1. Introduction

Half-cycle LPG refrigeration deviates from the conventional full-cycle vapor compression cycle by employing only two distinct processes instead of the usual four. These processes involve constant-pressure heat addition and isenthalpic expansion, effectively eliminating the need for constant-pressure heat rejection in the condenser and adiabatic compression in the mechanical compressor. In this system, LPG is utilized once and then transferred to an evaporator to absorb heat, after which it is directly burned in a hob or combustion chamber, rendering a condenser unnecessary. Moreover, as the LPG in-take originates from a high-pressure cylinder, there is no requirement for a compressor. Consequently, LPG refrigeration only requires half the usual refrigeration components.

Numerous studies have explored the use of LPG as a refrigerant. For example, reference [

1] compared the coefficient of performance (COP) of household refrigerators using both R134a and LPG in an international publication. Similarly, another study [

2] designed an LPG refrigeration system and conducted an energy comparison with a residential refrigerator. The term “zero-cost refrigeration system” is often associated with half-cycle LPG refrigeration.

A recent study presented the rapid cooling ability of liquid LPG on water temperature, achieved by leveraging its refrigerating properties, even under typical environmental conditions, followed by its eventual evaporation [

3]. Another study investigated the performance of a half-cycle air-conditioning system utilizing liquefied petroleum gas (LPG). The study thoroughly assessed the system’s efficiency and effectiveness, offering valuable insights for potential applications in cooling technologies [

4]. In this setup, the LPG undergoes a transformation into saturated vapors as it passes through the evaporator. However, reverting gaseous LPG back to a liquid state proves costly, making this configuration feasible only when the outgoing LPG is continuously consumed in the burner. The main goal of this project is to use LPG to its best extent, which includes passing it through a refrigerator to produce cooling effects, in addition to using it for burning.

2. Materials and Methods

2.1. Design Methodology

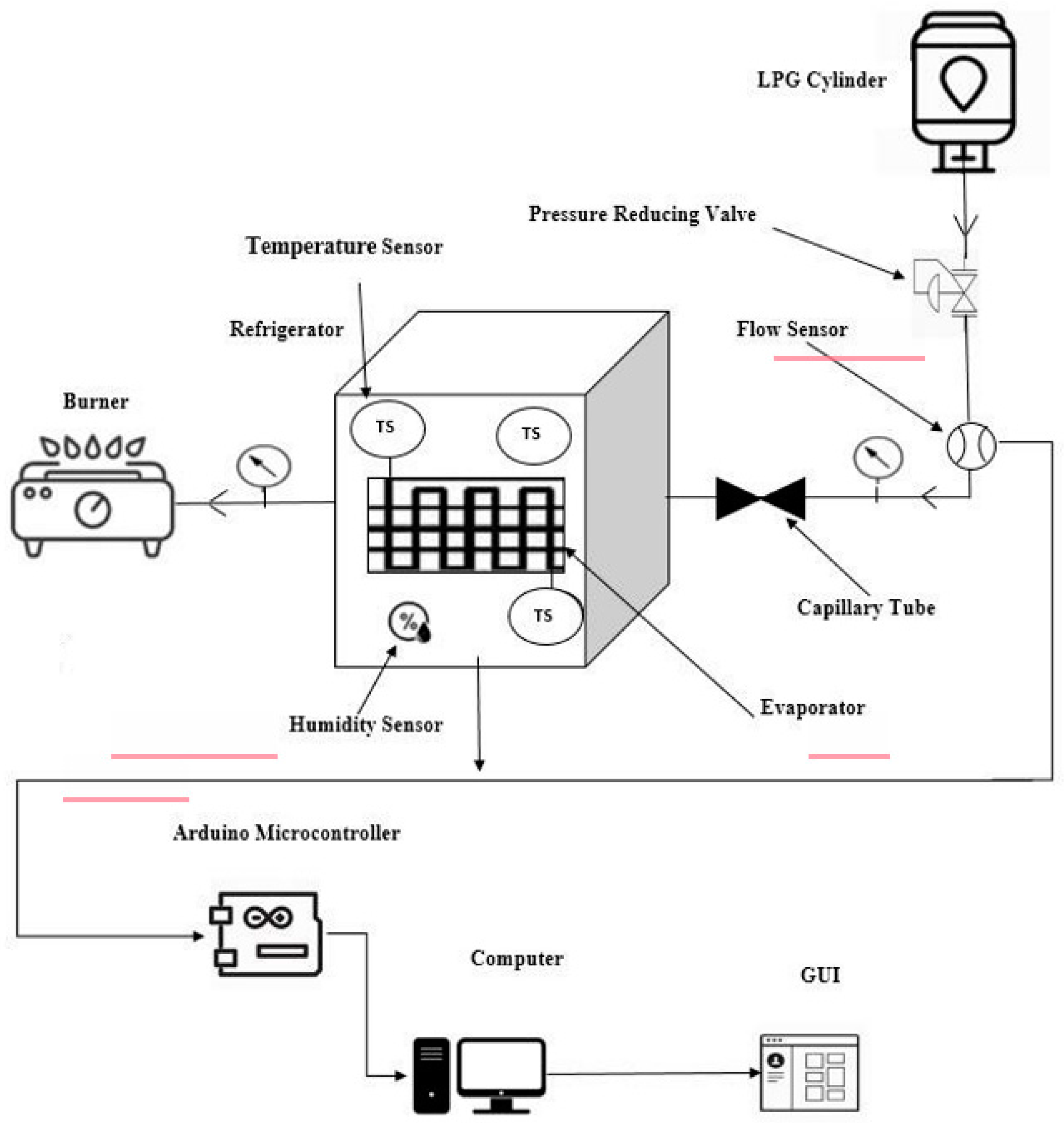

To attain the set objectives and goals, conducting experiments was deemed the most suitable research method, ensuring the effective and precise resolution of the problem at hand. The focus of this study was to fully exploit the potential of LPG found in cylinders for combustion purposes in various daily applications. The complete LPG-based refrigeration system is shown in

Figure 1.

The cooling effect generated by LPG was determined using the

equation as follows:

where

cp denotes the specific heat capacity and

T2 and

T1 are the final and initial temperature of the refrigerator compartment, respectively.

2.2. Description of Refrigerator

A small refrigerator with the specifications provided in the table below was chosen for the experiments.

3. Design of Experiment

Two types of experiments were performed using domestic refrigerator refer to

Table 1: first without a load in the compartment and the second with a load in the compartment. Each type of experiment was completed in two stages (30 min duration each): the first stage was the cooling of the compartment, and the second stage was the warming of the compartment with a zero-input pressure of LPG. Both types of experiments were performed for different input pressures, ranging from 3 bar up to 5 bar. The temperatures of the compartment and evaporator plate were measured using a digital thermometer and an LM-35, respectively.

4. Results and Discussion

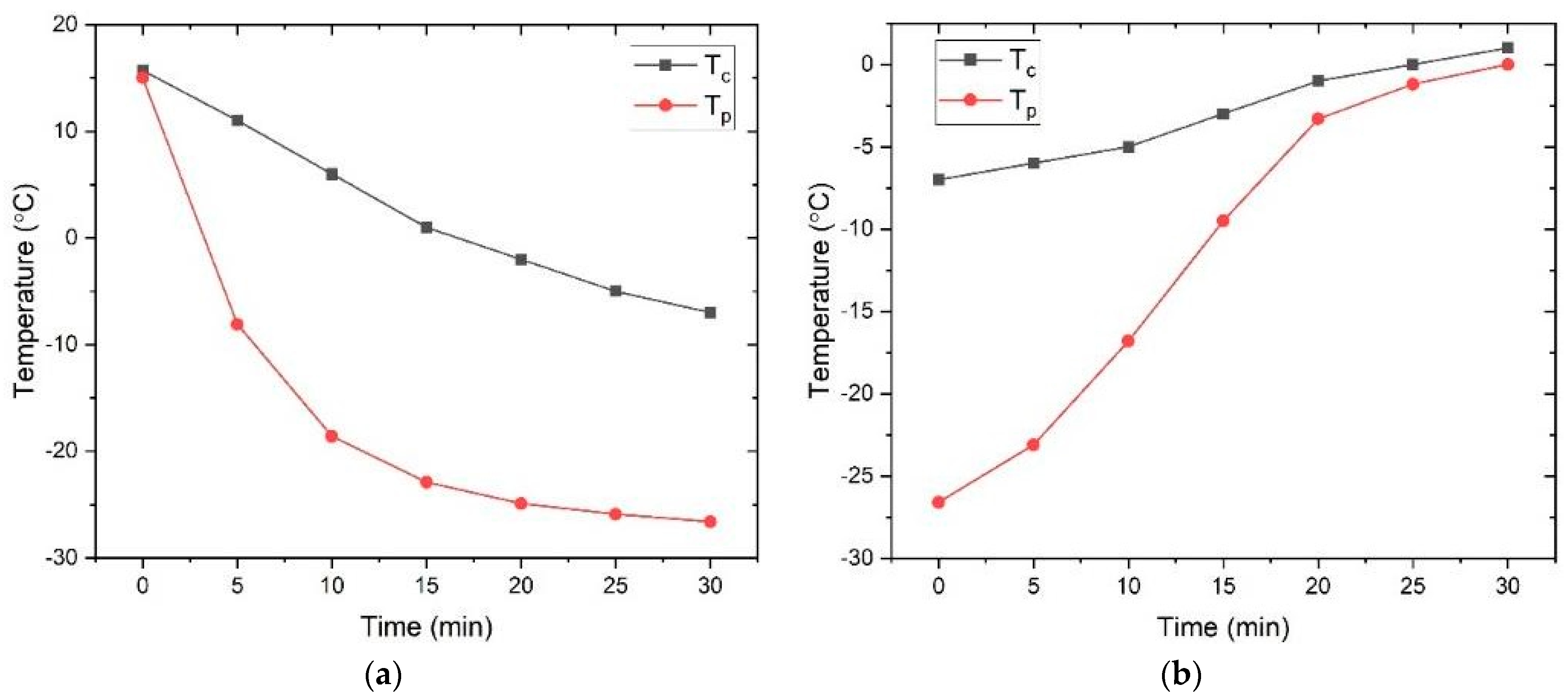

A number of experiments were performed by changing the condition of the input pressure. The compartment temperature variation was plotted against time at different input pressures, as shown in

Figure 2a–c.

Figure 2a shows the results of the experiment with an input pressure of LPG of 4.5 bar and 396 g of consumed LPG. The temperature of the compartment changed from 15.7 °C to −7 °C and that of the evaporator plate temperature changed from 15 °C to −26.6 °C in a 30 min duration of regular supply of LPG. As shown in

Figure 2b, during warming, that is, when the supply valve of the LPG is closed, the temperature of the evaporator plate changes rapidly, whereas that of the compartment changes slowly. The temperature of the evaporator plate increased from −26.6 to 0 °C, whereas that of the compartment increased from −7 °C to 1 °C in a duration of 30 min.

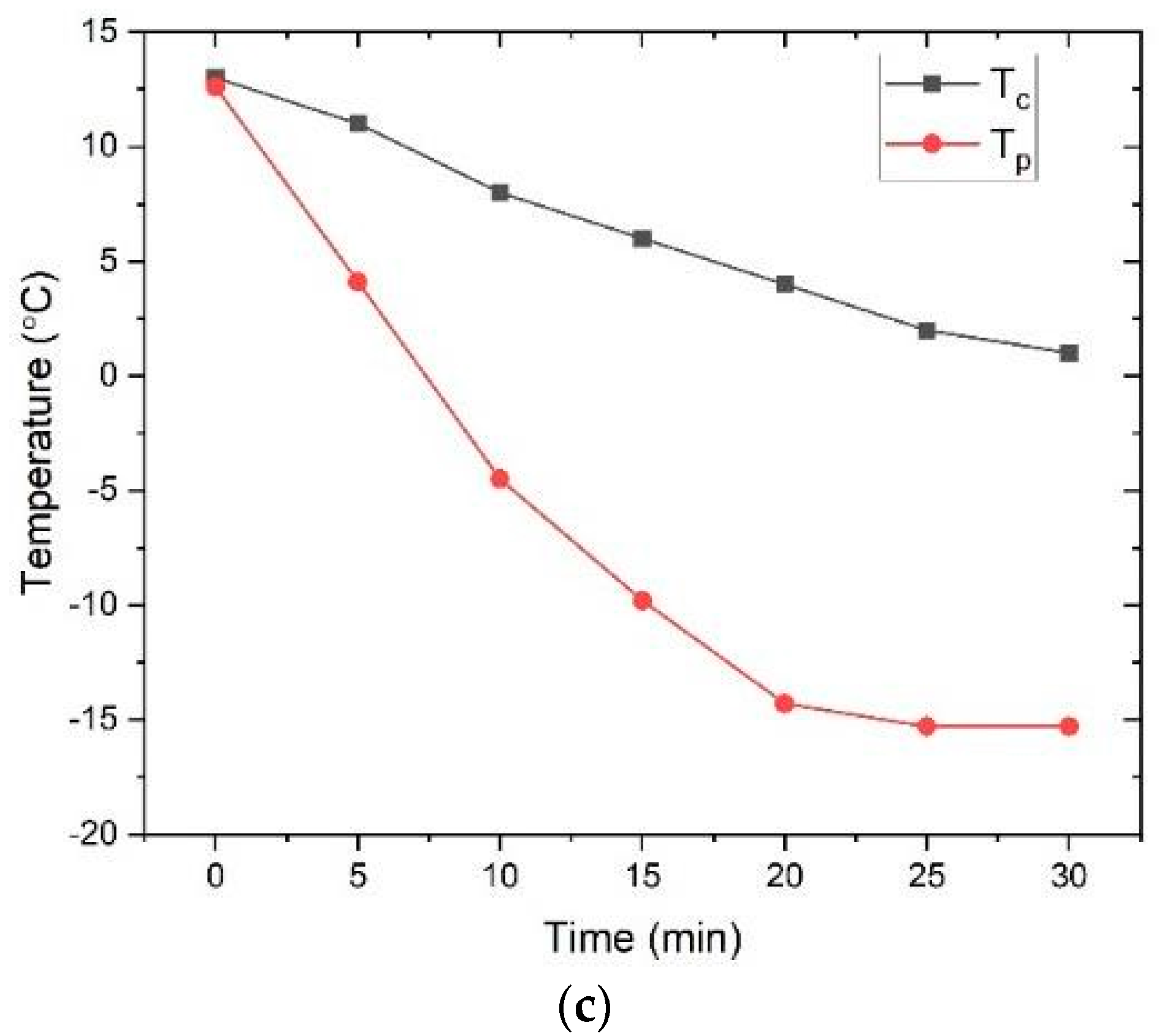

Figure 2c shows the experiment with an input pressure of LPG as 4 bar, and 1.5 L of water was taken as a load in the compartment. The temperature of water decreased from 12.8 °C to 9.2 °C in a duration of 30 min. At the same time, the temperature of the compartment decreased from 13 °C to 1 °C, whereas that of the evaporator plate decreased from 12.6 °C to −15.3 °C. From the results and plots, an important pattern is observed between the input pressure and cooling rate of the compartment. In addition to the benefit of the refrigeration effect, the combustion efficiency of LPG increases and CO emissions decrease during burning because of the preheating of LPG before burner. The preheating of LPG takes place in the compartment as a result of heat from the cold drinks and other food stuffs. This study was validated using a standard research article [

5].

Based on the data presented in

Figure 2 from the two types of experiments, it can be deduced that the temperature of the compartment exhibits a faster rate of change in the first case (without load) compared to the second case (with a load). In the first case, where only air was present in the compartment, the LPG solely absorbed heat from the air. Conversely, in the second case, with both air and water present, the LPG absorbed heat from both sources, resulting in a slower temperature change in the compartment.

5. Conclusions

In addition to its role as a fuel, LPG can be harnessed for refrigeration purposes due to its compressed nature. This study demonstrates the utilization of LPG as a refrigerant in domestic refrigerators, which eliminates the need for compressors and condensers (half-cycle refrigeration).

The system’s COP was 13.4, significantly surpassing that of typical domestic refrigerators. As a result, this innovative approach leads to electricity-free refrigeration, fully tapping into the potential of LPG for cooling applications.

Author Contributions

Conceptualization T.A.C.; methodology, G.A. and A.M.; software, S.F.S.; validation, T.A.C.; writing—original draft preparation, G.A.; writing—review and editing, A.M. and S.F.S.; experiments conducted, G.A. and A.M.; supervision, T.A.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data described in this study will be provided upon request.

Acknowledgments

The authors express their gratitude for the technical and financial support provided by the GIK Institute of Engineering Sciences and Technology, Topi 23460, Pakistan.

Conflicts of Interest

The corresponding author affirms that all authors have no conflict of interest to declare in relation to this submission.

References

- Kumar Rai, A.; Alabd Mohamed, S. Study of Performance Evaluation of Domestic Refrigerator with Mixture of Propane, Butane and Isobutene Refrigerant (LPG). Int. J. Mech. Eng. Technol. (IJMET) 2016, 7, 161–169. [Google Scholar]

- Hussain Shah, I.; Gupta, K. Design of LPG Refrigeration System and Comparative Energy Analysis with Domestic. Int. J. Eng. Sci. Res. Technol. 2014, 3, 206–213. [Google Scholar]

- Muzaffar, A.; Tariq, M.H.; Abbas, A.; Tayyab, M.; Cheema, T.A. Refrigeration Potential Investigation of Liquefied Petroleum Gas under Atmospheric Conditions. Eng. Proc. 2022, 23, 32. [Google Scholar]

- Muzaffar, A.; Cheema, T.A.; Abbas, A.; Tayyab, M.; Ilyas, M.; Park, C.W. Performance Analysis of Liquified Petroleum Gas (LPG) Driven Half-Cycle Air Conditioning System. Heat Mass Transf./Waerme-Und Stoffuebertragung 2020, 56, 3177–3197. [Google Scholar] [CrossRef]

- Aisyah, L.; Rulianto, D.; Setyo Wibowo, C. Analysis of the Effect of Preheating System to Improve Efficiency in LPG-Fuelled Small Industrial Burner. Energy Procedia 2015, 65, 180–185. [Google Scholar] [CrossRef]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).