Abstract

In digital microfluidics, discrete liquid droplets move on a dielectric surface with the help of AC or DC voltage. Digital microfluidics system has extended the scope of microfluidics by providing automated, precise flow control for point-of-care devices capable of medical diagnostics, environmental, and chemical sensing platforms. In this paper, we introduce a digital microfluidics platform based on electrowetting on a dielectric using PCB substrate designed on Easy EDA software. The platform’s performance was analyzed at various DC voltages between 200 V and 400 V for droplet actuation. PCB fabrication, the utilization of easily accessible and cheap materials such as cooking oil and grafting tape as a dielectric layer, allowed the fabrication to be affordable and simple. The results indicate that droplet actuation takes place at 220 V. The droplet velocity obtained was 2.6 mm/s and 1.51 mm/s using silicon oil and cooking oil, respectively, at 400 V. Our proposed digital microfluidics platform will play a vital role in droplet actuation and can be used for diagnostic applications such as DNA analysis and cell culture due to its simple fabrication and cost-effective technique.

1. Introduction

Microfluidics refers to the behavior and control of liquids constrained to volumes near to the microlevel range. The behavior of liquids in the micro domain differs greatly from macroscopic fluids in terms of surface tension, diffusion, and fast thermal relaxation. Electrowetting-on-dielectric (EWOD) is a technique in which we manipulate droplets on a dielectric surface with the help of an electric field developed via the potential difference between electrodes. EWOD applications are suitable for a variety of lab-on-a-chip applications. This capacity makes it possible to manage complex protocol needed for laboratory applications. It is also referred to as digital microfluidics (DMF), which has two types of configurations, i.e., open configuration and closed configuration [1]. The objectives of this platform are to actuate microliter droplets, automate the fluid transportation, and detect protocols for biological and chemical processes. For a variety of droplet activities, closed DMF devices are usually preferred due to their higher functionality and control compared to the open platform. Overall, DMF has the advantages of less reagent usage, quick heat transfer, and simple integration with other analytical methods [2].

There are different configurations used for DMF devices. For instance, a multilayer PCB configuration has been previously implemented using a replaceable membrane of a dielectric layer. The authors used an electrode array, with an ITO glass plate on top, and a replaceable hydrophobic Teflon membrane, which played a critical role in enhancing the reliability of the device [3]. A decade ago, microfluidics devices were not commercially available and were only used for research purposes. However, over the last few years, many researchers have asked the question whether a true lab-on-a-chip device is possible or not. At present, these devices are entering the commercial sector and are being used for a number of applications, most of which are in the field of diagnostics and cell culture [4]. Some researchers have recently considered using high-voltage metal-oxide-semiconductor field-effect transistors (MOSFETS) to overcome its limitations, like reducing power dissipation and increasing switching speed between ON and OFF voltages for electrodes [5].

In this study, we have used a grafting tape dielectric layer with silicon oil and cooking oil as hydrophobic layers, respectively, for the smooth actuation of a droplet on printed circuit board. The oil layer was used to slide the droplet on the PCB substrate with minimal thickness for the smooth movement of the droplet. Using two-dimensional digital microfluidics platforms can provide dynamic configurability and simplicity in automation. The key advantages of DMF devices are the use of a minimum sample volume to limit reagent usage and processing time. Moreover, it enables full automation using Arduino without requiring any manual input.

2. Theoretical Background

External electric field counteracts the surface tension forces, which affect the contact angle of a liquid droplet on a solid surface. The Young–Lippmann equation provides this change in contact angle, :

In this equation, the contact angle, following the application of voltage, is denoted as θ; and are the permittivity of vacuum and the relative permittivity of the material, respectively; d is the thickness of the dielectric layer; represents the surface tension of liquid; and V stands for the applied DC voltage to an electrode. The variable is the initial contact angle of the droplet before it is placed under the influence of the electric field.

3. Materials and Methods

Distilled water was used in all experiments. Printed circuit board (PCB) was purchased from Smart PCBs (Rawalpindi, Pakistan). The size of the electrodes was 2 × 2 mm and the gap between two successive electrodes was 0.2 mm. Grafting tape acting as dielectric layer was used with a thickness of 0.03 mm. Power supply having DC 1000 V and 0.5% ripple maximum current of 1 milliampere was supplied by Qosain Scientific (Lahore, Pakistan).

First, we prepared our sample by pouring the cooking oil on the surface of the electrodes. Afterward, grafting tape was placed on top of the electrodes. The oil layer helped remove any air between the grafting tape and electrodes. For smooth droplet movement, sliding layers of either silicon oil or cooking oil (purchased from the local market) were applied. By applying DC voltage between two electrodes, the droplet actuation was observed with the help of a mobile phone camera. We found contact angles and the velocity of the droplet by performing image analysis using ImageJ software.

4. Results and Discussion

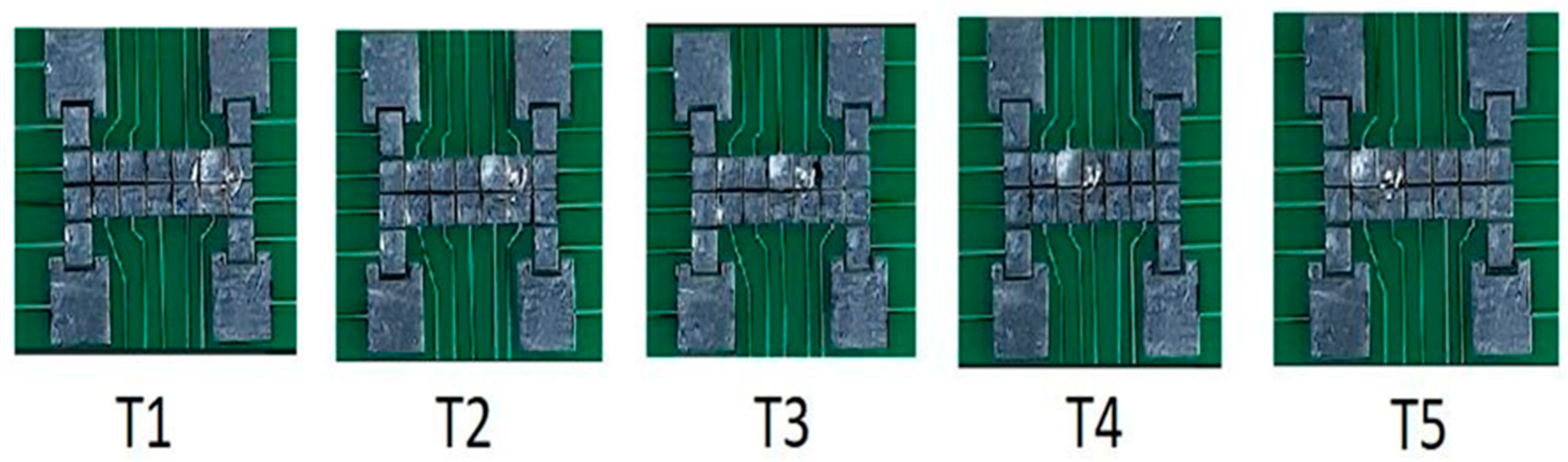

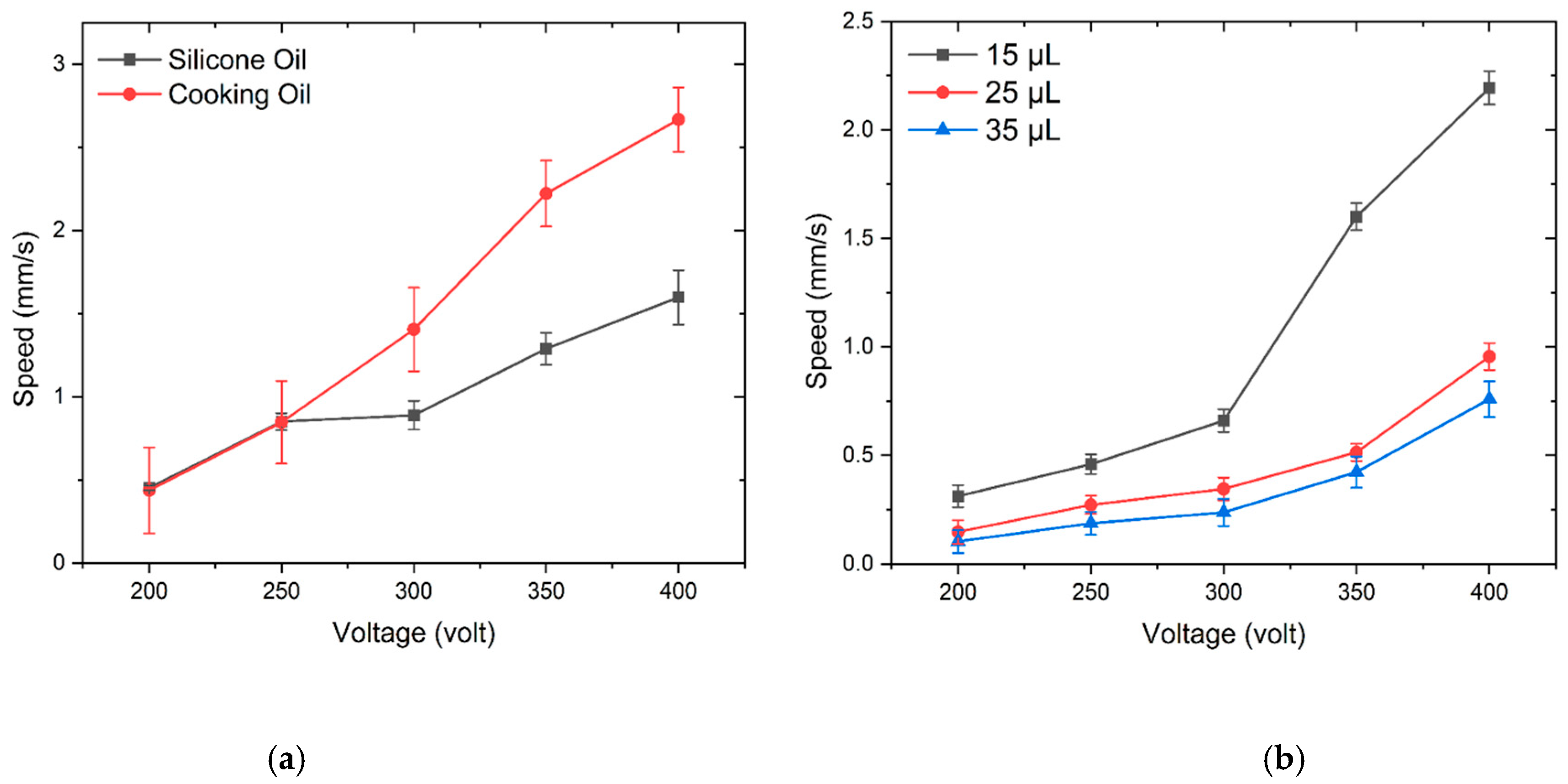

Figure 1 shows the results and validation of droplet movement by applying DC voltage. We found that the droplet movement starts at 220 V. The experimental results further prove that the droplet actuation speed increases with an increase in voltage (Figure 2). To observe other factors affecting speed, we changed the hydrophobic coating from silicon oil to cooking oil and repeated the same experimental procedure. From the scatter-line plot of the two oils, we can observe that for voltages up to 250 volts, the droplet speed on both oil surfaces is roughly the same; however, from 250 volts onward, there is a clear gap between them. The cooking oil yields better results for droplet speed reaching 2.6 mm/s at 400 V compared to 1.51 mm/s when the droplet is on silicon oil. Similar experiments were conducted while changing the electrode size and ultimately, the droplet volume. It is observed that a droplet with lower volume has better actuation results with higher voltages. Moreover, at higher voltages, the difference in droplet speed increases when comparing the three droplet volumes.

Figure 1.

Droplet actuation in 5 frames.

Figure 2.

(a) Droplet speed against applied voltage for silicon and cooking oil; (b) droplet speed with changing droplet volume.

We attribute this change in velocity to the viscosity of the oils used. The viscosity of silicon oil was comparably higher (around 3 times) compared to cooking oil. Since cooking oil is less viscous, it is therefore easy for the water droplet to slide across the electrodes as compared to silicon oil.

5. Conclusions

In this paper, we fabricated a digital microfluidics platform that uses electrowetting as a mechanism for the precise manipulation of microliter volumes of liquid samples. We conducted experiments to analyze the performance of the DMF platform at different voltage levels, ranging from 200 V to 400 V. The fabrication involves an open configuration design that allows for flexibility and versatility. Additionally, we utilized easily accessible materials such as cooking oil and grafting tape, which makes the platform cost-effective and practical for implementation at an industrial scale. Furthermore, we successfully achieved our targets, including developing a cost-efficient platform, achieving linear actuation for a precise liquid manipulation, and merging various components to create a functional system. The droplet velocity ranges from 0.5 mm/s to 2.6 mm/s under various conditions. The platform shows promising results and potential for future development for applications related to medical diagnostics, environmental monitoring, and chemical sensing applications.

Author Contributions

Conceptualization, H.U., F.S. and S.D.Z.; methodology, F.S., S.D.Z. and M.I.M.; software, S.D.Z.; validation, H.U., M.A. (Mubashar Ali) and M.A. (Moazzam Ali); investigation, H.U. and F.S.; resources, H.A.; writing—original draft preparation, H.U., F.S., S.D.Z. and M.I.M.; writing—review and editing, H.U. and A.T.J.; supervision, A.T.J.; project administration, A.T.J.; funding acquisition, A.T.J. All authors have read and agreed to the published version of the manuscript.

Funding

This work was funded by National Research Program for Universities (NRPU-14816) by Higher Education Commission (HEC) of Pakistan.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data is available on request from the corresponding author due to confidentiality.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Cho, S.K.; Moon, H.; Kim, C.-J. Creating, transporting, cutting, and merging liquid droplets by electrowetting-based actuation for digital microfluidic circuits. J. Microelectromechanical Syst. 2003, 12, 70–80. [Google Scholar]

- Choi, K.; Ng, A.H.C.; Fobel, R.; Wheeler, A.R. Digital microfluidics. Annu. Rev. Anal. Chem. 2012, 5, 413–440. [Google Scholar] [CrossRef] [PubMed]

- Xing, Y.; Liu, Y.; Chen, R.; Li, Y.; Zhang, C.; Jiang, Y.; Lu, Y.; Lin, B.; Chen, P.; Tian, R.; et al. A robust and scalable active-matrix driven digital microfluidic platform based on printed-circuit board technology. Lab Chip 2021, 21, 1886–1896. [Google Scholar] [CrossRef] [PubMed]

- Li, J. Current commercialization status of electrowetting-on-dielectric (EWOD) digital microfluidics. Lab Chip 2020, 20, 1705–1712. [Google Scholar] [CrossRef] [PubMed]

- Alistar, M.; Gaudenz, U. OpenDrop: An integrated do-it-yourself platform for personal use of biochips. Bioengineering 2017, 4, 45. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).