Field Trial of Solar-Powered Ion-Exchange Resin for the Industrial Wastewater Treatment Process †

Abstract

:1. Introduction

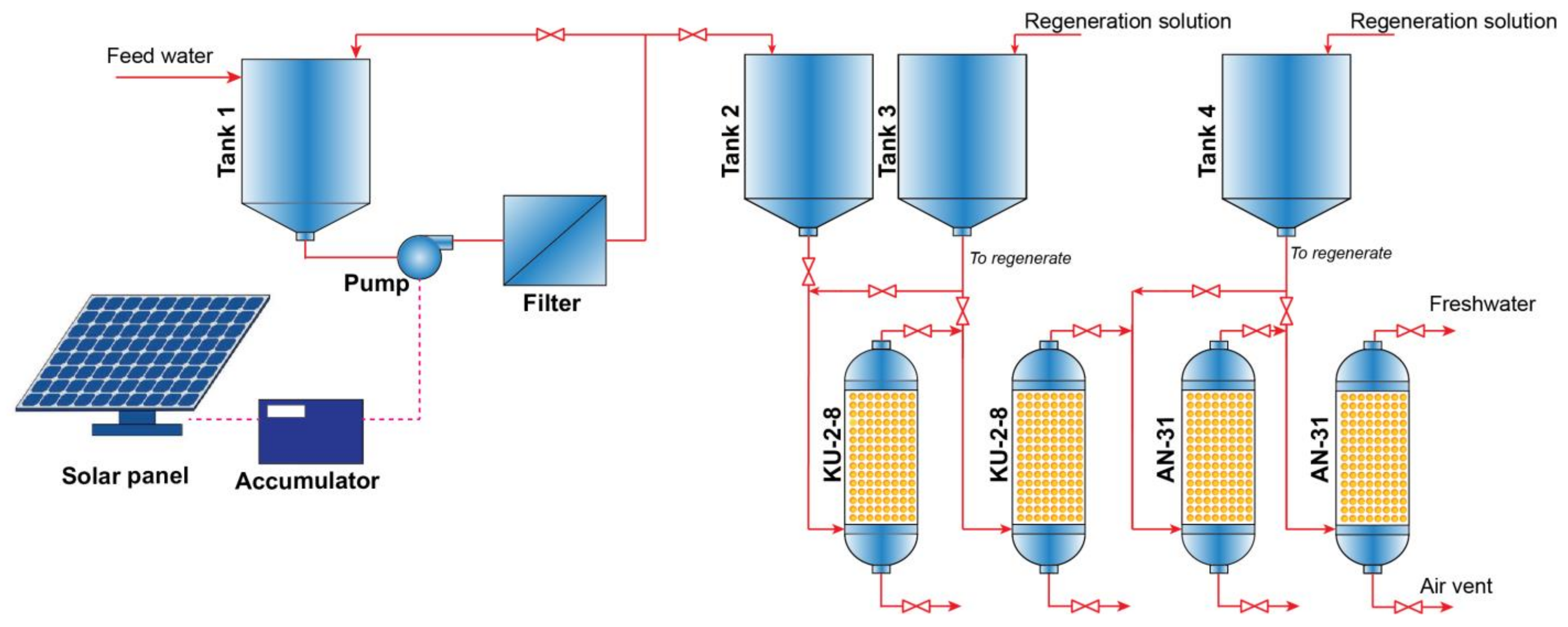

2. Materials and Methods

3. Result and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| TDS | Total dissolved solids |

| MSF | Multi-stage-flash distillation |

| MED | Multi-effect-distillation |

| RO | Reverse osmosis |

| FO | Forward osmosis |

| ED | Electro dialysis |

| EDR | Electro dialysis-reverse |

| H/DH | Humidification/dehumidification |

| MD | Membrane distillation |

| SSD | Solar still distillation |

| CDI | Capacitive deionization |

| IXR | Ion-exchange resin |

References

- Qasim, M.; Badrelzaman, M.; Darwish, N.N.; Darwish, N.A.; Hilal, N. Reverse Osmosis Desalination: A State-of-the-Art Review. Desalination 2019, 459, 59–104. [Google Scholar] [CrossRef]

- Darre, N.C.; Toor, G.S. Desalination of water: A Review. Curr. Pollut. Rep. 2018, 4, 104–111. [Google Scholar] [CrossRef]

- Esrafilian, M.; Ahmadi, R. Energy, Environmental and Economic Assessment of a Polygeneration System of Local Desalination and CCHP. Desalination 2019, 454, 20–37. [Google Scholar] [CrossRef]

- Nair, M.; Kumar, D. Water Desalination and Challenges: The Middle East Perspective: A Review. Desalin. Water Treat 2013, 51, 2030–2040. [Google Scholar] [CrossRef]

- Ihsanullah, I.; Atieh, M.A.; Sajid, M.; Nazal, M.K. Desalination and Environment: A Critical Analysis of Impacts, Mitigation Strategies, and Greener Desalination Technologies. Sci. Total Environ. 2021, 780, 146585. [Google Scholar] [CrossRef] [PubMed]

- Elsaid, K.; Sayed, E.T.; Abdelkareem, M.A.; Mahmoud, M.S.; Ramadan, M.; Olabi, A.G. Environmental Impact of Emerging Desalination Technologies: A Preliminary Evaluation. J. Environ. Chem. Eng. 2020, 8, 104099. [Google Scholar] [CrossRef]

- Panagopoulos, A. Water-Energy Nexus: Desalination Technologies and Renewable Energy Sources. Environ. Sci. Pollut. Res. 2021, 28, 21009–21022. [Google Scholar] [CrossRef] [PubMed]

- Curto, D.; Franzitta, V.; Guercio, A. A Review of the Water Desalination Technologies. Appl. Sci. 2021, 11, 670. [Google Scholar] [CrossRef]

- Kamolov, A.; Turakulov, Z.; Rejabov, S.; Díaz-Sainz, G.; Gómez-Coma, L.; Norkobilov, A.; Fallanza, M.; Irabien, A. Decarbonization of Power and Industrial Sectors: The Role of Membrane Processes. Membranes 2023, 13, 130. [Google Scholar] [CrossRef] [PubMed]

- Saleh, L.; Mezher, T. Techno-Economic Analysis of Sustainability and Externality Costs of Water Desalination Production. Renew. Sustain. Energy Rev. 2021, 150, 111465. [Google Scholar] [CrossRef]

- Davies, P.A.; Afifi, A.; Khatoon, F.; Kuldip, G.; Javed, S.; Khan, S.J. Double-Acting Batch-RO System for Desalination of Brackish Water with High Efficiency and High Recovery. Desalin. Water Treat 2021, 224, 1–11. [Google Scholar] [CrossRef]

- Pearce, G.K. UF/MF Pre-Treatment to RO in Seawater and Wastewater Reuse Applications: A Comparison of Energy Costs. Desalination 2008, 222, 66–73. [Google Scholar] [CrossRef]

| Name of Pointers | Unit | Plant’s Requirement for Treatment of Wastewater (No More Than) | Results of Analysis of Mixed Wastewater before Treatment in Equipment | Results of Analysis of Mixed Wastewater after Treatment in Equipment |

|---|---|---|---|---|

| Total hardness | mEq/L | 3.0 | 9.3 | 0.27 |

| Total alkalinity | - | 0.6 | 3.6 | 0.52 |

| Calcium (Ca2+) | mEq/L | 3.0 | 4.4 | 0.27 |

| Magnesium (Mg2+) | mEq/L | - | 4.9 | - |

| Chlorides (Cl−) | mg/L | 366.15 | 553 | 16.5 |

| Sulfates (SO42−) | mg/L | 662.81 | 827 | 10.6 |

| Total dissolved solids (TDS) | mg/L | 1605.81 | 1885.0 | 27.3 |

| Suspended solids | mg/L | 1.5 | 1.014 | 0.042 |

| Hydrogen carbonate indicator (pH) | - | 7/7.5 | 9.2 | 7.5 |

| Technology | Input | Recovery Ratio | Water Quality [ppm] | Energy Consumption Electrical [kWh/m3] | Energy Consumption Thermal [kWh/m3] |

|---|---|---|---|---|---|

| MSF | Brackish water | 0.33 | 10 | 2.5–4 | 7.5–12 |

| MED | Brackish water | 0.34 | 10 | 1.5–2 | 4–7 |

| RO | Wastewater | 0.65 | 200–500 | 1.5–2.5 | - |

| IXR | Wastewater | 0.8 | 27.3 | 1.2–1.8 | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Eshbobaev, J.; Norkobilov, A.; Turakulov, Z.; Khamidov, B.; Kodirov, O. Field Trial of Solar-Powered Ion-Exchange Resin for the Industrial Wastewater Treatment Process. Eng. Proc. 2023, 37, 47. https://doi.org/10.3390/ECP2023-14626

Eshbobaev J, Norkobilov A, Turakulov Z, Khamidov B, Kodirov O. Field Trial of Solar-Powered Ion-Exchange Resin for the Industrial Wastewater Treatment Process. Engineering Proceedings. 2023; 37(1):47. https://doi.org/10.3390/ECP2023-14626

Chicago/Turabian StyleEshbobaev, Jaloliddin, Adham Norkobilov, Zafar Turakulov, Bakhodir Khamidov, and Orifjon Kodirov. 2023. "Field Trial of Solar-Powered Ion-Exchange Resin for the Industrial Wastewater Treatment Process" Engineering Proceedings 37, no. 1: 47. https://doi.org/10.3390/ECP2023-14626

APA StyleEshbobaev, J., Norkobilov, A., Turakulov, Z., Khamidov, B., & Kodirov, O. (2023). Field Trial of Solar-Powered Ion-Exchange Resin for the Industrial Wastewater Treatment Process. Engineering Proceedings, 37(1), 47. https://doi.org/10.3390/ECP2023-14626