1. Introduction

Social and political trends as well as legal regulations have been enforcing sustainability in manufacturing and product design. Especially in the mobility industry, lightweight design is the key to improve energy and resource efficiency and reduce the carbon footprint. Substituting classic metallic materials by light metal alloys is one strategy to reduce component weight [

1]. Among these light metals, magnesium alloys (Mg) promise the best capability for lightweight design, as they provide beneficial density to strength ratio [

2]. However, inadequate corrosion properties and adhesion during tempered sheet forming currently limit their industrial application. To overcome these challenges, a protective coating can be applied [

3]. Coating a Mg core with surface layers made of an aluminum alloy (Al) combines the beneficial corrosion resistance of Al and the outstanding mechanical-technical properties of Mg in a lightweight compound material. When it comes to joining material combinations that are incompatible in fusion welding, such as Mg-Al [

4] or steel-aluminum [

5], roll cladding is still the method of choice [

6].

Roll cladding is a solid-state welding process in which two or more metallic materials form a solid compound [

7]. The process is based on conventional rolling and generates large area compounds of similar or dissimilar materials on an industrial scale fast and effectively [

8]. The bond strength is based on local cohesion and adhesion between the bonding partners, which are brought to atomic spacing under high pressure. Surface preparation (e.g., brushing or grinding) is required for adjusting the surface roughness, removing impurities, activating the surface and thus stimulating bonding [

9]. During forming, newly created and reactive surface areas establish stable local bonds, which take effect as macroscopic bond strength.

Roll cladding is divided into cold and hot roll cladding. The distinction is based on the recrystallization temperatures of the materials involved. In hot roll cladding, dynamic and meta-dynamic softening processes occur during cladding. This results in the removal of residual stress caused by the different material flow of the cladding materials. At the same time, diffusion processes can support bond formation, leading to a dissolution of the bond zone [

10]. In cold cladding, an annealing treatment as a final process step will achieve similar effects. Here, annealing parameters must be carefully selected to avoid formation of critical intermetallic phases in the bonding zone [

11]. A comprehensive review of the effective parameters’ influence on the resulting bond strength in cold roll bonding is provided in [

12]. Compared to cold cladding, the minimum shape changes required to achieve adhesion are significantly smaller in hot roll cladding, and the necessary process forces and pressures are lower. However, the minimum achievable thicknesses and the technically feasible tolerances are higher than in cold roll cladding. Furthermore, thermal residual stress that emerges during cooling due to different expansion coefficients must be considered [

13]. The importance of the surface roughness on the adhesion strength has been addressed by various authors (e.g., [

14,

15]). Based on adhesion models according to Bay and Zhang [

16,

17], Schmidtchen proposed a multi-scale approach that considers the influence of roughness [

14]. This resulted in optimal roughness ratios for an optimal adhesion build-up depending on the material combination.

In contrast to many other coating-technologies, roll cladding enables coating thicknesses of some hundredths of a millimeter up to several centimeters. Thereby, high coating thicknesses imply that corrosion resistance of the compound is still granted after mechanical stresses due to further processing (e.g., via bending, deep drawing, etc.) and use (e.g., due to stone or hail impact). As no reliable data about roll cladding of aluminum and Mg are available so far, this study aimed at analyzing the influence of important process parameters and investigating the suitability of the resulting compounds for further processing by sheet metal forming. The target thickness of the compound was set in the range of 1.5–2.0 mm, so that it can directly substitute monolithic steel and aluminum sheets with typical thicknesses of 0.6–1.5 mm. This allows for mass savings of up to 40% [

18] while maintaining the stiffness and strength values of the components. The thickness of the Al-coating must be sufficient to ensure the corrosion protective effect. At the same time, it must be thin enough to make sure that the weight properties of the compound are predominantly determined by the Mg-core. Here, a value of 0.2–0.3 mm was targeted. Concerning the analysis of compound manufacturing, parameters of the preparing brushing process and the hot roll cladding temperature were specifically regarded. Compound characterization was performed considering two aspects: The adhesion of the different layers was evaluated via lap shear tests and peel tests and the formability of the compound was characterized via Nakajima tests and deep drawing tests.

2. Materials and Methods

2.1. Base Materials

An AZ31 Mg sheet with an initial thickness of 2.0 mm was used as core material while the aluminum alloy EN AW-5754 with a thickness of 0.5 mm served as cover-layer. In order to quantify the forming limits of both materials, Nakajima tests were performed at the Institute for Metal Forming (IMF) at 300 °C, which is a typical temperature for processing Mg by sheet metal forming and therefore is assumed to be relevant for the Al/Mg/Al compound developed here, too.

Table 1 summarizes important results.

2.2. Compound Production

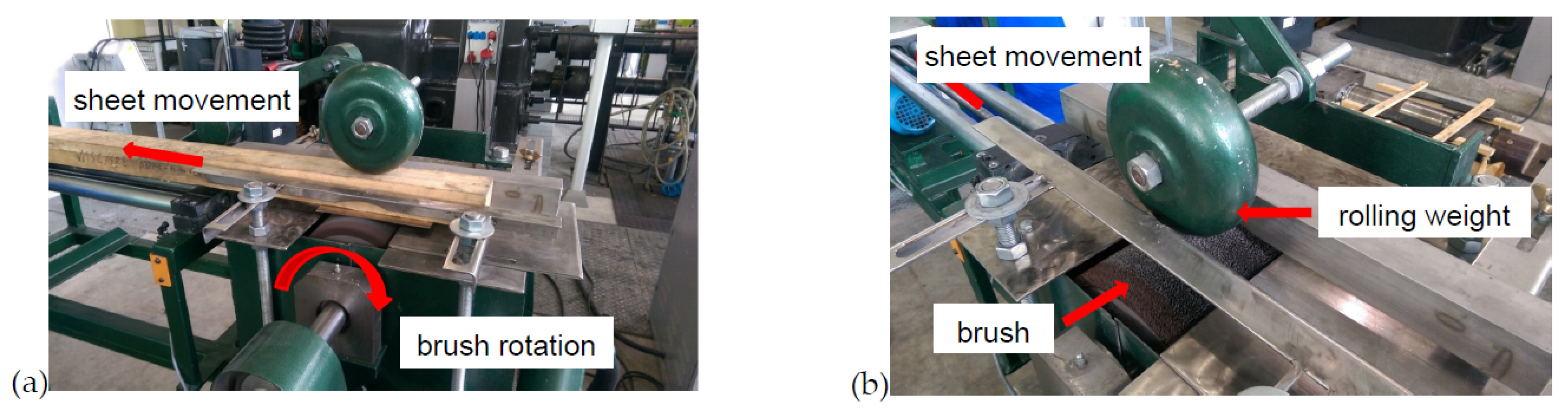

For compound production, sheets featuring a length of 250 mm and a width of 120 mm were used. In preparation of the rolling process, the contact surfaces of the sheets were cleaned with acetone and brushed using a brush by Kullen with a diameter of 240 mm and curled steel bristles with a length of 40 mm and a diameter of 0.15 mm (

Figure 1).

Table 2 lists the brushing parameters and the surface properties roughness depth (R

z), mean groove width (R

Sm) and normalized peak number (RP

C).

Directly after brushing and preparation of sandwiches, the specimens were heated in a chamber furnace, to 350 °C, 375 °C and 400 °C, with a holding time of 10–12 min. Then, the surface layers were assembled with the core materials to form cladding packs and fed to a SACK reversing stand at IMF. The rolls have a diameter of 360 mm and can be heated by heating mats in order to reduce heat dissipation from the rolled material and preserve the forming capacity. To achieve the defined final thickness precisely, the forming speed decreases as the number of rolling passes increases. For the tests, the rolls were heated to approx. 120 °C for several hours and the lubricant microjet W-SP 1/0510(100) was applied to the rolls. The rolling speed was set to 0.3 m/s. These forming parameters were selected on the basis of the investigations in [

8,

11] for AA1050/AZ31/AA1050 compound in order to make further improvements in the area of the highest possible adhesive strength by changing the forming temperature and surface roughness. After roll cladding, the compounds were firstly diffusion annealed at 200 °C for 60 min and then air cooled to increase the bond strength. Light microscopic investigations served for quantifying the individual layer thicknesses in the compound and detecting potential cracks or defects.

2.3. Compound Characterization

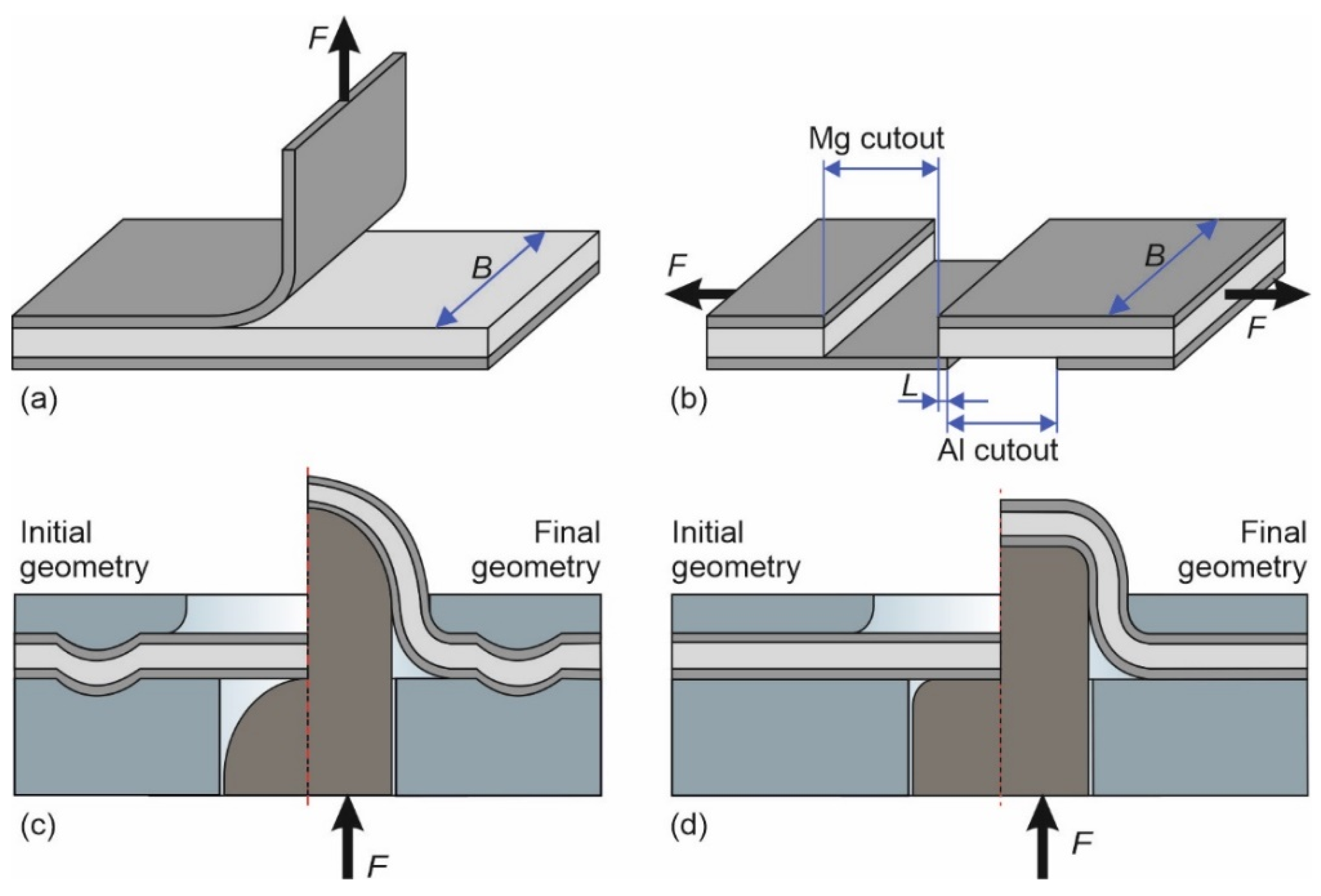

Compound characterization was performed via peel and lap shear tests as well as Nakajima and deep drawing tests. Five specimens per parameter set were evaluated. Peel tests performed by IMF and lap shear tests according to DIN EN 50162 performed by Fraunhofer Institute for Machine Tools and Forming Technology (IWU) aimed at determining the interlaminar adhesion quality in the compound. Sheet metal forming of Mg is usually carried out at elevated temperatures of at least 230 °C to activate additional slip planes thus improving formability. It was expected that similar temperatures are required for forming the Al/Mg/Al compound investigated, too. Nevertheless, peel and lap shear tests were carried out at room temperature, because in this condition, the flow stress and tensile strength of the base materials are higher (no thermal softening) so that higher force can be applied to the adhesion layer without failure of the base material. To prepare peel specimens, strips with a length of 120 mm and a width of 20 mm were cut from the test material, the Al cover-layer was peeled off by hand up to half of the specimen and bent at a 90° angle. The specimens were clamped in a tensile testing machine and the traverse moved at a constant speed of 1 mm/min, thus peeling the Al cover-layer off the Mg core-layer (compare

Figure 2a). Force-displacement data were recorded during the detachment of the Al cover-layer. The peel strength can be calculated as the quotient of the force required for peeling (F) and the width of the peel specimen (B).

Lap shear specimens were prepared by milling. As shown in

Figure 2b, the Mg corelayer was removed on one side of the specimen and the Al cover-layer on the other side. In between these milled sections remains a cladded area with a length “

L” and a width “

B” that corresponds to the specimen width of 20 mm. This is the test area. Applying a tension force “

F” to the specimen will lead to shear load between the Mg core-layer and the Al cover-layer in the test area. The shear stress (

τ) is calculated from the tensile force (

F), the length (

L) and the width (

B) according to equation (1). To avoid early failure of the specimen in the Al cover-layer, the shear zone (

L) must not be longer than the thickness of the cover layer. Therefore,

L was set to 0.2 mm, here. The shear stress directly before failure is used to characterize the shear strength of the compound.

The formability of the compound is evaluated by IMF via Nakajima tests. Here, room temperature and elevated temperatures of 200 °C, 250 °C and 300 °C were considered, because significantly improved formability of the Mg core material was expected for higher temperatures. The results of the Nakajima tests were interpreted as forming limit curves (FLC) according to ISO 12004. Different stress and strain states were considered by investigating circular specimens with a diameter of 120 mm and waisted specimens with widths of 60 mm and 20 mm. All specimens were prepared by milling and a grid was applied via laser to allow optical strain measurement during the tests. For the tests, tools (punch and drawing ring) and specimens were heated and a camera system that records 10 images per second was applied for strain measurement. The last image taken before surface crack initiation was evaluated to quantify the formability.

Supplementary to the Nakajima tests, deep-drawing tests were performed at IWU to provide information about the behavior of the compound under conditions that are close to the technological application. Circular blanks with a diameter of 100 mm were lubricated with WU 300 G from Raziol and deep drawn to square cups with side length of 50 mm and inlet and edge radii of 5 mm at the same temperatures that were considered in the Nakajima tests. During forming, the compounds were subjected to a combined tension–compression load that is typical to produce complex component geometries. In each test batch, the drawing depth was gradually increased until failure occurred. The maximum depth achievable without cracks characterizes the forming limit.

3. Results

3.1. Compound Production

In order to identify suitable parameters for preparing sheets for subsequent hot roll cladding, the influence of different brushing parameters on the surface was investigated.

Figure 3 summarizes the results considering the Mg sheets. It shows that there is a small process window, which allows maximum surface roughness. Therefore, a brush circumferential speed of 16 m/s, a feeding speed of 10.73 mm/s and a compressive force of 43 N were selected to prepare the Mg specimens for hot roll cladding.

Tests on the Al sheets showed that brushing with similarly high intensity caused the thin sheets to curl. Therefore, the brushing parameters were set in such a way that the Al sheet was brushed as strongly as possible without damaging the sheet, i.e., at a brush circumferential speed of 12.5 m/s, a feeding speed of 9 mm/s and a contact force of 35 N. This leads to a homogeneous surface finish and a surface roughness Rz of 10.44 μm.

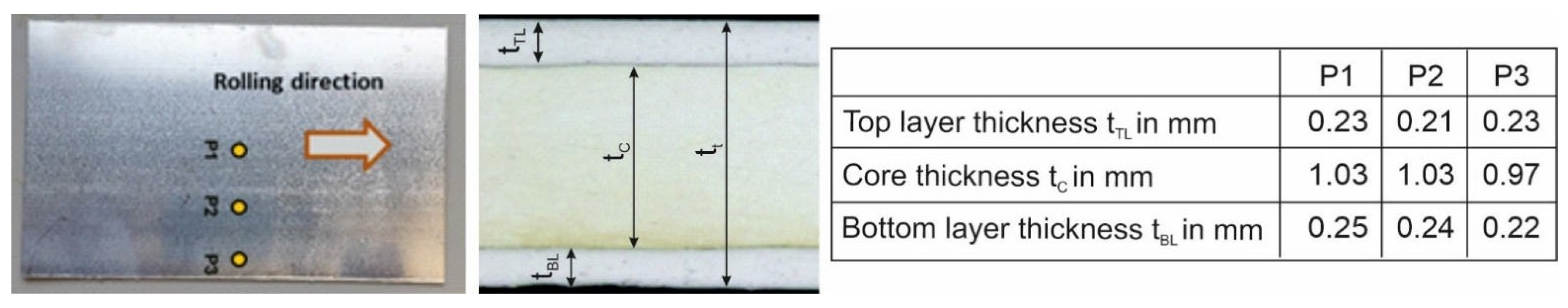

After hot roll cladding, aging and air cooling, straight sheets without any defects or thinning of the Al surface layer and with uniform stretching of the core and surface layers were achieved (compare

Figure 4). Only slight cracking in the edge area occurred. Due to the random occurrence of cracks in a small edge area, these could not be quantified further. However, this confirmed the general assumption that they occur when the cladding layers do not overlap ideally.

Light microscopic examinations carried out on sections of the hot-roll-clad compound sheets confirmed that the required compound thickness of 1.5 mm was achieved with a maximum deviation of 6% over the entire width of the semi-finished product. Details about the individual layer thicknesses are given in

Figure 4. They confirm a reduction in thickness of up to 58% for the Al cover-layer and 52% for the Mg core material. Both base materials and the bonding zones in–between them were free of defects.

3.2. Compound Characterization

3.2.1. Interlaminar Adhesion

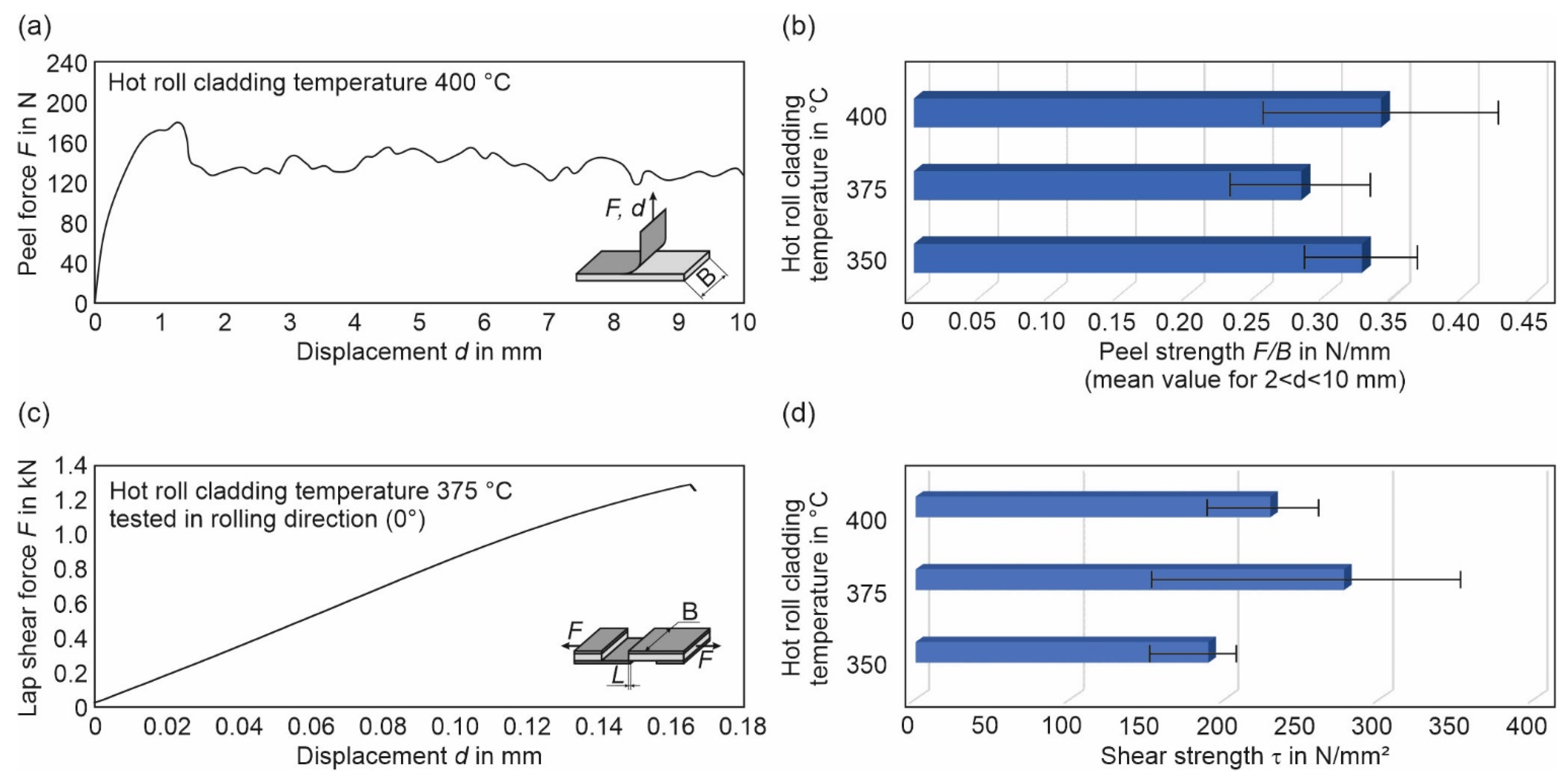

Figure 5 summarizes results of the peel and lap shear tests. Specifically,

Figure 5a shows a typical course of the peel force as a function of the displacement. The force rises quickly to a maximum level. Then, it decreases slightly and remains on a relatively constant level, indicating constant interlaminar adhesion quality. Peel strength is calculated by referring the mean peel force in the plateau area (i.e., for a displacement between 2 mm and 10 mm) to the width of the specimen. This peel strength varies slightly for different hot roll cladding temperatures. The highest peel strength was achieved for a hot roll cladding temperature of 400 °C (see

Figure 5b).

Similarly,

Figure 5c shows a representative course of the lap shear force as a function of the displacement. The curve is characterized by a large linear section, suggesting mainly elastic deformation of the specimen followed by a short non-linear area and a sudden drop indicating abrupt failure, when the applied load reaches the shear strength of the compound. Like the peel strength, also the shear strength depends on the hot roll cladding temperature, but in contrast to the peel tests, the highest strength is obtained for a rolling temperature of 375 °C, here (see

Figure 5d).

3.2.2. Forming Properties

To determine the formability of the compound sheets, Nakajima and deep drawing tests were carried out at room temperature and at 200 °C, 250 °C and at 300 °C. At room temperature, no significant deformation could be realized without material failure. The failure strain in Nakajima tests at room temperature hardly exceeded 0.1 even for the mostbeneficial strain condition (uniaxial tension). As expected, failure strain significantly increased at elevated temperatures.

Figure 6 summarizes important results of the Nakajima tests on the example of the test temperature of 300 °C in the form of a forming limit diagram and compares the forming limits of the Al/Mg/Al compounds to the corresponding values of the base materials. The data points on the left of the graph were determined for the waisted specimens with a width of 20 mm (uniaxial tension), the data points in the middle were determined using the specimens with a width of 60 mm (plain strain) and the data points on the right consider the full specimens (equibiaxial stretching). The diagram clearly shows that the forming limits of the Al/Mg/Al compounds are significantly extended compared to the reference values determined for the Mg core material. If the cladding parameters are well chosen, the forming limits can almost reach the limits of the Al cover material for selected load cases. A more detailed analysis of the influence of the hot roll cladding temperature reveals that 350 °C provides best forming capacity, here, while higher hot roll cladding temperatures lead to lower forming limits especially for equibiaxial stress and strain. Lower test temperatures of 200 °C and 250 °C proved the same trends at lower forming limits.

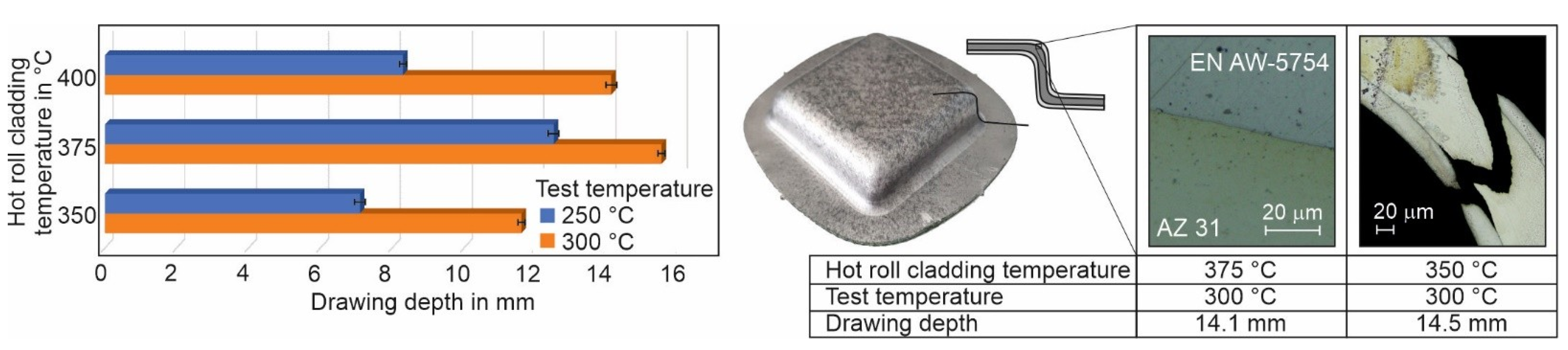

The aim of the deep drawing tests was to determine the maximum achievable drawing depth of the compound. However, at room temperature and 200 °C test temperature, this parameter was still too low for adequate punch control. Therefore, these tests could not be evaluated in detail. At higher temperatures, an increase in the achievable drawing depth with increasing test temperature could be observed for all hot roll cladding temperatures. Details are illustrated in

Figure 7. It clearly shows that for 250 °C and 300 °C test temperatures, highest drawing depths were achieved for a hot roll cladding temperature of 375 °C. For a hot roll cladding temperature of 400 °C, the achievable drawing depth was slightly lower and a hot roll cladding temperature of 350 °C led to the lowest achievable drawing depths. These results agree well with the compound behavior in the lap shear tests although lap shear tests were carried out at room temperature only.

Additional light microscopic analysis was performed on the deep drawn parts. Here, the most critical area regarding failure was considered. This is the outer bottom radius in the corner area of the square cup.

Figure 7 shows exemplarily light microscopic images of a good part and a torn part, both focusing on the joint in this area. The analysis showed that even for drawing depths closely below the failure limit, the joint between the Mg core-layer and the Al cover-layer is still intact. Further investigations considering different sections and other deep drawn parts without cracks proved comparable quality of the joint. The torn part proves high joint quality in close proximity of material failure. This suggests that cracking is initiated in the material and not in the joint.

4. Discussion

The different trends in the compounds’ behaviors in peel and lap shear tests might be attributed to the different load cases. In peel tests, the load acts perpendicular to the joining zone, while in lap shear tests, it is applied in parallel to the joining zone. The orthogonal load applied in peel tests is hardly representative for load cases of typical processing techniques such as e.g., deep drawing. Therefore, not all results obtained via peel tests can be directly transferred to describe the material behavior during forming. Nevertheless, these tests allow obtaining information about the homogeneity of the joint quality, which is not possible via lap shear tests focusing on a localized area of the bond. Lap shear tests, however, are more suitable to reflect the compound behavior in deep drawing because the acting shear load is much more representative for forming. Correspondingly, the material rolled at 375 °C provided the highest formability in the deep drawing tests followed by the material rolled at 400 °C and 350 °C.

Nakajima tests show that these observations are not valid for all stress and strain states, but, depending on the strain state, different rolling temperatures can have a particularly advantageous effect on the forming capacity, which differs from the behavior in lap shear tests. This might be because the stretch drawing state in the Nakajima test predominantly leads to tensile stresses, while in deep drawing, tensile-compressive stresses prevail. Especially in the strain states considered in the Nakajima tests performed here (uniaxial tension, plane strain and equibiaxial stretching), shear stress is not the predominant stress state. Instead, other properties that might include the formability of the Mg core seem to have more significant influence here. Irrespective of this, it was shown that for all rolling temperatures and stress and strain states, the forming capacity of the Al/Ma/Al compound is significantly above the forming limit curve of the Mg core material. In some cases, the formability nearly reaches the forming limit curve of the Al cover material.

5. Conclusions and Outlook

Altogether, it can be concluded that it was possible to provide a compound material with outstanding lightweight properties and very good formability for the direct substitution of monolithic steel and Al sheets. Suitable process parameters to produce such compounds were identified and implemented. Furthermore, different characterization methods were compared, and the significance of the individual results was assessed. It was found that peel tests are suitable for evaluating the homogeneity of the bond quality, but they cannot predict the influence of the hot roll cladding temperature on the formability in a deep drawing process or a Nakajima test. Especially for deep drawing, lap shear tests are much more suitable to predict this correlation.

The achieved research results have high innovation potential in all industries, where the use of lightweight materials has an increasing influence on product design and construction. Potential user groups of semi-finished products made from thin Al/Mg/Al compound sheets and components manufactured from them include mobility, consumer electronics and the sports and leisure industry. The resulting semi-finished product exhibits good surface quality and high interlaminar adhesion. With the aid of Nakajima and deepdrawing tests, it was demonstrated that the forming capacity of Mg can be significantly increased by applying an Al layer on both sides. At the same time, it can be expected that the strong adhesion tendency during forming will be reduced by the top layers to a value typical for Al. In addition, the Al layers can reduce the oxidation of the material and thus improve the strong corrosion tendency of Mg. However, further investigations are still necessary to validate these assumptions.

Author Contributions

Conceptualization, M.L., V.P. and M.S.; methodology, M.L., V.P. and M.S.; validation, M.L. and N.K.; formal analysis, M.L. and V.P.; investigation, M.L., N.K. and M.S.; resources, M.D. and U.P.; data curation, M.L., N.K., M.S. and F.K.; writing—original draft preparation, M.L. and V.P.; writing—review and editing, M.L., V.P., V.K., M.S. and U.P.; visualization, M.L., V.P. and F.K.; supervision, V.K., M.D. and U.P.; project administration, M.L. and M.S.; funding acquisition, N.K. and M.S. All authors have read and agreed to the published version of the manuscript.

Funding

The IGF project “Production and further processing of thin Al/Mg/Al compound sheets” of the research association EFB e.V., member of the Industrial Research Associations AiF, was funded under Grant Number 19762 BR by the German Federal Ministry for Economic Affairs and Energy based on a resolution of the German Bundestag.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Kleiner, M.; Geiger, M.; Klaus, A. Manufacturing of Lightweight Components by Metal Forming. CIRP Ann. 2003, 52, 521–542. [Google Scholar] [CrossRef]

- Psyk, V.; Beerwald, C.; Klaus, A.; Kleiner, M. Characterisation of extruded magnesium profiles for electromagnetic joining. J. Mater. Process. Technol. 2006, 177, 266–269. [Google Scholar] [CrossRef]

- Bae, J.H.; Prasada Rao, A.K.; Kim, K.H.; Kim, N.J. Cladding of Mg alloy with Al by twin-roll casting. Scr. Mater. 2011, 64, 836–839. [Google Scholar] [CrossRef]

- Cheepu, M.; Haribabu, S.; Ramachandraiah, T.; Srinivas, B.; Venkateswarulu, D.; Karna, S.; Alapati, S.; Che, W.S. Fabrication and Analysis of Accumulative Roll Bonding Process between Magnesium and Aluminum Multi-Layers. Appl. Mech. Mater. 2018, 877, 183–189. [Google Scholar] [CrossRef]

- Mori, T.; Kurimoto, S. Press-formability of stainless steel and aluminum clad sheet. J. Mater. Processing Technol. 1996, 56, 242–253. [Google Scholar] [CrossRef]

- Saha, M.K.; Das, S. A Review on Different Cladding Techniques Employed to Resist Corrosion. J. Assoc. Eng. 2016, 86, 1. [Google Scholar] [CrossRef]

- Cave, J.A.; Wiliams, J.D. The Mechanism of Cold Pressure Welding by Rolling. J. Inst. Met. 1973, 101, 203–207. [Google Scholar]

- El Mehtedi, M.; Lai, D.; Almehtedi, R.; Carta, M.; Buonadonna, P.; Aymerich, F. Bonding of similar AA3105 aluminum alloy by Accumulative Roll Bonding process. In Proceedings of the 24th International Conference on Material Forming, digital event, 14–16 April 2021. [Google Scholar]

- Jamaati, R.; Toroghinejad, M.R. Investigation of the parameters of the cold roll bonding (CRB) process. Mater. Sci. Eng. A 2010, 527, 2320–2326. [Google Scholar] [CrossRef]

- Schmidtchen, M.; Kawalla, R. Multiscale Modeling of Rolling Processes and Bond Strength Development for Layered Materials. St. Res. Int. 2010, 81, 230–233. [Google Scholar]

- Saleh, H.; Schmidtchen, M.; Kawalla, R. Hot Roll Bonding of Aluminum to Twin–Roll Cast (TRC) Magnesium and Its Subsequent Deformation Behavior. J. Mater. Eng. Perform. 2018, 27, 5069–5078. [Google Scholar] [CrossRef]

- Jamaati, R.; Toroghinejad, M.R. Cold roll bonding bond strengths: Review. Mater. Sci. Technol. 2013, 27, 1101–1108. [Google Scholar] [CrossRef]

- Schmidtchen, M. Walzplattieren von Flächigen Mehrlagenverbunden–Experiment und Theorie; Technologie der Werk-Stoffverbundherstellung Durch Umformen: Freiberg, Germany, 2004; pp. 81–110. [Google Scholar]

- Schmidtchen, M. Multi–Scale Modelling of Roll Cladding and Rolling of Metal Composites; Freiberger Forschungshefte B Werkstoffwissenschaften B 372; Habilitation Thesis TU Bergakademie Freiberg: Freiberg, Germany, 2017; ISBN 978-3-86012-566-3. [Google Scholar]

- Zhang, W. Bond Formation in Cold Welding of Metals. Ph.D. Thesis, Technical University of Denmark, Lyngby, Denmark, 1994. [Google Scholar]

- Zhang, W.; Bay, N. A numerical model for cold welding of metals. CIRP Ann. Manuf. Technol. 1996, 45, 215–220. [Google Scholar] [CrossRef]

- Zhang, W.; Bay, N. Cold welding–theoretical modeling of the weld formation. Weld. J. Incl. Weld. Res. Suppl. 1997, 76, 417–430. [Google Scholar]

- Reichelt, S.; Saleh, H.; Schmidtchen, M.; Kawalla, R. On the Bonding Strength of Mg-Mg and Mg-Al Material Compounds. Mat. Sci. For. 2014, 783–786, 455–460. [Google Scholar]

| Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).