Mechanical Properties Study of Borosilicate Glass Loaded with Vanadium and Cobalt by Nanoindentation Technique †

Abstract

:1. Introduction

2. Materials and Methods

3. Results

3.1. Load vs. Displacement Curve

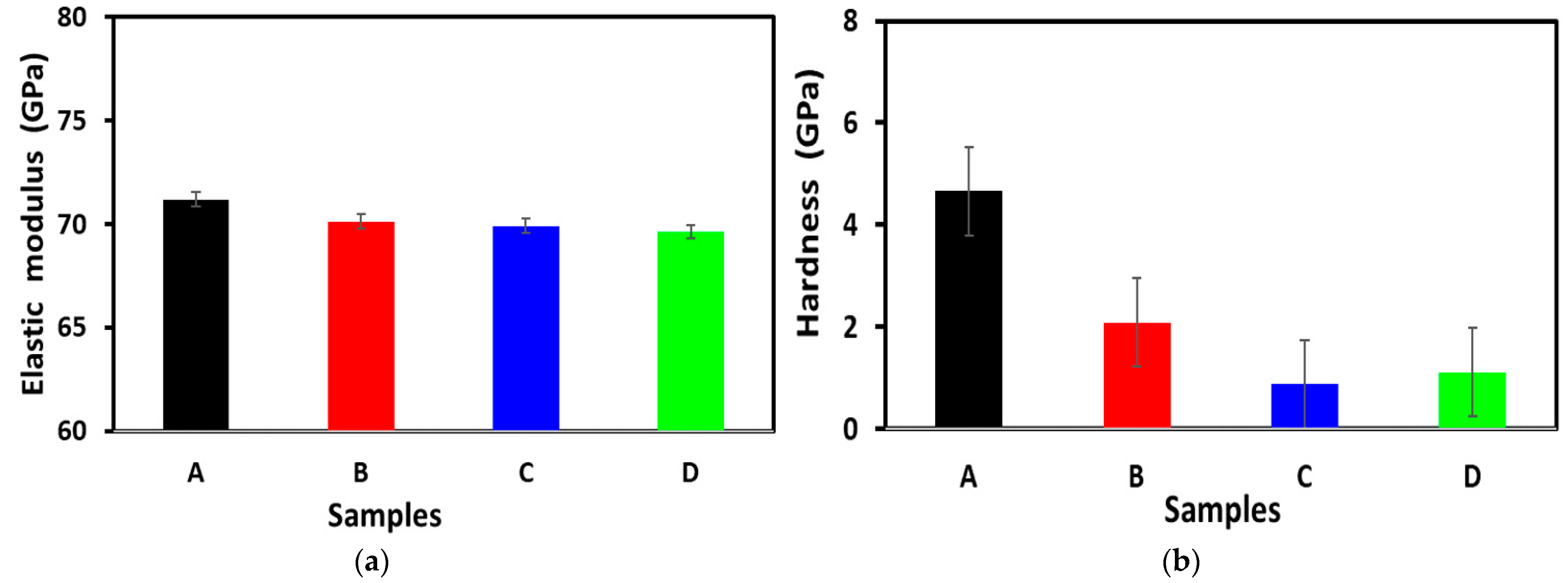

3.2. Elastic Modulus and Hardness Measurments

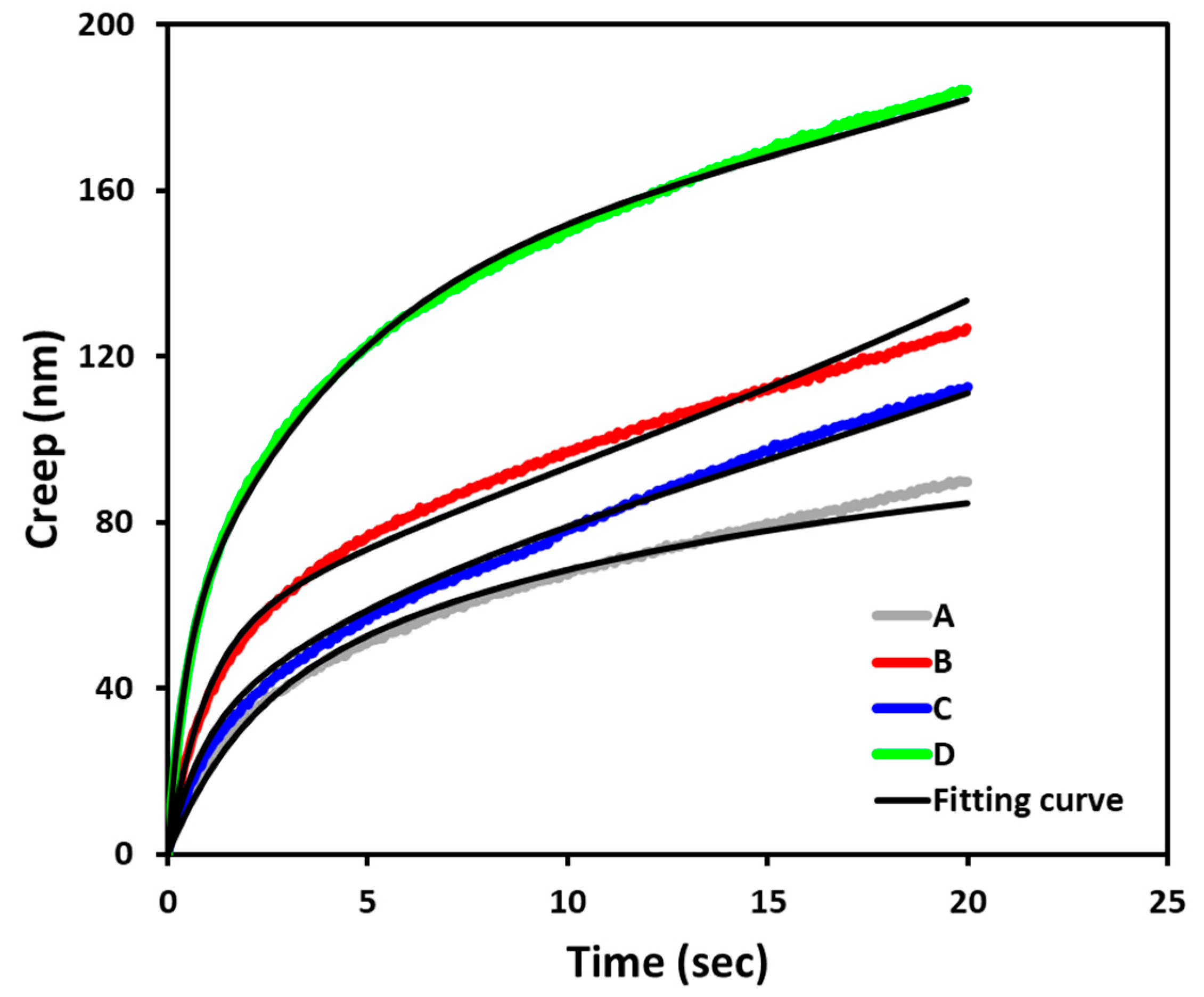

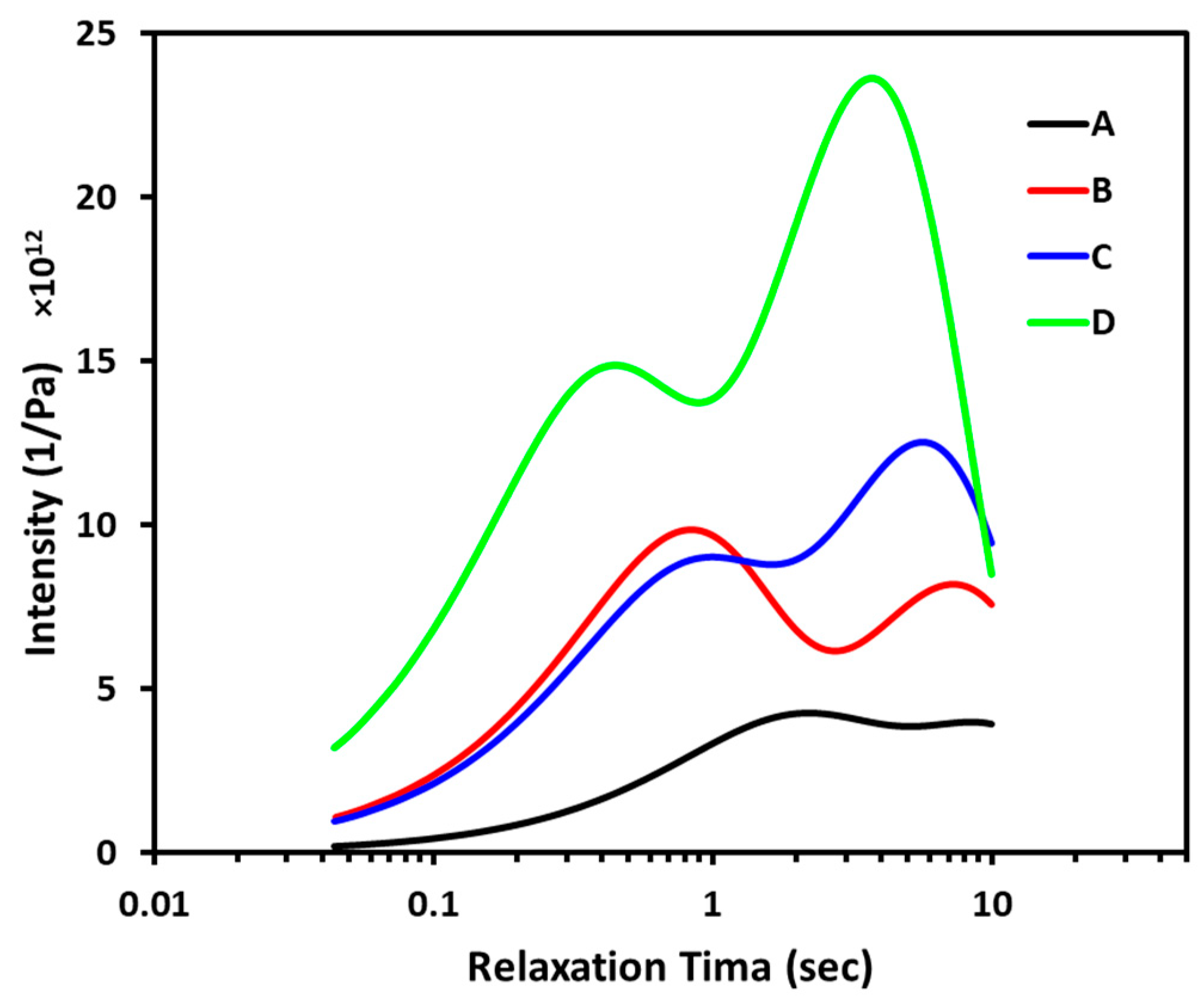

3.3. Creep Curve

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Wei, B.; Zhang, T.; Li, W.; Xing, D.; Zhang, L.; Wang, Y. Indentation Creep Behavior in Ce-Based Bulk Metallic Glasses at Room Temperature. Mater. Trans. 2005, 46, 2959–2962. [Google Scholar] [CrossRef]

- Marimuthu, K.P.; Lee, K.; Han, J.; Rickhey, F.; Lee, H. Nanoindentation of zirconium based bulk metallic glass and its nanomechanical properties. J. Mater. Res. Technol. 2019, 9, 104–114. [Google Scholar] [CrossRef]

- Hassaan, M.; Osman, H.; Hassan, H.; El-Deeb, A.; Helal, M. Optical and electrical studies of borosilicate glass containing vanadium and cobalt ions for smart windows applications. Ceram. Int. 2017, 43, 1795–1801. [Google Scholar] [CrossRef]

- ASTM E2546-15; Standard Practice for Instrumented Indentation Testing. ASTM International: West Conshohocken, PA, USA, 2015. [CrossRef]

- Anggono, A.D.; Elveny, M.; Abdelbasset, W.K.; Petrov, A.M.; Ershov, K.A.; Zhu, Y.; Yunusov, A.; Chupradit, S.; Mustafa, Y.F.; Surendar, A. Creep Deformation of Zr55Co25Al15Ni5 Bulk Metallic Glass Near Glass Transition Temperature: A Nanoindentation Study. Trans. Indian Inst. Met. 2021, 75, 673–680. [Google Scholar] [CrossRef]

- Song, S.; Bei, H.; Wadsworth, J.; Nieh, T. Flow serration in a Zr-based bulk metallic glass in compression at low strain rates. Intermetallics 2008, 16, 813–818. [Google Scholar] [CrossRef]

- Gong, J.; Miao, H.; Peng, Z. On the contact area for nanoindentation tests with Berkovich indenter: Case study on soda-lime glass. Mater. Lett. 2004, 58, 1349–1353. [Google Scholar] [CrossRef]

- Tao, K.; Qiao, J.; He, Q.; Song, K.; Yang, Y. Revealing the structural heterogeneity of metallic glass: Mechanical spectroscopy and nanoindentation experiments. Int. J. Mech. Sci. 2021, 201, 106469. [Google Scholar] [CrossRef]

- Raj, R.; Chyung, C. Solution-precipitation creep in glass ceramics. Acta Met. 1981, 29, 159–166. [Google Scholar] [CrossRef]

- Gong, P.; Jin, J.; Deng, L.; Wang, S.; Gu, J.; Yao, K.; Wang, X. Room Temperature Nanoindentation Creep Behavior of TiZrHfBeCu (Ni) High Entropy Bulk Metallic Glasses. Mater. Sci. Eng. A 2017, 688, 174–179. [Google Scholar] [CrossRef]

- Castellero, A.; Moser, B.; Uhlenhaut, D.I.; Dalla Torre, F.H.; Löffler, J.F. Room-Temperature Creep and Structural Relaxation of Mg–Cu–Y Metallic Glasses. Acta Mater. 2008, 56, 3777–3785. [Google Scholar] [CrossRef]

- Yuan, C.; Liu, R.; Pang, C.; Zuo, X.; Li, B.; Song, S.; Hu, J.; Zhu, W.; Shen, B. Anelastic and viscoplastic deformation in a Fe-based metallic glass. J. Alloys Compd. 2020, 853, 157233. [Google Scholar] [CrossRef]

| Samples | h1 | τ1 | h2 | τ2 | m |

|---|---|---|---|---|---|

| A | 35 | 1.9 | 50 | 11 | 2.58 |

| B | 50 | 0.9 | 50 | 9.0 | 3.2 |

| D | 27 | 0.8 | 59 | 7.0 | 3.74 |

| C | 48 | 0.4 | 110 | 4.6 | 3.96 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

El-Deeb, A.S.; Taha, E.O.; Kader, M.M.A.; Naguib, H.M.; Hassaan, M.Y. Mechanical Properties Study of Borosilicate Glass Loaded with Vanadium and Cobalt by Nanoindentation Technique. Eng. Proc. 2023, 31, 81. https://doi.org/10.3390/ASEC2022-13816

El-Deeb AS, Taha EO, Kader MMA, Naguib HM, Hassaan MY. Mechanical Properties Study of Borosilicate Glass Loaded with Vanadium and Cobalt by Nanoindentation Technique. Engineering Proceedings. 2023; 31(1):81. https://doi.org/10.3390/ASEC2022-13816

Chicago/Turabian StyleEl-Deeb, Asmaa S., Eman O. Taha, Marwa M. Abdel Kader, Hamdy M. Naguib, and Mohamed Y. Hassaan. 2023. "Mechanical Properties Study of Borosilicate Glass Loaded with Vanadium and Cobalt by Nanoindentation Technique" Engineering Proceedings 31, no. 1: 81. https://doi.org/10.3390/ASEC2022-13816

APA StyleEl-Deeb, A. S., Taha, E. O., Kader, M. M. A., Naguib, H. M., & Hassaan, M. Y. (2023). Mechanical Properties Study of Borosilicate Glass Loaded with Vanadium and Cobalt by Nanoindentation Technique. Engineering Proceedings, 31(1), 81. https://doi.org/10.3390/ASEC2022-13816