Abstract

Since it is impossible to reconstruct the top level that has collapsed, a formwork is constructed to squeegee mortar or spray mortar, and repair kits are being used in Korea to chip away the damaged concrete of the bridge deck structure. In Korea, a technique called hydro-demolition replaces water blasting and water jetting by using high-pressure water to remove not only asphalt but also old and broken concrete. Additionally, dry materials including cement, aggregate, and additives are carried via the inside of a hose to the field using compressed air, where they meet water and are ejected at a high rate of speed. This technique is known as dry mix shotcrete. Using the devised automatic hydraulic dismantling technology and high-performance dry-mix shotcrete, field application results are discussed in this study.

1. Introduction

A technique for removing concrete called hydro-demolition, which is also known as water blasting and water jetting in Korea, uses high-pressure water to blast away asphalt as well as hazardous and deteriorated concrete [1]. In order for this method to be effective, high-pressure water must be generated by a power pack and applied to concrete surfaces by a robot. This process creates an excellent bonding surface for the repaired material [2].

The dry components, such as cement, aggregates, and admixtures, are transported by compressed air through a delivery hose to the nozzle where water is added under pressure in the dry-mix shotcrete process. As the mixture is sprayed onto the surface from the nozzle at a high rate of speed, the water fully moistens the other ingredients. The water moistens the dry mix ingredients as it shoots. The nozzleman controls how much water is supplied during the dry mix shotcrete process [3].

To remove the cracked concrete from the bridge deck’s substructure, an automated hydro-demolition technique was developed. Additionally, a high-performance dry-mix shotcrete material was created in order to increase build-up thickness for overhead firing while decreasing rebound, dust, and dry shrinkage cracking. This paper details the field application outcomes employing the high-performance dry-mix shotcrete and the proposed automatic hydro-demolition process.

2. Methodology and Materials

2.1. Hydro Demolition

Utilizing high-pressure water to blast asphalt hazardous concrete, hydro-demolition, also known as water blasting and water jetting in Korea, is a technique for removing concrete [1]. Specialized machinery to create high-pressure water and specialized rails to apply to the concrete surface are needed for this technology to function. This procedure eliminates the damaged surface without creating micro cracks or shaking the entire structure.

Automated hydraulic demolition technology has been developed to remove cracked concrete from bridge deck substructures. This paper details field application results using high-performance dry mix shotcrete and the proposed automated hydraulic demolition process.

2.2. Dry-Mix Shotcrete

Dry shotcrete is a method in which dry mixed materials such as cement, aggregate, and quick-setting agent are moved inside the hose by compressed air and sprayed by applying pressure water from a nozzle. Dry shotcrete requires small equipment, so there are few restrictions on supply work, and it can be pumped over a relatively long distance. It has the advantage of being easy to clean and repair and can be easily applied to leaky areas [4,5].

2.3. Materials and Mix Design

Considering the mixed aggregate particle size gradation curve, the N1 variable altered the aggregate composition in comparison to the other mix designs in Table 1, and it also increased the aggregate amount. Through literature review, silica fume was also added at a rate of 3% of the total weight, and the amount of polymer was also changed. The shrinkage-reducing substance used was of the powder type. Concrete shrinkage is prevented with shrinkage inhibitors, which also increase cracking resistance. High-performance nylon fibers were substituted for the natural fibers that were originally integrated to minimize plastic shrinkage cracking since they agglomerated when the material was added. In addition to preventing fiber aggregation, nylon fiber is a hydrophilic, high-performance nylon-based fiber reinforcing material with outstanding dispersibility, chemical resistance, and crack resistance. Dust-reducing agents were eliminated since they had little impact and had a detrimental impact on compressive strength. In order to incorporate entrained air into the concrete, an AE agent in powder form was used.

Table 1.

Mix design.

3. Results and Discussion

To implement the bridge ceiling test, the test was carried out using the provided materials on an abandoned bridge in Yeongdong-gun, Chungcheongnam-do. With a depth of around 250 mm, the hydro-demolition process completely damaged the ceiling part.

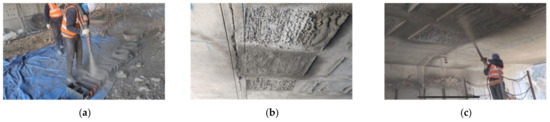

Dry shotcrete equipment was set up for spraying the ceiling, and a ceiling shotcrete experiment was carried out. The experiment was carried out by splitting the ceiling into two layers in order to provide enough adhesive thickness. It was determined that the actual adhesive thickness was roughly 300 mm, which was greater than the maximum depth of 250 mm, as shown in Figure 1a–c.

Figure 1.

(a–c) Hydrodemoltion and Dry shotcrete process in abandoned bridge. (a) Field sample preparation. (b) Repair section of after shooting. (c) Panoramic view of shooting.

The initial compressive strength of the modified new blend composition was higher than that of the previous blend composition based on the 3-day compressive strength measurement. Given that the dust reducer tends to diminish compressive strength, the T1 variable with the dust reducer included exhibited the lowest compressive strength.

The T4 variable, which used early-strength cement and contained 5% silica fume, exhibited the highest compressive strength, while the T3 variable, which used type 1 normal Portland cement, reported a lower compressive strength.

The rightmost column of the Table 2 contains the test results, and it displays the Korea Expressway Corporation’s concrete structure repair material quality criteria (2022). The test was conducted after asking a company that specializes in quality testing to conduct it. The test was performed by directly producing samples from the abandoned bridge. It is demonstrable that all test items produced test results that met quality test standards, and that the newly enhanced formulation table secured durability results appropriate for a repair material.

Table 2.

On-field sample test results based in Korea Expressway Corporation concrete structure repair material quality standards (2022).

4. Conclusions

In this study, the damaged concrete cross section on the bridge deck ceiling was repaired using hydro demolition and dry-mix shotcrete that was placed directly in the field. Traditionally, manual chipping of the concrete cross section required a person to climb to a great height; however, it can be argued that worker safety was ensured by crushing it using a mechanical device. Dry-mix shotcrete is more suited for cross-section repair using less material than wet-mix shotcrete since it requires less equipment and is simpler to clean. In conclusion, it was discovered that the actual adhesive thickness was close to 300 mm, exceeding the maximum depth of 250 mm. The highest compressive strength measured in this study was T4 variable, which included early-strength cement, and 5% silica fume. Because T1 has the largest amount of dust reducer, it also has the lowest compressive strength. Compressive strength afterwards tends to decline as a result of the dust reducer being increased.

Author Contributions

Conceptualization, K.Y., Y.K. and S.C.; methodology, K.Y., S.C. and M.S.H.; validation, M.S.H., K.Y. and C.S.; formal analysis, T.H. and C.S.; investigation, S.C., C.S., T.H. and V.P.; resources, K.Y. and M.S.H.; writing—original draft preparation, M.S.H. and C.S.; writing—review and editing, K.Y. and M.S.H.; supervision, K.Y. and V.P.; project administration, K.Y., Y.K. and S.C.; funding acquisition, K.Y. All authors have read and agreed to the published version of the manuscript.

Funding

This research was conducted by the Ministry of Land, Infrastructure and Transport/Korea Land, Transport, Science and Technology Promotion Agency (Task number: 21POQW-B152690-03, RS-2021-KA161910) and the National Research Foundation of Korea (assignment number: RS-2023-00208664) funded by the Ministry of Science and ICT.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All data are new and experimented.

Conflicts of Interest

The authors declare no conflict of interest.

References

- YUN, K.-K.; Lee, K.-R.; HAN, S.-Y.; KIM, Y.-G.; KWON, S.-A. Rehabilitation of Marine Concrete Structure with Under-Water Hydrodemolition and Sprayed Concrete. In Proceedings of the MATEC Web of Conferences, Cape Town, South Africa, 19–21 November 2018; EDP Sciences: Les Ulis, France, 2018; Volume 199, p. 07009. [Google Scholar]

- Chynoweth, G.; Stankie, R.R.; Allen, W.L.; Anderson, R.R.; Babcock, W.N.; Barlow, P.; Bartholomew, J.J.; Bergemann, G.O.; Bullock, R.E.; Constantino, F.J. Concrete repair guide. ACI Comm. Concr. Repair Man. 1996, 546, 287–327. [Google Scholar]

- Mukhopadhyay, M. Right Shotcrete Equipment and Skill of Nozzleman Ensure Good Quality Shotcrete in Tunnel Construction. INCOLD J. A Half Yrly. Tech. J. Indian Comm. Large Dams 2016, 5, 49–51. [Google Scholar]

- Yoggy, G.D. The history of shotcrete. Shotcrete 2000, 2, 28–29. [Google Scholar]

- Bernard, S. (Ed.) Shotcrete: Elements of a System; CRC Press: Boca Raton, FL, USA, 2010. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).