Effect of Milling Time on the Sensing Properties of Fly Ash Zeolite Composite Thin Films †

Abstract

:1. Introduction

2. Materials and Methods

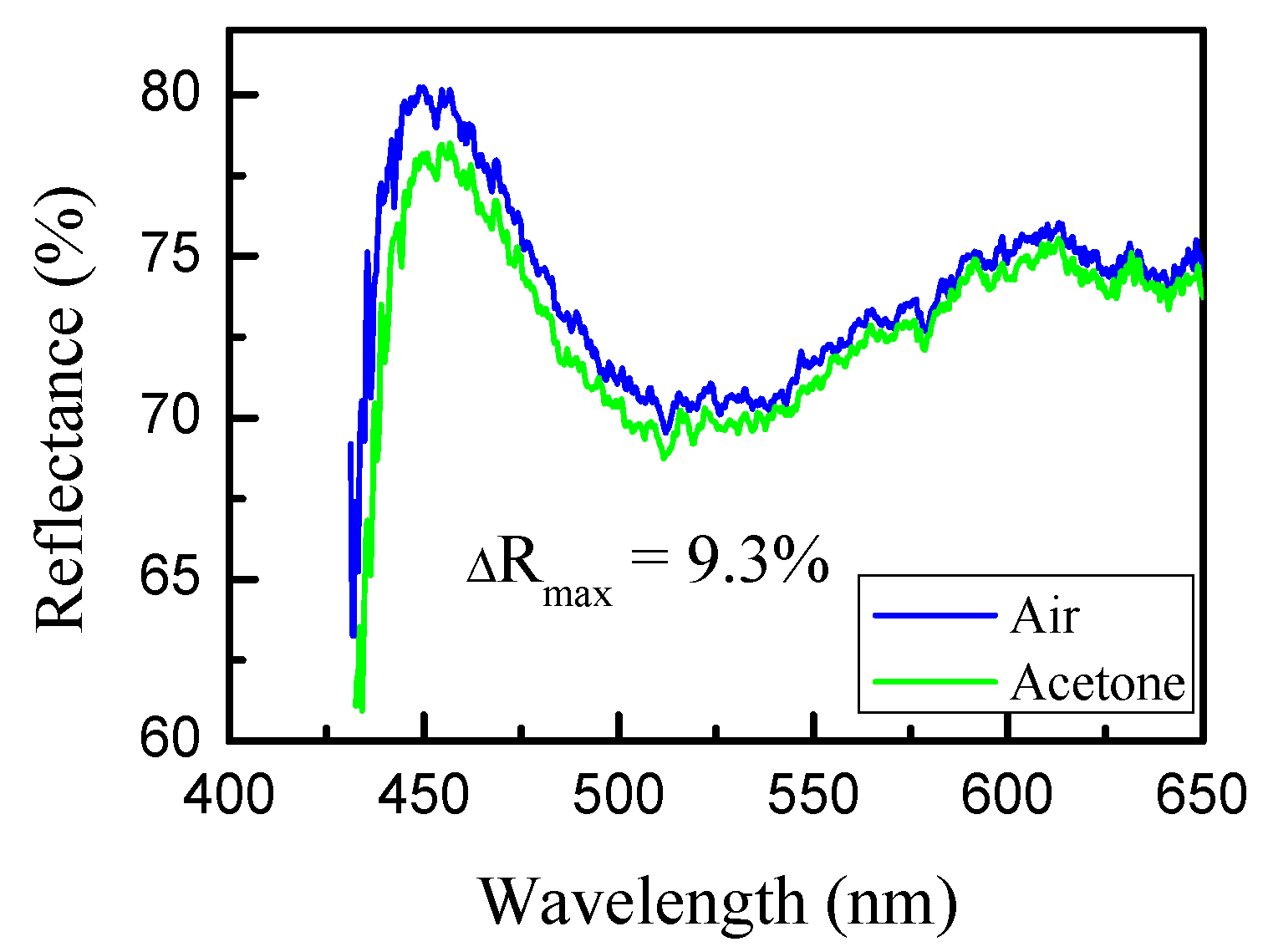

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lazarova, K.; Awala, H.; Fallah, J.; Vasileva, M.; Mintova, S.; Babeva, T. Optimization of optical and sensing properties of sol-gel oxides through zeolite doping. Bulg. Chem. Commun. 2017, 49, 88–94. [Google Scholar]

- Lazarova, K.; Boycheva, S.; Vasileva, M.; Zgureva, D.; Babeva, T. Influence of the Size of Coal Ash FAU Zeolites Used as Dopants on the Sensing Properties of Nb2O5 Thin Films. Mater. Proc. 2020, 2, 682. [Google Scholar] [CrossRef]

- Goldyn, K.; Anfray, C.; Komaty, S.; Ruaux, V.; Hélaine, C.; Retoux, R.; Valable, S.; Valtchev, V.; Mintova, S. Copper exchanged FAU nanozeolite as non-toxic nitric oxide and carbon dioxide gas carrier. Microporous Mesoporous Mater. 2019, 280, 271–276. [Google Scholar] [CrossRef]

- Boycheva, S.; Zgureva, D.; Lazarova, H.; Popova, M. Comparative studies of carbon capture onto coal fly ash zeolites Na-X and Na–Ca-X. Chemosphere 2021, 271, 129505. [Google Scholar] [CrossRef] [PubMed]

- Boycheva, S.; Marinov, I.; Miteva, S.; Zgureva, D. Conversion of coal fly ash into nanozeolite Na-X by applying ultrasound assisted hydrothermal and fusion-hydrothermal alkaline activation. Sustain. Chem. Pharm. 2020, 15, 100217. [Google Scholar] [CrossRef]

- Popova, M.; Boycheva, S.; Lazarova, H.; Zgureva, D.; Lázár, K.; Szegedi, Á. VOC oxidation and CO2 adsorption on dual adsorption/catalytic system based on fly ash zeolites. Catal. Today 2020, 357, 518–525. [Google Scholar] [CrossRef]

- Arfsten, N.J.; Gavlas, J.F. Niobium Oxide-Based Layers for Thin Film Optical Coatings and Processes for Producing the Same. U.S. Patent US6811901B1, 2 November 2004. [Google Scholar]

- Lazarova, K.; Vasileva, M.; Marinov, G.; Babeva, T. Optical characterization of sol–gel derived Nb2O5 thin films. Opt. Laser Technol. 2014, 58, 114–118. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lazarova, K.; Boycheva, S.; Vasileva, M.; Zgureva, D.; Babeva, T. Effect of Milling Time on the Sensing Properties of Fly Ash Zeolite Composite Thin Films. Eng. Proc. 2021, 6, 55. https://doi.org/10.3390/I3S2021Dresden-10068

Lazarova K, Boycheva S, Vasileva M, Zgureva D, Babeva T. Effect of Milling Time on the Sensing Properties of Fly Ash Zeolite Composite Thin Films. Engineering Proceedings. 2021; 6(1):55. https://doi.org/10.3390/I3S2021Dresden-10068

Chicago/Turabian StyleLazarova, Katerina, Silviya Boycheva, Marina Vasileva, Denitza Zgureva, and Tsvetanka Babeva. 2021. "Effect of Milling Time on the Sensing Properties of Fly Ash Zeolite Composite Thin Films" Engineering Proceedings 6, no. 1: 55. https://doi.org/10.3390/I3S2021Dresden-10068

APA StyleLazarova, K., Boycheva, S., Vasileva, M., Zgureva, D., & Babeva, T. (2021). Effect of Milling Time on the Sensing Properties of Fly Ash Zeolite Composite Thin Films. Engineering Proceedings, 6(1), 55. https://doi.org/10.3390/I3S2021Dresden-10068