1. Introduction

Asphalt pavement has a different performance life depending on quality management during production and construction. However, non-real-time quality management system does not guarantee sufficient performance. Recently, with the rapid development of Internet technology, the era of real-time management of pavement quality has arrived. A lot of research has already been conducted on how to solve the poor quality of pavement construction by monitoring the construction process in real-time [

1,

2]. Dong et al. applied IoT and 5G technologies to develop a technology to collect and transmit data from mixing plant, transportation vehicles, and paving and compaction processes [

3]. And Beainy developed a technology to evaluate the compaction quality in real-time and non-contact by measuring the vibration response of the compaction roller [

4]. This study aims to extend the performance life of asphalt pavement through the acquisition, transmission, and processing of quality information at each stage of asphalt pavement construction using IoT technology.

To achieve these objectives, a cloud-based IoT PQMS(Internet of Things Pavement Quality Management System) was developed in this study. A technology has been developed to transmit construction quality information of dump trucks, asphalt pavers, and compaction rollers to the cloud. Through the analysis and processing of transmitted information, drivers and managers can use monitors and apps to monitor construction information and identify problems.

2. Method

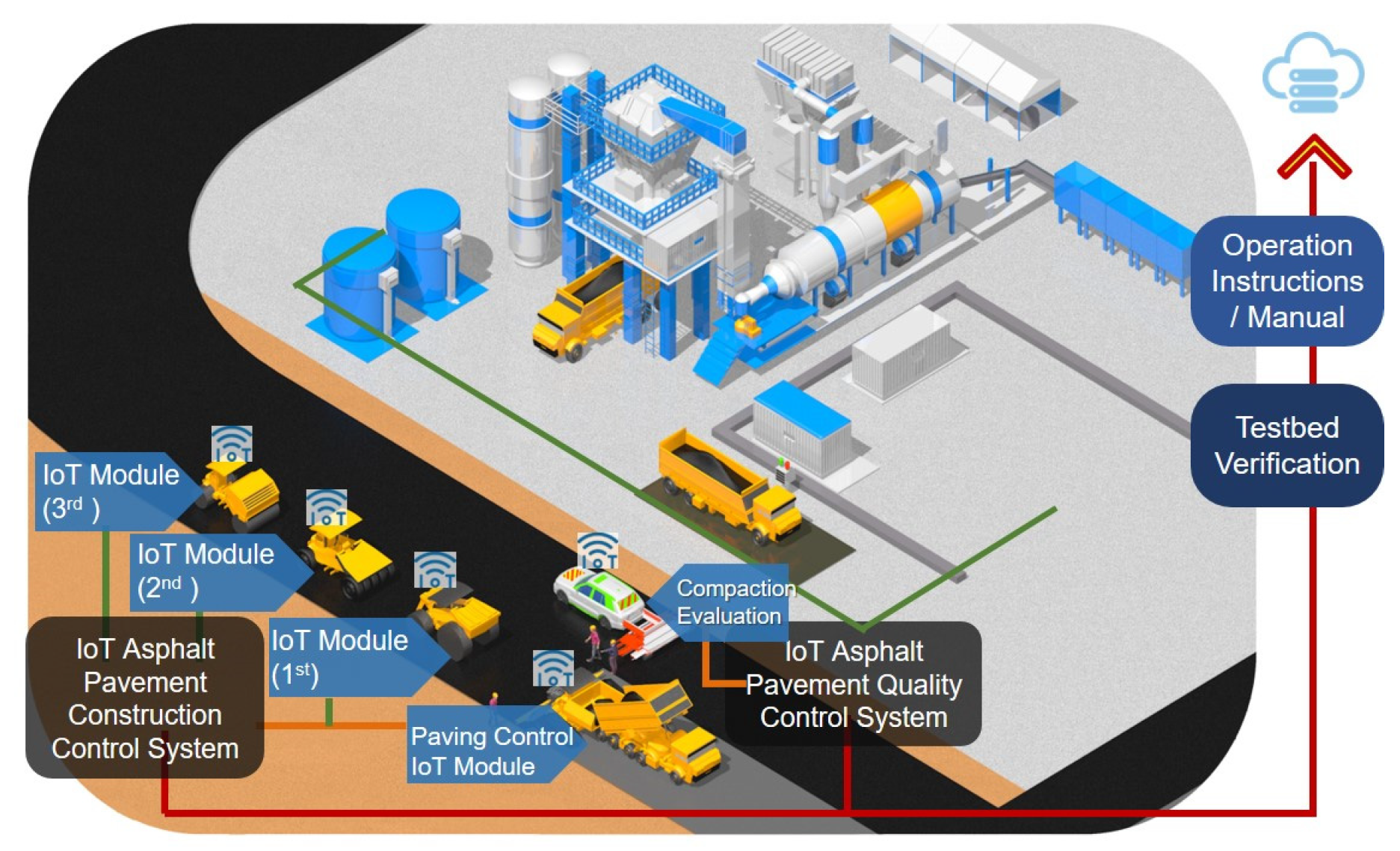

Real-time field quality management system for asphalt pavement construction developed in this study is shown in

Figure 1. The quality management process in asphalt pavement construction can be largely divided into three categories. First, at the asphalt paver, the quality related to the paving of the mixture can be managed through the paving control IoT module. Second, at the compaction roller, the quality related to compaction can be managed through the compaction control IoT module. Third, after construction, the final compaction quality can be managed with compaction test equipment. Quality management information can be transmitted to the cloud using IoT technology, and through this, the level of quality control can be improved. In this study, the modules to be attached to the equipment of each process was developed, and monitoring software that can check quality control information in real time was developed.

3. Results

The modules including various sensors and devices to be attached to asphalt paver, compaction roller, and compaction test equipment were developed. In addition, quality information and navigation monitoring software that operators of asphalt paver and compaction roller can utilize was developed.

3.1. Asphalt Paver

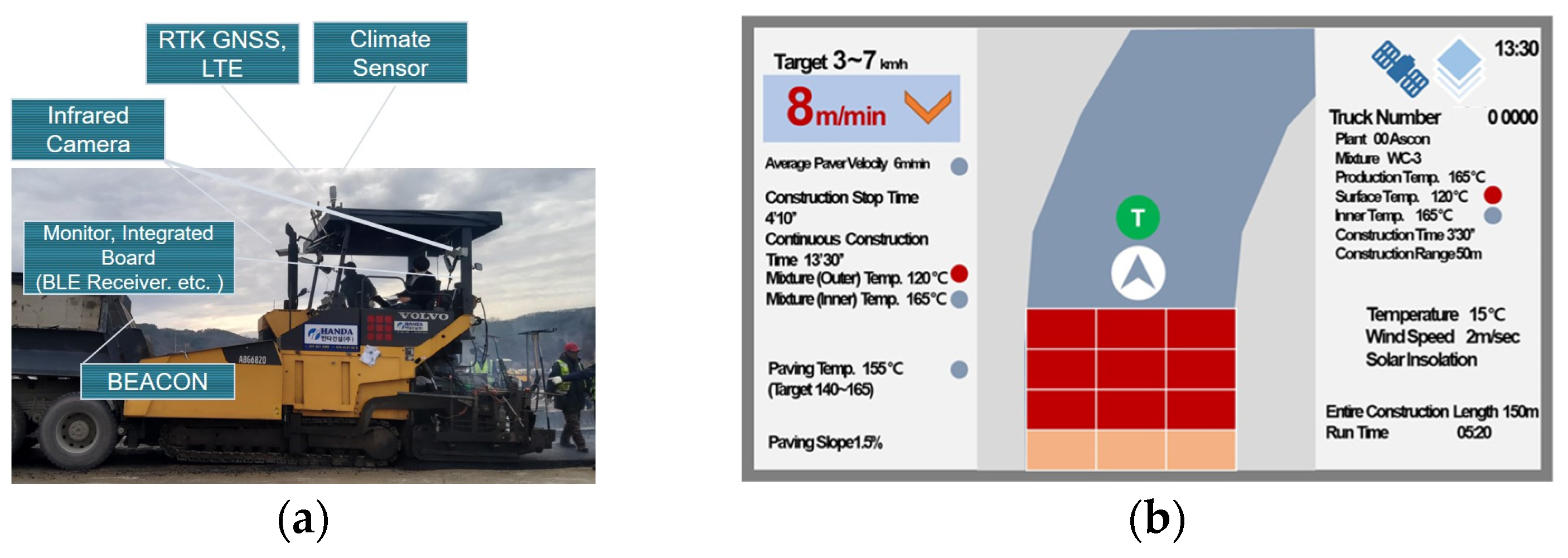

The climate sensor, RTK GNSS, LTE, infrared camera, monitor, integrated board, and beacon were attached to the asphalt paver as shown in

Figure 2a. The climate sensor collected weather information at the time of construction and will be used for big data analysis in the future. The RTK GNSS collected precise location information of asphalt paver during construction. The infrared camera collected the temperature of the mixture and the surface temperature of the pavement. The beacon recognized the truck that has arrived and made it possible to link the production information of the asphalt mixture. The integrated board stored the collected information, and the LTE device transmitted the stored information to the cloud. The information that the operator of the asphalt paver can see was as shown in

Figure 2b. The operator can check the collected information such as the location and speed of the paver, the temperature of the transported mixture, and the surface temperature of the pavement through the monitor.

3.2. Compaction Roller

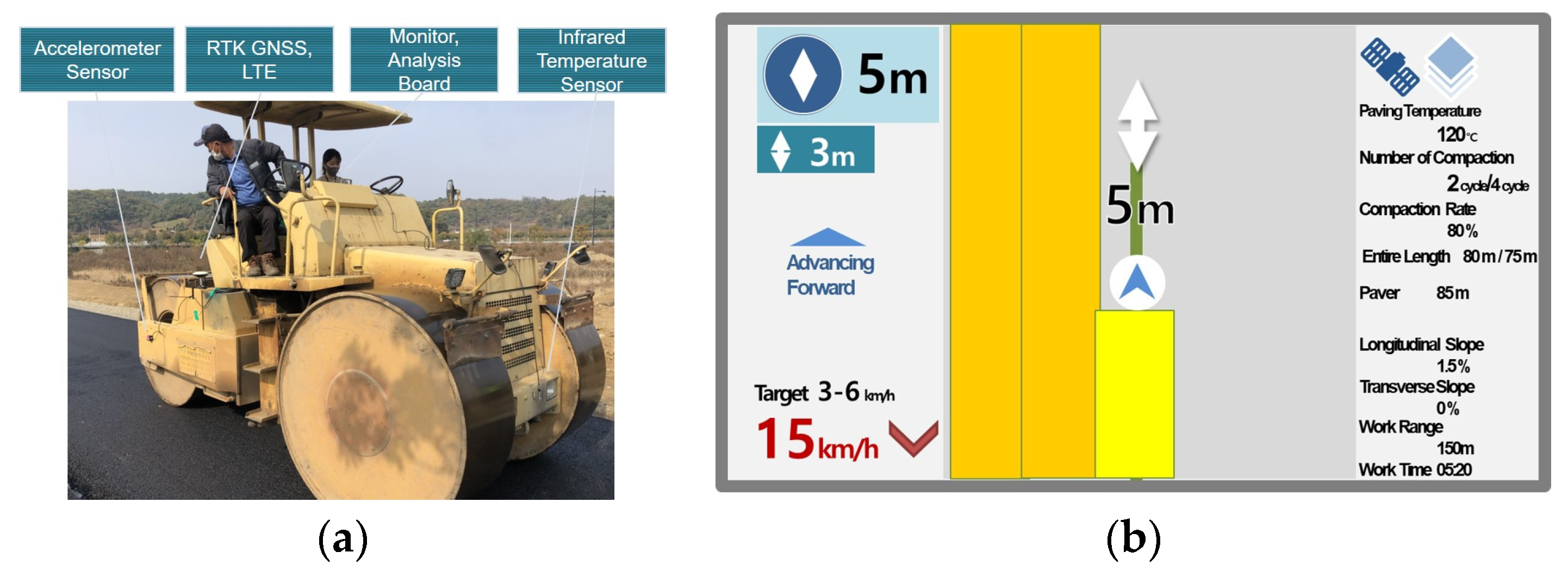

The accelerometer sensor, RTK (Real Time Kinematic) GNSS (Global Navigation Satelite System), LTE (Long Term Evolution), monitor, analysis board, and infrared temperature sensor were attached to the compaction roller as shown in

Figure 3a. The accelerometer sensor measured the vibration of the roller and estimated the degree of compaction. The RTK GNSS collected precise location information of compaction roller. The infrared temperature sensor collected the compaction temperature. The analysis board stored the collected information and analyzed the degree of compaction. And the LTE device transmitted the stored information to the cloud. The information that the operator of the compaction roller can see was as shown in the

Figure 3b. The operator can check the collected information such as the location and speed of the roller, the compaction temperature, and compaction navigating through the monitor.

3.3. Compaction Test Equipment

The lift sensor, image capturing sensor, RTK GNSS, road condition detection device, GPR (Ground Penetrating Radar) sensor, and DMI (Directional Movement Index) were attached to the compaction test equipment as shown in

Figure 4. The image capturing sensor and road condition detection device collected pavement condition information immediately after construction. The GPR sensor collected information inside the pavement to estimate the degree of compaction. DMI and RTK GNSS collected location information of equipment.

4. Discussion

The real-time quality control system for asphalt pavement construction developed in this study was tested at a test bed in Yeoncheon. The quality control information collected from the test bed is being compared and analyzed with actual information. It is planned to evaluate the applicability by solving the problems found in the analysis and applying it to the actual asphalt pavement section to be constructed by the Ministry of Land, Infrastructure and Transport.

5. Conclusions

In this study, a cloud-based IoT Pavement Quality Management System was developed to minimize quality degradation and address problems early by tightly coupling production and construction information of asphalt mixture and performing real-time quality control. Through the system, drivers and managers can monitor construction information and identify problems using monitors and apps. The proposed cloud-based IoT PQMS will be applied to national road construction sites in 2023 to verify its effectiveness and address potential problems. The results of this study demonstrate the potential of IoT technology in improving pavement quality management and paving the way for further development in this field.

Author Contributions

Conceptualization, K.-D.J. and D.-H.K.; methodology, J.-W.K.; software, D.-H.K.; validation, K.-D.J., D.-H.K. and J.-W.K.; formal analysis, N.-H.K.; investigation, N.-H.K.; resources, S.-A.K.; data curation, J.-W.K.; writing—original draft preparation, K.-D.J.; writing—review and editing, S.-D.H. and S.-A.K.; visualization, D.-H.K.; supervision, S.-D.H.; project administration, S.-D.H.; funding acquisition, S.-D.H. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Korea Agency for Infrastructure Technology Advancement (KAIA) grant funded by the Ministry of Land, Infrastructure and Transport Grant RS-2019-KA152690.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

This paper is not a data-based analysis paper, but a system construction paper, so there is no data that can be shared.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

References

- Yuan, J.; Li, X.; Ke, Y.; Xu, W.; Skibnewski, M. Developing a Building Information Modeling-Based Performance Management System for Public-Private Partnerships. Eng. Constr. Archit. Manag. 2020, 27, 1727–1762. [Google Scholar] [CrossRef]

- Ma, Z.; Zhang, J.; Philbin, S.P.; Li, H.; Yang, J.; Feng, Y.; Ballesteros-Perez, P.; Skitmore, M. Dynamic Quality Monitoring System to Assess the Quality of Asphalt Concrete Pavement. Buildings 2021, 11, 577. [Google Scholar] [CrossRef]

- Dong, J.; Meng, W.; Liu, Y.; Ti, J. A Framework of Pavement Management System based on IoT and Big Data. Adv. Eng. Inform. 2021, 47, 101226. [Google Scholar] [CrossRef]

- Beainy, F. Non-Contact Sensor for the Real-Time Measurement of Quality of Asphalt Pavements during Compaction. Ph.D. Thesis, University of Oklahoma, Norman, OK, USA, 2011. [Google Scholar]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).