Abstract

This study focused on the application of nano-/micro-sized fibers obtained from pyrolysis of Santa Maria feverfew (biochar) in cement mortars. The biochar was added in amounts of 0, 0.05 and 0.1 percent by mass of cement. The mechanical characteristics were determined after 3 and 7 days and matched with those of the control samples. The compressive strength remained unchanged with the biochar addition, whereas the flexural strength increased. Biochar is a carbon-rich material, and its use in building materials leads to carbon sequestration, which is in accordance with the sustainable development goals of the UNO.

1. Introduction

Pyrolysis is an energy-intensive method that involves the thermochemical breakdown of raw biomass in an inert atmosphere at high temperatures and pressures. This procedure yields different valuable products, like biochar, liquid bio-oil and fuel gases [1]. Biochar is a low-density dark-color carbon deposit. Scientists have used many different kinds of feedstock, including water hyacinth, oriental beech, corncob and many more [2,3,4]. Many researchers in the recent past have added biochar to cementitious products to enhance performance. Gupta et al. added biochar of sawdust at the rate 2% by mass of cement [5]. The results reveal that the addition enhanced the compressive strength and ductility of the end products. Tayyab et al. incorporated the biochar of millet and maize in mortar [6]. The authors reported an enhanced fracture toughness and ductility of the specimens, which was attributed to crack bridging/branching due to the fibrous nature of biochar. Iftekhar et al. studied the effect of adding the biochars of sugarcane bagasse and pine needles into cementitious mortars [7]. The authors reported enhanced interface shielding due to the addition. Restuccia et al. used the biochar of hazelnut shells as an additive in mortar specimens. They stated it enhanced compressive strength, flexural strength, toughness and ductility. Most of the previous studies focused on the effect of biochar on the hardened properties of the cementitious composites. The literature as regards the influence of biochar additions on the early-age properties of cementitious materials is limited.

The present study focused on the addition of the biochar of Santa Maria feverfew on the mechanical characteristics of cementitious mortar at an early age. As a matter of fact, the effect of biochar on the hardened properties of cementitious materials is well known; however, research on its effect on early-age mortar’s characteristics is limited. Santa Maria feverfew is a local plant also known as gajjar boti or gajjar ghass. This study involved the evaluation of cementitious mortar in terms of its compressive and flexural strengths.

2. Materials and Methods

Cementitious mortars containing both the control mix and specimens with added biochar were prepared. A C-53-grade local ordinary Portland cement was used; the physical and chemical properties are described in Table 1. Sand was acquired from Lawrencepur (a well-known quarry) and was used as a fine aggregate, and its physical characteristics are reported in Table 1. Unlike the control mix, the other two mixes were integrated with biochar of the Santa Maria feverfew plant, as shown in Figure 1. Three types of specimens were prepared: one control, and those containing 0.05% and 0.1% biochar by mass of cement. The composition of the materials is presented in Table 2. A 1:1.5 cement/sand mortar with a water-to-cement ratio of 0.35 was prepared. The admixture was added at the rate of 1% by mass of cement.

Table 1.

Chemical and physical characteristics of the ingredients of mortar.

Figure 1.

(a) Fresh Santa Maria feverfew plant, (b) dry plant, (c) biochar and (d) powdered biochar.

Table 2.

Composition of mortar.

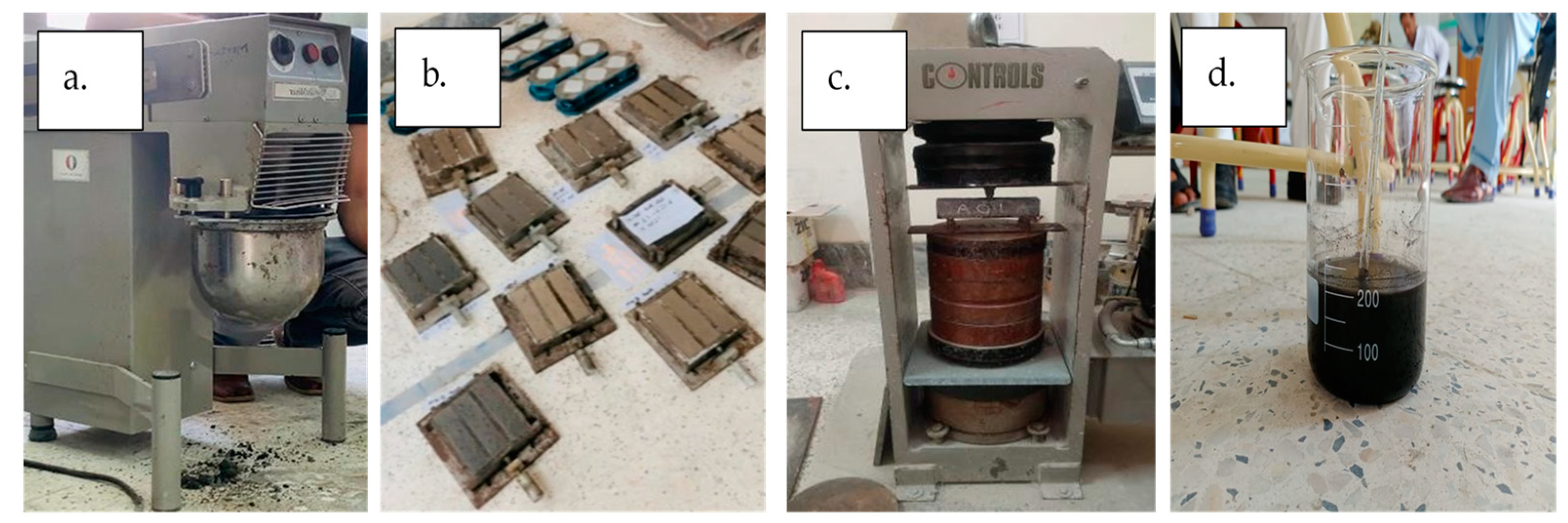

All the materials as described in Table 2 were mixed as per the ASTM C305-20 standard method [8]. To avoid agglomeration caused by the fine size of the biochar particles, the biochar was mixed in water using the UV-sonication technique. The admixture (super-plasticizer) was added (1% by mass of cement) to make the dispersion more effective. All the ingredients were mixed in a Hobart mixer. After mixing, the samples were cast in cubes (50 mm size) and prisms (40 × 40 × 160 mm) according to the ASTM C1314 method [9]. After a one-day period, the specimens were de-molded and immersed in water for curing. The compressive strength was measured through ASTM C109 [10]. The flexural strength of the specimens was determined using the ASTM C348 method [11]. The mixing machine, molding process, strength test and sonicated mix of biochar and water are shown in Figure 2.

Figure 2.

(a) Mixing, (b) molding, (c) flexural strength test and (d) UV-sonicated solution.

3. Results and Discussion

3.1. Compressive Strength

The strength results are presented in Table 3. The results show that there was a slight decrease in the compressive strength. The compressive strength of cementitious composites is closely related to their density [12]. Being porous and lightweight, biochar particles reduce density. A reduction in density might lead to a reduction in compressive strength [13,14]. In the hardened state, biochars are observed to enhance compressive strength [15,16].

Table 3.

Effect of biochar on compressive strength of cementitious mortar.

3.2. Flexural Strength

The influence of the biochar on the flexural strength of the cementitious mortar is shown in Table 4. The flexural strength was enhanced with the biochar addition. A previous study suggests that while the compressive strength mainly relies on the compactness of the material, the flexural strength is mainly dependent on the bond between the ingredients of cementitious materials [17]. As micro-/nano-fibers like those composing biochar enhance the cohesion between the particles, they may enhance the flexural strength [18].

Table 4.

Effect of biochar on flexural strength of cementitious mortar.

4. Conclusions

Based on the experimental outputs, the following conclusions are put forward. The biochar of the Santa Maria feverfew plant slightly reduces the compressive strength at an early age. The reduction in material density seems to be the cause of the reduction in compressive strength. The compressive strength is reduced by 8 and 5% with 0.05 and 0.1% additions of the biochar. Biochar enhances the flexural strength at an early age. Enhancement of material cohesion due to biochar’s fibrous character seems to be the cause of the enhancement of flexural strength. The flexural strength is enhanced by 26 and 42% with 0.05 and 0.1% additions of the biochar at 7 days. Biochars are highly carbon-rich particles. As such, their addition to cementitious mixes is beneficial for carbon capture, a key sustainable development goal. Its addition results in high flexural strength of the end products at an early age, which is beneficial in many construction projects.

Author Contributions

Conceptualization, A.K.; methodology, A.K.S. and M.N.; validation, A.K.S. and M.N.; formal analysis, A.K.S. and M.N.; investigation, A.K.S. and M.N.; resources, A.K.; data curation, A.K.S.; writing—original draft preparation, A.K.; writing—review and editing, A.K.; visualization, M.N.; supervision, A.K.; project administration, A.K.; funding acquisition, A.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research received external funding from Higher Education Commission of Pakistan through NRPU-7984 project.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The authors confirm that the data supporting the findings of this study are available within the article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Khitab, A.; Ahmad, S.; Khan, R.A.; Arshad, M.T.; Anwar, W.; Tariq, J.; Khan, A.S.R.; Khan, R.B.N.; Jalil, A.; Tariq, Z. Production of Biochar and Its Potential Application in Cementitious Composites. Crystals 2021, 11, 527. [Google Scholar] [CrossRef]

- Carnaje, N.P.; Talagon, R.B.; Peralta, J.P.; Shah, K.; Paz-Ferreiro, J. Development and characterisation of charcoal briquettes from water hyacinth (Eichhornia crassipes)-molasses blend. PLoS ONE 2018, 13, e0207135. [Google Scholar] [CrossRef]

- Aburas, H.; Demirbas, A. Evaluation of beech for production of bio-char, bio-oil and gaseous materials. Process Saf. Environ. Prot. 2015, 94, 29–36. [Google Scholar] [CrossRef]

- Gupta, G.K.; Ram, M.; Bala, R.; Kapur, M.; Mondal, M.K. Pyrolysis of chemically treated corncob for biochar production and its application in Cr(VI) removal. Environ. Prog. Sustain. Energy 2018, 37, 1606–1617. [Google Scholar] [CrossRef]

- Gupta, S.; Kua, H.W.; Low, C.Y. Use of biochar as carbon sequestering additive in cement mortar. Cem. Concr. Compos. 2018, 87, 110–129. [Google Scholar]

- Tayyab, S.; Khitab, A.; Iftikhar, A.; Khan, R.B.N.; Kirgiz, M.S. Manufacturing of high-performance light-weight mortar through addition of biochars of millet and maize. Waste Dispos. Sustain. Energy 2023, 5, 97–111. [Google Scholar]

- Iftikhar, A.; Arsalan Khushnood, R.; Khitab, A.; Ahmad, S. Improved fracture response and electromagnetic interference shielding effectiveness of cementitious composites incorporating pyrolytic bagasse fibers and pine needles. Constr. Build. Mater. 2023, 370, 130722. [Google Scholar]

- ASTM C305; Standard Practice for Mechanical Mixing of Hydraulic Cement Pastes and Mortars of Plastic Consistency. ASTM International: West Conshohocken, PA, USA, 2022.

- ASTM C1314-21; Standard Test Method for Compressive Strength of Masonry Prisms. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM C109/C109M-16a; Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube Specimens). ASTM International: West Conshohocken, PA, USA, 2016. [CrossRef]

- ASTM ASTM C348; Standard Test Method for Flexural Strength of Hydraulic-Cement Mortars1. ASTM International: West Conshohocken, PA, USA, 1998.

- Arif, R.; Khitab, A.; Kırgız, M.S.; Khan, R.B.N.; Tayyab, S.; Khan, R.A.; Anwar, W.; Arshad, M.T. Experimental analysis on partial replacement of cement with brick powder in concrete. Case Stud. Constr. Mater. 2021, 15, e00749. [Google Scholar] [CrossRef]

- Fityus, S.; Imre, E. The significance of relative density for particle damage in loaded and sheared gravels. EPJ Web Conf. 2017, 140, 07011. [Google Scholar] [CrossRef]

- Setina, J.; Gabrene, A.; Juhnevica, I. Effect of Pozzolanic Additives on Structure and Chemical Durability of Concrete. Procedia Eng. 2013, 57, 1005–1012. [Google Scholar]

- Khushnood, R.A.; Ahmad, S.; Restuccia, L.; Spoto, C.; Jagdale, P.; Tulliani, J.M.; Ferro, G.A. Carbonized nano/microparticles for enhanced mechanical properties and electromagnetic interference shielding of cementitious materials. Front. Struct. Civ. Eng. 2016, 10, 209–213. [Google Scholar] [CrossRef]

- Khushnood, R.A.; Ahmad, S.; Ferro, G.A.; Restuccia, L.; Tulliani, J.M.; Jagdale, P. Modified fracture properties of cement composites with nano/micro carbonized bagasse fibers. Frat. Integrità Strutt. 2015, 34, 534–542. [Google Scholar]

- Holm, T.A.; Bremner, T.W. State-of-the-Art Report on High-Strength, High-Durability Structural Low-Density Concrete for Applications in Severe Marine Environments; ERDC/SL TR-00-3; U.S. Army Engineer Research and Development Center: Vicksburg, MI, USA, 2000. [Google Scholar]

- Khitab, A.; Ahmad, S.; Khushnood, R.A.; Rizwan, S.A.; Ferro, G.A.; Restuccia, L.; Ali, M.; Mehmood, I. Fracture toughness and failure mechanism of high performance concrete incorporating carbon nanotubes. Frat. Integrità Strutt. 2017, 11, 238–248. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).