1. Introduction

Currently, road construction and base course construction ordered by the Ministry of Land, Infrastructure, Transport and Tourism are controlled by the degree of compaction as a quality control method. The Test Method for Soil Density by the Sand replacement method and Radio-Isotope(RI) instrumentation are commonly used to determine the degree of compaction.

These test methods are performed by setting several measurement points from the construction area where the compaction has been completed, which results in “point” control, and there is a concern that vulnerable points may be overlooked. In addition, human work is required due to the need to excavate or make boreholes. Therefore, at least one person in charge of quality control is required to conduct quality control tests. Since people often hunker down when working in the field, they may easily enter the blind spots of heavy machinery, such as compaction rollers, which may lead to serious accidents resulting from contact with heavy machinery.

In the Test Method for Soil Density by Sand Replacement method, the test results are not available until the next day at the earliest since the water content ratio test is conducted in a room after the on-site test. This time lag may lead to rework in the case of results that do not meet the specified values. The issues identified in response to the current situation described above are as follows.

Develop a method to measure not only “points” but also “surfaces” to prevent overlooking vulnerable points.

Eliminate human work, improve safety and reduce labor.

To grasp the measurement results in real time, to enable corrective measures to be taken during construction and to improve construction efficiency.

2. Technical Overview of Quality Control System for Ground Compaction

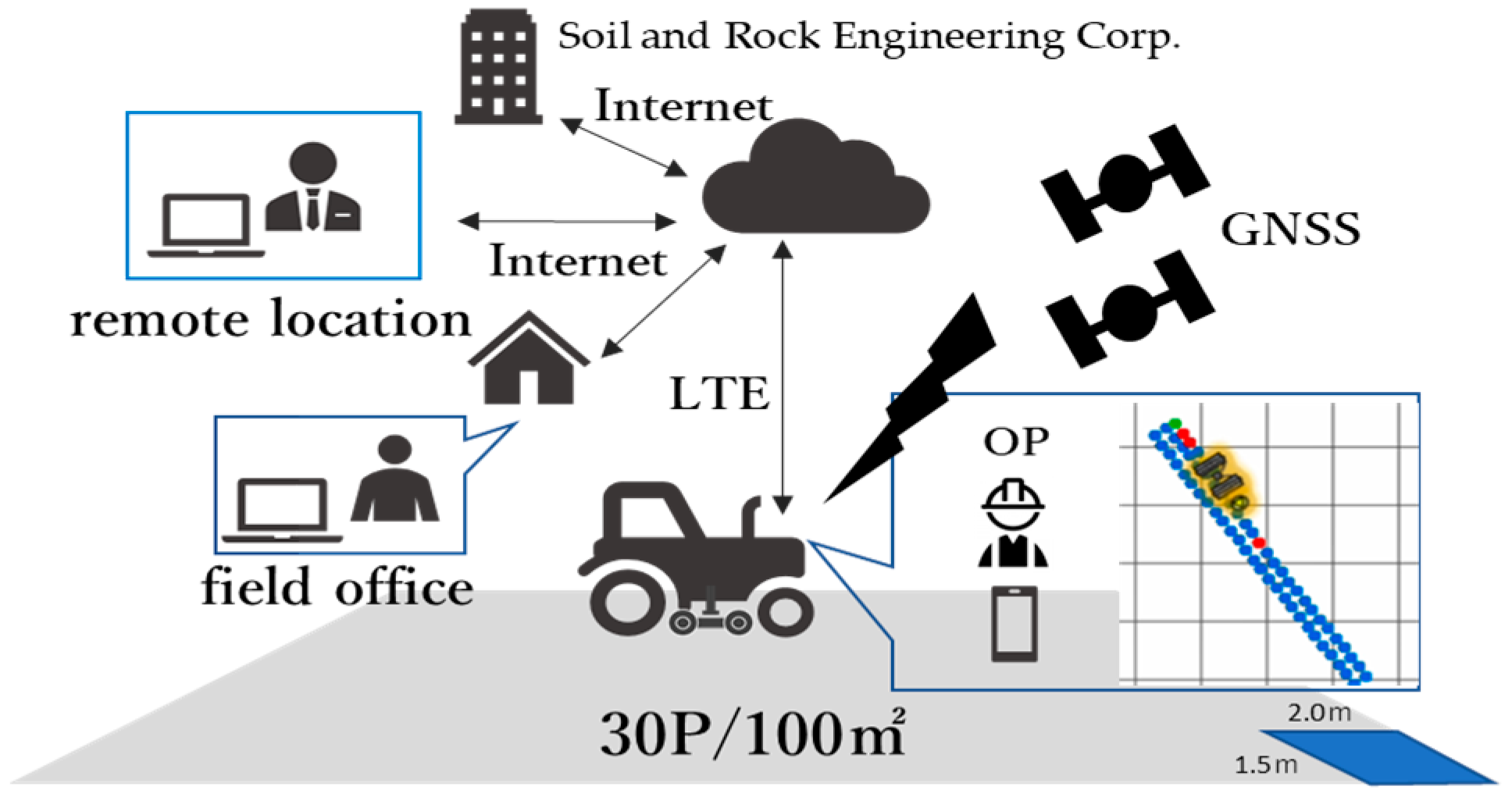

The ground compaction quality control system consists of a vibrating roller equipped with a rolling wheel-type RI instrument, as shown in

Figure 1. The rolling wheel-type RI instrument is rolled on the measuring surface to measure the degree of compaction automatically and non-destructively continuously. The rolling wheel-type RI instrument can be raised and lowered by an actuator, and measurement is performed with the instrument grounded on the measurement surface. It can be raised and lowered with a tablet installed on the operator’s seat. Since it is necessary to keep the rolling wheel RI instrument in close contact with the road surface during measurement, a mechanism has been developed to hold down the rolling wheel housing [

1].

As shown in

Figure 2, the measurement results are linked to the GNSS location information and displayed on a tablet terminal installed in the driver’s seat in the form of a heat map in real time, allowing the user to visually grasp the compaction level in the area of the measurement point. The measurement results uploaded to the cloud server can be processed into the required format and shared among the parties concerned at any time.

The measurement principle of the rolling wheel-type RI meter is the same as that of the current scattering type RI meter. For the RI source used in the rolling wheel-type RI meter, both the density and moisture gauges are in compliance with the Japanese laws and regulations established in accordance with international standards. In addition, they have been registered with the Nuclear Regulation Authority of Japan (NRAJ) as a design-certified instrument.

As shown in

Figure 3, a radiation source and a detector are built into the cylindrical density and moisture gauges, and the radiation emitted from the radiation source is scattered by the object to be measured and counted by the detector. The measured values of the degree of compaction by the rolling wheel-type RI meter are obtained by converting the gamma and neutron radiation readings. The wet density and water content ratio are calculated from the measured values using a calibration formula, and the degree of compaction is obtained from them. For the calibration equation, a calibration diagram showing the correspondence between the count rate ratio and the measured values was created by comparing the calibration equation with a reference measurement method, such as the Test Method for Soil Density by the Sand replacement method and the approximate curve was used.

Based on past findings [

2], the degree of compaction was calculated by counting the radiation emitted when the roller travels 2 m in the direction of travel as one measuring cell and estimating the density and moisture content based on the number of counts.

3. Verification of Applicability and Measurement Accuracy at Construction Sites

The Ministry of Land, Infrastructure, Transport and Tourism (MLIT) is promoting the “Project on the Introduction and Use of Innovative Technologies to Dramatically Improve Productivity at Construction Sites” using funds from the Public/Private R&D Investment Strategic Expansion PrograM (PRISM) promoted by the Cabinet Office. Currently, the project is being promoted, and the Ground Compaction Quality Management System has been adopted as a “technology to improve quality control in civil engineering works by utilizing data” in 2020 and 2021. Its applicability and measurement accuracy have also been verified at construction sites.

3.1. Results of Compaction Measurement of the Lower Base Course

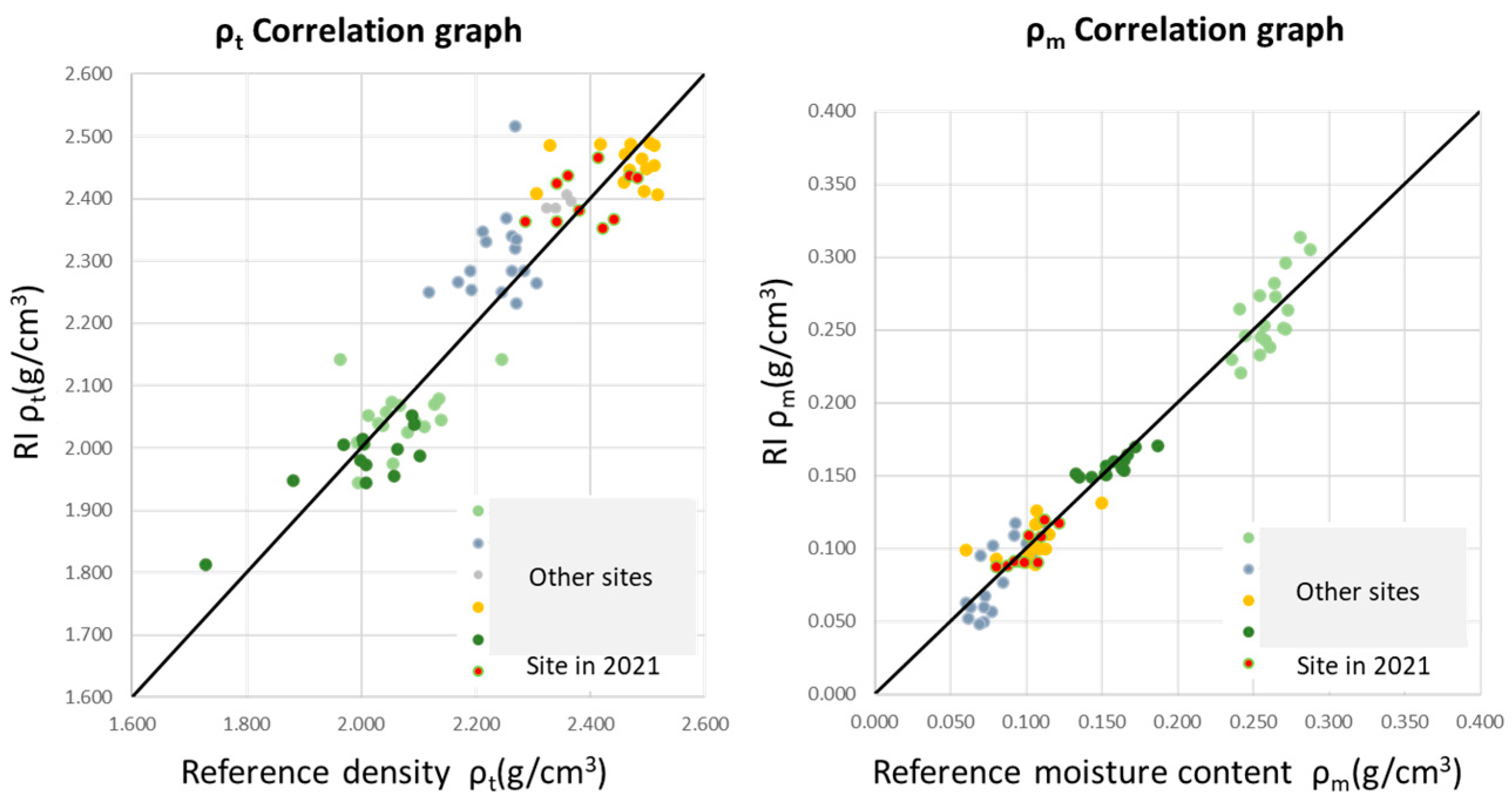

The density and water content of recycled crushed stone 0–40 used in the subbase course were examined to see if they could be measured using the calibration diagram created using the previously measured values. The results are shown in

Figure 4, which shows that the measurement accuracy of the rolling wheel-type RI meter used in this experiment was within ±0.1 [g/cm

3] for wet density and ±0.05 [g/cm

3] for water content compared to the transmission type RI meter at this experimental site. These values were found to be equivalent to the errors of commonly used transmission RI meters.

3.2. Effects Related to Reduction of Work Hours and Manpower

The rolling wheel-type RI meter used in this trial can measure the degree of compaction during construction, so there is no need to set aside time for a separate field test, as is the case in the current system. Therefore, the time required for field density tests at conventional pavement construction sites, as shown in

Table 1, can be reduced. Moreover, with this technology, there is no need for a person to conduct field density tests, a person to conduct laboratory tests, and a person to prepare forms, and all of these tasks can be performed by a single roller operator.

3.3. Effects on Quality Assurance and Improvement

The conventional management standard for base course construction is 1 point per 1000 m2, but this technology enables management at approximately 333 points per 1000 m2. Therefore, it is possible to prevent the overlooking of vulnerable areas and to more accurately determine the extent of ground improvement required. In addition, since the measurement results of the degree of compaction can be grasped in real time, corrective measures such as re-compaction can be taken promptly during construction to ensure and improve quality.

4. Conclusions

The use of the rolling wheel-type RI meter enabled us to grasp the ground conditions in real time and to control the surface, and the automatic measurement, which does not require human intervention, has confirmed the merits of advanced and labor-saving quality control. On the other hand, due to the characteristics of the rolling wheel-type RI meter, a problem in how to handle a counting error when the meter floats during measurement was also found. In the future, a verification process will be conducted to determine whether the errors are due to erroneous values or actual measurements.

Author Contributions

Conceptualization, H.A. and M.J.; methodology, H.A., Y.M. and M.J.; formal analysis, Y.M. and M.J.; investigation, K.S. and Y.M.; data curation, K.S., M.J. and Y.M.; writing—original draft preparation, K.S.; writing—review and editing, K.S. and M.J.; visualization, K.S.; supervision, M.J. All authors have read and agreed to the published version of the manuscript.

Funding

The demonstration at a construction site was funded by the “Project on the Introduction and Use of Innovative Technologies to Dramatically Improve Construction Site Productivity” promoted by the Ministry of Land, Infrastructure, Transport and Tourism under the Public/Private R&D Investment Strategic Expansion PrograM (PRISM) program promoted by the Cabinet Office. The funder for this project is the Ministry of Land, Infrastructure, Transport and Tourism.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

No new data were created or analyzed in this study. Data sharing is not applicable to this article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Hiroaki, A.; Koichi, G.; Taichi, I.; Yasuhiro, M.; Sosuke, K. Automatic compaction degree measurement using a rolling wheel type RI density moisture meter—Application to an automated vibrating roller. In Proceedings of the 75th JSCE Annual Conference VI-1138, Online, 7–9 September 2020. [Google Scholar]

- Koichi, G.; Hiroaki, A.; Taichi, I.; Yasuhiro, M.; Sosuke, K. Experiments on non-destructive measurement using a rolling wheel type RI density moisture meter—Toward application to an automatic traveling vibrating roller. In Proceedings of the JSCE 74th Annual Conference VI-356, Takamatsu, Japan, 3–5 September 2019. [Google Scholar]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).