1. Introduction

Due to incremental global electric power demand and modern international climatic stipulations, renewable energy resources such as ocean thermal energy conversion cycles (OTEC) are gaining high interest [

1]. OTEC cycles exploit the temperature gradient of the top and bottom layers of sea water for power generation. Since temperature gradients of the top and bottom layers of tropical oceans usually range from 22 °C to 26 °C [

2], the highest theoretical efficiency achievable from a Carnot cycle working on these temperature gradients is approximately 5–6%.

Recently, some thermodynamic investigations on OTEC systems were conducted using an organic Rankine cycle. J.I. Yoon et al introduced a highly efficient OTEC system equipped with a motive pump and liquid-vapor ejector using R152a as a working fluid. A comparative performance analysis is performed between the modified OTEC and basic OTEC systems. Results shows that the modified OTEC cycle produced higher power output than the basic OTEC cycle. Furthermore, the modified OTEC system at optimized operating conditions yields 38% gain in cycle efficiency as compared to the basic OTEC system [

3]. For improved efficiency and performance, an organic Rankine cycle (ORC) for OTEC system working with R717 was also investigated in [

1,

4]. Bernardoni et al. [

1] numerically evaluated an OTEC system for power generation using R717 working fluid. The system efficiency of OTEC was 2.2% at warm sea water temperature of 28 °C and cold sea water temperature of 4 °C. Nevertheless, a small temperature gradient between surface (warm) and cold sea water results in a limited amount of power production from the OTEC system. Therefore, in addition to modifying cycle configuration, which possibly leads to larger investment costs, another useful approach is to utilize new organic fluids or a mixture of organic fluids with good environmental properties as working fluids in a basic OTEC cycle with the aim to enhance turbine power, first law and second law efficiency.

In this study, thermodynamic performance of OTEC systems operating with R152a and R1234yf working fluids are analyzed for Arabian Sea environmental conditions. The aim is to study the effect of properties of two different working fluids on the thermodynamic performance of an OTEC system. Sensitivity analysis is performed at varying condenser saturation temperatures and evaporator saturation temperatures for both working fluids. Performance indicators considered for this parametric study are, thermal efficiency, exergy efficiency, turbine work and overall heat transfer coefficient time area (UA) of the evaporator and condenser. Performances of both OTEC cycles are compared at optimum points and the best performing working fluid is suggested for power generation.

2. Thermodynamic Model and Calculation Method

This study explored the energetic and exergetic performance of closed loop organic Rankine cycles powered by R152a and R1234yf working fluids for an OTEC system. These pure working fluids are selected on the basis of high vaporization capacity and favorable environmental attributes (

Table 1). The Peng-Robinson equation (PR-EOS) of state is used in this parametric study to compute thermo-physical properties of both working fluids. In this study, all thermal calculations by employing PR-EOS are carried out in Aspen Plus V10 simulation tool.

As a preliminary study, design point analysis is carried out using average temperature and pressure data from the Arabian sea [

5] as the heat source and heat sink data (reported in

Table 1). The closed loop simple cycle configuration of the ORC is considered for power production, which is presented in

Figure 1a.

A thermodynamic model and simulation of an organic Rankine cycle are performed in Aspen Plus V10 process simulation software. For sensitivity analysis, the saturation temperature of an evaporator is varied between 17–24 °C and condensation temperature in a condenser is varied within 12–16 °C. Performance parameters studied are: pump work, turbine work, heat exchangers duties, UA, enthalpy and entropy generations in each cycle component, 1st law and second law thermodynamic cycle efficiency of the cycle. At last, an optimum performance point is decided for both OTEC cycles based on maximum exergy efficiency and turbine work and minimum UA values. A T-s diagram of R152a OTEC cycle at optimum performance point is presented in

Figure 1b. The value of UA is calculated for both heat exchangers (evaporator and condenser) based on the LMTD and net heat duties.

3. Results and Discussion

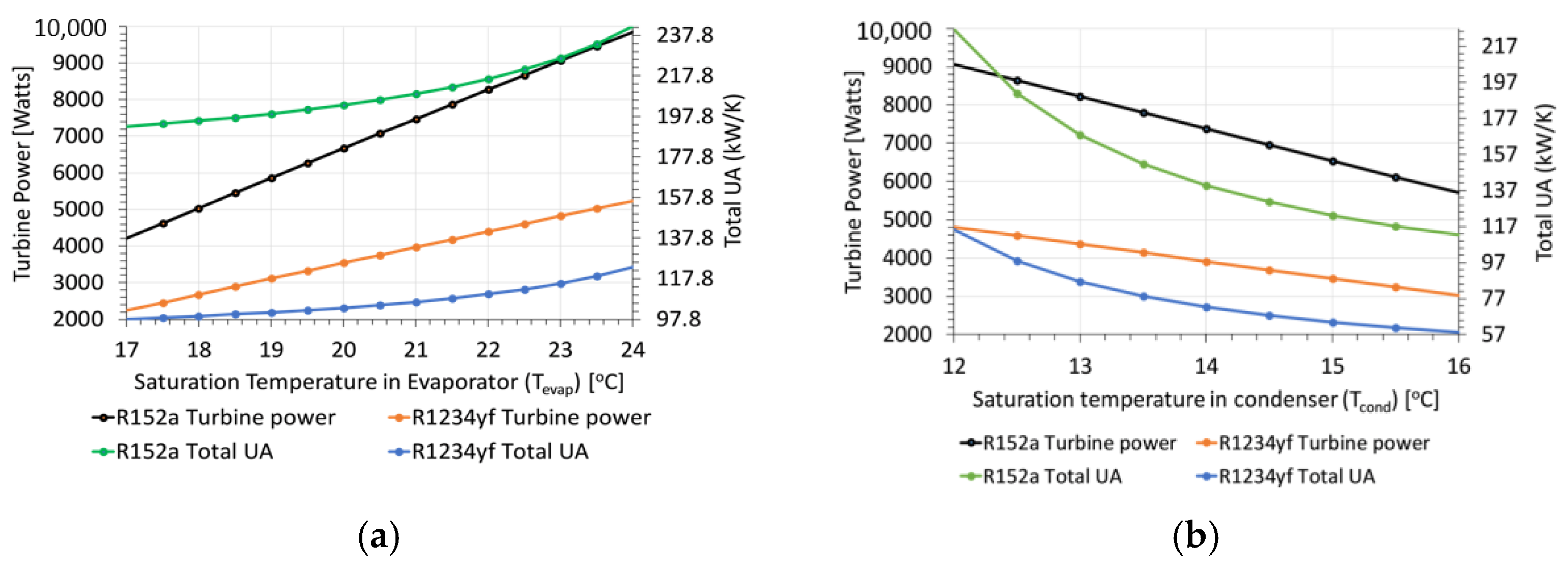

The variation of turbine power and total UA (UA

evaporator + UA

condenser) with respect to variation in evaporator saturation temperature (

Tevap) and condenser saturation temperature (

Tcond) is demonstrated in

Figure 2a,b, respectively. The increase in saturation temperature in the evaporator increases turbine inlet temperature and also turbine inlet pressure, which results in larger expansion in the turbine and larger turbine power. Similarly, by keeping the saturation temperature of the evaporator constant at 23 °C, the rise in condenser saturation temperature or the turbine outlet temperature leads to reduction in temperature ratio (T

3/T

4) across the turbine and reduction in turbine outlet pressure, and, consequently, a reduction in power output is observed, as evident from

Figure 2b.

In summary, higher evaporator saturation temperature (Tevap) and lower condenser saturation temperature (Tcond) results in larger power output from the turbine. Moreover, a turbine operating with R152a working fluid produced more power output compared to R1234yf working fluid at all values of evaporator saturation temperature and condenser saturation temperature. For a Tevap of 23 °C and Tcond of 12 °C, power output from R152a is 9063 W and for R1234yf, it is 4818 W. Total UA in the case of R1234yf working fluid is lower than in the case of R152a working fluid, owing to lower heat duty of the evaporator and condenser for R1234yf. For a fixed value of Tevap, the rise in Tcond brings about an increase in MITA and LMTD of the condenser, which reduces total UA.

4. Conclusions

The study explores the thermodynamic performance of organic Rankine cycles operating with R152a and R1234yf working fluid for ocean thermal energy conversion. For both working fluids, the power output increases with a rise in evaporator temperature and a reduction in condenser temperature. Secondly, the power output in the case of R152a working fluid is higher than R1234yf working fluid but the value of total UA (indicator for size of condenser and evaporator) is comparatively higher in the case of R152a working fluid. The maximum first law efficiency and second law efficiency obtained for R152a working fluid are 2.8% and 47.9%, respectively.

Author Contributions

Conceptualization, M.H. and A.A.; methodology, A.A.; software, M.H.; validation, M.A. and A.-B.S.; formal analysis, M.H.; investigation, M.H.; resources, A.A.; data curation, M.A. and A.-B.S.; writing—original draft preparation, M.H.; writing—review and editing, M.H. and A.A.; supervision, N.A.S. and A.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Bernardoni, C.; Binotti, M.; Giostri, A. Techno-Economic Analysis of Closed OTEC Cycles for Power Generation. Renew. Energy 2019, 132, 1018–1033. [Google Scholar] [CrossRef]

- Avery, W.H.; Wu, C. Renewable Energy from the Ocean: A Guide to OTEC, 1st ed.; Oxford University Press: Oxford, UK, 1994; ISBN 978-0195071993. [Google Scholar]

- Yoon, J.I.; Seol, S.H.; Son, C.H.; Jung, S.H.; Kim, Y.B.; Lee, H.S.; Kim, H.J.; Moon, J.H. Analysis of the High-Efficiency EP-OTEC Cycle Using R152a. Renew. Energy 2017, 105, 366–373. [Google Scholar] [CrossRef]

- Yang, M.H.; Yeh, R.H. Investigation of the Potential of R717 Blends as Working Fluids in the Organic Rankine Cycle (ORC) for Ocean Thermal Energy Conversion (OTEC). Energy 2022, 245, 123317. [Google Scholar] [CrossRef]

- Niazi, B.; Amjad, S. Harnessing Ocean Energy from Coastal and Offshore Pakistan. Engineering 2022, 12, 78. [Google Scholar] [CrossRef]

| Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).