1. Introduction

Asphalt mixtures reinforced with fibers can be adopted to improve pavement performance. Fibers have been used to strengthen paving materials for decades [

1,

2]. They are commonly used in Stone Matrix Asphalt (SMA), porous asphalt mixtures, and open gradation asphalt mixtures to mitigate binder drain-down [

3,

4]. Incorporating fibers can improve fatigue cracking and the permanent deformation resistance of asphalt mixtures [

5].

Cracking is the primary concern for road pavements [

6]; so, identifying a potential material to reduce cracking can be very beneficial. Due to their inherent compatibility with the asphalt binder and better mechanical properties, fibers offer an excellent resource for reinforcing asphalt mixtures [

7]. Many types of fibers are available for incorporation into asphalt mixtures. Cellulose and mineral fibers are commonly used in gap-graded SMA and open-graded or porous mixtures [

8]. Polypropylene and polyester fibers have been used in dense-graded asphalt mixtures and are still somewhat used in SMA [

9]. Various polymers and steel wool fibers have been added to asphalt mixtures [

10]. Recently, aramid fibers have been used to reinforce asphalt mixtures due to their strength [

11].

Research has been conducted to study the impact of aramid fibers on asphalt mixtures and road pavements, mainly to reduce pavement cracking and rutting. An extensive testing program was carried out by [

7], where they performed binder and mixture characterization tests. They performed triaxial strength, permanent deformation, dynamic modulus, fatigue cracking flexural strength indirect tensile and cracking propagation tests for asphalt mixture. Despite the conclusions obtained where it is visible that the asphalt mixture improves performance using aramid fibers, some aspects should be studied to clarify the effect of these fibers that are characterized by a diameter less than 0.1 mm, and high strength. Their length varies from around 20 mm to 50 mm, influencing how fibers support the distress modes. So, this paper contributes to understanding how fibers work on fatigue and rutting by looking at the behavior of asphalt binders with aramid fibers.

2. Materials

This work was carried out using 0.012 mm diameter aramid fibers with three different lengths, namely 25, 38, and 50 mm. These lengths suit asphalt mixtures with 12.5, 19, and 25 mm maximum aggregate sizes. These fibers were mixed into asphalt binder in 0.12%, 0.14%. 0.17% and 0.20% by weight of binder, meaning 12 asphalt binders were produced. They were tested for rheological properties through the MSCR (Multiple Stress Creep and Recovery), LAS (Linear Amplitude Sweep), and shear complex modulus tests, as represented in

Figure 1. Test specimen names were defined based on the fiber content and fiber length, such as C12L25, meaning that fiber content is 0.12% and the fiber length is 25 mm. The SF specimen refers to asphalt binder without fibers, used as reference. The 35/50 pen asphalt binder was used.

Aramid fibers with a melt temperature greater than 500 °C were added to the asphalt binder by the wet process, mixing them on the hot asphalt (150 °C), as observed in

Figure 2 (left), obtaining test specimens as observed on the right-hand part of the figure. Aramid fibers do not melt in the asphalt. The 8 and 25 mm diameter specimens were cut from the hot-prepared samples to be used in a dynamic shear rheometer, where tests were performed. A 1 mm gap was set in the rheologic tests.

3. Results

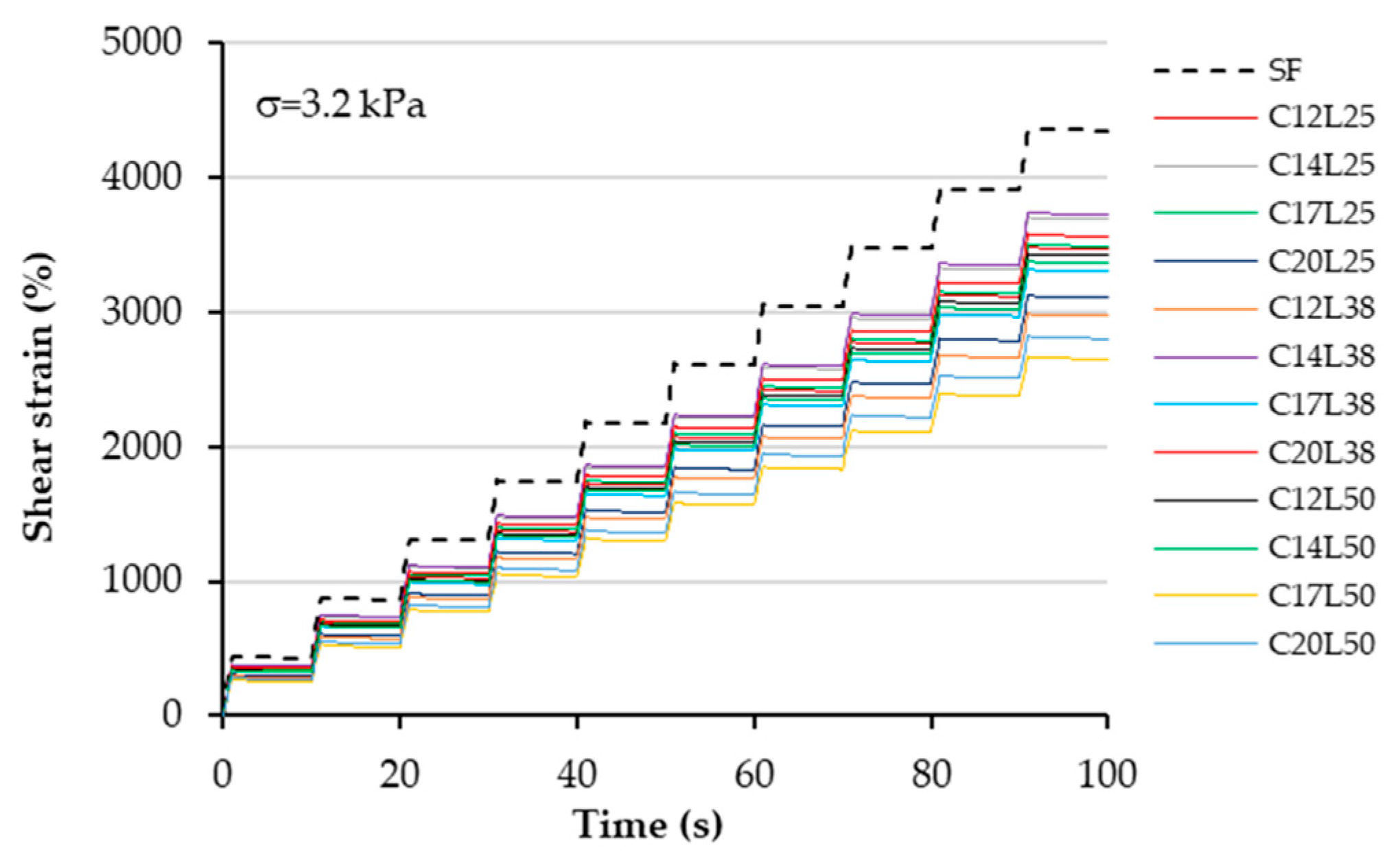

MSCR tests were carried out on all specimens to obtain the fiber-modified binder recovery. The evolution of the shear strain during the test for an applied 3.2 kPa shear strain is presented in

Figure 3, where it is possible to observe a minimal recovery obtained in this experiment. It was expected for the base bitumen. The presence of fiber reduced the accumulation of rutting more than that obtained for the case without fibers. It can also be observed that longer fibers and their content minimize the accumulation of rutting.

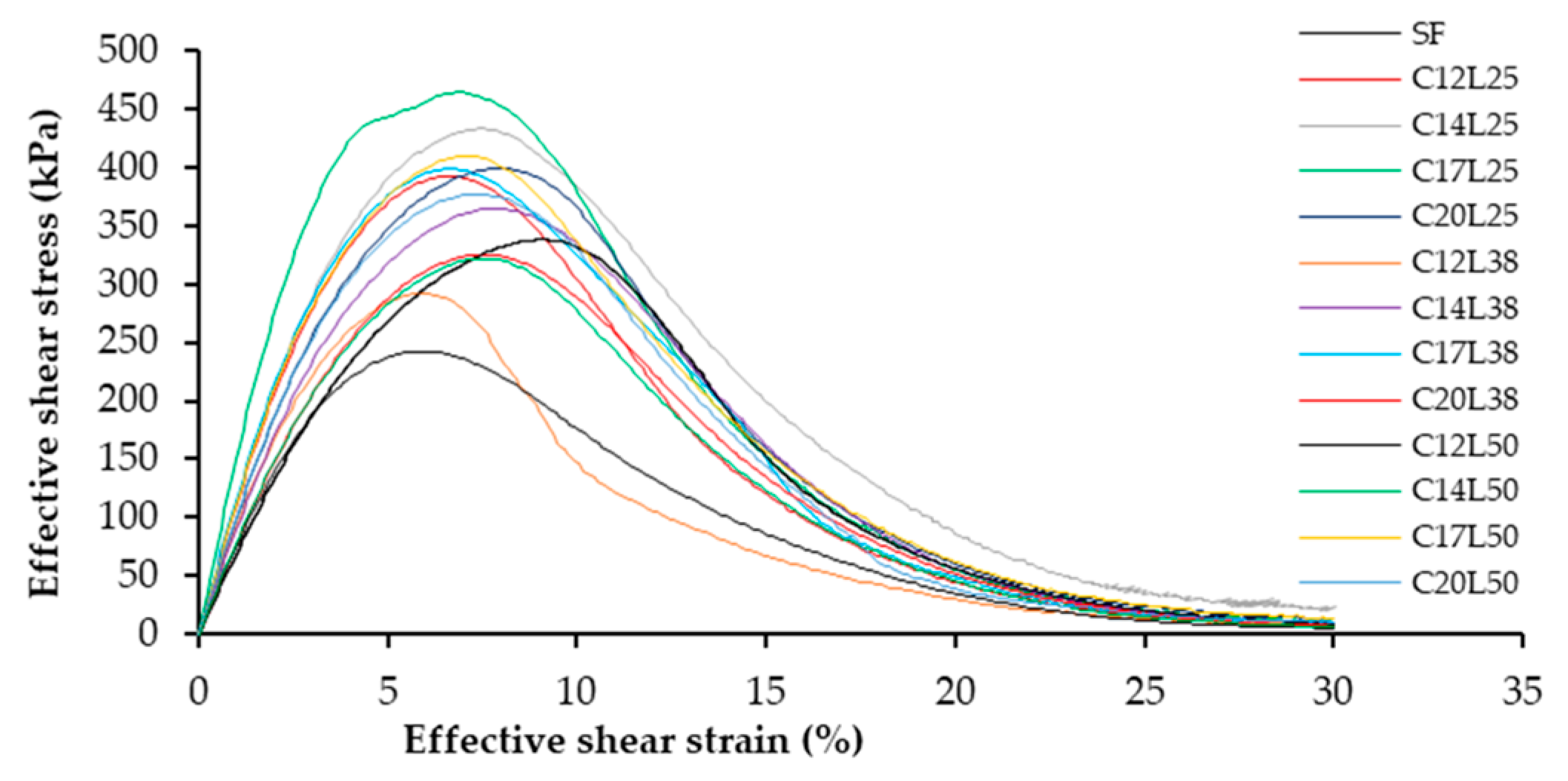

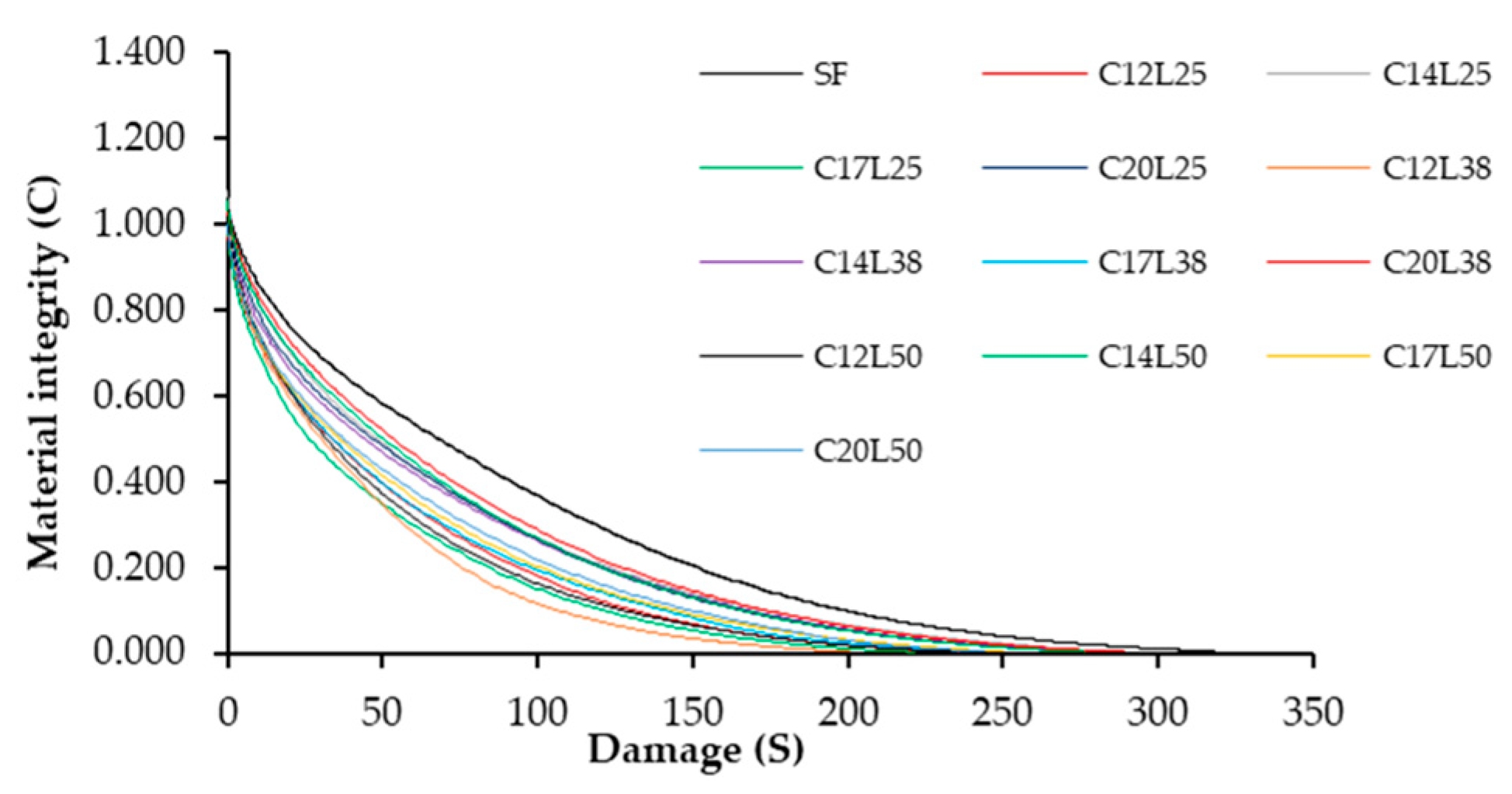

LAS tests on all specimens produced the results presented in

Figure 4 and

Figure 5, where a significant difference is visible between the cases studied in terms of curve slopes and energy (

Figure 4). In terms of C-S characteristic curves (

Figure 5), different behaviors are visible, meaning that the presence of fiber influences the asphalt-binder behavior. It is also observed that increasing the fiber’s content and length has a positive effect on the cracking resistance of the binder, meaning that there is an expected improvement of the fatigue resistance of the asphalt mixtures.

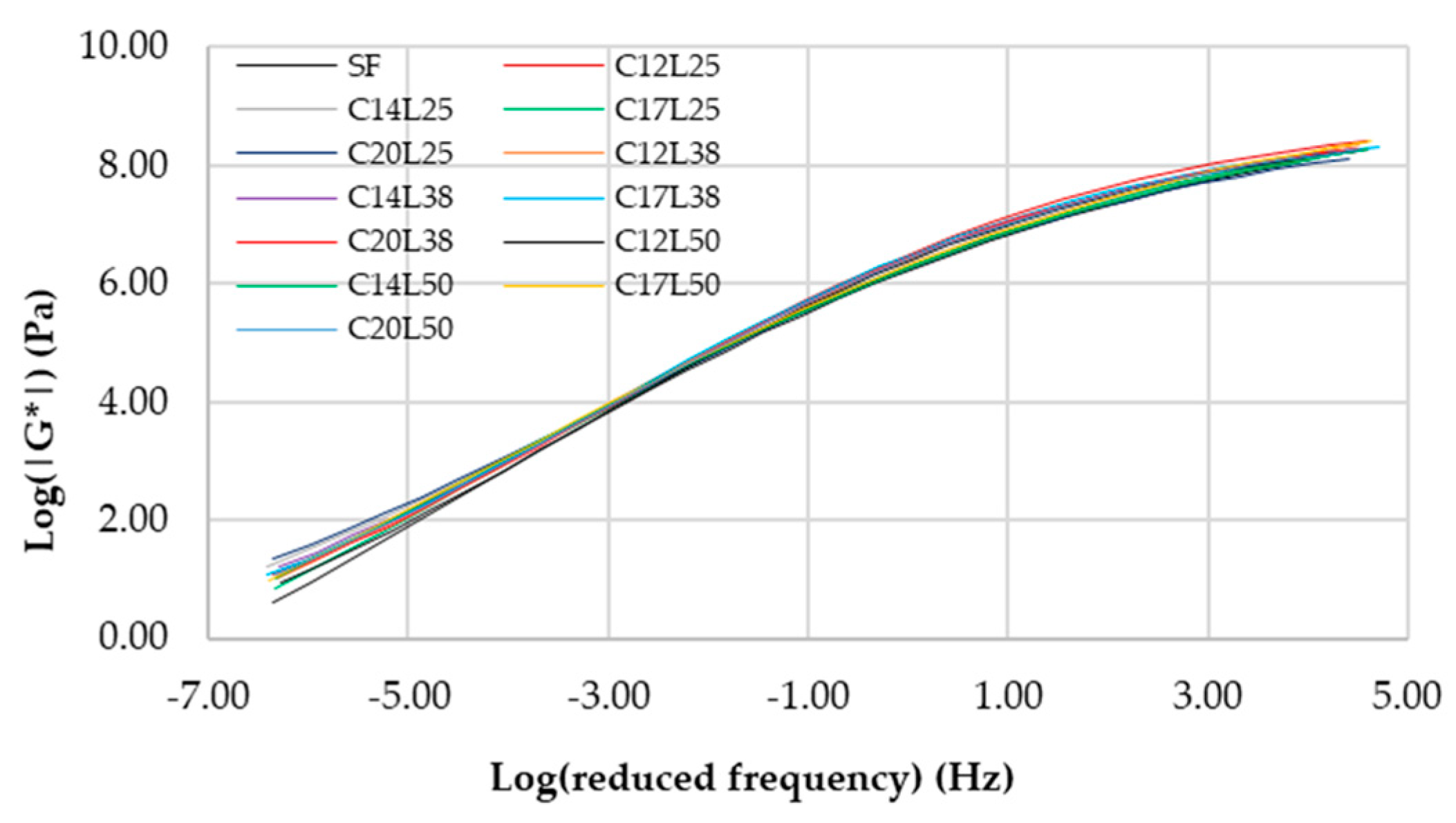

Tests to obtain the complex shear modulus (

Figure 6) show a slight variation of the modulus amount in the different case studies (fiber content and length). These master curves were obtained for 20 °C using the WLF model. All asphalt binders with fiber seem to exhibit the same complex shear modulus as the reference asphalt binder.

Despite the minor differences observed in the master curves, they are represented in a log–log scale which means that these minor differences represent significant variations in the complex shear modulus. There is a crossover frequency where all master curves cross, around log(−3.0) Hz.

4. Conclusions

This paper presented a procedure to assess the behavior of asphalt binders with aramid fibers where those fibers were added to the asphalt while wet and proceeded to produce specimens for dynamic shear tests, namely, to evaluate the creep and recovery response, linear analysis, and complex shear modulus.

The developed process seems useful for adding aramid fibers to the asphalt binder. Still, the dispersion of the fiber into the asphalt binder is problematic due to the microscopic fibers’ diameter. This problem also appears in the asphalt mixtures and should be carefully treated.

Based on the results obtained from this experimental procedure, it is possible to conclude that a longer and higher content of aramid fibers in the asphalt binder improves fatigue and rutting resistance.

Author Contributions

Conceptualization, J.P.; methodology, J.P. and G.N.; formal analysis, J.P.; investigation, G.N.; data curation, G.N., original draft preparation, J.P., G.N. and J.C.; writing—review and editing, J.P., G.N., J.C. and P.P. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data available by request.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Mrema, A.H.; Noh, S.-H.; Kwon, O.-S.; Lee, J.-J. Performance of Glass Wool Fibers in Asphalt Concrete Mixtures. Materials 2020, 13, 4699. [Google Scholar] [CrossRef] [PubMed]

- Mohajerani, A.; Hui, S.-Q.; Mirzababaei, M.; Arulrajah, A.; Horpibulsuk, S.; Abdul Kadir, A.; Rahman, M.T.; Maghool, F. Amazing Types, Properties, and Applications of Fibres in Construction Materials. Materials 2019, 12, 2513. [Google Scholar] [CrossRef] [PubMed]

- Poulikakos, L.; Gilani, M.S.; Derome, D.; Jerjen, I.; Vontobel, P. Time resolved analysis of water drainage in porous asphalt concrete using neutron radiography. Appl. Radiat. Isot. 2013, 77, 5–13. [Google Scholar] [CrossRef]

- Jamieson, S.; White, G. Laboratory Evaluation of the Performance of Stone Mastic Asphalt as an Ungrooved Runway Surface. Materials 2021, 14, 502. [Google Scholar] [CrossRef] [PubMed]

- Landi, D.; Marconi, M.; Bocci, E.; Germani, M. Comparative life cycle assessment of standard, cellulose-reinforced and end of life tires fiber-reinforced hot mix asphalt mixtures. J. Clean. Prod. 2020, 248, 119295. [Google Scholar] [CrossRef]

- Decker, D.S. Best practices for crack treatments in asphalt pavements. In Proceedings of the 6th Eurasphalt & Eurobitume Congress, Prague, Czech Republic, 1–3 June 2016. [Google Scholar]

- Klinsky, L.; Kaloush, K.; Faria, V.; Bardini, V. Performance characteristics of fiber modified hot mix asphalt. Constr. Build. Mater. 2018, 176, 747–752. [Google Scholar] [CrossRef]

- Asi, I.M. Laboratory comparison study for the use of stone matrix asphalt in hot weather climates. Constr. Build. Mater. 2006, 20, 982–989. [Google Scholar] [CrossRef]

- Putman, B.J.; Amirkhanian, S.N. Utilization of waste fibers in stone matrix asphalt mixtures. Resour. Conserv. Recycl. 2004, 42, 265–274. [Google Scholar] [CrossRef]

- Tang, N.; Huang, W.; Hao, G. Effect of aging on morphology, rheology, and chemical properties of highly polymer modified asphalt binders. Constr. Build. Mater. 2021, 281, 122595. [Google Scholar] [CrossRef]

- Li, H.; Yu, J.; Liu, Q.; Li, Y.; Wu, Y.; Xu, H. Induction Heating and Healing Behaviors of Asphalt Concretes Doped with Different Conductive Additives. Adv. Mater. Sci. Eng. 2019, 2019, 1–10. [Google Scholar] [CrossRef]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).