1. Introduction

The construction of building projects needs different resources in particular quantities at different stages in the construction process. The resources may be cost, materials, machinery, apparatuses, tools, or workmanship. The management of these resources has very sharp effects on both the economy of the project and the timeline. If the management of these resources is not carried out properly, it will leave severe damage to the project in terms of cost, material losses, and time delays.

During scheduling, project managers might plan activities in parallel. A real dilemma occurs when a similar resource is to be used in two or more activities, while its availability is limited. Project managers can settle such confrontations using resource-leveling software packages. Resource leveling is a resource optimization approach that is used to finish a project with available resources without over-reserving them or mushrooming them remotely, while its intent is to divide resources over work fairly [

1].

A research study has been conducted on the use of project management (PM) software [

2]. In addition, a comparative study has been conducted on using various PM software packages. It found that almost all construction industries use PM software, 83% of which use it for planning and control, and that in the construction industry, resource leveling is used by 58% and by 44% for project control. The same studies found that MS project was the well-liked and heavily used PM software in the overall study, whereas Primavera was the top trend in the construction industry. The results of MS project were close to primavera [

3].

Most PM software carries out resource leveling by applying priority-based heuristics. It has two characteristic components: a scheduling scheme and a priority rule. Furthermore, scheduling schemes may be serial or parallel. Serial and parallel scheduling both have a decision set of unscheduled activities, but in the first one, they are precedence-feasible, whereas in parallel, the activities are precedence- and resource-feasible. One activity is then selected on the basis of priority rules that are to be scheduled [

4].

2. Literature Review

The main types of resources in building construction projects are:

Work (human and equipment) resources, material resources, and cost resources.

2.1. Work Resources

Exceptional achievements are directly and immediately related to human resource management. Organizing and training the project team are the main purposes of human resource management [

4]. Up to 50% of the total cost of building construction projects is allocated to labor and other technical staff [

5]. Equipment resource management is of prime importance to construction projects because it ensures the project’s cost and on-time completion. Great care should be taken during the selection of equipment as it has cryptic relations with the availability of space, mobility, versatility, suitability and capability of equipment, type of materials, what distances materials are to be moved, ground grade, and atmospheric conditions [

6].

2.2. Material Resources

Providence of materials at the right time at the right place in a specified quantity to achieve the scheduled level of production at minimum cost is said to be material resource management [

7]. The main dimension of material resource management is to monitor the latest information related to materials and their flow [

8]. It has been reported that at the construction site, the main problem with material resource management is the lack of material tracking [

5] Previous literature recommended computer-based material management [

8].

2.3. Resource Leveling

Technically speaking, resource leveling is a technique that assures resource demand is not exceeding resource availability [

9]. The aim of resource leveling is to attain a uniform level of required resources both at peak demand periods and off-peak times [

5]. It has been stated that labor and equipment resource management are the fundamental parameters of resource leveling [

9].

Resource-constrained and time-constrained are the two main types [

10] In time-constrained leveling, time is critical; that is, deadline delays are not allowed and the project should be completed with limited resources at a certain time. In contrast, resource-constrained leveling considers that the project will be completed in the near future without crossing a certain level of resource availability [

5].

Fast-tracking, crashing, delay-critical path tasks, extend-critical path tasks, non-sequential pieces of tasks, authorized overtime, and Microsoft (MS) project are the techniques used for resource leveling [

5]. Microsoft Project can perform resource leveling by itself, using resource schemes, activity types, activity dependencies, and their constraints input by the user. If there are resource clashes, then MS project has the option to delay, add or remove activities, place resources to different tasks, or revise dependencies [

5].

3. Research Significance

Each year, the construction industry expands. To handle this expansion, it is necessary to conduct more studies and practice. Construction companies strive to conserve resources to lower the project’s overall cost, especially when they are involved in several different projects that share resources. To solve this problem, resource optimization (resource leveling) is necessary. As a result of resource leveling, the contractor should know when and where to use each resource, and this will minimize importing more expensive resources from outside the company. So, this study will briefly show how beneficial MS project is to small construction industries also.

4. Methodology

4.1. Selection of a Residential Flat Building

We have selected a residential (three-story) building with a 5600 square feet cover area for our case study; the details are in

Table 1. Activities are computed in MS project and connected by various dependencies, e.g., finish–start, start–start, start–finish, and finish–finish.

4.2. Plan of Basement, Ground, 1st, and 2nd Floor

Figure 1 shows the layout of the basement in which there are sixteen columns of dimensions 4 ft × 4 ft of the square type. There are two types of girders (type A and B) and a beam. The height of the basement is 10 ft. The number of girders of type A is 12 and type B is 8, and there are 4 beams. The ground floor consists of five flats and

Figure 2 shows the detail of the 1st, 2nd, and ground floors.

5. Results and Discussion

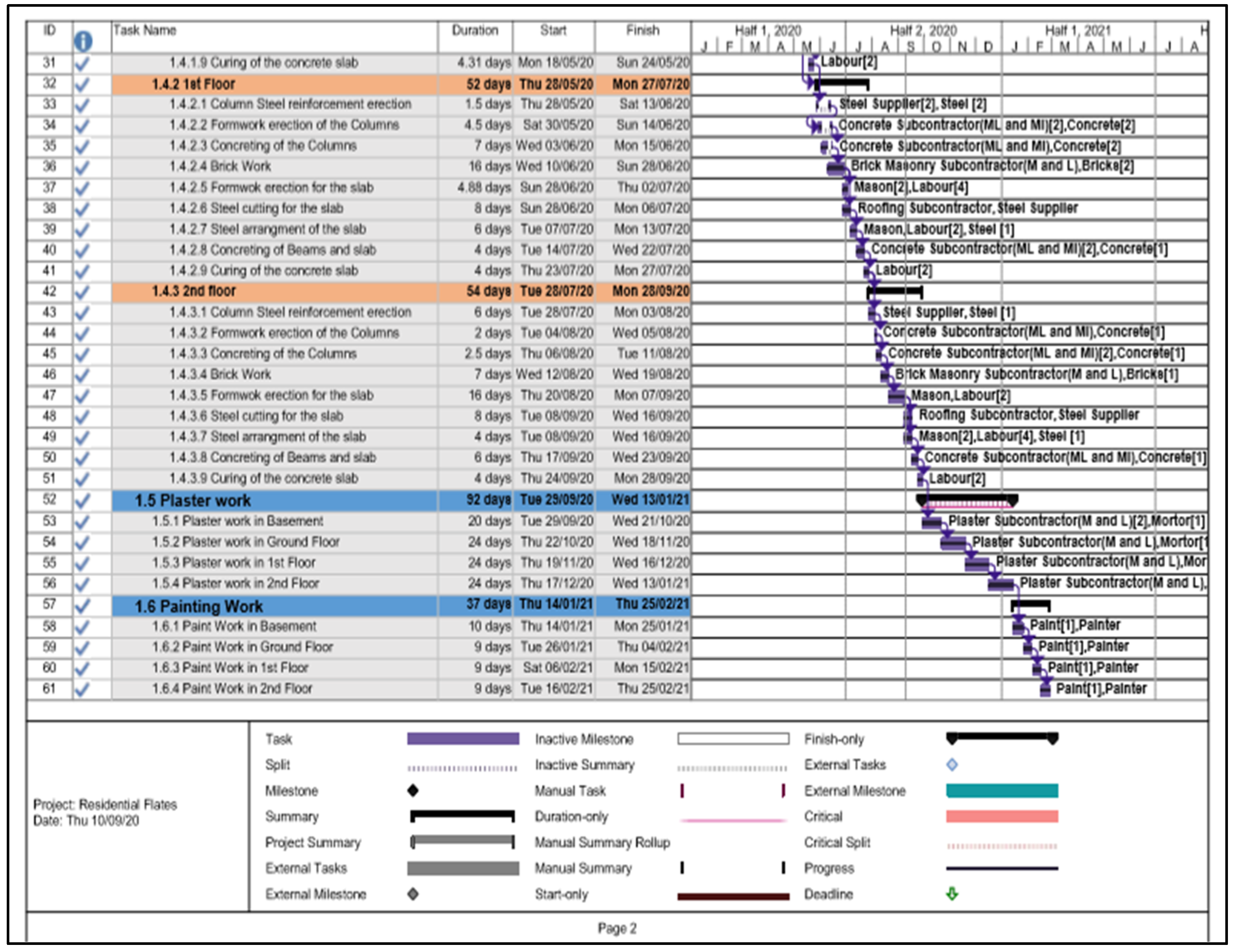

Planning of activities in MS Project: The activities are enlisted in MS Project and the cost of each resource is taken from the Market Rate System of Communication and Work Department.

Figure 3 shows the activities in MS Project.

5.1. Cash Flow of a Project

The cash flow of a project is shown by

Figure 4 which shows the cost of a project before and after the optimization of an activity.

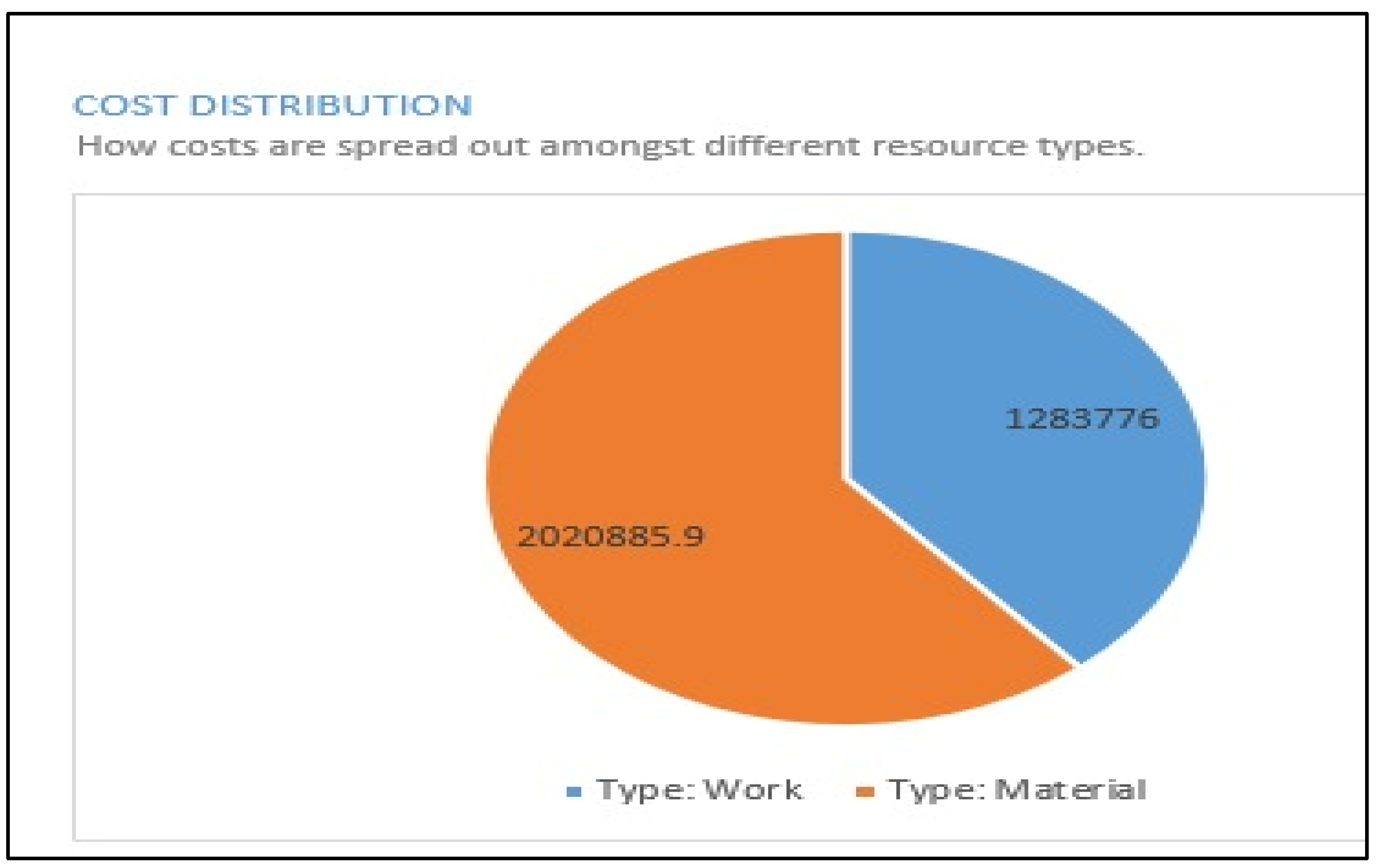

5.2. Resource Cost Overview

(1) Cost overview for work resources: the cost of different types of work resource. (2) Distribution of cost between work and material resources: the cost allocated to each resource as shown in

Figure 5.

5.3. Resource Overview

Figure 6 shows the status of each type of work.

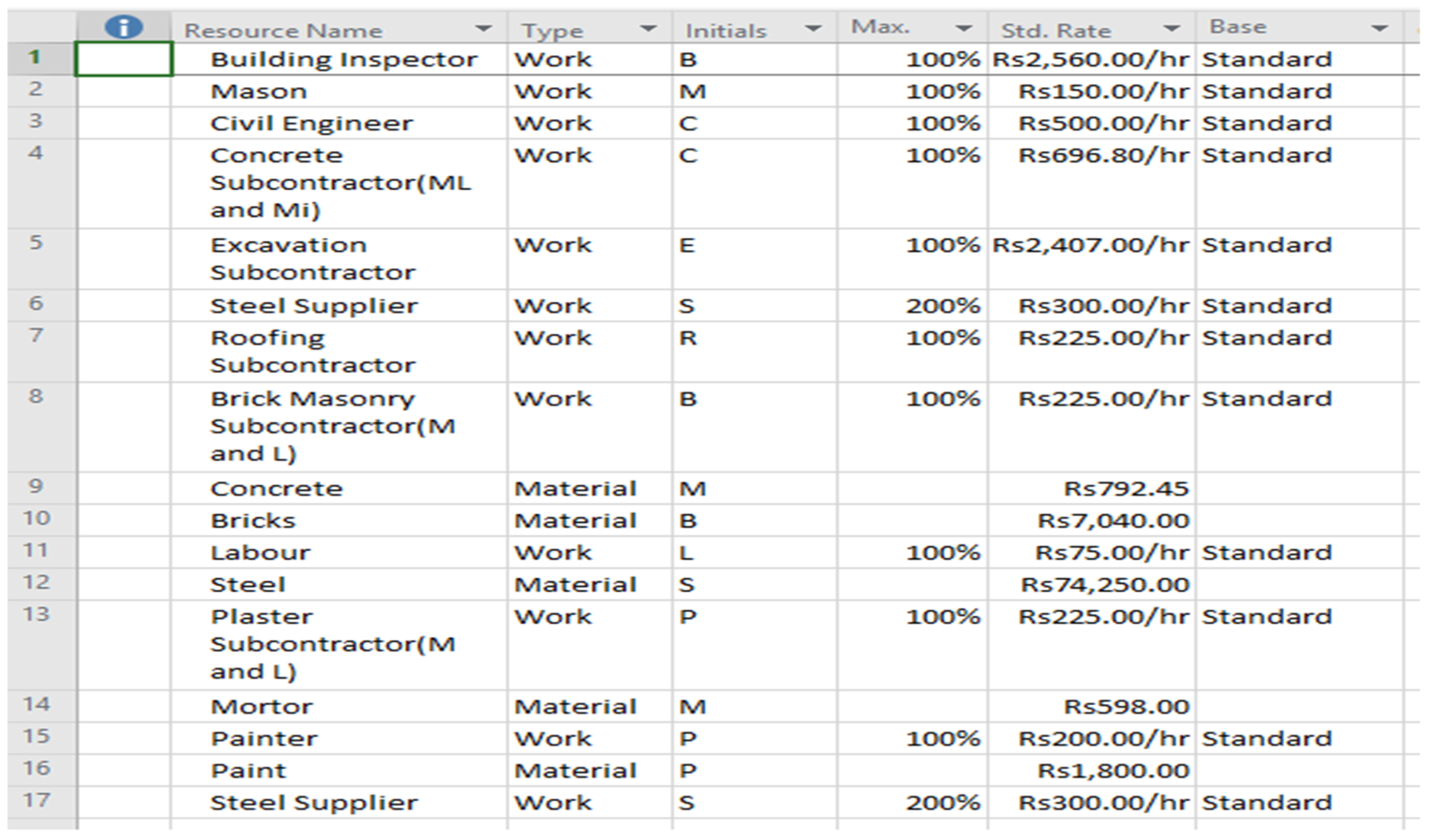

5.4. Resource Sheet Prepared in MS Project

The resource sheet prepared in MS Project with costs assigned to each resource as per the Market Rate System is shown in

Figure 7.

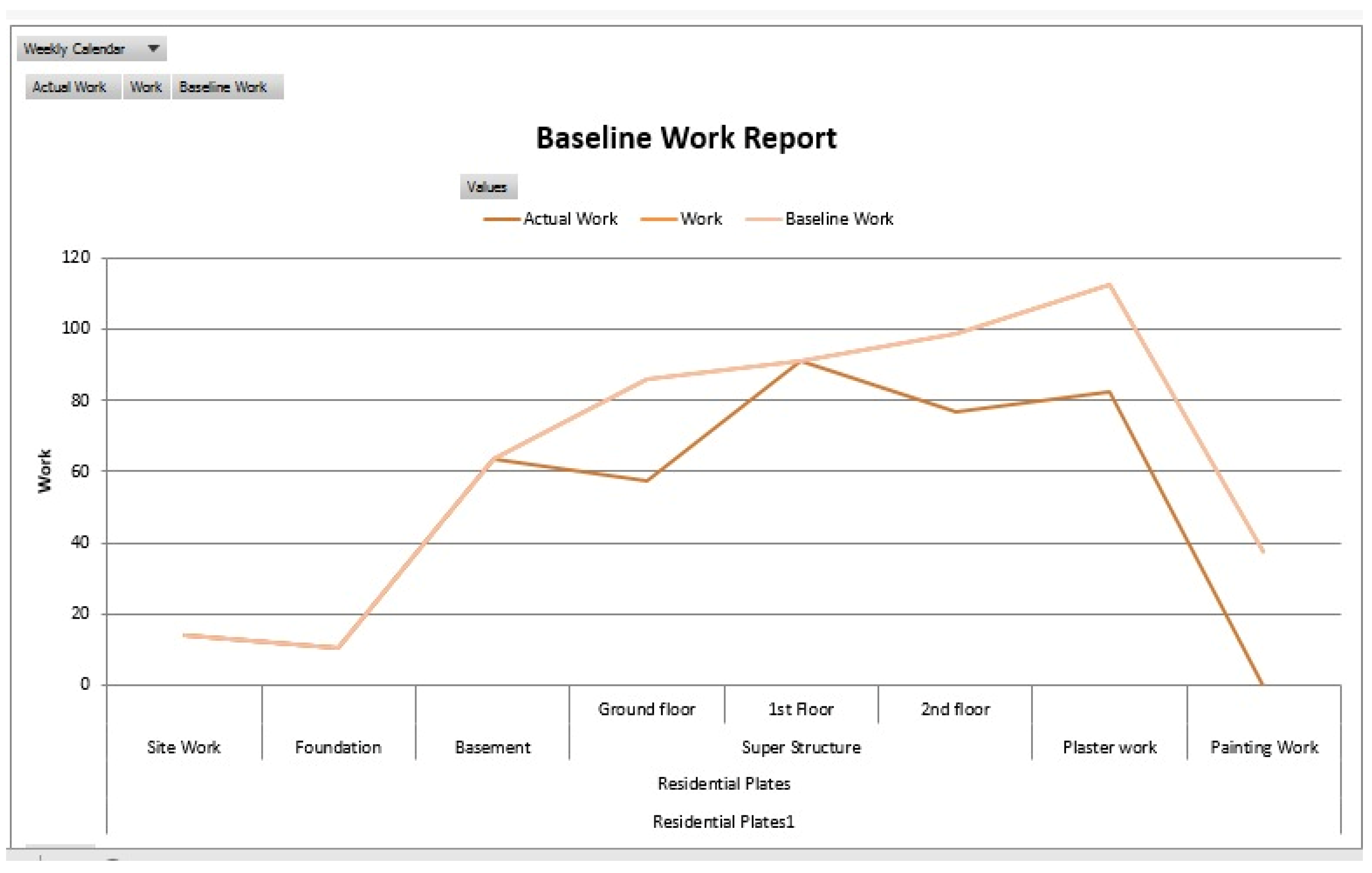

5.5. Graph between Baseline and Actual Work Performed

Figure 8 shows the baseline and actual work.

6. Conclusions

The following conclusions are drawn from the results:

The best option for resource leveling in Microsoft Project is the manual option, not the automatic one, because the software does not know about the real conditions in the field. So, it is good to perform resource leveling manually. In the case of automatic resource leveling, the schedule should be rechecked and revised many times so that it may meet the real conditions.

The duration of activities extends as the resource leveling is carried outs. This is okay because the overallocation of resources may be removed only in this way.

In Microsoft Project, a single resource cannot be allocated to two activities running in parallel. It is recommended to work on and update Microsoft Project.

Resource leveling makes small construction industries very productive even with very limited resources.

MS project is best when you are using it, especially for small construction projects. It is simple and has both the options to level resources automatically or manually.

Author Contributions

Conceptualization, S.H. (Salman Hamad) and M.K.; data collection, S.H. (Saddam Hussain); writing and draft preparation, S.H. (Saddam Hussain) and M.K.; writing overview and editing, L.Z.; formatting, S.M.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Iryna Viter. What is Resource Leveling? A Visual Guide for Project Managers. Available online: https://www.forecast.app/blog/resource-leveling-guide (accessed on 8 February 2021).

- Liberatore, M.J.; Pollack-Johnson, B.; Smith, C.A. Project Management in Construction: Software Use and Research Directions. J. Constr. Eng. Manag. 2001, 127, 101–107. [Google Scholar] [CrossRef]

- Kastor, A.; Sirakoulis, K. The effectiveness of resource levelling tools for Resource Constraint Project Scheduling Problem. Int. J. Proj. Manag. 2009, 27, 493–500. [Google Scholar] [CrossRef]

- Christodoulou, S.E.; Michaelidou-Kamenou, A.; Ellinas, G. Heuristic Methods for Resource Leveling Problems. In Handbook on Project Management and Scheduling; Schwindt, C., Zimmermann, J., Eds.; Springer International Publishing: Berlin/Heidelberg, Germany, 2015; Volume 1, pp. 389–407. [Google Scholar] [CrossRef]

- Simon, S.M. Evaluation of the Resource Leveling Techniques Employed by Contractors in the Kenyan Construction Industry. Int. J. Innov. Technol. Explor. Eng. 2018, 7, 8–12. [Google Scholar]

- Sharma, P.; Chrisman, J.J.; Chua, J.H. Strategic Management of the Family Business: Past Research and Future Challenges. Fam. Bus. Rev. 1997, 10, 1–35. [Google Scholar] [CrossRef]

- Tersine, R.J.; Campbell, J.H. Modern Materials Management; North Holland Publishing Co.: New York, NY, USA, 1977. [Google Scholar]

- Navon, D. Resources—A theoretical soup stone? Psychol. Rev. 1984, 91, 216. [Google Scholar] [CrossRef]

- Khan, M.T.; Paul, D.V.K. Resource Leveling Using Genetic Algorithm. 12. Available online: https://www.researchgate.net/publication/357517234_Resource_Leveling_Using_Genetic_Algorithm (accessed on 13 February 2021).

- Managing Resource Leveling. Available online: https://www.ronwinterconsulting.com/Managing_Resource_Leveling.pdf (accessed on 10 February 2021).

| Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).