Analysis of Mechanical Strength of Indium-Doped SAC 105 Lead-Free Solder Alloy †

Abstract

:1. Introduction

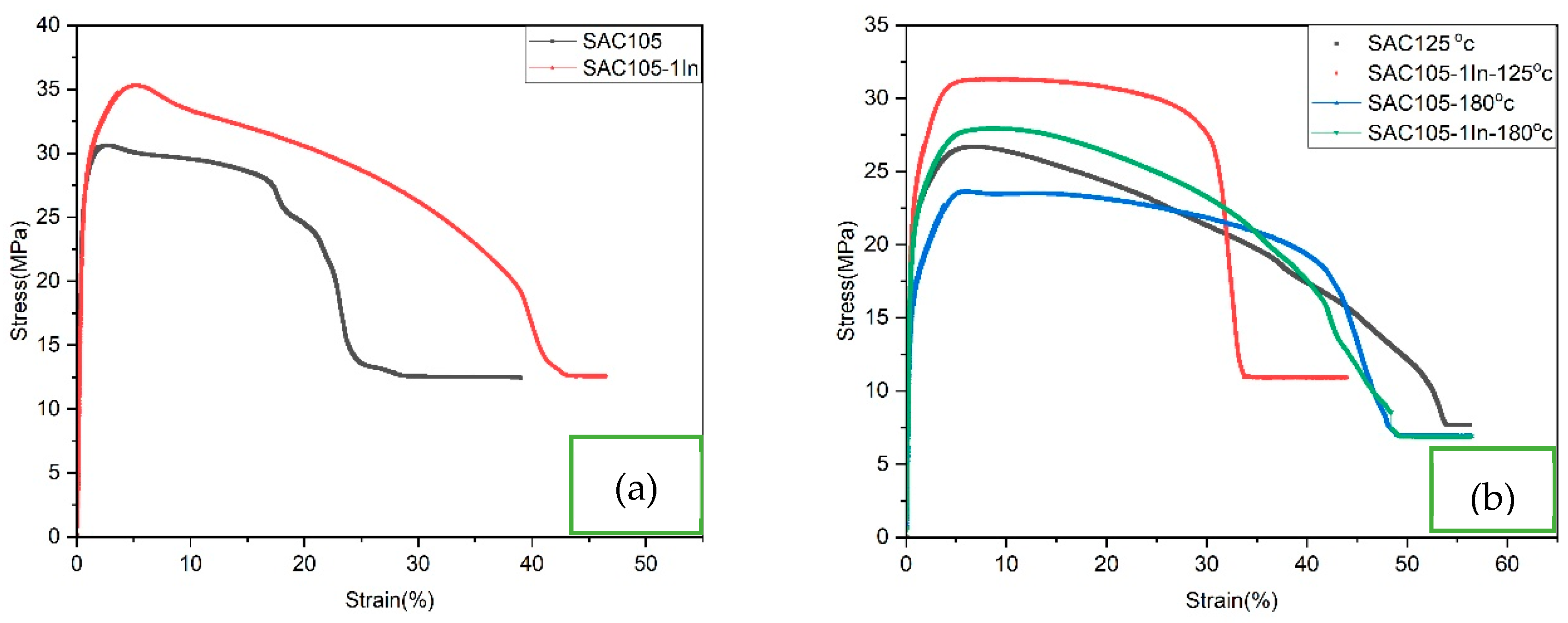

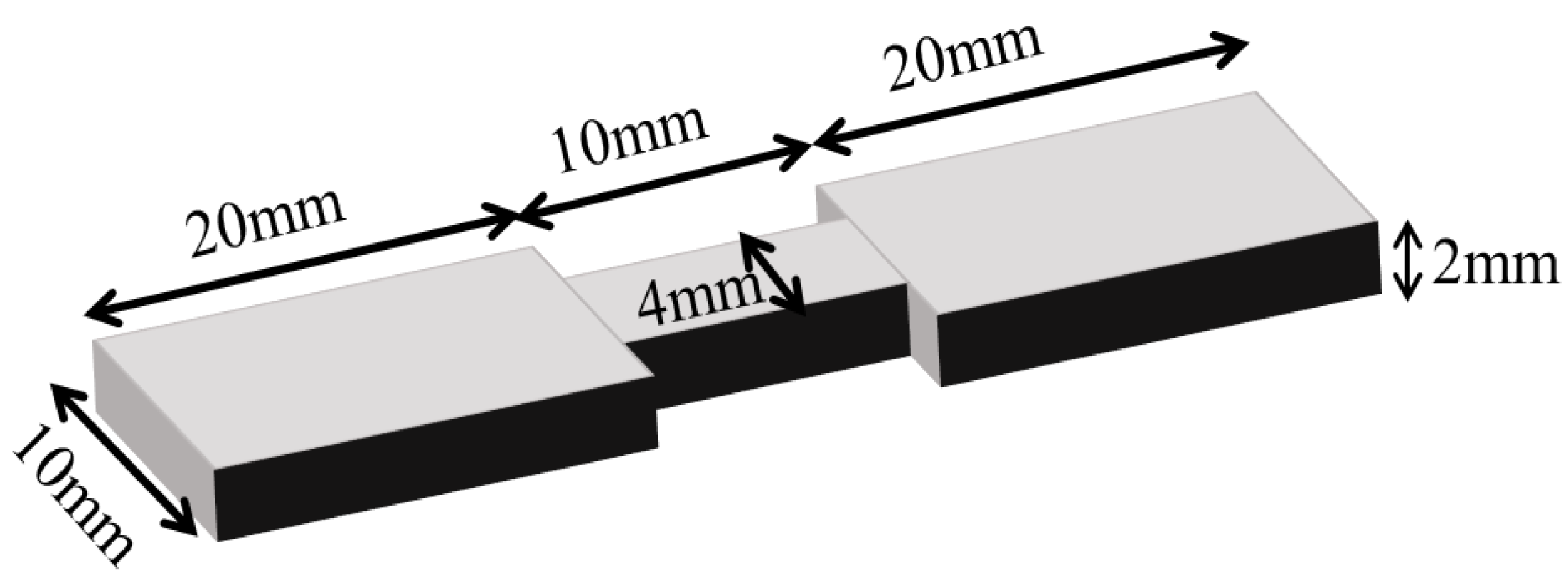

2. Experimental Procedure

3. Results and Discussion

ASTM Standard

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fazal, M.A.; Liyana, N.K.; Rubaiee, S.; Anas, A. A critical review on performance, microstructure and corrosion resistance of Pb-free solders. Meas. J. Int. Meas. Confed. 2019, 134, 897–907. [Google Scholar] [CrossRef]

- Aamir, M.; Muhammad, R.; Tolouei-Rad, M.; Giasin, K.; Silberschmidt, V.V. A review: Microstructure and properties of tin-silver-copper lead-free solder series for the applications of electronics. Solder. Surf. Mt. Technol. 2020, 32, 115–126. [Google Scholar] [CrossRef]

- Sun, L.; Zhang, L. Review Article: Properties and Microstructures of Sn-Ag-Cu-X Lead-Free Solder. Adv. Mater. Sci. Eng. 2015, 2015, 639028. [Google Scholar] [CrossRef]

- El-Daly, A.A.; Hammad, A.E.; Fawzy, A.; Nasrallh, D.A. Microstructure, mechanical properties, and deformation behavior of Sn-1.0Ag-0.5Cu solder after Ni and Sb additions. Mater. Des. 2013, 43, 40–49. [Google Scholar] [CrossRef]

- Ma, H.; Suhling, J.C. A review of mechanical properties of lead-free solders for electronic packaging. J. Mater. Sci. 2009, 44, 1141–1158. [Google Scholar] [CrossRef]

- Ali, U.; Khan, H.; Aamir, M.; Giasin, K.; Habib, N.; Awan, M.O. Analysis of microstructure and mechanical properties of bismuth-doped SAC305 lead-free solder alloy at high temperature. Metals 2021, 11, 1077. [Google Scholar] [CrossRef]

- Yang, T.; Chen, Y.; You, K.; Dong, Z.; Jia, Y.; Wang, G.; Peng, J.; Cai, S.; Luo, X.; Liu, C.; et al. Effect of Bi, Sb, and Ti on Microstructure and Mechanical Properties of SAC105 Alloys. Materials 2022, 15, 4727. [Google Scholar] [CrossRef] [PubMed]

- Chantaramanee, S.; Sriwittayakul, W. Effects of Antimony and Indium Addition on Wettability and Interfacial Reaction of Sn-3.0Ag-0.5Cu Lead Free Solder on Copper Substrate. Mater. Sci. Forum 2018, 928, 188–193. [Google Scholar] [CrossRef]

- Sungkhaphaitoon, P.; Chantaramanee, S. Effects of Indium Content on Microstructural, Mechanical Properties and Melting Temperature of SAC305 Solder Alloys. Russ. J. Non-Ferrous Met. 2018, 59, 385–392. [Google Scholar] [CrossRef]

- Mahdavifard, M.H.; Sabri, M.F.M.; Said, S.M.; Rozali, S. High stability and aging resistance Sn-1Ag-0.5Cu solder alloy by Fe and Bi minor alloying. Microelectron. Eng. 2019, 208, 29–38. [Google Scholar] [CrossRef]

- Fallahi, H.; Nurulakmal, M.S.; Fallahi, A.; Abdullah, J. Modifying the mechanical properties of lead-free solder by adding iron and indium and using a lap joint test. J. Mater. Sci. Mater. Electron. 2012, 23, 1739–1749. [Google Scholar] [CrossRef]

| Sr. No. | Alloy | Wt.% | |||

|---|---|---|---|---|---|

| Sn | Ag | Cu | In | ||

| 1 | SAC105 | 98.50 | 1.0 | 0.5 | 0.0 |

| 2 | SAC105-1In | 97.50 | 1.0 | 0.5 | 1.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hameed, M.S.; Wakeel, A.; Pasha, R.A.; Ullah, B.; Ali, U. Analysis of Mechanical Strength of Indium-Doped SAC 105 Lead-Free Solder Alloy. Eng. Proc. 2023, 45, 18. https://doi.org/10.3390/engproc2023045018

Hameed MS, Wakeel A, Pasha RA, Ullah B, Ali U. Analysis of Mechanical Strength of Indium-Doped SAC 105 Lead-Free Solder Alloy. Engineering Proceedings. 2023; 45(1):18. https://doi.org/10.3390/engproc2023045018

Chicago/Turabian StyleHameed, Muhammad Sohail, Aneela Wakeel, Riffat Asim Pasha, Barkat Ullah, and Umair Ali. 2023. "Analysis of Mechanical Strength of Indium-Doped SAC 105 Lead-Free Solder Alloy" Engineering Proceedings 45, no. 1: 18. https://doi.org/10.3390/engproc2023045018

APA StyleHameed, M. S., Wakeel, A., Pasha, R. A., Ullah, B., & Ali, U. (2023). Analysis of Mechanical Strength of Indium-Doped SAC 105 Lead-Free Solder Alloy. Engineering Proceedings, 45(1), 18. https://doi.org/10.3390/engproc2023045018