1. Introduction

Designing secure infrastructures, in addition to considering the conventional design loads that the building must withstand during its service life, must pursue complete structural integrity to minimize personal and material damage in the presence of potential extreme loads that may occur, whether they are of a voluntary or accidental origin. Therefore, when facing events with direct consequences on individuals and material assets, such as ballistic impacts and explosions, it is necessary to understand the appropriate application measures that help minimize their effects and implement these during the design phase.

Specifically when evaluating the case of projectiles, complex phenomena come into play, both in the projectile launching process and on its impact against the target. When they are in the trajectory of a projectile, common materials used in the construction of structures add complexity to the mechanical behavior of the effects produced by high-speed impacts and, therefore, their strain-rate dependance. For this reason, having more complete constitutive models is key to improving protection.

However, most observable phenomena and their interactions require simplifications and pragmatic approaches in order to draw conclusions that can be applied in the field. This fact has been confirmed by many authors. Johnson and Holmquist showed that one of the main disadvantages of their phenomenological model was the difficulty to obtain the relationship between pressure and volumetric deformation [

1]. Also, Zhang et al. recently made an attempt to define a complete group of parameters for a Riedel–Hiermaier–Thoma (RTH) constitutive model, concluding that some parameters should be assumed in order to simulate clay behavior.

Additionally, the economic and time costs of this experimentation make it impractical in many cases to directly obtain and verify these parameters in the field.

Interest in this subject has recently increased, as several researchers use new composite materials to develop brick units. New components, mostly of an organic nature, have been included in the base materials for clay bricks. These materials, some of them presented in

Table 1, are mixed with clay and heated up to 1000 °C to improve the properties of the bricks, or to simply produce good characteristics with very economical costs while using residual materials.

These types of bricks have been mechanically characterized in quasi-static conditions but not at a high strain rate, due to the testing difficulties. As can be seen in

Table 1, in comparison to conventional materials, they can be considered as potentially promising protective materials given their compressive strength.

Hence, in this work, a methodology is proposed for obtaining constitutive model parameters for common construction and protective materials, allowing for the rapid and economic characterization of any type of material by performing ballistics tests and using the bibliographic background.

2. Material Model

The model chosen by the authors was developed by Johnson and Holmquist in 1993 (JH-2). The reason for choosing this model was its phenomenological nature, specifically defined for numerical codes applied to brittle materials subjected to large strains.

Firstly, to be able to apply the methodology described, it is necessary to know the relationship between the sensitivity of the model and its effect on the ballistic penetration curve. To this end, the authors have developed a series of numerical models from which the corresponding ballistic curve is obtained by varying one of the parameters in each case.

The model used is clearly oriented towards the application of numeric hydrostatic codes. From the outset, it is well known that there is no direct procedure for obtaining the variables of the model and that the model is sensitive to slight variations in their value [

9], a fact that is not incompatible with being able to apply an inverse adjustment of the variables from the ballistic curve of the material.

According to the proposed approach, the JH2 model can be considered to transform the incident velocity into a residual velocity. If the solid resists the impact of the projectile, the exit velocity (Vr) is zero; whereas if the solid is unable to withstand the pre-shock produced by the projectile, the residual velocity is greater than zero (Vr > 0).

This approach required us to understand the sensibility of the model and its response to changes. In the first stage, the variation in residual velocity was checked when changes take place in one parameter. Secondly, parameters were grouped and we studied the variation produced in the residual velocity. One of the conclusions from this is that the Johnson–Holmquist model shows little sensibility to changes in one parameter, whereas changing groups of variables had greater effects. This is an advantage of the model; the authors have benefitted to reach enough agreement between numerical Lambert–Jonas curves and tests.

The Johnson–Holmquist model has been described frequently by several authors [

1,

10], being counted on for very interesting reviews and improvements [

11]. Here, only the fundamental equations will be described in

Table 2. The model consists of three different equations; one describes the material strength, another describes the damage accumulation, and the last one relates to the pressures and the volumetric strain, detailed as follows:

On another level, Lambert and Jonas [

12] developed an adjustment expression to represent the ballistic curve as a function of impact velocity (Vs) and residual velocity (Vr).

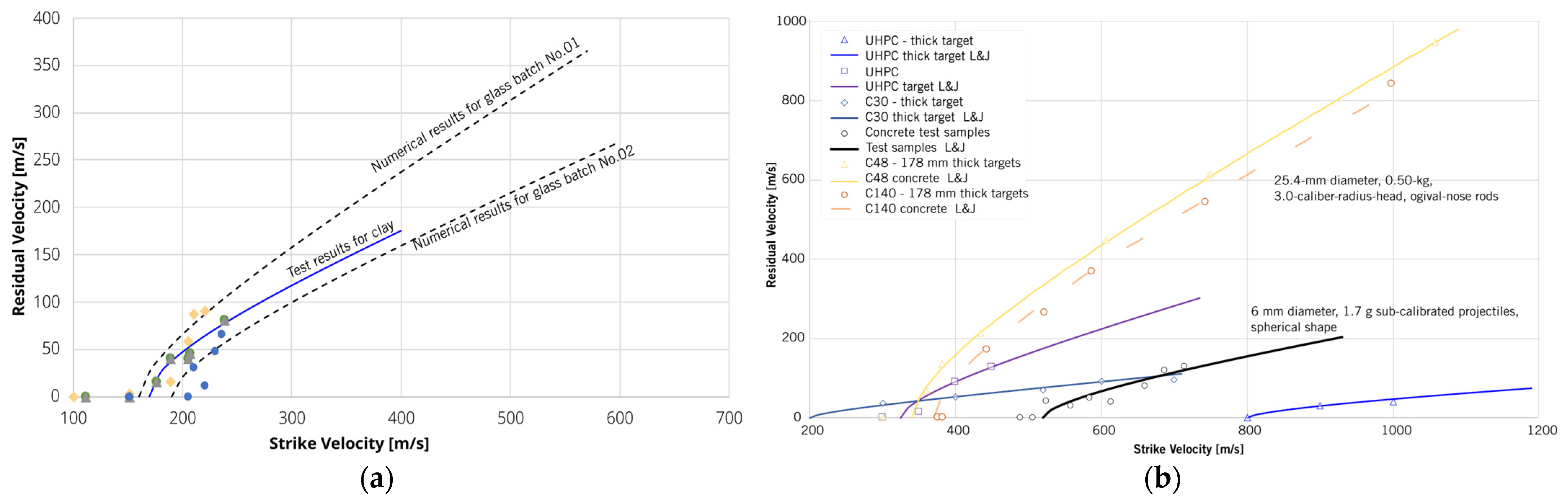

The above was then applied to both clay and concrete samples. In

Figure 1a, two ballistic curves obtained numerically with two sets of parameters from the JH-2 model and published in the literature can be seen. When superimposing both curves next to the one obtained by ballistic penetration tests, it lies between the two. One of the advantages of doing so is that both the numerical models and the tests performed by the authors have the same characteristics of the projectile used and the sample. In

Figure 1b, both the thickness and dimension effects are shown for the C30-class concrete and Ultra High-Performance Concrete (UHPC) numerical curves, together with the C48- and C140-class concrete impact tests produced with different thickness samples and projectiles. Thus, sample thickness and the characteristics of the projectile have an important effect on the resulting ballistic curve.

We can see that the values from the tests carried out by the authors lie between the ballistic curves from the two batches of numerical curves made of residual velocities using two different parameters for glass from the literature. Hence, the values are now at an interval between both, and it is just needed to modify one of them in order to yield an approximate curve for clay.

3. Experimental Methodology

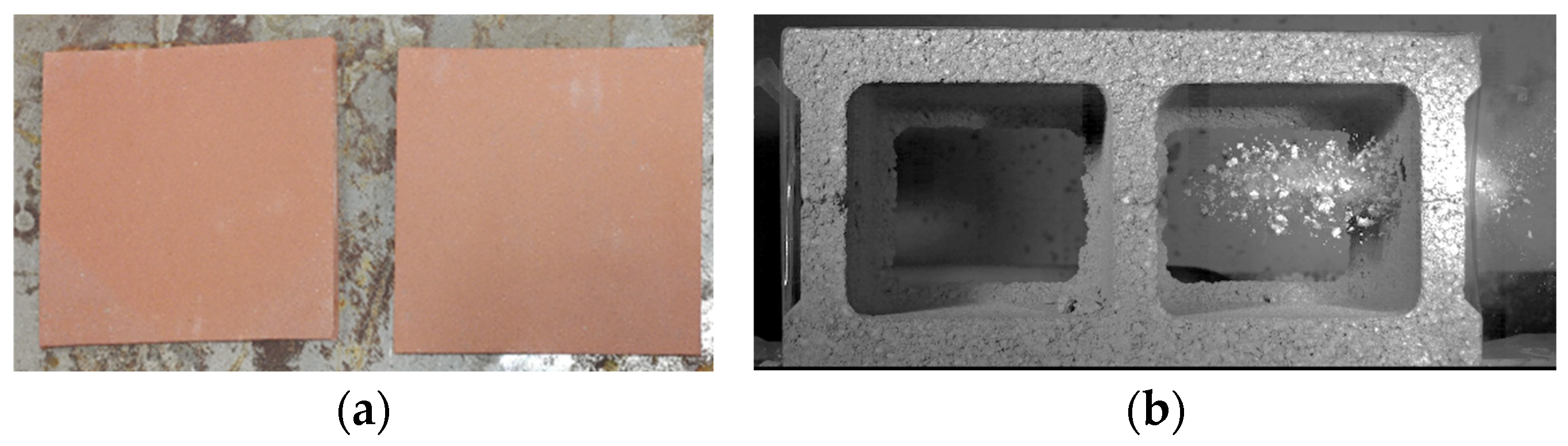

The experimental methodology used consisted of testing eight different types of construction materials under a spherical projectile ballistic impact. Specifically, two of them were chosen to present the methodology: clay slabs and cement blocks (

Figure 2).

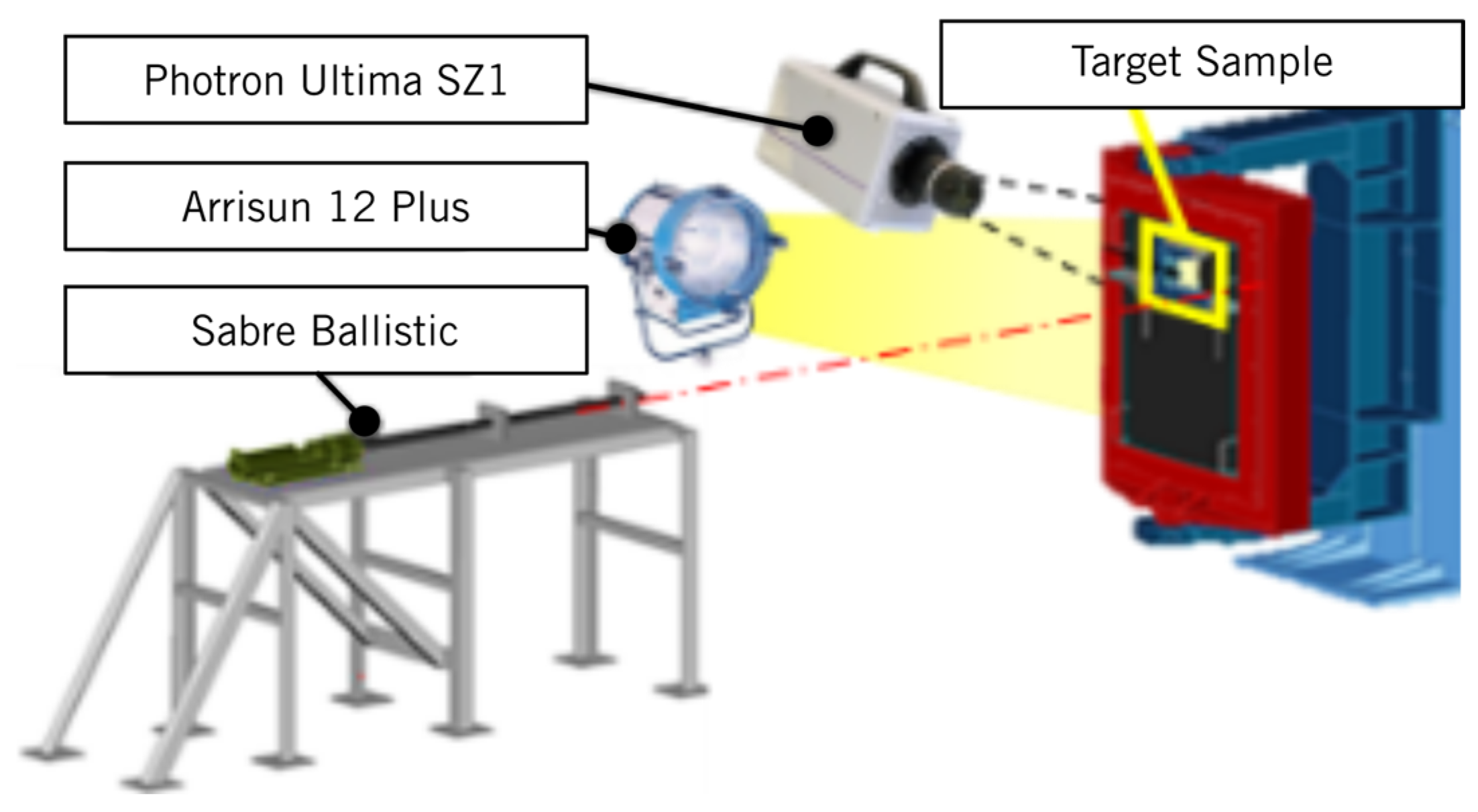

The impact tests were carried out at the Structural Impact Laboratory of the Universidad Carlos III de Madrid, using mild steel spherical projectiles of 7.5 mm diameter and 1.6 g mass, launched using a Sabre Ballistics gas-gun (see

Figure 3).

The projectile was propelled by compressed helium, reaching impact velocities of up to 850 m/s. Using a high-speed camera system capable of acquiring up to 2.1 × 106 FPS (frames per second) and an illumination system, both qualitative and quantitative data on the impact process was obtained, determining the impact velocity of the projectile, , and the residual velocity after impact, , with a measurement error of about 15 m/s.

To minimize the effects of impact inertia, which often lead to premature fracturing of the sample, the slabs were taped to a metal frame. The system was sufficiently solid to reduce the generation of additional debris that would impede the tracking of the projectile. In the case of the concrete blocks, the fixing was more complex since, due to their size, it was not possible to use a metal frame and it had to be ensured that the impact did not dislodge the block.

The procedure followed to obtain the critical velocity was that described by Jonas and Lambert in their report on the standardization of ballistic curves [

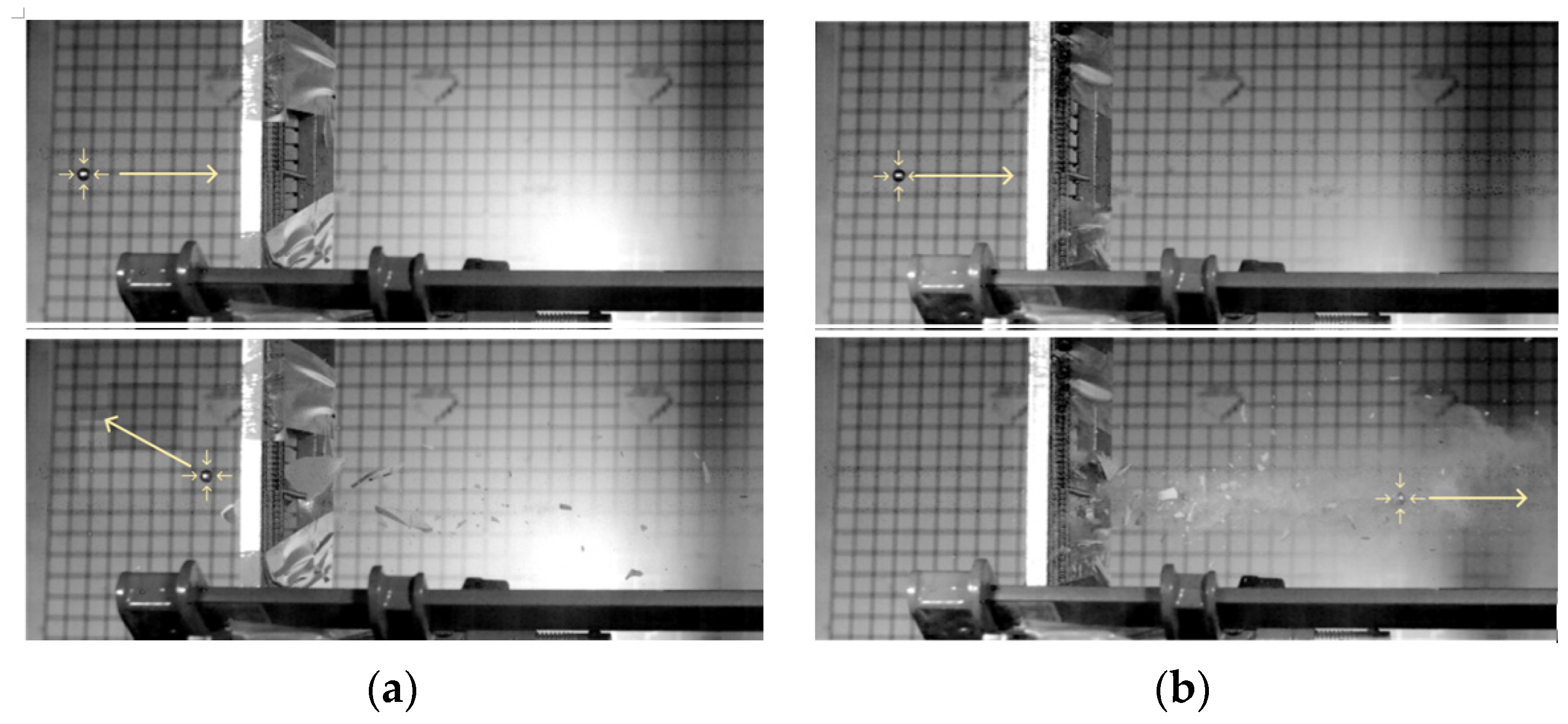

4]. It should be noted that, out of all the materials tested, clay slabs and concrete blocks produced the most visible results (See

Figure 4).

4. Numerical Models

Numerical models were carried out to include a study of sensibility related to the ballistic curve. Previous works evaluated the sensibility of other testing techniques like impact disc and Hopkinson’s pressure bar, but none, to the authors’ knowledge, have been performed on ballistic penetration curves related to the variation of the JH-2 variables.

One of the main conclusions of the sensibility study is that the limit velocity is highly dependent on the combination of the coupled damage variables . Therefore, adjusting both variables at the same time is key to yield the corresponding displacement of the curve; matching the experimental result firstly depends on the variation of these two parameters.

5. Results and Discussion

The ballistic curve of two materials frequently employed as construction materials, as depicted in

Figure 5, have been empirically derived through the utilization of a JH-2 constitutive model. In both cases, the values used led to a conservative numerical ballistic limit velocity value with less than 2% deviation for clay, and 4% for concrete, which substantially improves the initial proposal. The model’s parameters were obtained based on previously documented values from the literature to closely match the experimental outcomes. Subsequently, a comparison was conducted between the ballistic curves of concrete and clay and their respective experimental counterparts.

6. Conclusions

In conclusion, this model demonstrates a commendable level of precision in predicting the ballistic limit, making the acquired parameters well-suited for applications exposed to impulsive loads characterized by similarly high strain rates, such as blast impact scenarios, all the while preserving cost-effectiveness. Consequently, the employment of ballistic impact tests has proven to be an efficient approach for enhancing the performance of ceramic material constitutive models, leading to improved outcomes when applying published parameters within these models.