Abstract

This paper presents the combined effect of polypropylene fibres (PPF), silica fume (SF), and fly ash (FA) on the characteristics of normal strength self-compacting concrete (NSSCC). NSSCC is proposed to be prepared by several combinations of PPF and class C FA as partial replacement of cement. NSSCC was prepared by incorporation of SF at 10% and PPF at 0.5%, 1%, and 1.5% by mass of Portland cement. Cohesion and adhesion properties of concrete become much better, along with increased tightness and excellent deformability due to the binding strength of PPF. These fibres inhibit the formation of pores in the concrete matrix and prevent the crack formation and its spread along with the matrix. The chloride migration coefficient was determined in accordance with NT Build 492. Mass diffusivity of chloride ions reduces with increasing concentrations of fly ash in concrete. Results indicate that fibre-reinforced concrete has the improved durability compared to other methods.

1. Introduction

In recent years, self-compacting concrete (SCC) became the most innovative concrete and a part of discussion. The difference between the SCC and ordinary concrete is just because of the mixing proportions of materials and superplasticizer. SCC is known as the innovative concrete of the era and having the property of self-settlement in a construction area without any vibratory force. In other words, no exterior force (Vibrating force) is required for placement or settlement of SCC. SCC settles under its own weight by making its path like a fluid. Self-compacting concrete (SCC) is in great demand because it has proven much more cost-effective, resilient, and is recognized as a concrete with extraordinary performance [1]. SCC has many advantages which set it apart from other types of concrete. Due to its excellent deformability, it slowly fills the whole framework. It passes through reinforcements easily with a homogeneous distribution of aggregate particles in all directions [2]. One of the most significant disadvantages of SCC is its brittle nature when put under tensile pressure. However, random distribution of discrete fibres inhibits or regulates fracture development, which might optimize concrete’s structural and durability characteristics [3]. Fibres incorporated into the concrete matrix increase several physical qualities such as increased durability [4].

Concrete durability is mostly affected by chloride attacks. Almost 40% of the structural failures in concrete are caused due to chloride attacks [5]. Corrosion takes place in the presence of atmospheric oxygen and moisture. Such is the example of a chloride attack that drastically reduces the structural strength of an infrastructure. Hydrochloric acid is produced due to the reaction between chloride ions and steel and other cementitious materials. This acid produced further reacts with the surrounding steel reinforcements, which eventually causes the concrete to develop cracks and collapse the whole infrastructure [6]. Components of the concrete mixture and environment are the two major sources of chloride ions [7]. Components of concrete mixture include sand, water, and additives (aggregates or other cementitious materials). At the same time, the environment includes the use of marine water, i.e., salt spraying, direct wetting, etc., or when concrete contact chloride-rich soils. De-icing salts and chemical use also cause it. Chloride ions enter the concrete by a diffusion process [8]. To measure chloride diffusivity by chloride migration process a scale is used to show resistance of concrete from Low to Extremely high, which is shown in Table 1.

Table 1.

Scale for classifying different sorts of concrete mixtures based on chloride migration for 28 days [8].

2. Research Methodology

2.1. Materials

2.1.1. Coarse Aggregate

Coarse aggregate is important material in construction because this material provide strength. Aggregate is a wide range material because of its availability in different sizes. This is crushed part of stones and mostly obtain from mines. Aggregate used during this aggregate is less than 19 mm and which meets the requirement of ASTM C33M having following properties given in Table 2.

Table 2.

Properties of coarse and fine aggregate.

2.1.2. Fine Aggregate

Fine aggregate means sand is an essential for concreting and is used as a filling material in SCC mixes. This material used during experiment having size less than 4.75 mm. This material named as filler material just to fill the voids performed during concreting. Fine aggregates which meet the requirements of ASTMC33 were used in this research and having some properties mention in Table 2.

2.1.3. Binder

Cement is an essential and very important binding material. In this research, both cement and silica fume are used as binding materials. Cement is widely used binding material in whole world during construction. In this experimental procedure cement named as “Lucky” which is OPC with registration code ISO 9001:2000 and this meets our requirement of ASTM C150 having properties mention in Table 3.

Table 3.

Binder properties.

2.1.4. PPF

Polypropylene fibres are produced from the monomer C3H6. These are chemical resistant fibres. The white colour 12 mm diameter polypropylene fibres were used in the research for the experimental program.

2.1.5. Fly Ash

Fly ash is a material which is heterogeneous and manufactured as a by-product during the process of combustion of coal which is used in power stations. It is a grey coloured fine powder material having glassy particles with spherical shape that rise with the flue gases. It is a fine that is low in lime content.

2.1.6. Water and Super Plasticizer

Tap water is used for this experimental investigation while super plasticizer (SP) indicates a chemical used to enhance the properties of concrete or used as water reducing agent. This type of chemicals is mostly or widely known as admixtures. Admixtures used during construction to attain desired results at minimum cost. During this research high water reducing SP named as Viscocrete-3110 is used to attain high workability or flow ability [9]. Physical properties are mentioned in Table 4.

Table 4.

Super plasticizer properties.

2.2. Mix Proportions

Data of all design mixes are given in Table 5, where design generates based on self-compacting concrete codes by varying PPF in mixes at 0%, 0.5%, 1%, and 1.5%, while amount of silica remains constant in all mixes. Two different proportions of FA are used. Mixes M1, M2, M3, and M4 contain 10 % FA, while M5, M6, M7, and M8 contain 20%.

Table 5.

Mix proportions of concrete mixtures.

2.3. Preparation and Testing of Samples

All concrete samples are 50 mm-high derived from a 100 mm cylindrical specimen. Rubber sleeves were used to fit the sample. Two clamps were used to prevent any leakage of an anolyte solution containing 0.3 M sodium hydroxide (NaOH) to a catholyte solution containing 10% sodium chloride (NaCl). Specimens are subjected to anolyte solution within the sleeves and placed on plastic support in the catholyte reservoir. The initial current of 30 V was applied from an external electric source. Then, the voltage and duration of the test were calculated based on the initial reading of the current. The calculated voltage is then applied to drive the chloride ions into the specimen from the salt solution. Ultimately all specimens were cut “across its circular cross section”, and a 0.1 molar silver nitrate (AgNO3) solution was applied onto “the split surface” to record the infiltration of AgNO3 precipitates. Although the mix proportions of concrete mixes are listed in Table 2.

NT Build 492 test from Nord Test Family of test methods was performed to determine the resistance of various concrete samples against diffusion of chloride ions. The primary objective of this test is to force the chloride ions to diffuse into the concrete samples by applying an electrical potential externally

3. Results and Discussion

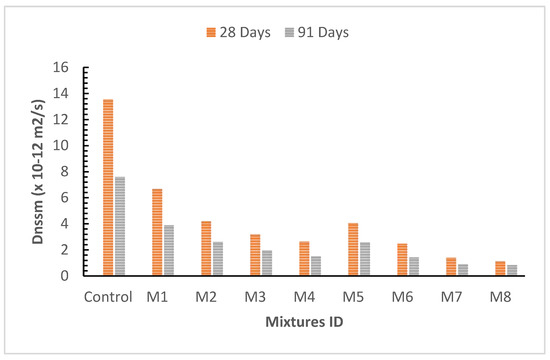

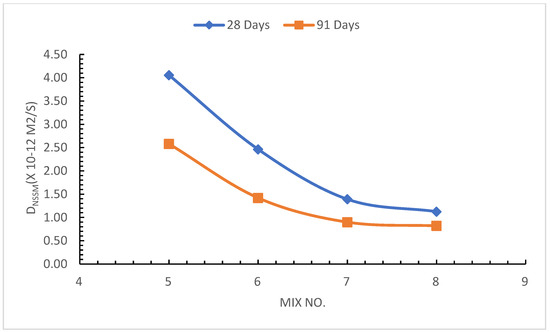

In the long run, one of the most critical properties that affect the performance of concrete is its permeability. Concrete permeability is influenced by microstructural features, such as shape, volume, density, and connectivity of pores and small cracks. The chloride diffusivity classification of all mixes are presented in Table 6 and demonstrated graphically in Figure 1 and Figure 2. These are classified based on resistance towards chloride migration coefficient of concretes.

Table 6.

Results of chloride migration coefficient and classification.

Figure 1.

Chloride migration coefficient (Dnssm) of all mixes at 28, 90 days curing period.

Figure 2.

Comparison of Dnssm of 0.1 SF 0.2 FA mixes (M5-M8) at 28, 90 days curing period.

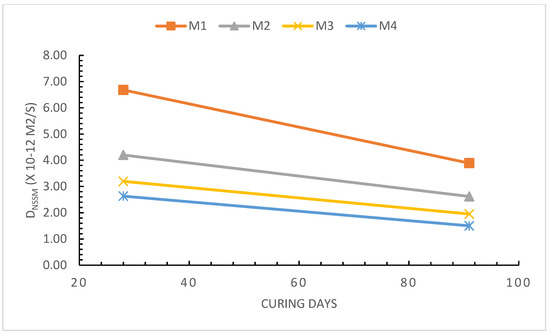

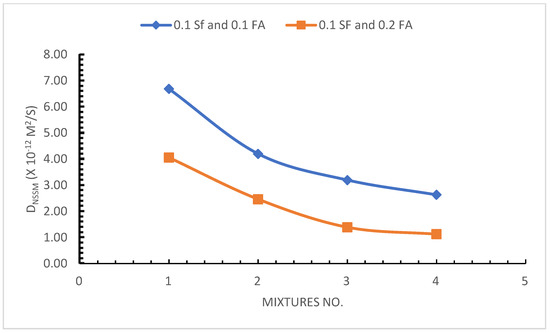

SF greatly decreases the chloride diffusivity into concrete. By mixing SF at a rate of 10% into cement weight, migration of chloride ions was reduced by 70% in contrast to the control group. This is because SF formed C-S-H gel compacts the microspores’ size and makes a transition zone that significantly decreases chloride diffusivity into concrete. FA also decreases chloride diffusivity by enhancing the binding strengths and causing compactness, which also improves concrete durability. FA concentration in concrete and chloride migration are indirectly related to each other, as it can be seen in Figure 3 and Figure 4.

Figure 3.

Comparison of Dnssm of 0.1 SF 0.1 FA (M1–M4) at 28, 90 curing period.

Figure 4.

Comparison of Dnssm of 0.1 SF 0.1 FA and 0.1 SF 0.2 FA composition mixes M1–M4.

4. Conclusions

This research investigated the value of chloride migration coefficient in concrete mixtures with silica fumes (SF) and PPF. Conclusions based on the experiments are listed below.

- ▪

- SF and PPF both reduce workability and make tasks more difficult than the usage of plain concrete. Superplasticizers used in high concentrations helps in this case.

- ▪

- SF enhance the structural characteristics of concrete mixtures.

- ▪

- By mixing SF at a rate of 10% into cement weight, migration of chloride ions was reduced by 70% in contrast to the control group.

- ▪

- The use of PPF increase the compactness of concrete and reduces the size of micropores which helps in decreasing chloride ion migration.

- ▪

- Research indicates that chloride diffusivity can be significantly reduced if a mixture of SF and FA at the same concentration and same concentration of PPF is used in concrete mixtures.

Author Contributions

M.H.: Conceptualization, methodology, writing—original draft preparation A.E.: validation, writing—review and editing, supervision M.A.: formal analysis, investigation, visualization. All authors have read and agreed to the published version of the manuscript

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable

Informed Consent Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Yehia, S.; Douba, A.E.; Abdullahi, O.; Farrag, S. Mechanical and durability evaluation of fiber-reinforced self-compacting concrete. Constr. Build. Mater. 2016, 121, 120–133. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, L.; Cao, K.; Sun, L. Review on the Durability of Polypropylene Fibre-Reinforced Concrete. Adv. Civ. Eng. 2021, 2021, 6652077. [Google Scholar] [CrossRef]

- Gencel, O.; Ozel, C.; Brostow, W.; Martínez-Barrera, G. Mechanical properties of self-compacting concrete reinforced with polypropylene fibres. Mater. Res. Innov. 2011, 15, 216–225. [Google Scholar] [CrossRef]

- Rani, B.S.; Priyanka, N. Self Compacting Concrete using Polypropylene Fibers. Int. J. Res. Stud. Sci. Eng. Technol. 2017, 4, 16–19. [Google Scholar]

- Raczkiewicz, W. Use of polypropylene fibres to increase the resistance of reinforcement to chloride corrosion in concretes. Sci. Eng. Compos. Mater. 2021, 28, 555–567. [Google Scholar] [CrossRef]

- Pontes, J.; Bogas, J.A.; Real, S.; Silva, A. The rapid chloride migration test in assessing the chloride penetration resistance of normal and lightweight concrete. Appl. Sci. 2021, 11, 7251. [Google Scholar] [CrossRef]

- Liu, J.; Liu, J.; Huang, Z.; Zhu, J.; Liu, W.; Zhang, W. Effect of fly ash as cement replacement on chloride diffusion, chloride binding capacity, and micro-properties of concrete in a water soaking environment. Appl. Sci. 2020, 10, 6271. [Google Scholar] [CrossRef]

- Afroughsabet, V.; Biolzi, L.; Monteiro, P.J.M. The effect of steel and polypropylene fibers on the chloride diffusivity and drying shrinkage of high-strength concrete. Compos. Part B Eng. 2018, 139, 84–96. [Google Scholar] [CrossRef]

- Sika ® ViscoCrete ®-3110 W Sika ® ViscoCrete Sika ® ViscoCrete ®-3110 W Product Description Sika ® ViscoCrete. [Online]. Available online: www.pak.sika.com (accessed on 20 September 2020).

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).