Large-Scale Test Setup of Concrete Pavement Slabs Jointed by Carbon Fiber-Reinforced Polymer Dowel Bars as Load Transfer Devices †

Abstract

1. Introduction

2. Research Methodology

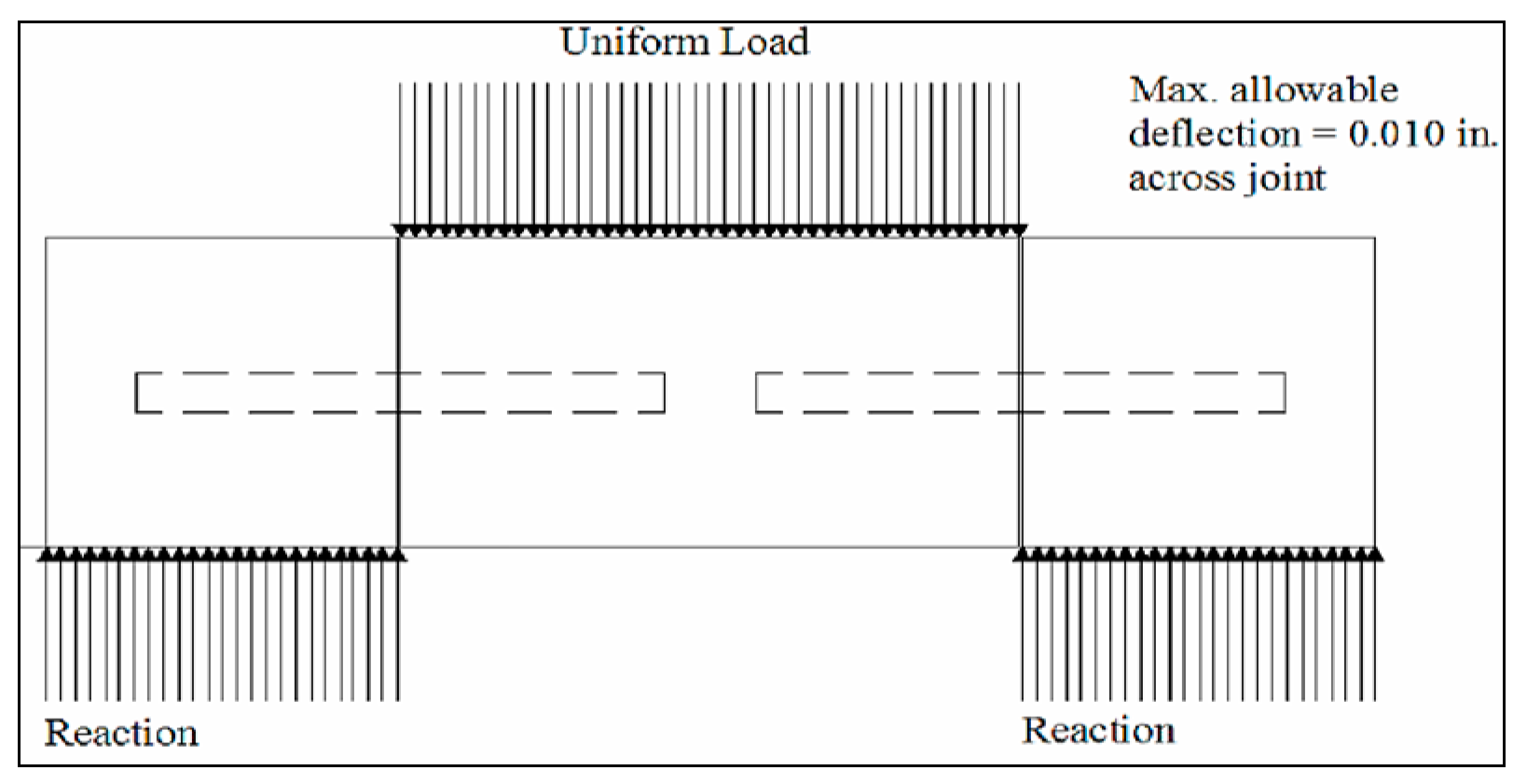

2.1. Load Transfer Efficiency (LTE) Test

2.2. Shear Strength Test

3. Results and Discussion

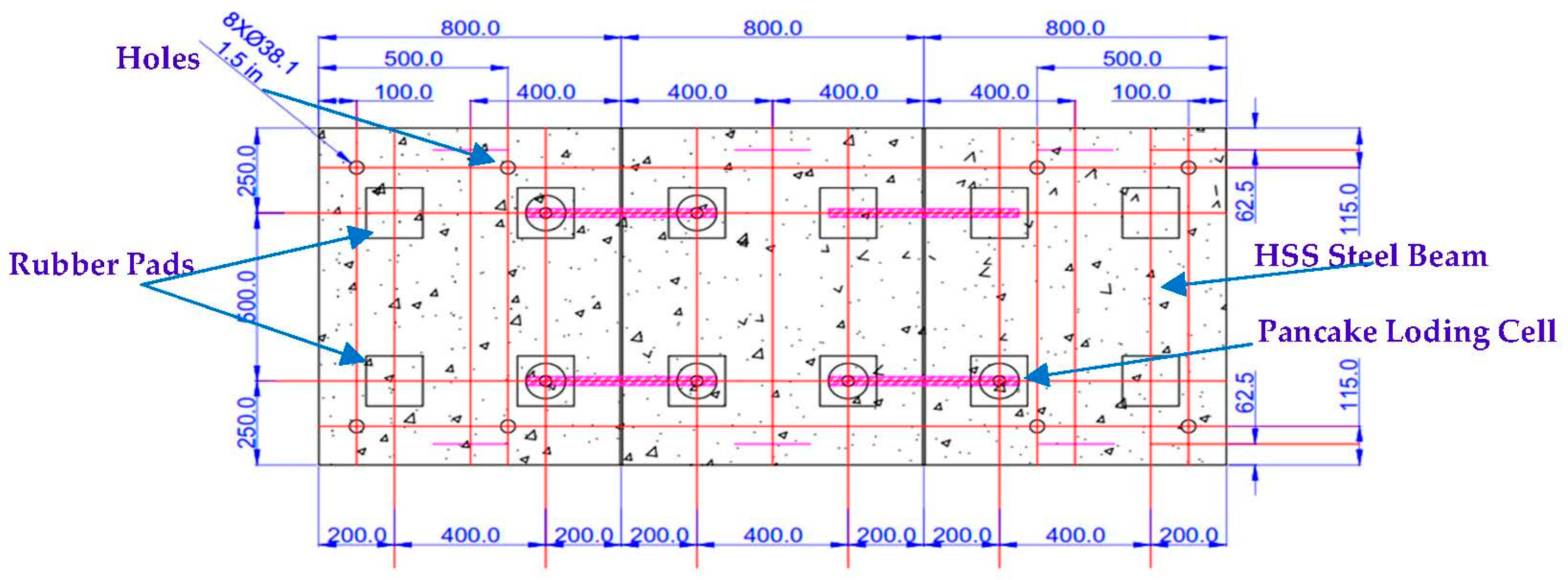

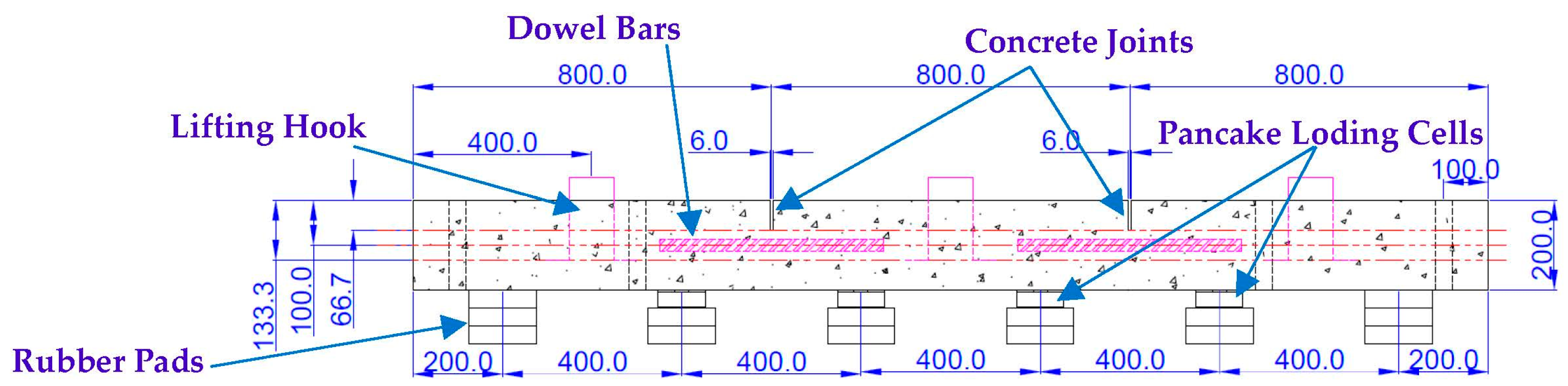

3.1. Load Transfer Efficiency (LTE) Test Setup

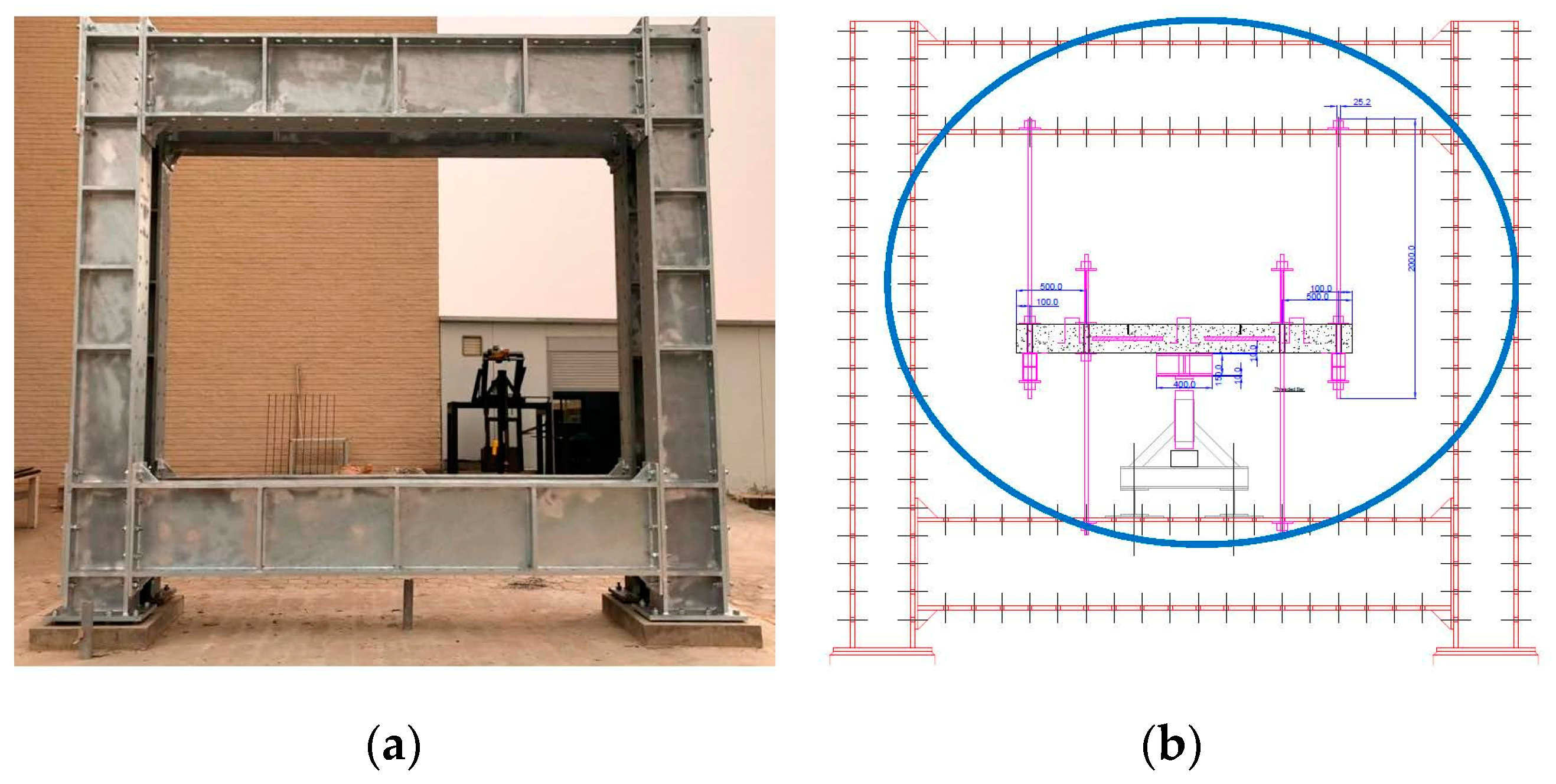

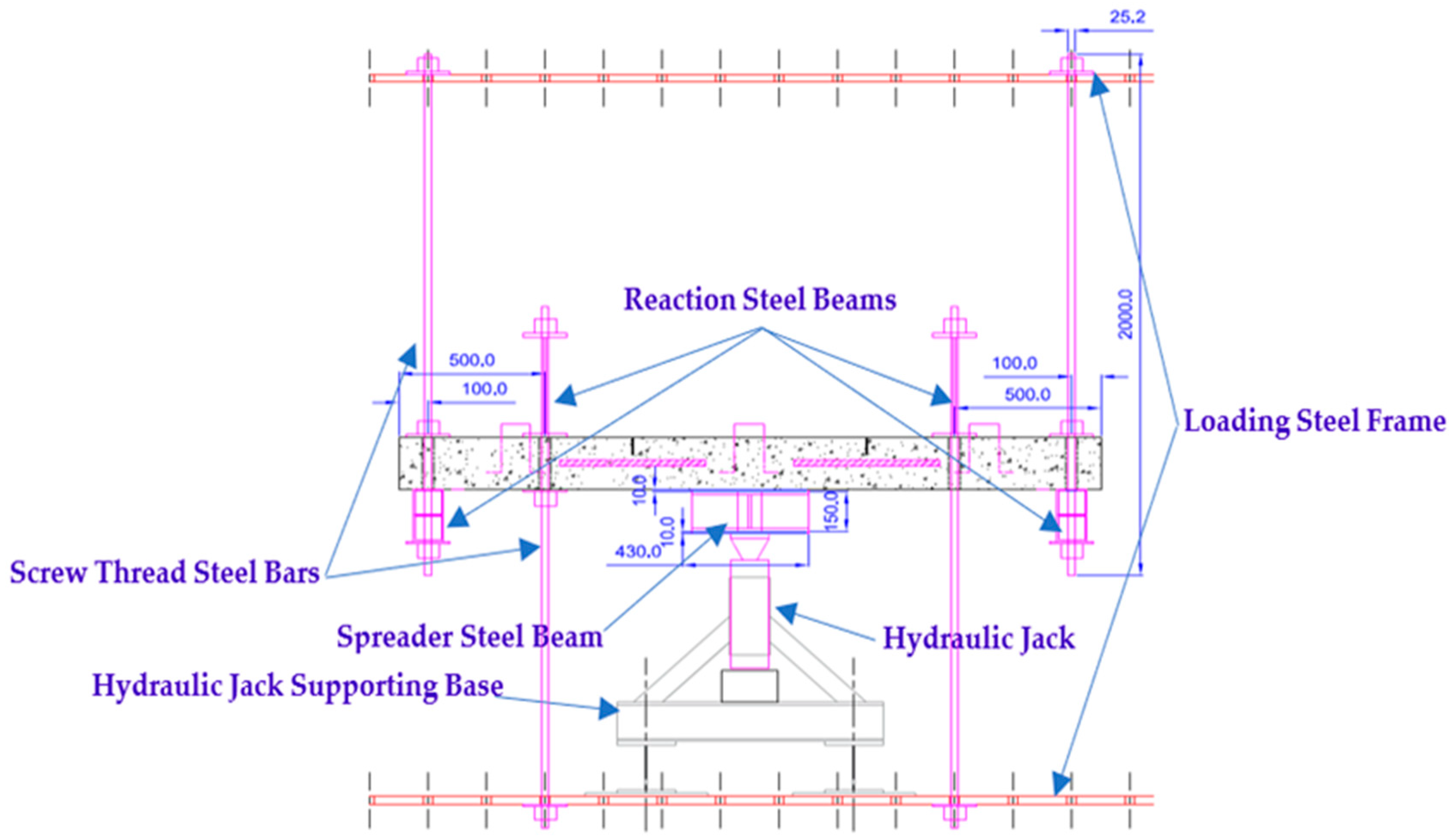

3.2. Shear Strength Test Set-Up

4. Conclusions and Ongoing Work

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Larson, R.M.; Smith, K.D. Evaluation of Alternative Dowel bar Materials and Coatings; Ohio Department of Transportation: Columbus, OH, USA, 2011.

- Hu, C.; Ma, J.; Zhao, J.; Leng, Z.; Jelagin, D. Experimental Study of Dowel Bar Alternatives Based on Similarity Model Test. Hindawi Adv. Mater. Sci. Eng. 2017, 2017, 3981908. [Google Scholar] [CrossRef]

- Larson, R.M.; Smith, K.D. Evaluating the Use of Fiber-Reinforced Polymer Bars in Continuously Reinforced Concrete Pavement; CPTP Tech Brief (FHWA-HRT-05-081); Federal Highway Administration (FHWA): Washington, DC, USA, 2017.

- Sadeghi, V.; Hesami, S. Investigation of load transfer efficiency in jointed plain concrete pavements (JPCP) using FEM. Int. J. Pavement Res. Technol. 2018, 11, 245–252. [Google Scholar] [CrossRef]

- American Association of State Highway and Transportation Officials (AASHTO). Guide for Design of Pavement Structures; AASHTO: Washington, DC, USA, 1993. [Google Scholar]

- Harrington, J.F. Comparison of Alternative Laboratory Dowel Bar Testing Procedures. Master’s Thesis, Iowa State University, Ames, IA, USA, 2006. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahmed, T.; Saad, A.; Kazem, A.; Radwan, A.; AlMutairi, A.; Ashkanani, S. Large-Scale Test Setup of Concrete Pavement Slabs Jointed by Carbon Fiber-Reinforced Polymer Dowel Bars as Load Transfer Devices. Eng. Proc. 2023, 36, 21. https://doi.org/10.3390/engproc2023036021

Ahmed T, Saad A, Kazem A, Radwan A, AlMutairi A, Ashkanani S. Large-Scale Test Setup of Concrete Pavement Slabs Jointed by Carbon Fiber-Reinforced Polymer Dowel Bars as Load Transfer Devices. Engineering Proceedings. 2023; 36(1):21. https://doi.org/10.3390/engproc2023036021

Chicago/Turabian StyleAhmed, Taha, Ahmad Saad, Abdulhadi Kazem, Ali Radwan, Ali AlMutairi, and Sarah Ashkanani. 2023. "Large-Scale Test Setup of Concrete Pavement Slabs Jointed by Carbon Fiber-Reinforced Polymer Dowel Bars as Load Transfer Devices" Engineering Proceedings 36, no. 1: 21. https://doi.org/10.3390/engproc2023036021

APA StyleAhmed, T., Saad, A., Kazem, A., Radwan, A., AlMutairi, A., & Ashkanani, S. (2023). Large-Scale Test Setup of Concrete Pavement Slabs Jointed by Carbon Fiber-Reinforced Polymer Dowel Bars as Load Transfer Devices. Engineering Proceedings, 36(1), 21. https://doi.org/10.3390/engproc2023036021