Abstract

The performance of gas-liquid mixing processes in agitated vessels is commonly measured by the degree of gas dispersion, and local measurements of this parameter can provide a more accurate description of the mixing, especially for non-Newtonian fluids. For instance, the fluid flow of complex yield-pseudoplastic solutions is highly affected by the local shear stress, leading to a non-homogeneous air distribution throughout the mixing vessel. Coaxial mixers have demonstrated energy-efficient characteristics for non-Newtonian fluids that improve mixing homogeneity due to the independent rotation of a central impeller and a close-clearance impeller. Therefore, this work aims to investigate the axial profile of the local gas holdup in a PBT-anchor coaxial mixer containing xanthan gum solutions, which is a biopolymer widely utilized as an emulsion stabilizer, dispersing agent, and thickener. The rheological behavior of the solutions was described by the Herschel-Bulkley model, and the effect of the xanthan gum concentration on the gas holdup distribution was analyzed. Electrical resistance tomography (ERT) was employed to obtain the gas holdup from the conductivity measurements of the mixture in each of the four horizontal planes. Results show that the gas holdup increased downward for all solutions, and a lower xanthan gum concentration reduced the non-homogeneity in gas distribution and the overall gas volume fraction. In contrast, higher xanthan gum concentrations enhanced gas holdup in high shear stress regions while weakening air dispersion distant from those regions due to higher viscous forces.

1. Introduction

Gas–liquid mixing in stirred vessels is a crucial process in the chemical and biochemical industries [1]. Achieving homogeneous gas dispersion is essential for ensuring the effectiveness of these systems. Measurement of local gas–liquid mixing performance variables has been shown to provide valuable insights into the degree of gas dispersion [2,3,4]. For a mixing system containing non-Newtonian fluids, the gas distribution is expected to be more non-uniform due to the variation in viscosity throughout the mixing vessel. To overcome this challenge, designing mixing vessels that ensure energy-efficient operations while enhancing homogeneity is highly desirable.

Coaxial mixers have recently been investigated for promoting suitable and more homogeneous gas dispersion in pseudoplastic and yield-pseudoplastic fluids [5,6,7,8,9,10]. However, the high complexity of these systems requires additional analysis of the mixing performance upon varying the rheological parameters. Therefore, this study aims to investigate the local gas holdup distribution of a PBT-anchor containing yield-pseudoplastic biopolymer solutions at different concentrations. In fact, the experimental analysis of the effect of the biopolymer concentration is valuable for improving the design of more efficient mixing systems for these fluids.

2. Materials and Methods

A PBT-anchor coaxial mixer and a ring sparger were used to disperse air into xanthan gum solutions with varying concentrations. The vessel diameter and liquid height were equal to 400 mm, with an aspect ratio of 1:1, which resulted in a total liquid volume of 50 L. The central impeller was positioned in the vessel through the top shaft, while the anchor impeller was attached to the bottom shaft. The two shafts rotated independently using electric motors with capacities of 1.5 hp and 2 hp, respectively. To control the impeller speed, one variable frequency drive (AC Technology Corporation, Uxbridge, MA, USA) was installed in each electric motor, and the rotational speed of each impeller was measured using a tachometer (DT-205LR, Shimpo Instruments, Lynbrook, NY, USA).

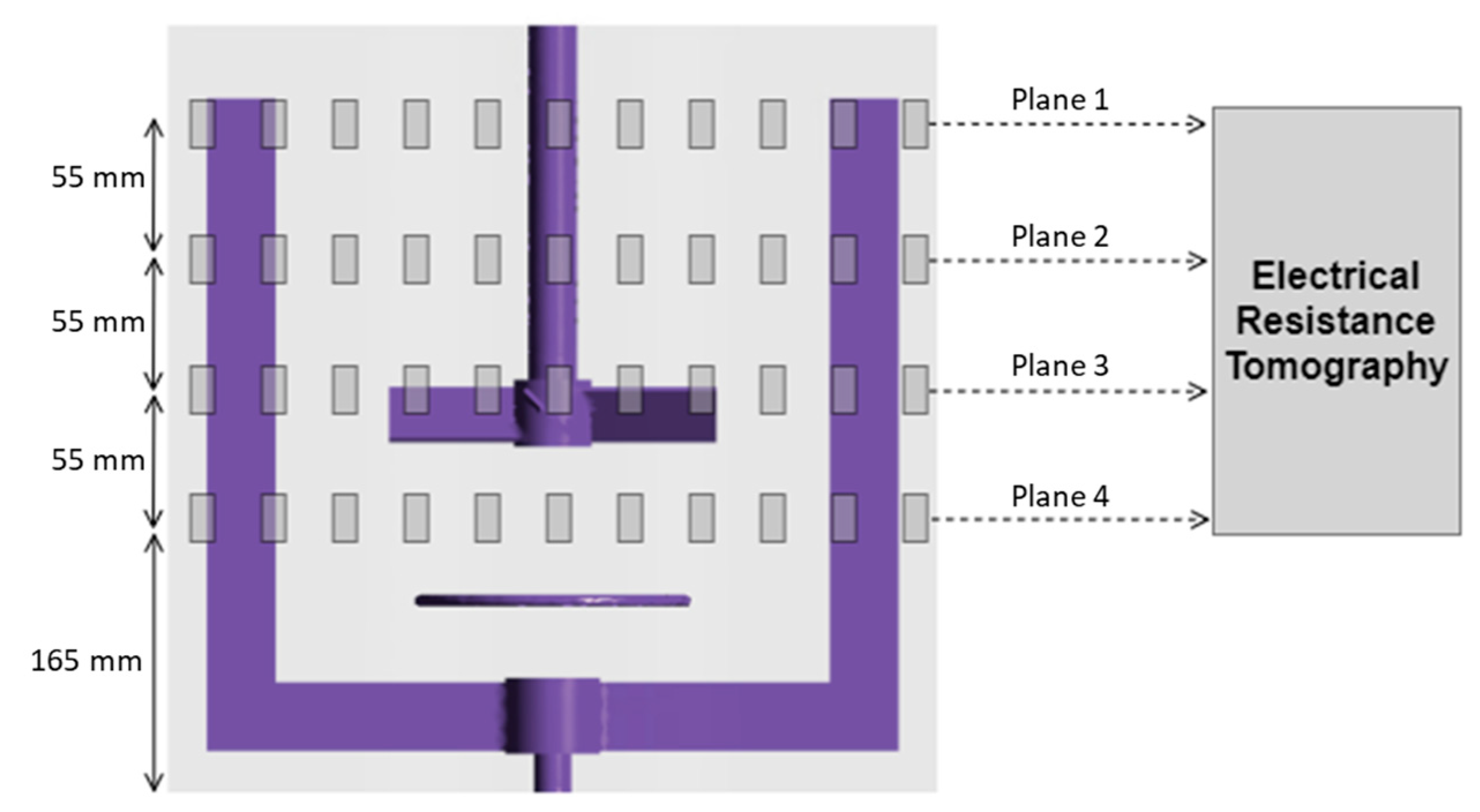

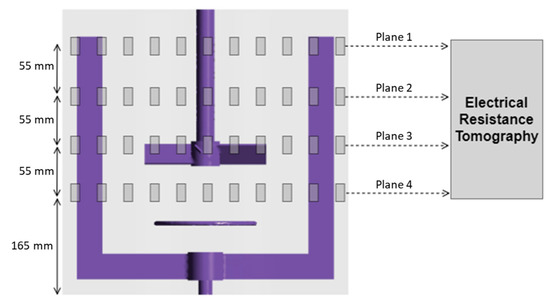

The gas holdup was obtained at each radial plane using the electrical resistance tomography (ERT) technique, as illustrated in Figure 1. The ERT system comprised three components: multiple electrodes attached to the vessel wall, a data acquisition system (DAS), and a host computer equipped with data processing software. Sixteen stainless steel electrodes were evenly distributed in four different axial positions (ERT planes) that were spaced 55 mm apart. The electrodes were placed in contact with the material inside the tank without modifying the fluid flow. Furthermore, the ERT system (ITS 2000 p2+) employed the adjacent strategy for data collection with an injection current set to 1.5 mA, a frequency of the data acquisition system of 4800 Hz, and a sampling time interval of 55 ms. The electrodes were connected to the data acquisition system, and the signal was sent to the computer for image reconstruction using the ITS tool suite software. As a result, the local conductivity values were obtained by averaging 150 frames, and the gas holdup values were calculated using Maxwell’s equation [11].

Figure 1.

Experimental setup for the gas holdup measurement in a PBT-anchor coaxial mixer.

The PBT-anchor coaxial mixer was evaluated at a constant PBT speed of 500 rpm, an anchor speed of 40 rpm, and an aeration rate of 20 L/min. To evaluate the effect of xanthan gum concentration on the local gas holdup, three different concentrations of Ketrol F xanthan gum were considered, and their rheological behavior was determined using a coaxial cylinder rheometer (Kinexus Ultra+, NETZSCH). All xanthan gum solutions were characterized as yield-pseudoplastic fluids, and their rheological parameters are presented in Table 1.

Table 1.

Herschel-Bulkley parameters of the xanthan gum solutions.

3. Results and Discussion

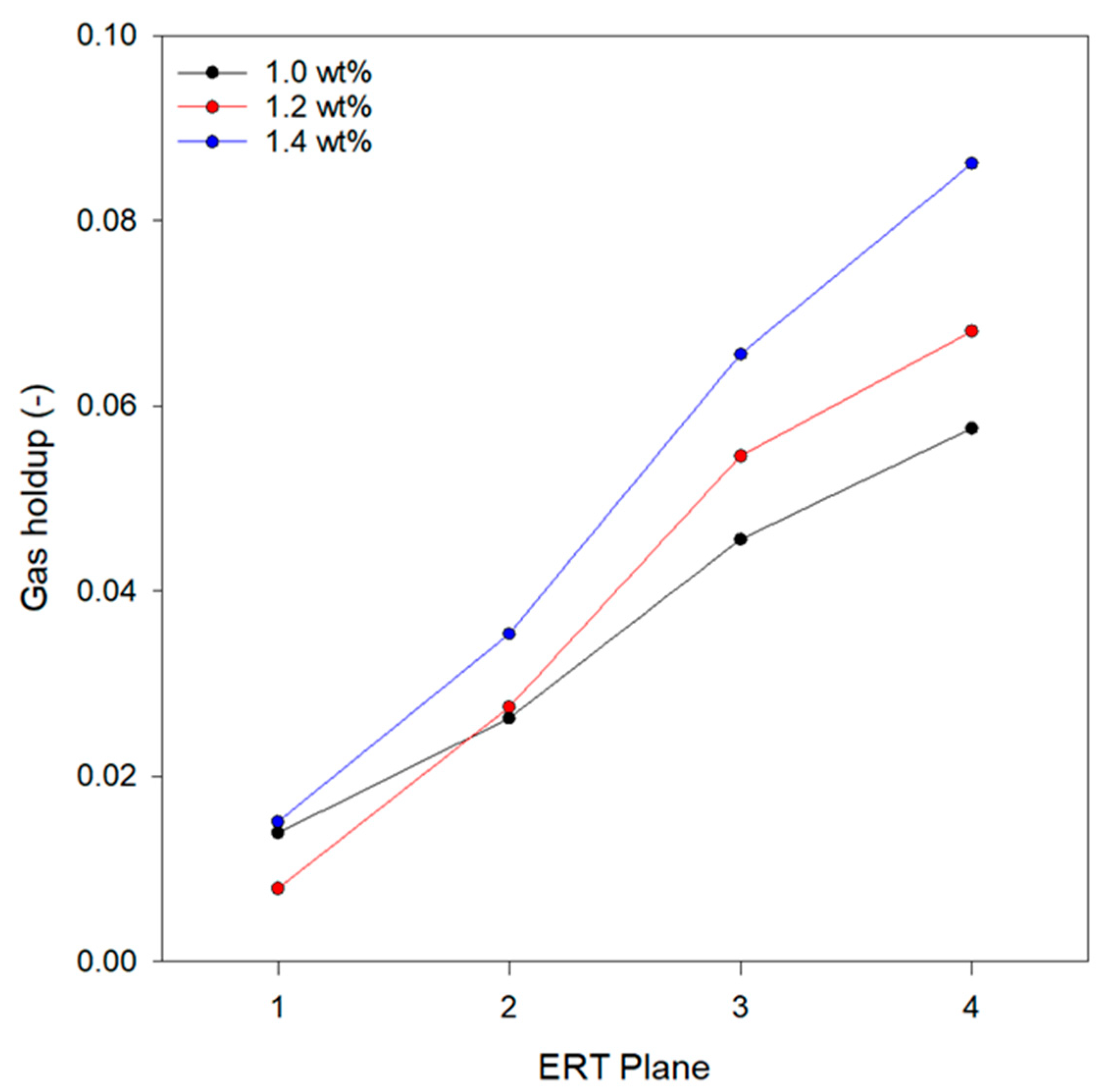

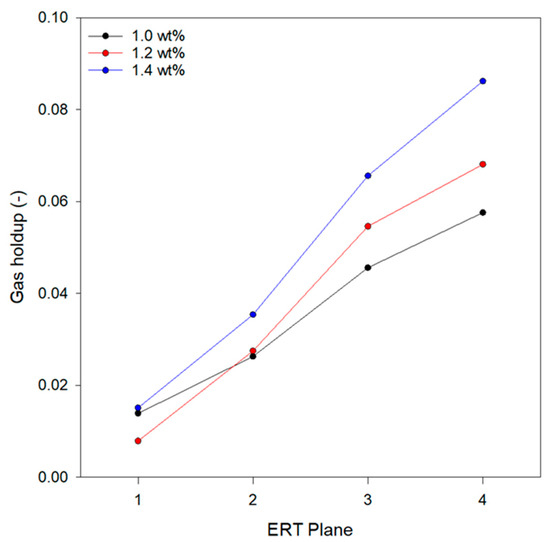

This study investigated the effect of increasing biopolymer concentration on the local gas holdup, as illustrated in Figure 2. Results demonstrate a decrease in gas holdup from Plane 4 to Plane 1 for all concentrations; however, the rate of decrease was more pronounced with increasing the xanthan gum concentration.

Figure 2.

Effect of the xanthan gum concentration on the local gas holdup.

The higher gas holdup observed in Planes 3 and 4 indicated that the air bubbles are concentrated below the central impeller. Furthermore, increasing biopolymer concentration led to higher gas holdup in this region, which was attributed to the increased viscous forces that hindered air distribution and promoted bubble coalescence. However, it is worth noting that an increase in gas volume fraction did not correspond to enhanced mixing performance, as indicated by the deviation in gas holdup between the ERT Planes presented in Table 2.

Table 2.

Global gas holdup and deviation for each xanthan gum concentration.

Table 2 shows that increasing xanthan gum concentration resulted in a higher global gas holdup and greater variation in the local gas holdup (at different planes). In fact, these results indicated a higher degree of homogeneity at the lowest biopolymer concentration. In contrast, higher xanthan gum concentrations enhanced gas holdup in high shear stress regions while weakening air dispersion away from those regions due to the higher viscous forces, resulting in a lower degree of homogeneity.

4. Conclusions

This study investigated the main effect of xanthan gum concentration on the local gas holdup in a coaxial mixing system. The experimental results demonstrated that local gas holdup decreased towards the liquid surface for all configurations. However, the rate of decrease was larger for the higher xanthan gum concentration due to the elevated viscous forces, which resulted in a higher global gas holdup and greater non-homogeneity in the mixing system. These findings provided a more comprehensive understanding of the relationship between biopolymer concentration, local and global gas holdup, and the mixing performance of the complex gas dispersion in yield-pseudoplastic solutions using coaxial mixers.

Author Contributions

P.L.B.: Conceptualization, Methodology, Software, Validation, Formal analysis, Writing—original draft. F.E.-M.: Conceptualization, Resources, Methodology, Writing—review and editing, Supervision, Project administration, Funding acquisition. A.L.: Conceptualization, Resources, Methodology, Writing—review and editing, Supervision, Project administration, Funding acquisition. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Natural Sciences and Engineering Research Council of Canada (NSERC) [grant numbers RGPIN-2019-04644, RGPIN-2019-05644].

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The authors gratefully acknowledge the financial support of the Natural Sciences and Engineering Research Council of Canada.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Sher, F.; Sajid, Z.; Tokay, B.; Khzouz, M.; Sadiq, H. Study of gas–liquid mixing in stirred vessel using electrical resistance tomography. Asia-Pac. J. Chem. Eng. 2016, 11, 855–865. [Google Scholar] [CrossRef]

- Laakkonen, M.; Honkanen, M.; Saarenrinne, P.; Aittamaa, J. Local bubble size distributions, gas–liquid interfacial areas and gas holdups in a stirred vessel with particle image velocimetry. Chem. Eng. J. 2005, 109, 37–47. [Google Scholar] [CrossRef]

- Mueller, S.G.; Dudukovic, M.P. Gas Holdup in Gas-Liquid Stirred Tanks. Ind. Eng. Chem. Res. 2010, 49, 10744–10750. [Google Scholar] [CrossRef]

- Jamshidzadeh, M.; Ein-Mozaffari, F.; Lohi, A. Local and overall gas holdup in an aerated coaxial mixing system containing a non-Newtonian fluid. AIChE J. 2020, 66, e17016. [Google Scholar] [CrossRef]

- Liu, B.; Liu, J.; Zhang, Y.; Chen, M.; Qin, F.; Jin, Z. Experimental Research on the Power Consumption of a Coaxial Mixer in a Fluid with High Viscosity. Ind. Eng. Chem. Res. 2013, 52, 6862–6867. [Google Scholar] [CrossRef]

- Foucault, S.; Ascanio, G.; Tanguy, P.A. Mixing Times in Coaxial Mixers with Newtonian and Non-Newtonian Fluids. Ind. Eng. Chem. Res. 2006, 45, 352–359. [Google Scholar] [CrossRef]

- Jamshidzadeh, M.; Kazemzadeh, A.; Ein-Mozaffari, F.; Lohi, A. Intensification of gas dispersion in pseudoplastic fluids with coaxial mixers. Chem. Eng. Process. Process Intensif. 2020, 155, 108058. [Google Scholar] [CrossRef]

- Jegatheeswaran, S.; Kazemzadeh, A.; Ein-Mozaffari, F. Enhanced aeration efficiency in non-Newtonian fluids using coaxial mixers: High-solidity ratio central impeller with an anchor. Chem. Eng. J. 2019, 378, 122081. [Google Scholar] [CrossRef]

- Barros, P.L.; Ein-Mozaffari, F.; Lohi, A. Power Consumption Characterization of Energy-Efficient Aerated Coaxial Mixers Containing Yield-Stress Biopolymer Solutions. Ind. Eng. Chem. Res. 2022, 61, 12813–12824. [Google Scholar] [CrossRef]

- Sharifi, F.; Behzadfar, E.; Ein-Mozaffari, F. Intensified gas-liquid mixing in bioreactors equipped with a dual coaxial mixer containing biopolymer solutions. Chem. Eng. Res. Des. 2023, 191, 109–126. [Google Scholar] [CrossRef]

- Maxwell, J.C. A Treatise on Electricity and Magnetism; Clarendon Press: Oxford, UK, 1873; Volume 1. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).