1. Introduction

The recycling of plastics in Hot Mix Asphalt (HMA) pavements is gaining attention worldwide [

1] as plastic waste (PW) is a primary source of environmental pollution [

2] with a current generation that is twice as much as it was two decades ago [

3]. According to the OECD, the bulk of PW ends up in landfill, incinerated or leaking into the environment, and only 9% is successfully recycled [

3]. As stated in [

1], “research is needed to establish a better understanding of the impact of recycled plastics on the performance, especially durability and cracking resistance, of asphalt binders and mixtures”.

This paper presents preliminary mechanical testing findings of a study involving both mechanical testing and microplastics and plastic additives testing performed from three field HMA mixes, of which two contained recycled PW. The mixes were obtained from paving performed for the Hawaii Department of Transportation (HDOT) for a pilot project in Honolulu, Hawaii. Testing results to date with a Hamburg Wheel Tracker (HWT) and an Asphalt Mixture Performance Tester (AMPT) have shown benefits in terms of rutting and a priori expected variations in the dynamic modulus. On the other hand, the results of Cracking Tolerance Index (CTIndex) (ASTM D8225-19) obtained in IDEAL-CT testing are inconclusive in terms of fatigue cracking performance. The CTIndex results show high variability within each mix, unexpected trends between mixes and, for each mix, inconsistent results between tests performed without and with moisture sensitivity conditioning using a Moisture Induced Stress Tester (MIST). The initial findings of this characterization effort have been encouraging, but alternative tests for evaluating cracking performance in Hawaii need to be evaluated.

2. Materials and Methods

The three mixes evaluated were obtained from paving for a pilot project performed in November 2022 on the southern end of Fort Weaver Road, a two-lane bi-directional road in Oahu, Hawaii, that carries 6200 vehicles per day on average. The 1.3-mile-long roadway segment was divided into three sections with the design gradations shown in

Table 1, meeting the Hawaii State IV mix requirements (similar to those for a Superpave 12.5 mm mix) and incorporating 20% Reclaimed Asphalt Pavement (RAP).

Control section: 5.3% asphalt content by total weight of mix (TWM) of Polymer Modified Asphalt or PMA (PG64E-22) (0.95% by TWM contributed by RAP binder);

PMA NR Plastic section: 5.2% asphalt content by TWM of PMA PG64E-22 binder (0.96% by TWM contributed by RAP), incorporating 2 lb. per ton of mix of plastic pellets (0.1% by mass of mix) as recommended by the supplier;

HMA NR Plastic section: 5.1% asphalt content by TWM of neat PG64-16 binder (0.96% by TWM contributed by RAP) with 2 lb. per ton of mix of plastic pellets.

Pacific GeoSourse provided NewRoad plastic pellets consisting mostly of post-industrial high-density polyethylene (HDPE), which were added to the mix at the plant. No pellets were visible in the field samples, indicating that they had mostly melted into the mix.

Trial specimens were compacted to find the appropriate amount of mix to compact specimens with 7 ± 0.5% air voids for the different tests: HWT, AMPT dynamic modulus and permanent deformation, and IDEAL-CT. The specimens were re-heated to the compaction temperature and tested without any additional aging, as specified in ASTM D8225 [

4].

3. Results

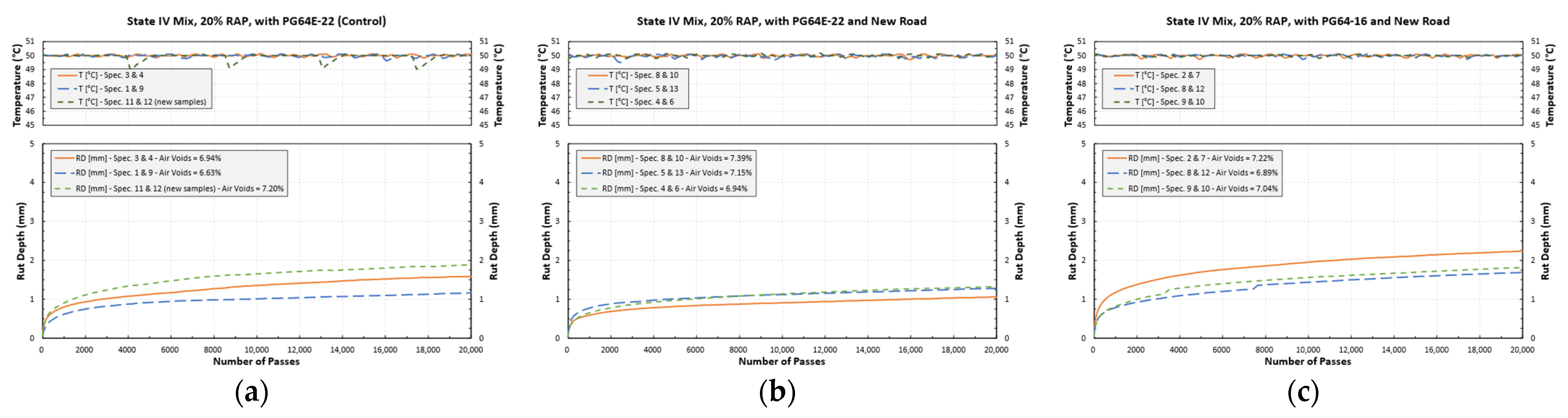

Figure 1 shows the HWT results at 50 °C for the three mixes. None of the mixes exhibited a stripping point, and they had low final rutting values, ranging from slightly above 1 mm to 2.25 mm. Thus, all mixes were expected to be rutting resistant. Despite the small values, it can be seen that the addition of NR to the control mix reduced the rutting. The HMA NR mix did not perform as well as the control mix, but it still exhibited a good performance.

As shown in

Figure 2, cylindrical samples of the control and PMA NR mixes tested for permanent deformation (PD) at 54 °C without and with MiST conditioning (20 h at 50 °C followed by 3500 pressure cycles at 276 kPa) provided basically the same results. These PD tests were carried out after dynamic modulus (|E*|) testing on the same samples. Both without and with conditioning, the PMA NR (PG64-22NR) sample exhibited less rutting than the control mix (PG64E-22) sample with the same type of conditioning.

Furthermore, for each mix, conditioning in the MiST resulted in larger PD values, which was the a priori expected result.

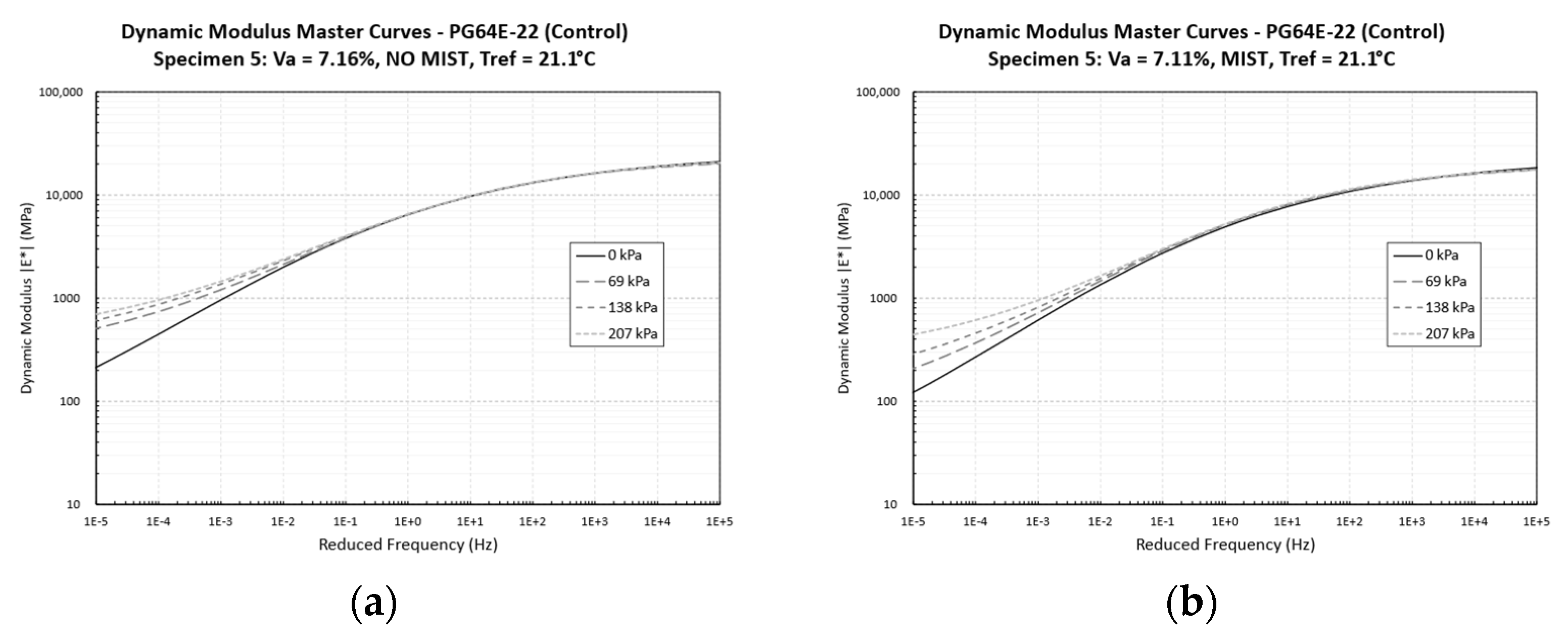

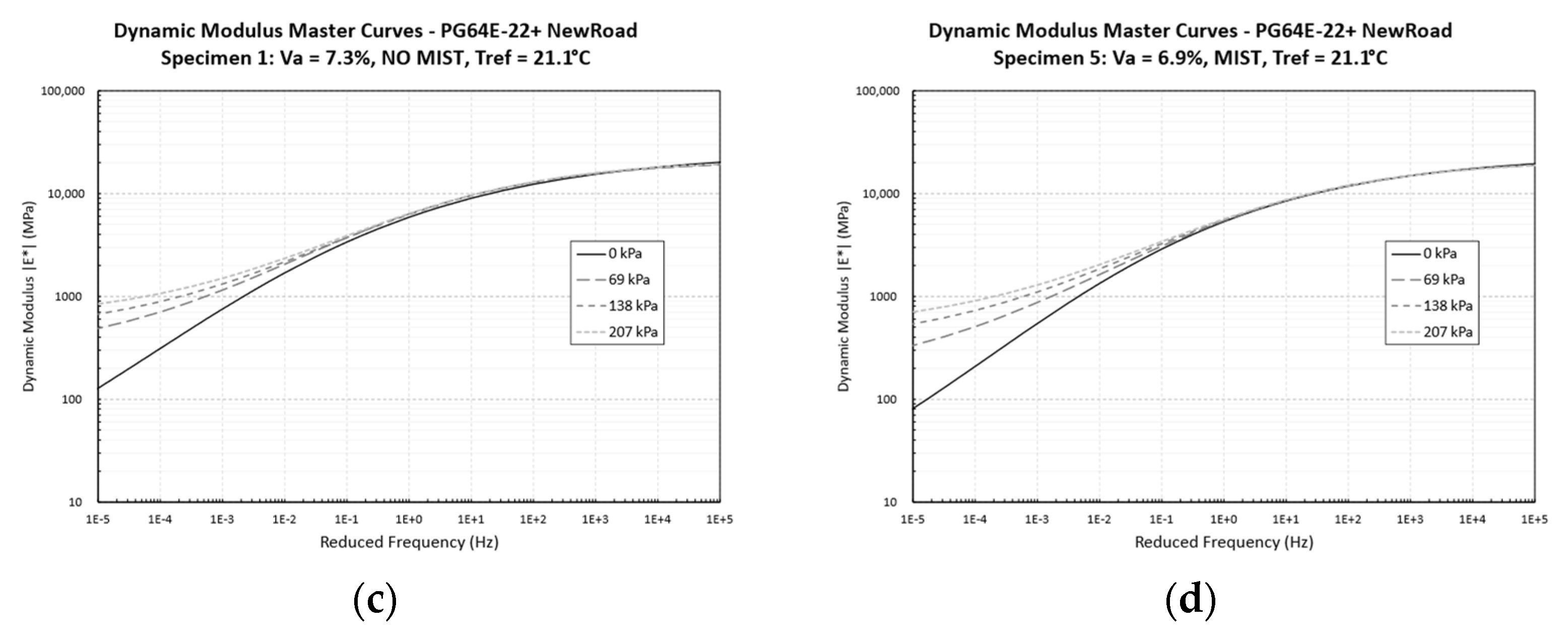

The dynamic modulus (|E*|) of the same four samples was also consistent in terms of MiST conditioning. As shown in

Figure 3, for each mix, the master curves consistently dropped after MiST conditioning (compare (a) to (b) and (c) to (d)). The comparison between mixes indicated that regardless of conditioning, the master curve of the PMA NR mix was lower than the control mix without confinement, and higher with 138 kPa and 207 kPa confinement (compare (a) to (c) and (b) to (d)).

The |E*| and PD results presented above are based on a single specimen under each condition. Consequently, one should be cautious when drawing a strong conclusion from these. Nevertheless, the results are consistent with previous testing by the last author, with similar PMA mixes in Hawaii, and with the a priori expectations of the effect of moisture damage on these properties.

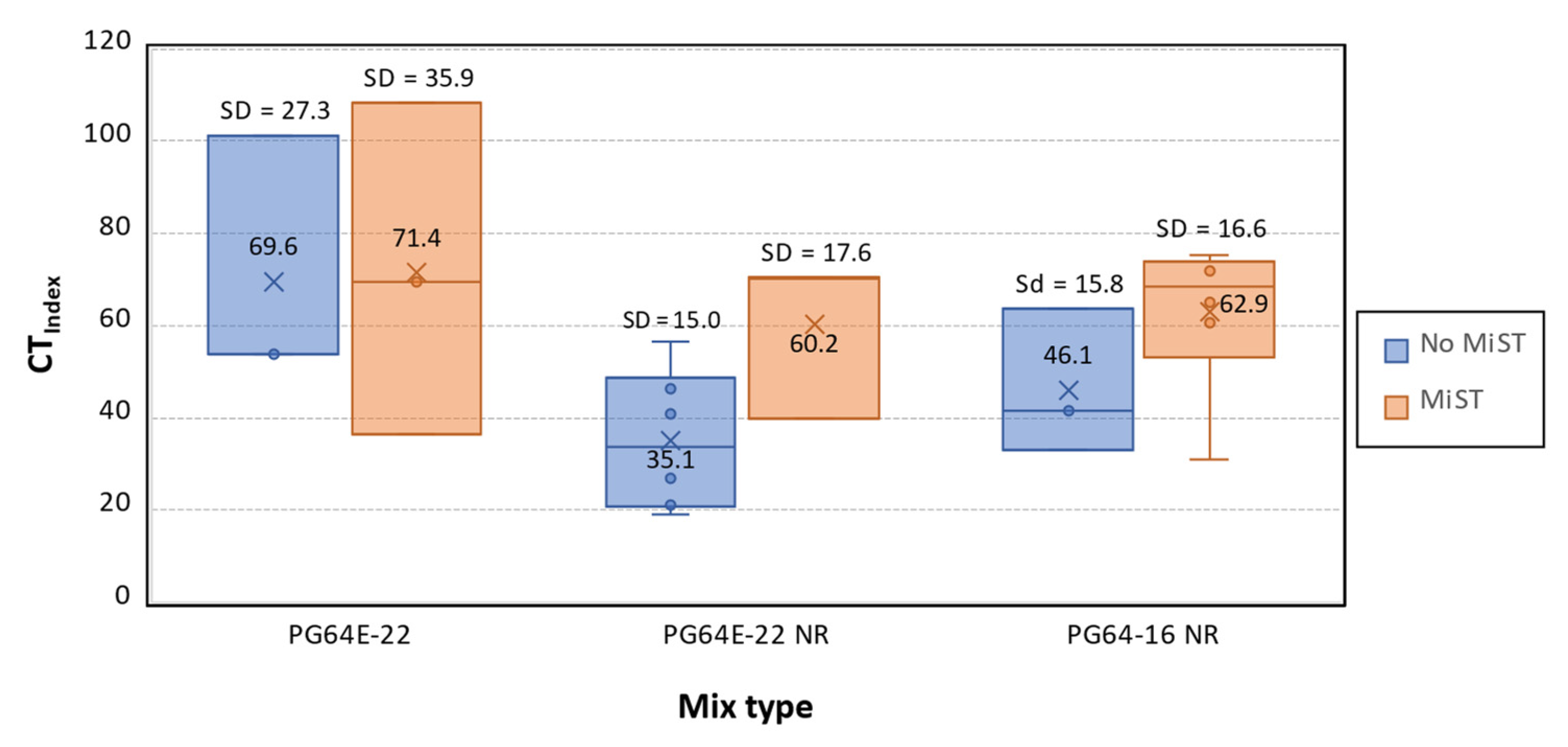

Figure 4 shows the CT

Index values obtained to date. The Figure presents a stem and leaf plot, but since there are only three samples for most combinations of mix and conditioning, it is mostly helpful to visualize the mean value (identified with a cross symbol), the range of values, and the standard deviation (SD). Note that, in general, there is very high variability. It can also be seen that without MiST conditioning, the values for the PMA NR mix were generally lower than for the control mix. Although there is an overlap for the PMA NR and HMA NR, the average tended to increase with the HMA NR, which is counterintuitive. Similar differences can be seen after mix conditioning, but the variability for the control mix was substantially higher. Even more concerning is the fact that better (higher) values were obtained on average after MiST conditioning for each mix, which is again contrary to expectations.

4. Conclusions

The testing of mixes from the field pilot study with sections containing recycled PW showed benefits in rutting and expected variations in dynamic modulus with moisture sensitivity conditioning. The CTIndex results were inconclusive, since they were counterintuitive: without MiST conditioning, the results for the control, PMA NR, and HMA NR mixes implied not only that the addition of PW is detrimental to cracking, but that it also negates all the well-known benefits of polymer modification relative to the mix with the neat binder. Also, the increases of the means for the three mixes after MiST conditioning were counterintuitive and the opposite of what the dynamic modulus and permanent deformation results with the AMPT indicated, albeit not for the same performance measure. Consequently, it appears that the CTIndex does not capture the benefits of polymer modification and the effects of moisture damage for these mixes. These factors also make the comparison between the mixes less reliable. Consequently, it is recommended that in future HDOT efforts IDEAL-CT testing be complemented or replaced with a test more capable of capturing the effects of these generally well-known factors for these Hawaiian mixes on long-term-aged samples.

Author Contributions

Conceptualization, S.Y.B.S. 10%, S.P. 10%, A.S.J. 10% and A.R.A. 70%; methodology, S.Y.B.S. 10%, S.P. 10%, A.S.J. 10% and A.R.A. 70%; formal analysis, S.Y.B.S. 10%, S.P. 10%, A.S.J. 10% and A.R.A. 70%; data collection, S.Y.B.S. 25%, S.P. 25%, A.S.J. 25% and A.R.A. 25%; writing—original draft preparation, S.Y.B.S. 5%, S.P. 5%, A.S.J. 5% and A.R.A. 85%; writing—review and editing, A.R.A. 100%. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Hawaii Department of Transportation—Project Number DOT-10-030. The contents of this paper reflect the view of the writers, who are responsible for the facts and accuracy of the data presented herein. The contents do not necessarily reflect the official views or policies of the State of Hawaii Department of Transportation or the Federal Highway Administration.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data used in this study was collected for the Hawaii Department of Transportation (HDOT). The data are not publicly available due to restrictions imposed by the DOT, and access may be subject to approval and compliance with their data sharing policies.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Yin, F.; Moraes, R.; Fortunatus, M.; Tran, N.; Elwardany, M.; Planche, J. Performance Evaluation and Chemical Characterization of Asphalt Binders and Mixtures Containing Recycled Polyethylene; Final Report for Plastics Industry Association: Washington, DC, USA, 2019. [Google Scholar]

- Gourmelon, G. Global Plastic Production Rises, Recycling Lags; World Watch Institute: Washington, DC, USA, 2016. [Google Scholar]

- OECD. Global Plastics Outlook: Economic Drivers, Environmental Impacts and Policy Options; OECD Publishing: Paris, France, 2022. [Google Scholar] [CrossRef]

- ASTM D8225-19; Standard Test Method for Determination of Cracking Tolerance Index of Asphalt Mixture Using the Indirect Tensile Cracking Test at Intermediate Temperature. ASTM International: West Conshohocken, PA, USA, 2019.

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).