Aspen Plus Modelling and Simulation of Supercritical Steam and Poultry Litter Gasification for the Production of Hydrogen Fuel and Electricity †

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

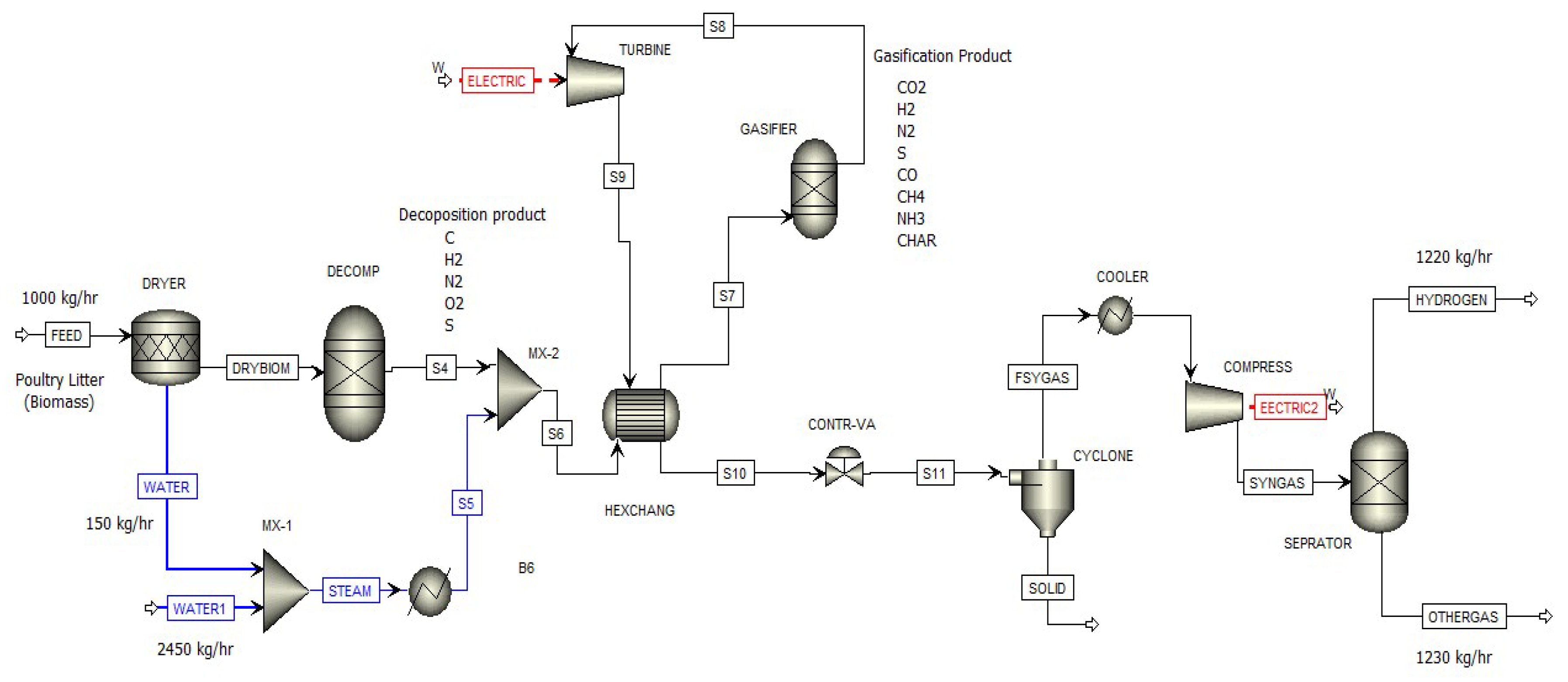

2.2.1. Process Description

2.2.2. Modelling and Simulation

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Singh, D.K.; Tirkey, J.V. Process modelling and thermodynamic performance optimization of biomass air gasification fuelled with waste poultry litter pellet by integrating Aspen plus with RSM. Biomass Bioenergy 2022, 158, 106370. [Google Scholar] [CrossRef]

- Martínez-Rodríguez, A.; Abánades, A. Comparative Analysis of Energy and Exergy Performance of Hydrogen Production Methods. Entropy 2020, 22, 1286. [Google Scholar] [CrossRef] [PubMed]

- Khan, M.A.; Al-Shankiti, I.; Ziani, A.; Idriss, H. Demonstration of green hydrogen production using solar energy at 28% efficiency and evaluation of its economic viability. Sustain. Energy Fuels 2021, 5, 1085–1094. [Google Scholar] [CrossRef]

- Singh, N.S.; Vineet, K.S. Fundamentals and Use of Hydrogen as A Fuel. ISST J. Mech. Eng. 2015, 6, 63–68. [Google Scholar]

- Oruc, O.; Dincer, I. Assessing the potential of thermo-chemical water splitting cycles: A bridge towards clean and sustainable hydrogen generation. Fuel 2021, 286, 119325. [Google Scholar] [CrossRef]

- Mohammadidoust, A.; Branch, K.; Omidvar, M.R. Simulation and modelling of hydrogen production and power from wheat straw biomass at supercritical condition through Aspen Plus and ANN approach. Biomass Convers. Biorefinery 2022, 12, 3857–3873. [Google Scholar] [CrossRef]

- Al-Qahtani, A.; Parkinson, B.; Hellgardt, K.; Shah, N.; Guillen-Gosalbez, G. Uncovering the true cost of hydrogen production routes using life cycle monetisation. Appl. Energy 2021, 281, 115958. [Google Scholar] [CrossRef]

- Inuwa, A.M.; Giwa, S.O.; Joel, A.S. Optimization of Linear Alkyl Benzene Yield through Modelling and Simulation. ABUAD J. Eng. Res. Dev. 2023, 5, 62–73. [Google Scholar]

- Singh, A.K.; Das, C.; Indra, A. Scope and prospect of transition metal-based co-catalysts for visible-light-driven photocatalytic hydrogen evolution with graphitic carbon nitride. Coord. Chem. Rev. 2022, 465, 214516. [Google Scholar] [CrossRef]

- Hussain, M.; Multan, T. A kinetic-based simulation model of palm kernel shell steam gasification in a circulating fluidized bed using Aspen Plus®: A case study. Biofuels 2018, 9, 635–646. [Google Scholar] [CrossRef]

- Mansoori, G.A.; Agyarko, L.B.; Estévez, L.; Fallahi, B.; Gladyshev, G.; Gonçalves, R.; Niaki, S.; Perišić, O.; Sillanpää, M.; Tumba, K.; et al. Fuels of the Future for Renewable Energy Sources (Ammonia, Biofuels, Hydrogen). arXiv, arXiv:2102.00439.

| Materials | Uses |

|---|---|

| 1. Aspen Plus version 11.0 | Aspen Plus is a chemical engineering simulator used for the modelling and simulation of the design process. |

| 2. Data sheet of poultry litter | This consists of the feed specifications: 3 ultimate, proximate and composition analyses of poultry litter from an online literature review. |

| Ultimate Analysis (wt. %) | Poultry Litter |

|---|---|

| Carbon | 43.98 |

| Hydrogen | 5.16 |

| Nitrogen | 4.63 |

| Oxygen Sulphur | 31.98 0.75 |

| Proximate Analysis (wt. %) | Poultry Litter |

| Volatile matter | 63.6 |

| Fixed carbon | 15.3 |

| Moisture content | 7.6 |

| Ash | 13.5 |

| Feed | Amount |

|---|---|

| Biomass (Poultry litter) | 1000 kg/h |

| Temperature | 25 °C |

| Pressure | 1 atm |

| Steam | 2000 kg/h |

| Reaction No. | Reaction Name | Reaction Equation | Heat of Reaction ΔH(KJ/mol) |

|---|---|---|---|

| 1 | Combustion reaction | −111 | |

| 2 | Combustion reaction | −283 | |

| 3 | Boudouard reaction | +172 | |

| 4 | Methanation reaction | −75 | |

| 5 | Methanation reaction | +103 | |

| 6 | Water gas shift reaction | +131 | |

| 7 | Water gas shift reaction | −41 | |

| 8 | H2S formation reaction | −170.5 | |

| 9 | Steam reforming | +206 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Inuwa, A.M.; Jato, I.; Giwa, S.O. Aspen Plus Modelling and Simulation of Supercritical Steam and Poultry Litter Gasification for the Production of Hydrogen Fuel and Electricity. Eng. Proc. 2023, 37, 102. https://doi.org/10.3390/ECP2023-14723

Inuwa AM, Jato I, Giwa SO. Aspen Plus Modelling and Simulation of Supercritical Steam and Poultry Litter Gasification for the Production of Hydrogen Fuel and Electricity. Engineering Proceedings. 2023; 37(1):102. https://doi.org/10.3390/ECP2023-14723

Chicago/Turabian StyleInuwa, Ahmed Mohammed, Isaac Jato, and Saidat Olanipekun Giwa. 2023. "Aspen Plus Modelling and Simulation of Supercritical Steam and Poultry Litter Gasification for the Production of Hydrogen Fuel and Electricity" Engineering Proceedings 37, no. 1: 102. https://doi.org/10.3390/ECP2023-14723

APA StyleInuwa, A. M., Jato, I., & Giwa, S. O. (2023). Aspen Plus Modelling and Simulation of Supercritical Steam and Poultry Litter Gasification for the Production of Hydrogen Fuel and Electricity. Engineering Proceedings, 37(1), 102. https://doi.org/10.3390/ECP2023-14723