Design and Evaluation of Ultra-Thin Overlay with High Viscosity and High Elasticity †

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

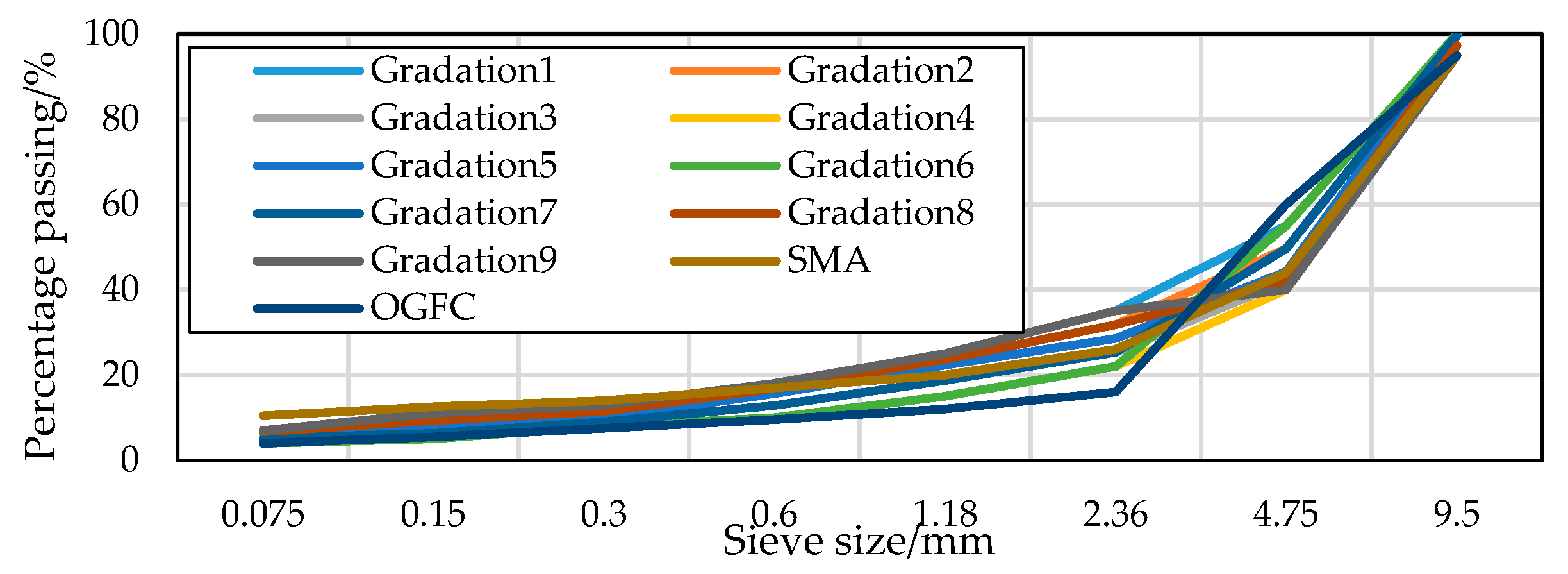

Gradation Design of UT-10

3. Results and Discussion

3.1. Determination of Air Void Ratio

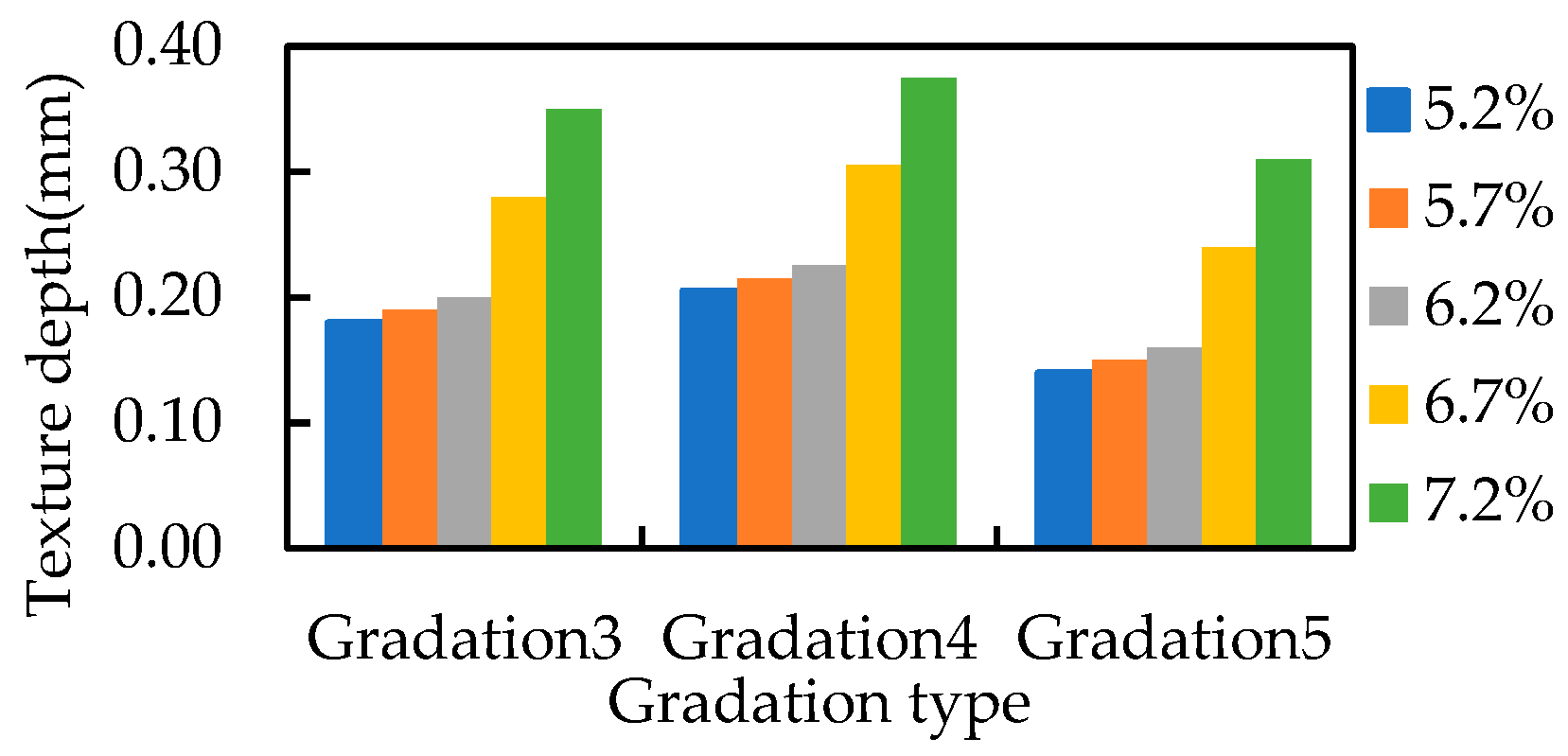

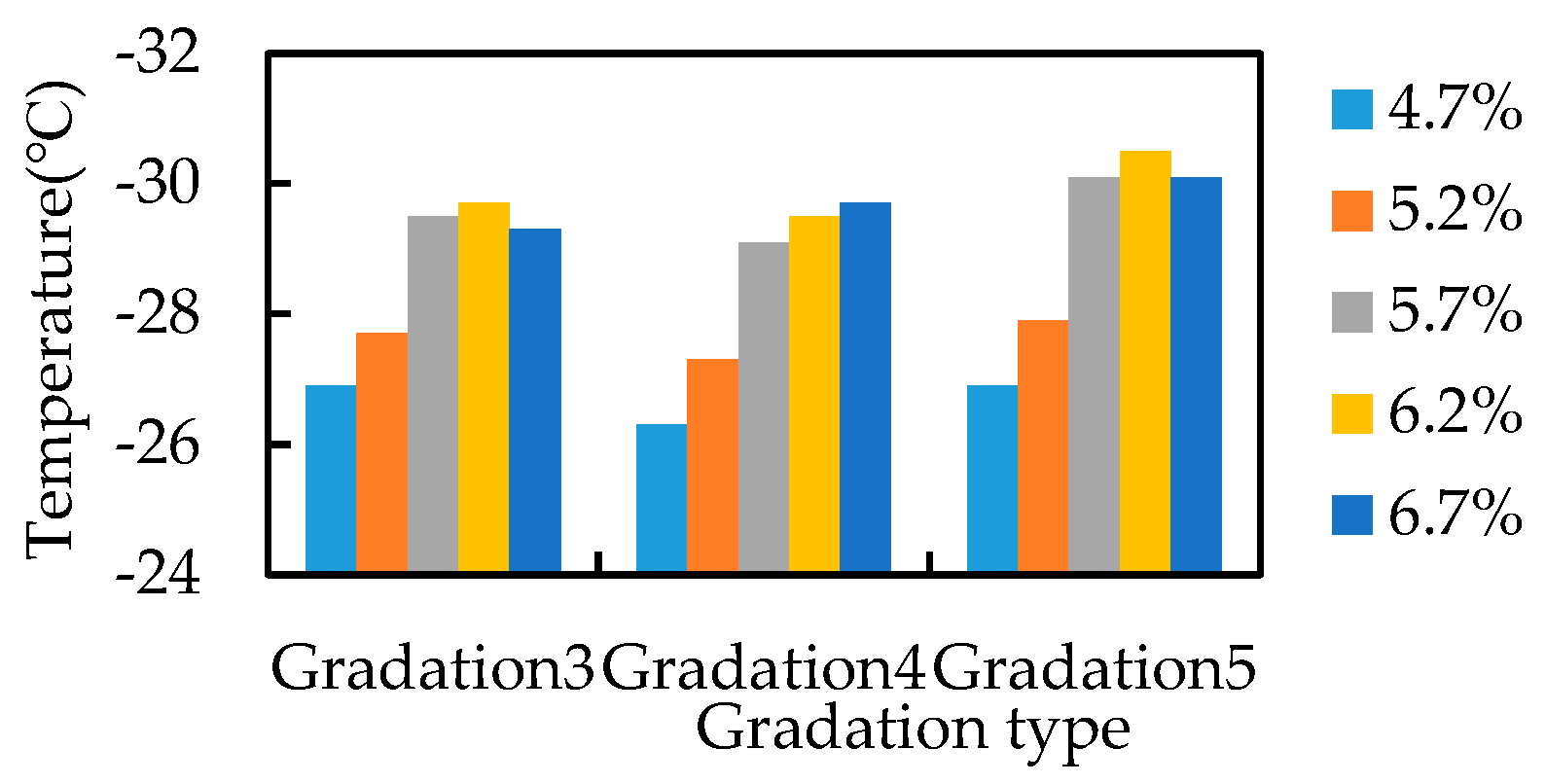

3.2. Determination of Asphalt Aggregate Ratio

3.3. Evaluation of Mixture Performance

4. Conclusions

- The performance of HVHE asphalt with gradation 5, 5.7% asphalt aggregate ratios, and 13.9% air void ratio fully meets the technical requirements (JTG E20-2011); the Brinell rotational viscosity of HVHE asphalt reaches 580,000 Pa·s, exhibiting superior bonding properties;

- When the air void ratio of the HVHE mixture is between 12 and 15%, based on the immersion rutting test, it can drain the rainwater in time and reduce the water damage under the vehicle loads;

- Based on the texture depth decay test, When the asphalt aggregate ratio is between 5.2 and 6.2%, it can guarantee the simultaneous durability of skid resistance and crack resistance under low temperature of the HVHE;

- Based on the TSRST test, The HVHE mixture exhibits excellent high- and low-temperature performance, showing promising applications in North America.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kim, Y.K.; Lee, S.W. Performance evaluation of bonded concrete overlay. Constr Build Mater. 2013, 49, 464–470. [Google Scholar] [CrossRef]

- Huang, L.; Fang, G.; Ni, F.; Fan, H. Study on the application of ultra-thin cover in cement concrete bridge deck pavement. Highw. Traffic Sci. Technol. 2008, 4, 10–12. (In Chinese) [Google Scholar]

- Wan, J.; Wu, S.; Xiao, Y.; Fang, M.; Song, W.; Pan, P.; Zhang, D. Enhanced ice and snow melting efficiency of steel slag based ultra-thin friction courses with steel fiber. J. Clean. Prod. 2019, 236, 117613. [Google Scholar]

- Ding, L.; Wang, X.; Cui, X.; Zhang, M.; Chen, B. Development and performance research of new sensitive materials for microwave deicing pavement at different frequencies. Cold Reg. Sci. Technol. 2021, 181, 103176. [Google Scholar]

- Chen, S.; Gong, F.; Ge, D.; You, Z.; Sousa, J.B. Use of reacted and activated rubber in ultra-thin hot mixture asphalt overlay for wet-freeze climates. J. Clean. Prod. 2019, 232, 369–378. [Google Scholar] [CrossRef]

- Geng, L.; Ma, T.; Zhang, J.; Huang, X.; Hu, P. Research on performance of a dense graded ultra-thin wearing course mixture. Appl. Sci. 2017, 7, 800. [Google Scholar] [CrossRef]

- Ding, L.; Wang, X.; Zhang, M.; Chen, Z.; Meng, J.; Shao, X. Morphology and properties changes of virgin and aged asphalt after fusion. Constr. Build. Mater. 2021, 291, 123284. [Google Scholar] [CrossRef]

- Ahmed, S.; Dave, E.V.; Buttlar, W.G.; Exline, M.K. Cracking resistance of thin-bonded overlays using fracture test, numerical simulations and early field performance. Int. J. Pavement Eng. 2013, 14, 540–552. [Google Scholar] [CrossRef]

- Li, X.; Ye, J.; Badjona, Y.; Chen, Y.; Luo, S.; Song, X.; Zhang, H.; Yao, H.; Yang, L.E.; You, L.; et al. Preparation and performance of colored Ultra-Thin overlay for preventive maintenance. Constr. Build. Mater. 2020, 249, 118619. [Google Scholar] [CrossRef]

- Budiarto, A.; Purnomo, H.R.; Setyawan, A. The structural properties evaluation on ultra-thin surfacing hot mixture asphalt concrete. Appl. Mech. Mater. 2015, 754, 828–832. [Google Scholar] [CrossRef]

- JTG E20-2011; Standard Test Methods of Bitumen and Bituminous Mixture for Highway Engineering. Ministry of Transportation: Beijing, China, 2011.

| Technical Indexes | Unit | Results | Requirements | Test Protocols | |

|---|---|---|---|---|---|

| Penetration (25 °C) | 0.1 mm | 61.9 | 40–80 | T 0604-2011 | |

| Soft point | °C | 92 | ≥90 | T 0606-2011 | |

| Ductility (5 °C) | cm | 45.4 | ≥40 | T 0605-2011 | |

| Brinell rotational viscosity (60 °C) | Pa·s | >580,000 | ≥300,000 | T 0620-2000 | |

| Elastic recovery | % | 99 | ≥95 | T 0662-2000 | |

| Evaporated residue | Quality loss | % | 0.44 | ±1.0 | T 0610-2011 |

| Penetration (25 °C) | 0.1 mm | 91 | ≥80 | T 0604-2011 | |

| Ductility (5 °C) | cm | 33 | ≥25 | T 0605-2011 | |

| Technical Indexes | Unit | Results | Requirements |

|---|---|---|---|

| Leakage loss | % | 0.1 | ≤0.3 |

| Cantabro loss | % | 1.71 | ≤8 |

| Residential stability | % | 87.0 | ≥85 |

| TSR | % | 81.6 | ≥80 |

| Dynamic stability (60 °C) | loads/mm | 6631 | ≥3200 |

| Bending strain (−10 °C) | µε | 3864 | ≥2500 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Y.; Liao, Z.; Chen, L.; Ma, T.; Tighe, S.; Li, N. Design and Evaluation of Ultra-Thin Overlay with High Viscosity and High Elasticity. Eng. Proc. 2023, 36, 59. https://doi.org/10.3390/engproc2023036059

Chen Y, Liao Z, Chen L, Ma T, Tighe S, Li N. Design and Evaluation of Ultra-Thin Overlay with High Viscosity and High Elasticity. Engineering Proceedings. 2023; 36(1):59. https://doi.org/10.3390/engproc2023036059

Chicago/Turabian StyleChen, Yijia, Zhi Liao, Lide Chen, Tao Ma, Susan Tighe, and Ningyuan Li. 2023. "Design and Evaluation of Ultra-Thin Overlay with High Viscosity and High Elasticity" Engineering Proceedings 36, no. 1: 59. https://doi.org/10.3390/engproc2023036059

APA StyleChen, Y., Liao, Z., Chen, L., Ma, T., Tighe, S., & Li, N. (2023). Design and Evaluation of Ultra-Thin Overlay with High Viscosity and High Elasticity. Engineering Proceedings, 36(1), 59. https://doi.org/10.3390/engproc2023036059