Tool Wear Parameter Optimization in Machining a Squeeze-Cast Metal Matrix Composite (Al6061-SiC) †

Abstract

:1. Introduction

2. Materials and Methods

3. Experiment Design & Setup

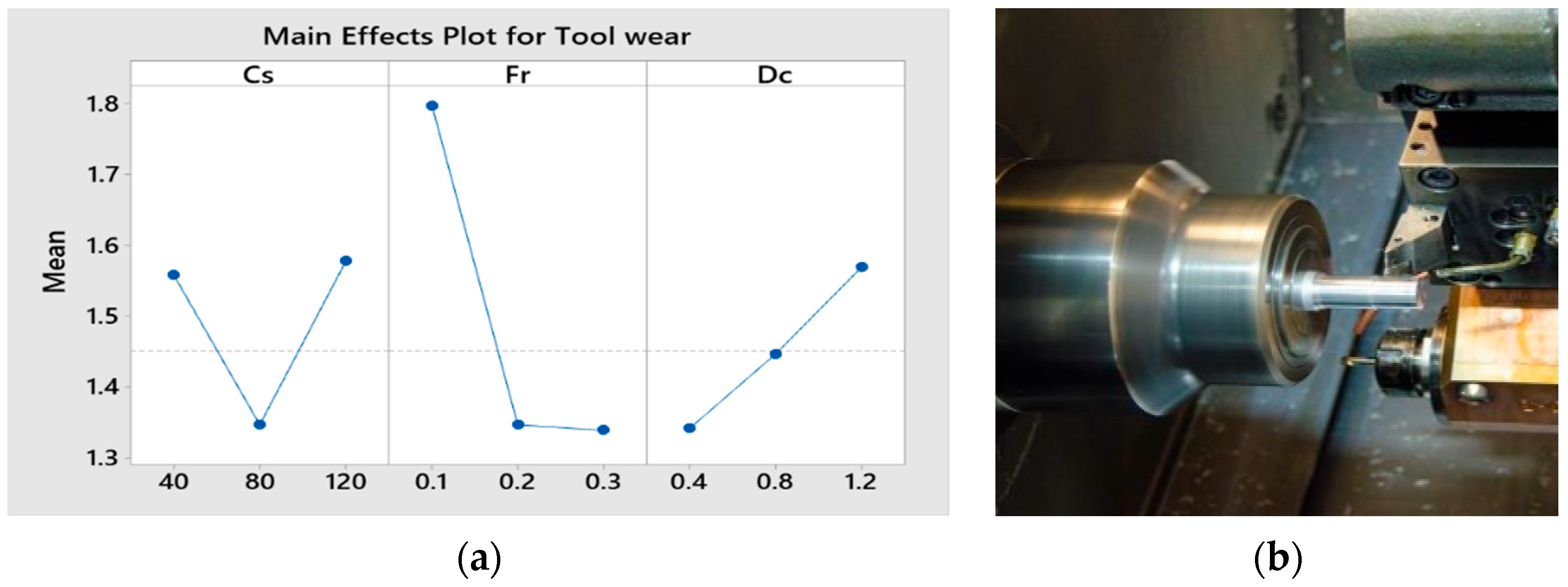

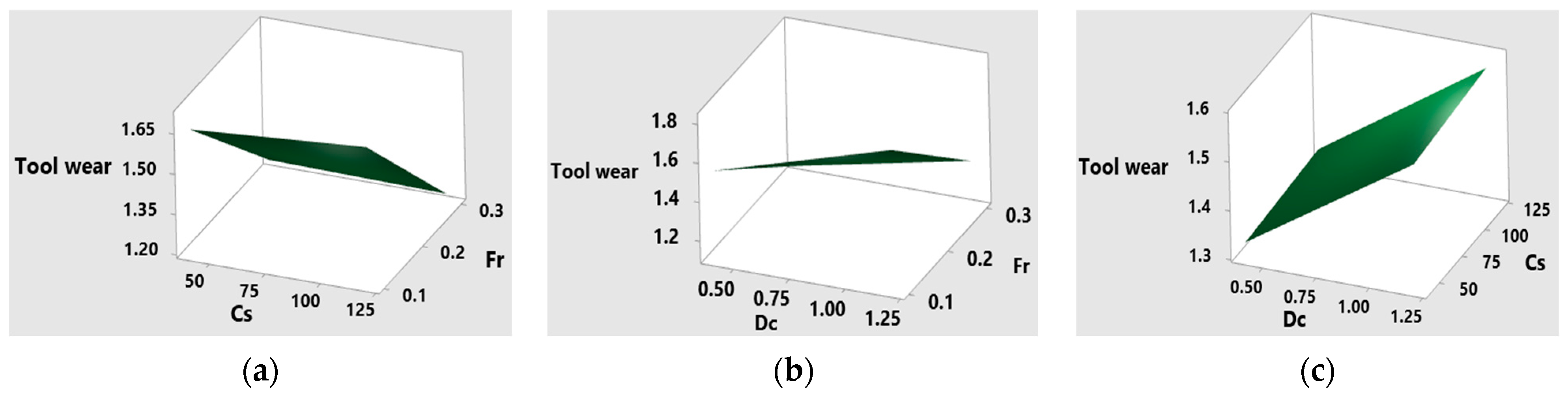

4. Results and Discussion

5. Validations

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sarfraz, M.H.; Jahanzaib, M.; Ahmed, W.; Hussain, S. Multi-response parametric optimization of squeeze casting process for fabricating Al 6061-SiC composite. Int. J. Adv. Manuf. Technol. 2019, 102, 759–773. [Google Scholar] [CrossRef]

- Seeman, M.; Ganesan, G.; Karthikeyan, R.; Velayudham, A. Study on tool wear and surface roughness in machining of particulate aluminum metal matrix composite-response surface methodology approach. Int. J. Adv. Manuf. Technol. 2010, 48, 613–624. [Google Scholar] [CrossRef]

- Suresh, R.; Basavarajappa, S.; Gaitonde, V.; Samuel, G. Machinability investigations on hardened AISI 4340 steel using coated carbide insert. Int. J. Refract. Met. Hard Mater. 2012, 33, 75–86. [Google Scholar] [CrossRef]

- Youssef, H.; EL-Hofy, H. Basic Elements and Mechanisms of Machine Tools. In Traditional Machining Technology, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2020; pp. 11–57. [Google Scholar]

- Baburaj, E.; Mohana Sundaram, K.; Senthil, P. Effect of high-speed turning operation on surface roughness of hybrid metal matrix (Al-SiC p-fly ash) composite. J. Mech. Sci. Technol. 2016, 30, 89–95. [Google Scholar] [CrossRef]

- Hanif, M.W.; Wasim, A.; Sajid, M.; Hussain, S.; Jawad, M.; Jahanzaib, M. Evaluation of microstructure and mechanical properties of squeeze overcast Al7075−Cu composite joints. China Foundry 2023, 20, 29–39. [Google Scholar] [CrossRef]

- Hanif, M.W.; Wasim, A.; Sajid, M. Evaluating the Effect of Process Parameters on the Mechanical Properties of an AA7075-Cu Overcast Joint Using the Taguchi Method. Eng. Proc. 2022, 23, 3. [Google Scholar]

- Haider, F.; Jahanzaib, M.; Hanif, M.W. Optimizing the process parameters of Fiction Stir Welded dissimilar 2024Al-5754Al Joint using the Taguchi Method. In Proceedings of the 1st International Conference on Modern Technologies in Mechanical & Materials Engineering (MTME-2023), Topi, Pakistan, 6 May 2023; p. 02006. [Google Scholar]

| Elements | Al | Mg | Fe | Si | Cu | Ti | Mn | Cr | Zn |

|---|---|---|---|---|---|---|---|---|---|

| Weight Percent. (Al) | 97.05 | 0.14 | 0.7 | 0.43 | 0.24 | 0.15 | 0.24 | 0.8 | 0.25 |

| Experiment No. | Input Variables | Output Response (Tool Wear) | ||

|---|---|---|---|---|

| Cs | Fr | Dc | Average Value (mm) | |

| 1 | 40 | 0.1 | 0.8 | 1.884 |

| 2 | 120 | 0.1 | 0.8 | 1.956 |

| 3 | 40 | 0.3 | 0.8 | 1.436 |

| 4 | 120 | 0.3 | 0.8 | 1.448 |

| 5 | 40 | 0.2 | 0.4 | 1.4592 |

| 6 | 120 | 0.2 | 0.4 | 1.452 |

| 7 | 40 | 0.2 | 1.2 | 1.456 |

| 8 | 120 | 0.2 | 1.2 | 1.456 |

| 9 | 80 | 0.1 | 0.4 | 1.428 |

| 10 | 80 | 0.3 | 0.4 | 1.028 |

| 11 | 80 | 0.1 | 1.2 | 1.924 |

| 12 | 80 | 0.3 | 1.2 | 1.444 |

| 13 | 80 | 0.2 | 0.8 | 0.964 |

| 14 | 80 | 0.2 | 0.8 | 1.456 |

| 15 | 80 | 0.2 | 0.8 | 1.468 |

| 16 | 80 | 0.2 | 0.8 | 0.968 |

| 17 | 80 | 0.2 | 0.8 | 1.444 |

| Source | SS | Adj SS. | Adj MS. | F | p | |

|---|---|---|---|---|---|---|

| Model | 1.31 | 3 | 0.44 | 1267.99 | <0.0001 | significant |

| Cs | 0.45 | 1 | 0.45 | 1302.4 | <0.001 | significant |

| Fr | 0.47 | 1 | 0.47 | 1368.05 | <0.0001 | significant |

| Dc | 0.39 | 1 | 0.39 | 1133.51 | <0.0001 | significant |

| Residual | 4.85 × 10−03 | 13 | 3.45 × 10−04 | |||

| Lack of Fit | 3.88 × 10−03 | 9 | 4.31 × 10−04 | 2.83 | 0.1178 | not significant |

| Pure Error | 6.08 × 10−03 | 4 | 1.52 × 10−04 | |||

| Cor Total | 1.32 | 16 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Imran, A.; Hanif, M.W.; Sajid, M.; Salim, S.; Haider, F.; Azeem, M. Tool Wear Parameter Optimization in Machining a Squeeze-Cast Metal Matrix Composite (Al6061-SiC). Eng. Proc. 2023, 45, 1. https://doi.org/10.3390/engproc2023045001

Imran A, Hanif MW, Sajid M, Salim S, Haider F, Azeem M. Tool Wear Parameter Optimization in Machining a Squeeze-Cast Metal Matrix Composite (Al6061-SiC). Engineering Proceedings. 2023; 45(1):1. https://doi.org/10.3390/engproc2023045001

Chicago/Turabian StyleImran, Asif, Muhammad Waqas Hanif, Muhammad Sajid, Shahab Salim, Feroz Haider, and Muhammad Azeem. 2023. "Tool Wear Parameter Optimization in Machining a Squeeze-Cast Metal Matrix Composite (Al6061-SiC)" Engineering Proceedings 45, no. 1: 1. https://doi.org/10.3390/engproc2023045001

APA StyleImran, A., Hanif, M. W., Sajid, M., Salim, S., Haider, F., & Azeem, M. (2023). Tool Wear Parameter Optimization in Machining a Squeeze-Cast Metal Matrix Composite (Al6061-SiC). Engineering Proceedings, 45(1), 1. https://doi.org/10.3390/engproc2023045001