Abstract

In this study, the viability of the commercial production of ambient air perovskite solar cells is investigated. In order to address issues with overlapping and non-uniform layers and minimize recombination losses, this study suggests a novel device architecture. A 2 × 2cm2 perovskite solar cell with a 4.2% power conversion efficiency (PCE) was successfully created utilizing a straightforward screen-printing technique. After humidity treatment, the short-circuit current (jsc) and open-circuit voltage (Voc) were stabilized at 5.36% due to layer optimization. These results show the potential for the widespread industrial production of more durable and efficient perovskite solar cells.

1. Introduction

The perovskite solar cells (PSCs) have received a lot of interest in recent years from academics due to their unique characteristics [1,2,3]. Although the reported power conversion efficiencies (PCEs) of PSCs have improved significantly, the perovskite community is currently placing more attention on improving device stability [4]. The high durability of carbon-based back electrodes (CPSCs) across a variety of environmental and operating situations has been noted [5,6]. It is important to note that their PCEs still fall short of those of cutting-edge PSCs that use metal-based electrodes [7].

A hybrid organic–inorganic perovskite substance called MAPbI3 is regarded as one of the most alluring options for inexpensive yet powerful absorber materials for solar energy applications [8,9]. The power conversion efficiency (PCE) of perovskite solar cells based on methylammonium lead iodide (MAPbI3) has significantly improved recently, with reported PCEs rising from 3.8% to 20.01% [10]. In a recent study, MAPbI3 was mechanically deposited onto the TiO2 layer in order to create a completely printable mesoscopic solar cell utilizing TiO2/ZrO2/Carbon (TZC) sheets [11]. Because an organic hole-transporting material (HTM) is not present, TZC-based materials offer lower material costs and better stability.

During this research, we successfully fabricated a perovskite solar cell in the laboratory under full ambient conditions using a FTO/C-TiO2/M-TiO2/ZrO2/carbon/MAPbI3 architecture. By carefully optimizing the pattern of each layer to prevent the material from overlapping, we achieved a promising power conversion efficiency (PCE) of 4.2%. Moreover, the device’s performance was significantly improved to a PCE of 5.36% through humidity treatment. These findings underscore the potential of ambient air perovskite solar cells as a cost-effective and efficient approach for commercial production. The demonstrated stability and performance enhancements lay the foundation for upscaling perovskite solar cell manufacturing on an industrial level, offering a hopeful path towards sustainable and renewable energy solutions.

2. Cell Fabrication by Using Screen Printing Methodology

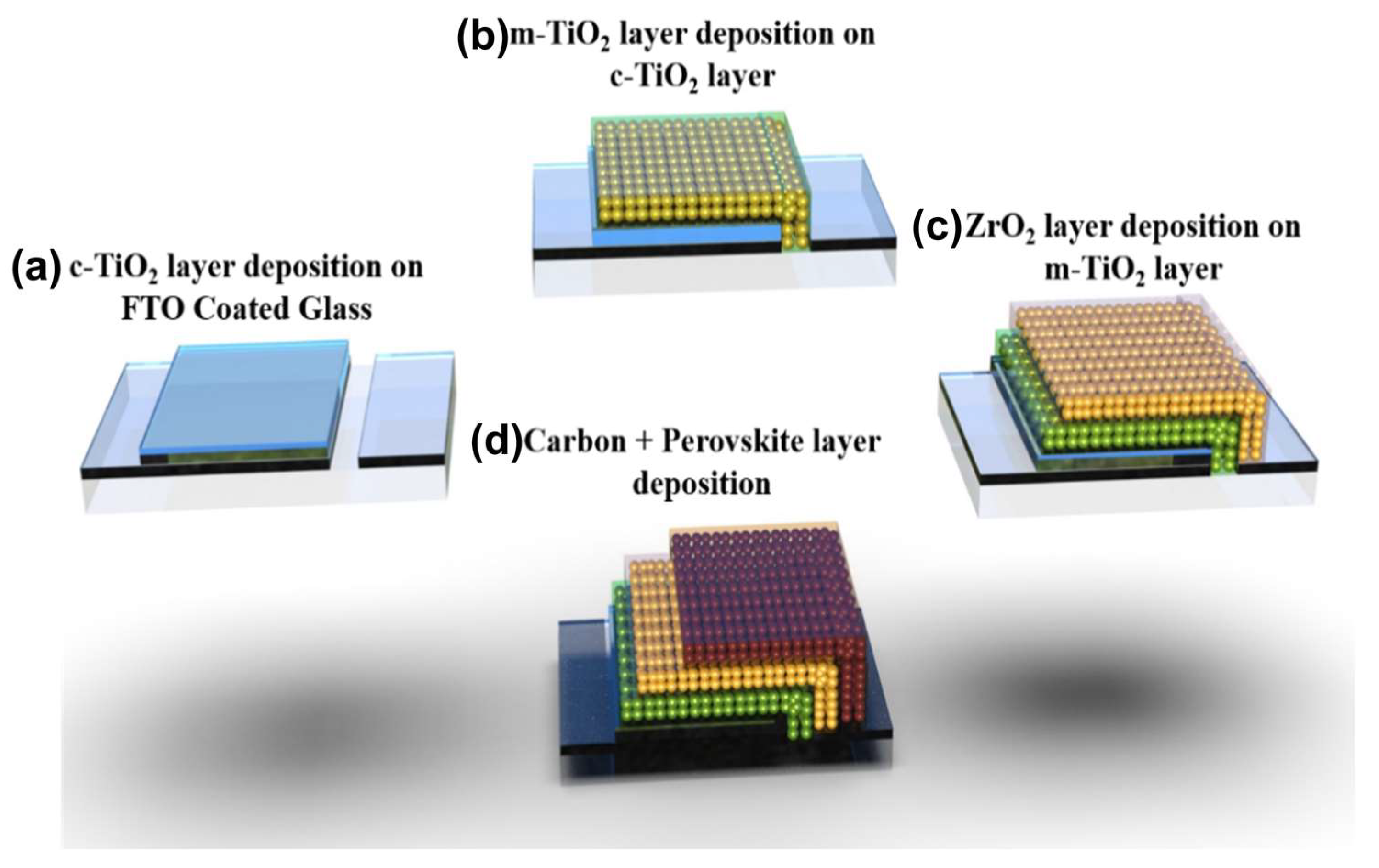

The normal cleaning procedure is washing the samples with hand soap detergent, followed by 15 min of sonication in deionized (DI) water. The samples are then subjected to a 15 min sonication process with acetone, isopropyl alcohol (IPA), and acetone at a temperature of 40 °C. The samples are then dried with a flow of nitrogen gas after being sonicated with the abovementioned solvents, and they are then kept at room temperature for quick usage in the next phases. In the second phase, we created and deposited the perovskite solar architecture “FTO/C-TiO2/M-TiO2/ZrO2/Carbon paste/MAPbI3” using the screen printing technique, as shown in the Figure 1 [12]. To create a solar cell, several meshes are employed for various materials. The open mesh pores hold the viscous ink in place when it is applied to the screen by a squeegee. Compact TiO2 is thinly placed over a glass surface that has been coated in fluorine-doped tin oxide (FTO) to prepare the substrate. Utilising ethanol and acetone, the compact TiO2 layer’s mesh structure is cleaned. The film is then given a 30 min annealing treatment at 500 °C to encourage crystallization. Mesoporous TiO2 (m-TiO2) is the fourth layer in the manufacturing process. This layer is essential to perovskite solar cells (PSCs) because it serves as a scaffold for perovskite crystal growth as well as being a selective contact for electron extraction. On top of the compact TiO2 (C-TiO2) layer that was previously deposited, the M-TiO2 layer is applied. Following deposition, the substrate is subjected to a 30 min annealing process at 500 °C to encourage the crystallization and structural stability of the M-TiO2 layer. Applying a ZrO2 paste using a screen-printing process over the TiO2 layer is the following step. After that, control cells are put through a 30 min sintering process at 400 °C. The carbon back electrode is placed onto the ZrO2 layer after the prior procedures. The sample is subsequently heated to 40 °C for 30 min to guarantee adequate bonding and structural stability. The perovskite solar cell’s performance and general efficiency are improved by this technique. Using the drop casting method, the last layer of perovskite is put onto the substrate. The perovskite film is then improved by annealing it for an hour at 70 °C to promote further crystallization [13].

Figure 1.

Fabrication steps of the perovskite solar cell. (a) c-TiO2 layer deposition on FTO Coated Glass, (b) m-TiO2 layer deposition on c-TiO2 layer, (c) ZrO2 layer deposition on m-TiO2, (d) carbon + Perovskite layer deposition.

3. Result and Discussion

The fabricated perovskite solar cell comprised of the FTO/C-TIO2/M-TIO2/ZrO2/carbon/MAPbI3 architecture exhibited an initial efficiency of 4.2%. This efficient structure offered several advantages; notably, a well-defined interface which potentially improved the charge collection and light absorption capabilities, thus leading to increased efficiency.

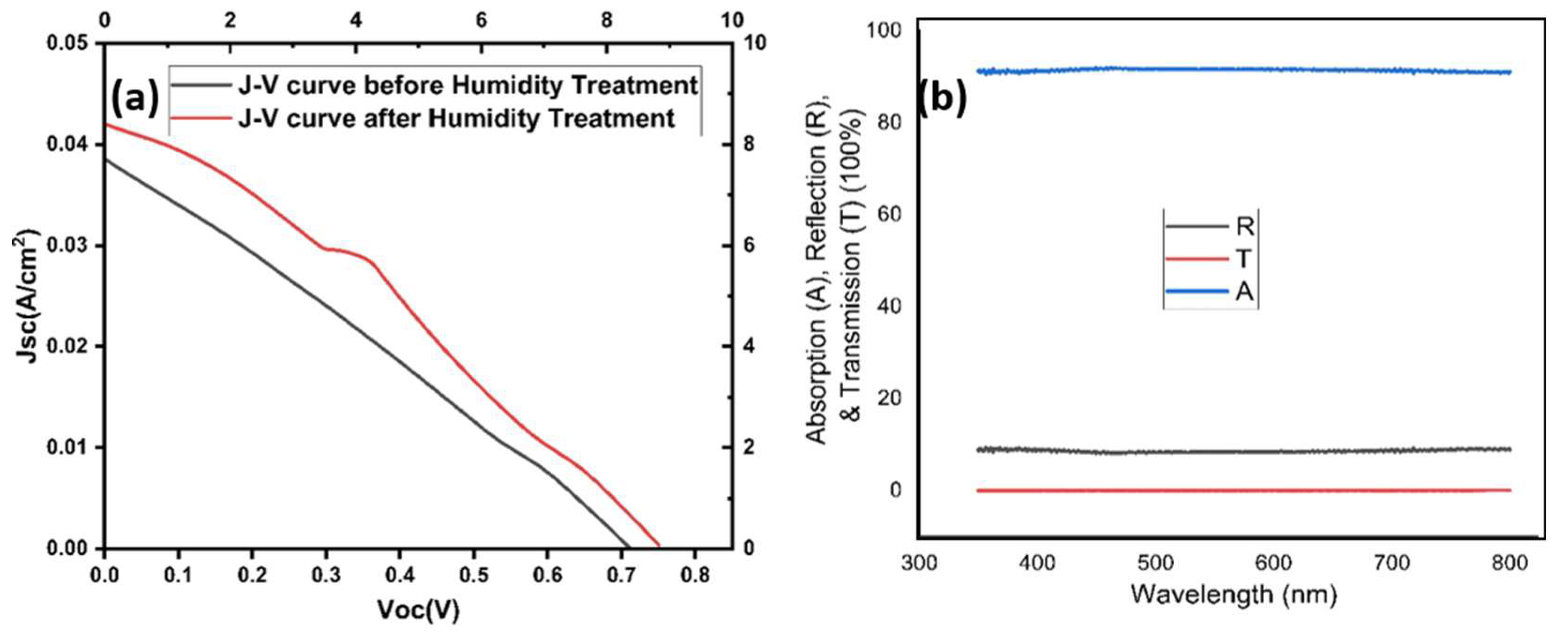

Post fabrication, the solar cell underwent a humidity treatment, resulting in a noticeable enhancement in the overall efficiency to 5.36%. This could be attributed to the fact that a controlled humidity environment can facilitate the crystallization of perovskite, enhancing the perovskite layer’s quality and, hence, the device performance. Moreover, the induced humidity could potentially have optimized the morphology of the MAPbI3 layer, which can further contribute to efficiency enhancement. Figure 2a shows the J-V curve before and after humidity treatment of the perovskite solar cell.

Figure 2.

(a) J-V curve before and after humidity treatment of perovskite solar cell, and (b) absorption, reflection and transmission spectra of the perovskite solar cell.

Figure 2b shows the absorption, reflection, and transmission spectra of the perovskite solar cell, in which almost 90% of the absorption was achieved in our device and only a low amount of reflection has been observed of approximately 10%. Moreover, it can be seen that nearly 0% transmission has been observed.

4. Conclusions

A highly stable 5.36% efficient solar cell is reported which can be scaled up to fabricate large-area perovskite-based solar modules. This structure utilizes the mesoporous zirconia layer, which is used as an insulation layer, as an alternative for the hole transport layer, which is highly stable. Though this layer reduces the efficiency, it is cost effective and increases the stability of the structure, thus increasing its prospects for commercialization. A dual titania layer, i.e., thin compact titania along with a mesoporous titania, is used as an electron transport layer. The structure utilizes a carbon black blend along with graphite particles as the hole selector layer, as well as cathode. Due to its hydrophobic nature, this layer provides a protective cover to perovskite crystals, thus increasing the lifetime of this solar cell. The perovskite precursor solution 5-AVA-MAPbI3 is infiltrated in the mesoporous layers. Due to the presence of aminovaleric acid along with organic cation, this perovskite is more stable compared to conventional methylammonium lead iodide crystals. Silver is used at both electrodes for charge collection due to its cost-effectiveness and efficient charge transportation. Thus, these solar cells are an excellent alternative for conventional silicon-based solar cells since these cells are cost effective and have simple fabrication processes. The screen printing technique is used for the fabrication of these solar cells, which can easily be used for layer thickness optimization and scaling up the module size. Moreover, these solar cells can be used as a basic model for the commercialization and initiation of perovskite solar manufacturing in Pakistan.

Author Contributions

Conceptualization, A.B.; methodology, A.B., A.D.K. (Aimal Daud Khan); fabrication, A.B., A.D.K. (Aimal Daud Khan); characterization, A.B., A.D.K. (Aimal Daud Khan); resources, A.D.K. (Adnan Daud Khan); writing—original draft preparation, A.B.; review and editing, A.D.K. (Aimal Daud Khan); supervision, A.D.K. (Adnan Daud Khan) All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not Applicable.

Informed Consent Statement

Not Applicable.

Data Availability Statement

Not Applicable.

Acknowledgments

All authors are grateful to US-Pakistan Center for Advanced Studies in Energy, University of Engineering & Technology, Peshawar for providing the facilitation to fabricate the perovskite solar cell.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Kim, J.Y.; Lee, J.-W.; Jung, H.S.; Shin, H.; Park, N.-G. High-efficiency perovskite solar cells. Chem. Rev. 2020, 120, 7867–7918. [Google Scholar] [CrossRef] [PubMed]

- Correa-Baena, J.-P.; Saliba, M.; Buonassisi, T.; Grätzel, M.; Abate, A.; Tress, W.; Hagfeldt, A. Promises and challenges of perovskite solar cells. Science 2017, 358, 739–744. [Google Scholar] [CrossRef] [PubMed]

- Rong, Y.; Hu, Y.; Mei, A.; Tan, H.; Saidaminov, M.I.; Seok, S.I.; McGehee, M.D.; Sargent, E.H.; Han, H. Challenges for commercializing perovskite solar cells. Science 2018, 361, eaat8235. [Google Scholar] [CrossRef] [PubMed]

- Wang, Q.; Phung, N.; Di Girolamo, D.; Vivo, P.; Abate, A. Enhancement in lifespan of halide perovskite solar cells. Energy Environ. Sci. 2019, 12, 865–886. [Google Scholar] [CrossRef]

- Mei, A.; Sheng, Y.; Ming, Y.; Hu, Y.; Rong, Y.; Zhang, W.; Luo, S.; Na, G.; Tian, C.; Hou, X. Stabilizing perovskite solar cells to IEC61215: 2016 standards with over 9,000-h operational tracking. Joule 2020, 4, 2646–2660. [Google Scholar] [CrossRef]

- Bogachuk, D.; Saddedine, K.; Martineau, D.; Narbey, S.; Verma, A.; Gebhardt, P.; Herterich, J.P.; Glissmann, N.; Zouhair, S.; Markert, J. Perovskite Photovoltaic Devices with Carbon-Based Electrodes Withstanding Reverse-Bias Voltages up to–9 V and Surpassing IEC 61215: 2016 International Standard. Solar Rrl 2022, 6, 2100527. [Google Scholar] [CrossRef]

- Bogachuk, D.; Zouhair, S.; Wojciechowski, K.; Yang, B.; Babu, V.; Wagner, L.; Xu, B.; Lim, J.; Mastroianni, S.; Pettersson, H. Low-temperature carbon-based electrodes in perovskite solar cells. Energy Environ. Sci. 2020, 13, 3880–3916. [Google Scholar] [CrossRef]

- Idrissi, S.; Ziti, S.; Labrim, H.; Bahmad, L. Band gaps of the solar perovskites photovoltaic CsXCl3 (X = Sn, Pb or Ge). Mater. Sci. Semicond. Process. 2021, 122, 105484. [Google Scholar] [CrossRef]

- Lee, M.M.; Teuscher, J.; Miyasaka, T.; Murakami, T.N.; Snaith, H.J. Efficient hybrid solar cells based on meso-superstructured organometal halide perovskites. Science 2012, 338, 643–647. [Google Scholar] [CrossRef] [PubMed]

- Yang, X.; Yu, H.; Guo, X.; Ding, Q.; Pullerits, T.; Wang, R.; Zhang, G.; Liang, W.; Sun, M. Materials Today Energy. Mater. Today 2017, 5, 72–78. [Google Scholar]

- Ku, Z.; Rong, Y.; Xu, M.; Liu, T.; Han, H. Full printable processed mesoscopic CH3NH3PbI3/TiO2 heterojunction solar cells with carbon counter electrode. Sci. Rep. 2013, 3, 3132. [Google Scholar] [CrossRef] [PubMed]

- Baker, J.; Hooper, K.; Meroni, S.; Pockett, A.; McGettrick, J.; Wei, Z.; Escalante, R.; Oskam, G.; Carnie, M.; Watson, T. High throughput fabrication of mesoporous carbon perovskite solar cells. J. Mater. Chem. A 2017, 5, 18643–18650. [Google Scholar] [CrossRef]

- Duan, M.; Hu, Y.; Mei, A.; Rong, Y.; Han, H. Printable carbon-based hole-conductor-free mesoscopic perovskite solar cells: From lab to market. Mater. Today Energy 2018, 7, 221–231. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).