1. Introduction

A chip seal, often referred to as a bituminous surface treatment (BST), is a pavement preservation treatment technique that is usually used on lower-volume routes by States and many local agencies. In addition to providing a low-cost surface treatment, other benefits of chip seals include improving skid resistance and reducing the deterioration of the existing underlying pavement. Roads treated with chip seal, however, do deteriorate over time due to construction quality, traffic, and environmental effects. The performance of chip seals is significantly affected by the existing conditions and the pretreatment carried out before the chip seal is applied. Therefore, to achieve the desired performance, it is recommended to apply the right treatment on the right pavement at the right time [

1].

Several researchers have studied the field performance of chip seal over time. Jalali and Vargas-Nordcbeck (2021) assessed whether chip seal application extends the pavement lifespan based on the initial conditions and the type of chip seal applied. In their study, six different chip seal treatments placed on LR-159 in Auburn, Alabama, were evaluated and compared to a control section which was not treated by chip seal. The treatments included: (1) single chip seal, (2) single chip seal with crack sealing, (3) double chip seal, (4) triple chip seal, (5) fiber mat chip seal, and (6) scrub seal. Cracking performance data collected since 2012 were analyzed. Findings showed that, generally, treated sections performed better than untreated sections. It was also found that the pavements that were in good condition and those whose cracks were filled before chip seal was applied can last at least 10 years, depending on traffic volume. Moreover, multilayered chip seal performed better than a single layer, with a median time to failure (MTTF) of more than 10 years [

2].

In Louisiana, Mousa et al. (2020) also studied the pavement life extension when chip seal is applied. The researchers analyzed cracking, roughness, and overall pavement condition of 47 flexible and composite pavement sections. The study concluded that chip seal treatments extended pavement life by 4 to 17 years depending on the pretreatment condition, as well as the type of pavement treated (flexible or composite) [

3].

Mamlouk and Dosa (2014) evaluated the life-extending benefits of single chip seal using data from the Long-Term Pavement Performance (LTTP) [

4]. Pavement initial conditions were classified as rough, medium, or smooth, based on the international roughness index (IRI). As in the previous study, treated sections were compared with untreated sections, and the results showed a better performance for treated sections than untreated sections. This study also found a high life extension for the pavements that were smooth at the time chip seal was applied. The results showed a life extension of 4–7 years, 2–3 years, and 0–1 year for smooth, medium, and rough pavements, respectively. A similar study was conducted by the Federal Highway Administration (FHWA) in 2010 with the aim of highlighting the degree to which pavement preservation treatments extend the service life of pavements [

5]. Performance data was collected from six target states (California, Kansas, Michigan, Minnesota, Texas, and Washington) selected based on their developed pavement management system or other information gathering systems. Results showed that chip seal treatments extended pavement service life for 3 to 8 years.

2. Methodology

The pavement management system is a system for recording all data on pavement condition to monitor deterioration, thus planning for maintenance and repair as well as mobilizing funds on time. Data are mostly managed through a computer program in which all information about roads and highways in a certain state is recorded. Like other States, WSDOT has a pavement management system known as the Washington pavement management system (WSPMS). In this program, various data components such as cracking, rutting, roughness, lane configuration, cross section, location, and construction history, among others, can be retrieved. In this study, twelve (12) road sections in Eastern Washington which were previously paved with hot mix asphalt (HMA) or chip seal and later maintained with chip seal were selected for analysis. An assessment of how chip seals impacted their performance was carried out in terms of cracking, rutting, and roughness index (IRI) over a period of 23 years (1996–2019), which included performance of pavement prior to chip seals and the performance of chip seals.

3. Results

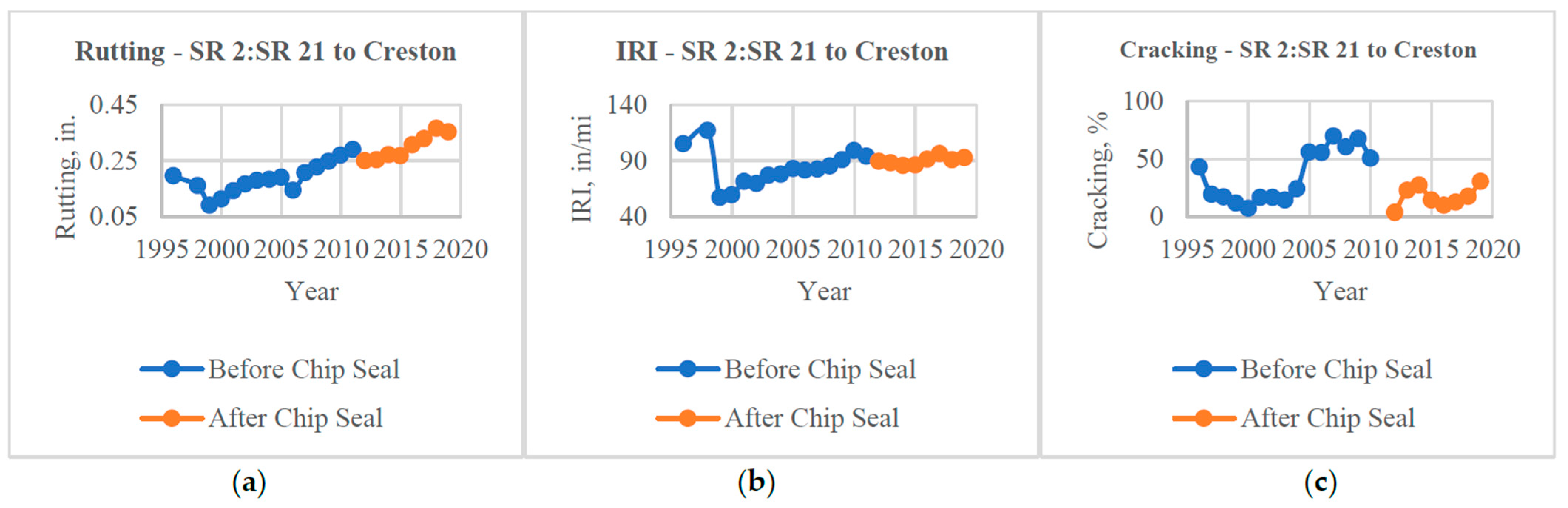

Based on the construction history, all sections were retrieved and the results of rutting, IRI, and cracking were plotted. An example of the data plots is shown in

Figure 1 below:

For most of the sections, rutting results indicated a slight decrease after the chip seal was applied, then rose again. This soaring can be explained by the presence of rutting in the old pavement. While IRI was found to be slightly improved after chip seal was applied, a substantial decrease in cracking was observed. The growth rate for each section was calculated before and after chip seal by computing the slope between two data points then averaging them. The immediate reduction after the application of chip seal was included in the calculation of the growth rate. Results are shown in

Table 1 below. The downward trend (negative data) obtained for the cracking and IRI can be justified by maintenance activities that were performed after the application of chip seal.

Paired t-test was performed to determine the effectiveness of chip seal on the growth rates of rutting, IRI, and cracking, for the projects converted from ACP to chip seal. Project 4 (Pend Oreille Co Line to SR 211) was not included in the analysis because the conversion was from chip seal to chip seal. Results showed that chip seal significantly affected crack growth rate. However, it did not affect the roughness and rutting growth rate. p-values were 0.15 for rutting, 0.37 for IRI, and 0.02 for cracking.

4. Conclusions

Generally, results showed considerable improvement in terms of cracking for all projects. This improvement can be attributed to one of functions of chip seal, which is to seal minor cracks.

Rutting slightly decreased for a few sections and for others an upward trend was noticed. This change in rutting may have resulted from the type of rutting in the existing pavement. The studded tire wear may be the major cause of the rutting. The placement of chip seal does not mitigate the studded tire wear.

A slight decrease in the roughness was also observed. This minor drop can be justified by the texture of chip seal. Cover aggregate in chip seal are macrotexture and result in a rough surface which improve the skid resistance.

The pavements analyzed had different service life length. Some were less than 10 years old, while others were more than 10 years. It was hard to compare how chip seal improved the pavement life span. Therefore, the growth rate was used instead of pavement life. However, slowed growth rates of cracking, rutting, and roughness can result in increased service life.

Author Contributions

Conceptualization, A.U. and H.W.; methodology, A.U. and H.W.; software, A.U., H.W. and K.L.; validation, A.U., H.W. and K.L.; formal analysis, A.U. and H.W.; investigation, A.U., H.W. and K.L.; resources, A.U., H.W. and K.L.; data curation, A.U.; writing—original draft preparation, A.U.; writing—review and editing, A.U., H.W. and K.L.; visualization, A.U.; supervision, H.W.; project administration, H.W. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data is contained within the article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Peshkin, D.G.; Hoerner, T.E.; Zimmernan, K.A. Optimal Timing of Pavement Preventive Maintenance Treatment Applications; NCHRP Report 523; Transportation Research Board: Washington, DC, USA, 2004. [Google Scholar]

- Jalali, F.; Vargas-Nordcbeck, A. Life-extending benefit of chip sealing for pavement preservation. Transp. Res. Rec. 2021, 2675, 104–116. [Google Scholar] [CrossRef]

- Mousa, M.R.; Elseifi, M.A.; Bashar, M.Z.; Zhang, Z.; Gaspard, K. Short and Long-Term Field Performances and Optimal Timing of Chip Seal in Hot and Humid Climates. Transp. Res. Rec. 2020, 2674, 33–43. [Google Scholar] [CrossRef]

- Mamlouk, M.S.; Dosa, M. Verification of effectiveness of chip seal as a pavement preventive maintenance treatment using LTPP data. Int. J. Pavement Eng. 2014, 15, 879–888. [Google Scholar] [CrossRef]

- Wu, Z.; Groeger, J.L.; Simpson, A.L.; Hicks, R.G. Performance Evaluation of Various Rehabilitation and Preservation Treatments; No. FHWA-HIF-10-020; U.S. Department of Transportation, Federal Highway Administration, Office of Asset Management: Washington, DC, USA, 2010. [Google Scholar]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).