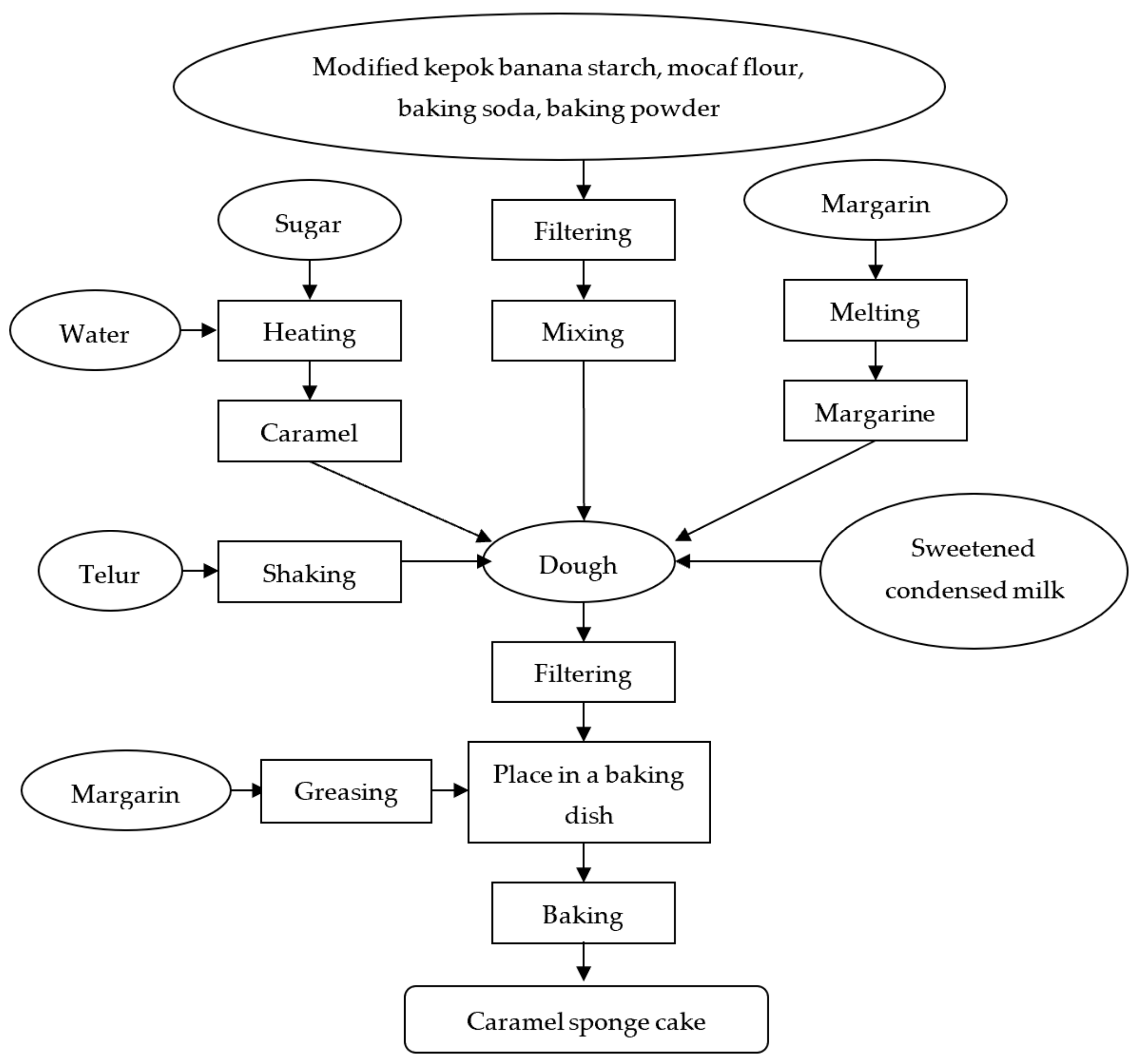

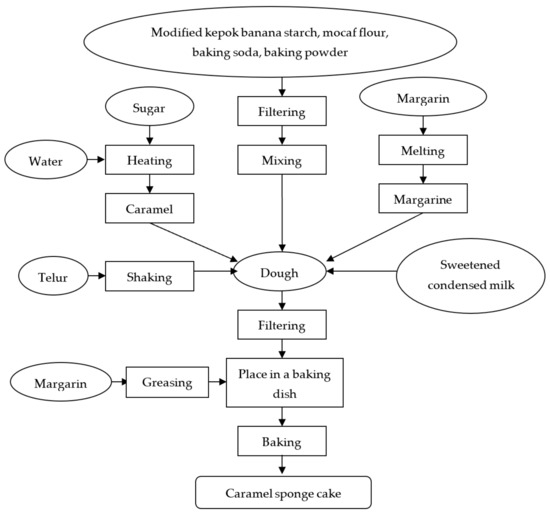

The procedure for processing the caramel cake is shown in Figure 1. The process involved adding sugar (200 g) to a frying pan until it melted. The sugar was cooked over low heat and hot water was added (200 mL) bit by bit and was stirred well. Margarin was melted over low heat, eggs (300 g) were added to the pan, and the mixture was stirred well using a mixer. Then, sweetened condensed milk (200 g) was added, as was, modified kepok banana starch and mocaf flour (0%, 20%, 40%, and 60%). Then baking powder (5 g) and baking soda (5 g) were added and dry (flour) and margarin were added alternately. The mixture was stirred until smooth. Liquid sugar was added to the mixture and the mixture was mixed. Then, the mixture was strained so that the lumpy ingredients were removed. The mixture was baked in a baking pan in the oven for 45–50 min at 180 °C. Once dry, the caramel cake was ready.

Figure 1.

Procedure for processing caramel cake.

2.5. Texture Test Procedure for Caramel Sponge

The parameters of the caramel sponge texture test included hardness, adhesiveness, cohesiveness, and gumminess. The caramel cake sample that was tested was 3 × 3 × 3 cm3 in size. The process began with preparing the Texture Profile Analyzer (TPA) by adapting the tool to a ball probe and the samples. When the tool was tested, the ball probe applied a compressive force to the sample being tested. Then, the results appeared in the form of a curve on the computer monitor [14].

2.6. Color Test Procedure for Caramel Sponge

The color test conducted on the caramel cake obtained the values L, a, and b. The color test was conducted using Chromameter Konica Minolta (CR-400). The test started by preparing a caramel sponge sample. Then, the tools were, programmed (Minolta Reflectance Chrommameter in ON) and calibrated. The sample was positioned for color testing, and L, a, and b color testing values were obtained [15].

2.7. Data Analysis

Data analysis was conducted using SPSS 23 software. Shapiro Wilk test was conducted to determine the normality of the data. The hardness data was analyzed using a one way ANOVA test. A significant difference (p < 0.05) was observed for the substitution of modified kepok banana starch on the hardness of caramel sponge cake, so the statistical analysis was continued using the Duncan Multiple Range Test (DMRT) to determine the differences in each treatment. The cohesiveness and gumminess data was analyzed using a one way ANOVA test. No significant difference was found (p > 0.05). A Kruskal Wallis test was conducted to determine the effect of substituting modified kepok banana starch on the adhesiveness, L value, a value, and b value. There was a significant difference (p < 0.05) observed for the substitution of modified kepok banana starch on the L value, so the Dunnet test was conducted to determine the differences in each treatment. There was no significant difference for adhesiveness, value a, or value b (p > 0.05).

3. Result and Discussion

3.1. Texture

3.1.1. Hardness

The average values of hardness for caramel cake are presented in Table 1.

Table 1.

Average hardness for caramel sponge.

Based on the one-way ANOVA test result, modified kepok banana starch substitution influenced the hardness of caramel sponge (p < 0.05). Statistical tests were then continued using Duncan (DMRT) test, which showed that there was a significant difference betweem the P4 treatments. Based on Table 1, the higher hardness value indicates that the mocaf flour caramel cake had a harder texture.

The hardness level of a food product is influenced by the protein component in flour. Mocaf flour caramel sponge cake does not contain gluten. If non-gluten flour is used, the rising of bread cannot be maximized and denser and harder bread will produced. Without gluten content in bread making, the dough framework cannot form perfectly, so the bread does not sufficiently rise and it has a hard texture [16].

Apart from protein content, the level of hardness is also influenced by starch content. Based on the results in Table. 1, it can be observed that the greater the content of modified kepok banana, the lower the hardness value of the mocaf flour caramel sponge. An increase in the hardness of caramel sponge was observed when treated with a percentage of mocaf flour, which tended to be higher than modified kepok banana starch. Starch with a high amylose content produces a gel that is firm and somewhat hard. The amylose content can form a gel, increasing water binding in the product and narrowing the space between molecules. This results in a compact and somewhat hard texture for the product [17]. The gelation of polymer starch is mainly caused by the aggregation of amylose. As a result, the gelation of starch depends on the presence of amylose [18].

The level of hardness of caramel sponge is also be influenced by the fiber content in the flour used. Mocaf flour contains fiber, and a high fiber content can make the texture of the bread harder. Dietary fiber and hardness are directly proportional relationship; the higher the dietary fiber content, the value higher the hardness value [19]

3.1.2. Adhesiveness

The average values of caramel cake adhesiveness are presented in Table 2.

Table 2.

Average adhesiveness of caramel sponge.

Based on the results of the Kruskal Wallis test, there was no effect of modified kepok banana starch substitution on the adhesiveness of the caramel sponge (p > 0.05). The higher the value of adhesiveness, the higher the stickiness of the material [20]. Adhesiveness is a rheological property related to the attractive force between the surface of food and the surface of other materials in contact with that food [21]. Adhesiveness can be used as an illustration of the stickiness of a product, and is related to starch content. Stickiness is related to the starch content of the material, which forms a gel during the heating process [20]. The amylopectin content in mocaf flour is higher (88.93%), than the amylose content (11.07%) [22]. The amylopectin contained in starch can increase adhesiveness, which will also affect stickiness [23].

3.1.3. Cohesiveness

The average values of the cohesiveness of caramel cake are presented in Table 3.

Table 3.

Average cohesiveness of caramel sponge.

Based on the results of the one way ANOVA, there was no effect of modified kepok banana starch substitution on caramel sponge cohesiveness (p > 0.05). Higher cohesiveness (wholeness) values indicate higher integrity or cohesiveness [20]. Cohesiveness is an indication of the internal forces that shape the food. Higher cohesiveness values suggest that the food product produced is denser and has a more compact texture [24].

Based on the results of the cohesiveness test, the highest level of cohesiveness for caramel cake was obtained with treatment P2. It is suspected that the high amylopectin content resulted from the blend of flour compositions used, which included mocaf flour and modified kepok banana starch. Amylopectin has high adhesive properties, so it can further increase product compactness [23].

3.1.4. Gumminess

The average values of gumminess for caramel sponge are presented in Table 4.

Table 4.

Average gumminess of caramel sponge.

Based on the results of the one way ANOVA, there was no effect of modified kepok banana starch substitution on gumminess for bolu caramel (p > 0.05). Gumminess represents the energy needed to crush food until it is ready to be swallowed [25]. The level of gumminess was obtained by considering the value hardness and cohesiveness by multiplying the two parameters [26]. Based on the overall value of gumminess, the value obtained tended to decrease. This was due to decreased hardness of the caramel sponge with increased modified starch substitution.

3.2. Color

Data regarding the average values of L, a, and b obtained from the color test analysis of caramel sponge cake are presented in Table 5.

Table 5.

Average color of mocaf flour caramel sponge.

3.2.1. The Value of L

Based on the results of the Kruskal Wallis test, there was an effect of modified kepok banana starch substitution on the L value (brightness) of the mocaf flour caramel cake (p < 0.05). The Dunnet test was used to determine whether or not there was a difference in brightness between the treatments. The substitution of modified kepok banana starch in treatment P1 was not significantly different from treatments P2 and P3. The substitution of modified kepok banana starch in treatment P2 was significantly different from the substitution of modified kepok banana starch in treatment P4. The modified kepok banana starch substitution for treatment P3 was not significantly different from P1, P2, or P4. Treatment P4 was not significantly different from treatment P3, but was significantly different from treatments P1 and P2.

The color of caramel cake is influenced by the addition of sugar as a color maker in caramel sponge. Sugar melted into caramel will give a black brown color to caramel sponge [27]. This is related to the caramelization reaction occurring in the sugar added to the dough. Based on the L value test results (Table 5), caramel sponge cake was obtained by substituting a greater percentage of mocaf flour, resulting in a darker caramel sponge color due to the presence of amino acids that react with sugar in the Maillard reaction. The Maillard reaction involves reducing sugars and amine groups from proteins at high temperatures. Following this, a new brown compound appears, namely melanoidin [28].

The substitution of a greater percentage of mocaf flour produces a darker caramel sponge color due to the presence of amino acids that react with sugar in the Maillard reaction. The greater the substitution of modified kepok banana starch, the brighter the color of the caramel cake. Starch-based foods contain fewer amino acids and proteins [29]. Hence, there is a decrease in the Maillard reaction, which is caused by a decrease in amino acid content with the addition of modified kepok banana starch. The decrease in the Maillard reaction can cause a decrease in the brown color of the caramel sponge product, resulting in a brighter colored mocaf flour caramel sponge.

3.2.2. The Value of a

Based on the Kruskal Wallis test results, there was no effect of modified kepok banana starch substitution on the a value (redness) (p > 0.05). The highest a value for caramel cake was obtained in treatment P2 and the lowest value was obtained in treatment P4. Overall, the a value did not show different results, and a positive a value was obtained, namely in the red value range. The a value is represents a mixture of red and green. A positive a value is between 0 and 100 for red whereas a negative a value is between 0 and -80 for green [30].

The test results for the a value (Table 5) demonstrate no significant difference in the positive a value for the caramel cake. All positive a notation values indicate a reddish color. This reddish color is caused by the initial process of adding sugar which has gone through a caramelization process. These results were obtained from color testing using a Lovibond tintometer, a brown product which tends to be a combination of red and yellow [31].

3.2.3. The Value of b

Based on the Kruskal Wallis test results, the b value data shows that the substitution of modified kepok banana starch had no real effect on the b value (yellowness) of the caramel cake (p > 0.05). The overall b value was positive, indicating that the caramel sponge fell within the b value range associated with a yellow color. Positive b values between 0 and 70 indicate yellow, whereas negative b values between 0 and 70 indicate blue [30].

The sugar caramelization process creates a brown crust on the sweet bread so that the bread looks burnt. The level of starch containing amylose in modified kepok banana starch and mocaf flour can cause the color of the caramel sponge to become yellow white. The function of sugar in making caramel cake is to give it a yellow brown color, resulting from the caramelization process [32].

4. Conclusions

There was no effect of modified kepok banana starch substitution on the texture, adhesiveness, cohesiveness, or gumminess profiles of mocaf flour caramel cake. Modified kepok banana starch substitution influenced the hardness of the mocaf flour caramel cake. Modified kepok banana starch substitution affected the color L (brightness) of the mocaf flour caramel cake, but it had no effect on the values of a (reddish color) and b (yellow color) for the mocaf flour caramel cake.

Author Contributions

Conceptualization, N.A.L. and A.S.; methodology, N.A.L. and A.S.; data analysis, N.A.L.; discussion, N.A.L. and A.S.; conclusion N.A.L. and A.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

This research results in this article were carried out in the food agricultural product technology laboratory, faculty of agricultural technology, Gajah Mada University.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

Authors declare no conflicts of interest.

References

- Faridah, A.; Jannah, R.; Marlis, M. Organoleptic Analysis Of The Honeycomb Cake (Kue Sarang Semut). Foodscitech 2020, 3, 24–32. [Google Scholar] [CrossRef]

- Food Quality and Standards Service (AGNS), Food and Agriculture Organization (FAO). Report on Functional Foods. Available online: http://ernaehrungsdenkwerkstatt.de/fileadmin/user_upload/EDWText/TextElemente/PHN-Texte/WHO_FAO_Report/Functional_Foods_Report_FAO_Nov2007.pdf (accessed on 12 January 2023).

- Musita, N. Kajian Kandungan dan Karakteristiknya Pati Resisten Dari Berbagai Varietas Pisang. J. Din. Penelit. Ind. 2012, 23, 57–65. [Google Scholar]

- Nur, A.; Suloi, F. Potensi Pati Resisten Dari Berbagai Jenis Pisang-A Review (Potential Resisten Starch Prepared by Banana-A Review). J. Penelit. Dan Pengemb. Agrokompleks 2019, 2, 92–96. [Google Scholar]

- Birt, D.F.; Boylston, T.; Hendrich, S.; Jane, J.L.; Hollis, J.; Li, L.; Whitley, E.M. Resistant Starch: Promise for Improving Human Health. Adv. Nutr. 2013, 4, 587–601. [Google Scholar] [CrossRef] [PubMed]

- Rasyid, M.I.; Maryati, S.; Triandita, N.; Yuliani, H.; Angraeni, L. Karakteristik Sensori Cookies Mocaf dengan Substitusi Tepung Labu Kuning. J. Teknol. Pengolah. Pertan. 2020, 2, 1–7. [Google Scholar] [CrossRef]

- Salim, E. Mengolah Ubi Kayu (Manihot utilisima) Menjadi Tepug Mocaf Bisnis Produk Alternatif Pangan Pengganti Terigu; Lily Publisher: Yogyakarta, Indonesia, 2011. [Google Scholar]

- Suharno. Tepung Mocaf Sebagai Alternatif Pengganti Tepung Terigu; BPTP: Yogyakarta, Indonesia, 2012. [Google Scholar]

- Santoso, U.; Setyaningsih, W.; Ningrum, A.; Ardhi, A. Analisis Pangan; Dian Rakyat: Jakarta, Indonesia, 2011. [Google Scholar]

- Winarno. Kimia Pangan dan Gizi; Gramedia: Jakarta, Indonesia, 2004. [Google Scholar]

- GLi, W.; Li, G.; Su, B.; Tian, X.; Xu, S. Effect of Sodium Stearoyl Lactylate on Refinement of Crisp Bread and the Microstructure of Dough. Adv. J. Food Sci. Technol. 2013, 5, 682–687. [Google Scholar] [CrossRef]

- Hetty, P.A.; Timur, P.I.; Sri, A.W. Karakteristik pati pisang kepok (Musa paradisiaca var. formatipyca) termodifikasi dengan metode ikatan silang menggunakan sodium tripolyphosphat (stpp). J. Ilmu Dan Teknol. Pangan 2016, 5, 1–10. [Google Scholar]

- Wiadnyani AA, I.S.; Permana ID, G.M.; Widarta, I.R. Modifikasi Pati Keladi Dengan Metode Autoclaving-Cooling Sebagai Sumber Pangan Fungsional. Sci. J. Food Technol. 2017, 4, 94–102. [Google Scholar]

- Choy, A.L.; Hughes, J.G.; Small, D.M. The Effect of Microbial Transglutaminase, Sodium Steroyl Lactylate and Water on The Quality of Instan Fried Noodle. J. Food Chem. 2010, 122, 957–964. [Google Scholar] [CrossRef]

- Setyadjit, R.R.N.; Apriani, M.A. Karakteristis Empat Jenis Umbi Talas Varian Mnetega, Hijau, Smeir, dan Beneng Serta Tepung Yang Dihasilkan Dari Keempat Varian Umbi Talas. J. Ilm. Dan Penelit. Ilmu Pangan 2011, 1, 1. [Google Scholar]

- Zhu, J.H.; Yang, X.Q.; Ahmad, I.; Li, L.; Wang, X.Y.; Liu, C. Rheological properties of Kcarrageenan and soybean glycinin mixed gels. Food Res. Int. 2008, 41, 219–228. [Google Scholar] [CrossRef]

- Dipowaseso, D.A.; Hintono, A. Karakteristik Fisik Dan Daya Oles Selai Kolang-Kaling yang Dibuat Melalui Substitusi Pektin dengan Modified Cassava Flour (MOCAF) sebagai Bahan Pengental Physcal Characteristics and Smearing Ability of Sugar Palm Fruit Jam Made Through Pectin Substitution with Modified Cassava Flour (MOCAF) as Thickening Agent. Available online: www.ejournal-s1.undip.ac.id/index.php/tekpangan (accessed on 12 January 2023).

- Javanmard, M.; Chin, N.; Yusof, Y.; Endan, J. Application of sago starch as a gelling agent in jam. CyTA-J. Food 2012, 10, 275–286. [Google Scholar] [CrossRef]

- Yulifianti, R.; Ginting, E.; Utomo, J.S. Rahmi Yulifianti, Tepung Kasava Modifikasi Sebagai Bahan Substitusiterigu Mendukung Diversifikasi Pangan. Bul. Palawija 2012, 23, 1–12. [Google Scholar]

- Shaliha, L.A.; Abduh SB, M.; Hintono, A. Aktivitas antioksidan, tekstur dan kecerahan ubi jalar ungu (Ipomea batatas) yang dikukus pada berbagai lama waktu pemanasan. J. Apl. Teknol. Pangan 2017, 6, 141–144. [Google Scholar]

- De Man, M.J. Principles of Food Chemistry, 3rd ed.; Aspen Publishers: Gaithersburg, MA, USA, 1999. [Google Scholar]

- Indrianti, N.; Kumalasari, R.; Ekafitri, R.; Andy, D. Darmajana Pengaruh Penggunaan Pati Ganyong, Tapioka, dan Mocaf Sebagai bahan Substitusi Terhadap Sifat Fisik Mie Jagung Instan. Agritech. 2013, 33, 391–398. [Google Scholar]

- Tjokrodikoesomo, P.S. HFS Dan Industri Ubi Kayu Lainnya; Gramedia: Jakarta, Indonesia, 1986. [Google Scholar]

- Haliza, W.; Kailaku, S.I.; Yuliani, S. Penggunaan Mixture Response Surface Methodology Pada Optimasi Formula Brownies Berbasis Tepung Talas Banten (Xanthosoma Undipes K. Koch) Sebagai Alternatif Pangan Sumber Serat. Jurnal Pascapanen 2012, 9, 96–106. [Google Scholar] [CrossRef]

- Szczesniak, A.S. Texture is a sensory property. J. Food Qual. Prefer. 2002, 13, 215–225. [Google Scholar] [CrossRef]

- Trinh, K.T.; Glasgow, S. On the Texture Profile Analysis Test. Available online: https://ibf.iuh.edu.vn/wp-content/uploads/2019/09/tpatest.pdf (accessed on 12 January 2023).

- Jatmiko, F. Pengaruh Suhu Karamel Terhadap Kualitas Kue Sarang Semut; Universitas Negeri Padang: Padang, Indonesia, 2017. [Google Scholar]

- Rauf, R. Kimia Pangan; Penerbit Andi: Yogyakarta, Indonesia, 2015. [Google Scholar]

- Dan, B.Y.M.; Supriyanto, S. Kineteika perubahan kadar 5-Hidroxymethyl-2-Furfural (HMF) bahan makanan berpati selama penggorengan. J. Teknol. Dan Ind. Pangan 2006, 17, 109–119. [Google Scholar]

- Deeth, H.; Lewis, M.J. High Temperature Processing of Milk and Milk Products; John Wiley & Sons: Hoboken, NJ, USA, 2017. [Google Scholar]

- Husin, H.; Rahmi, S.; Pakpahan, N. Pengaruh Substitusi Tepung Modified Cassava Flour (Mocaf) dan Lama Suhu Pemanggangan Terhadap Mutu Roiti Manis. In Prosiding Seminar Nasional Pertanian; Fakultas Pertanian Universitas Samudra: Kota Langsa, Indonesia, 2019. [Google Scholar]

- Ananto, D.S. Sponge Cake: 23 Variasi Cake Dari Satu Adonan Dasar; Demedia: Jakarta, Indonesia, 2012. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).