Abstract

The properties of self-compacting concrete mainly depend upon the properties of the cement paste phase. Some published literature exists on the use of acacia gums in self-compacting cementitious systems, but no previous work has reported the utilization of AM gum powder as viscosity-modifying agent in self-compacting paste systems (SCPs). This study focuses on the utilization of Acacia Modesta (AM) gum powder as viscosity-enhancing agent in SCPs. AM gum powder with average particle size (D50) of 135 microns is used with variable Acacia Modesta (AM) gum powder dosages in the range of 0.25% to 1% by weight of the cement. Superplasticizer demand, flow and viscosity, apparent viscosity, air content, fresh density, hardened density, and compressive strength tests are performed. The result indicates that super-plasticizer demand, flow and viscosity, apparent viscosity, and air content of SCPs containing AM gum powder increases with the increase in the percentage of the AM gum powder. While, fresh density, hardened density, and compressive strength decrease with the increase in the percentage of the AM gum powder. On the basis of these results, it can be concluded that AM gum powder can be used as viscosity-modifying agent in SCPs by changing the amount of AM gum powder in such systems due to nature and composition of the AM gum powder.

1. Introduction

Self-compacting paste (SCPs) is the basic part of the self-compacting concrete (SCC), which is a highly flow-able, non-segregating concrete that can spread into place, fill the formwork, and encapsulate the reinforcement without any mechanical consolidation. The properties of self-compacting concrete mainly depend upon the properties of the self-compacting paste (SCPs) phase [1,2]. Flow and viscosity are the two major aspects of SCPs and SCC. In order to attain the both, various types of chemical and natural admixtures are used by various researchers. In order to enhance the properties of SCPs (flow and viscosity especially), this study is focused on the possible use of Acacia Modesta (AM) powder in SCPs as viscosity-modifying agent. Some published work exists on use of acacia gum in self-compacting cementitious systems [3,4,5], but no previous work reports the utilization of such organic powders as viscosity-modifying agent.

In the ancient times, acacia gum was used as ink and adhesive agent and is still being used as a medicine in developing countries for many diseases including digestion of lipids, throat and chest-related issues and as anti-oxidant agent [6,7]. In the modern world, it is being used in medicine, textile, food, cosmetics, glue, and printing industries [8] and now finds many useful applications in self-compacting cementitious systems [3,4,5], which can further be exploited in the construction industry.

Different species of acacia gums are available in the world, the types of major functional groups present in these gums are more or less the same but with little variation in their chemical structure and that little variation causes significant response differences in self-compacting cementitious systems [3,4,5]. The chemical composition of various acacia gum powders varies with origin, source, age of the tree, harvesting season, climatic and processing conditions [9].

Self-compacting paste system acts as a vehicle for the transport of the aggregate phase [10] in self-compacting mortar (SCM) and self-compacting concrete (SCC) systems and it affects the overall properties of the SCC system [11,12]. The addition of suitable admixtures to self-compacting paste systems can lead to an improved overall response [5,11,13]. In the past, supplementary cementitious materials were used to modify the viscosity of the SCPs [14], but they have their own drawbacks. On the other hand, botanical Acacia Modesta (AM) gum is a natural organic ooze-out of Acacia Modesta trees, locally known as “Phulai” and its powder is added in self-compacting paste systems (SCPs) during the mixing stage as admixture [15,16,17] and as viscosity-enhancing agent [18]. AM gum powder is a naturally available admixture and helps in producing eco-friendly high-performance SCPs [19].

2. Experimental Program

2.1. Raw Materials

OPC grade 53 [20] and poly-carboxylate ether (PCE)-based powdered super-plasticizer [21] is used. Acacia Modesta gum powder with average particle size of 135 µm is added in self-compacting paste systems.

2.2. Mixing Regime

All components are initially weighed in dry conditions and mixed in a Hobart mixer. Then, 27% water is added and mixed again for 3 min. Table 1 gives the SCPs formulations studied in this study along with the amounts of various powders added in various formulations.

Table 1.

SCPs formulations.

2.3. Testing

The following tests are conducted to investigate the effect of AM gum powder in SCPs as viscosity-modifying agent.

- Superplasticizer demand determination using Hagerman’s mini-cone slump apparatus;

- Viscosity measurement using Hagerman’s mini-slump cone test and rheometric investigation test;

- Fresh tests (air content and fresh density test);

- Hardness tests (hardened density and compressive strength test).

3. Results and Discussion

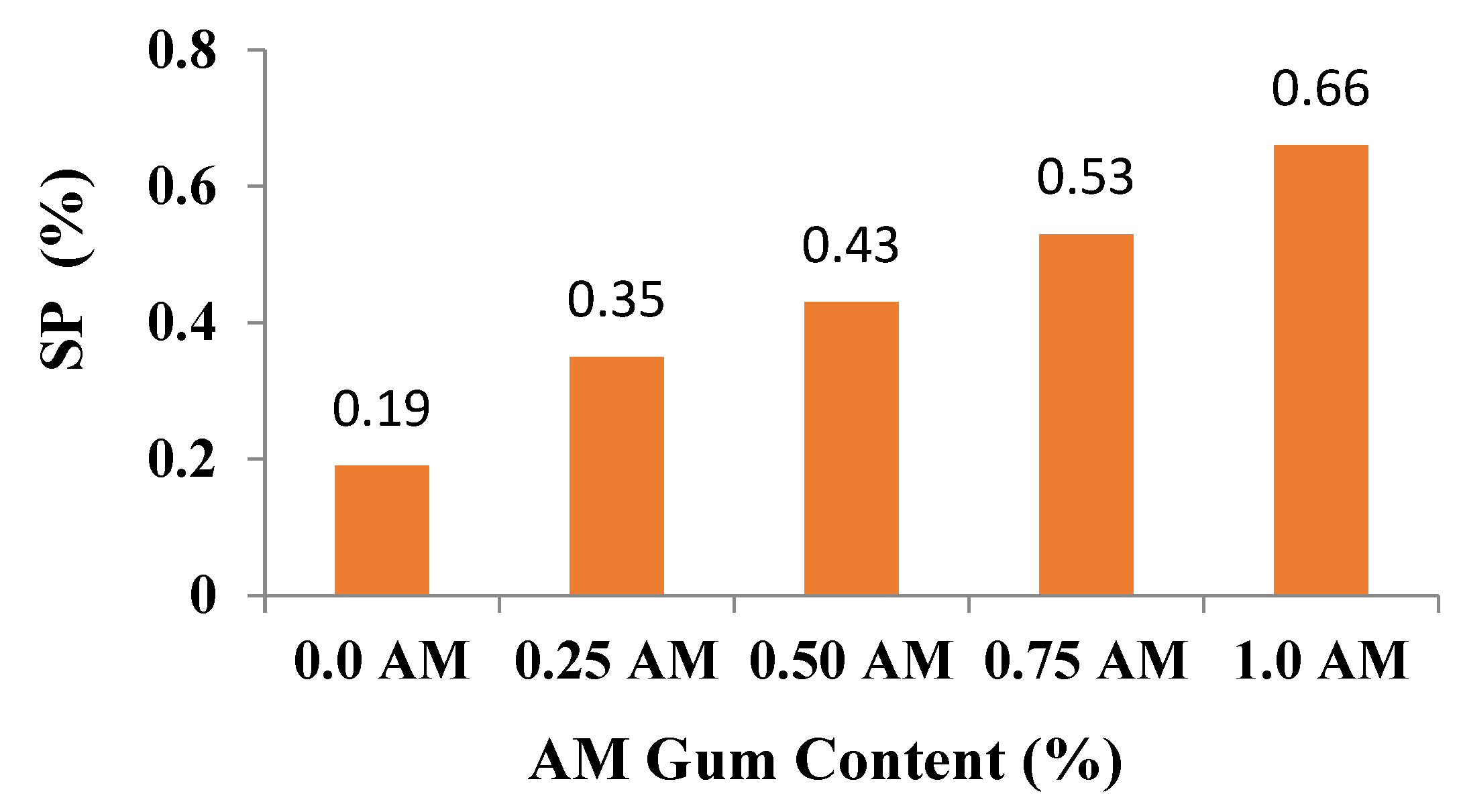

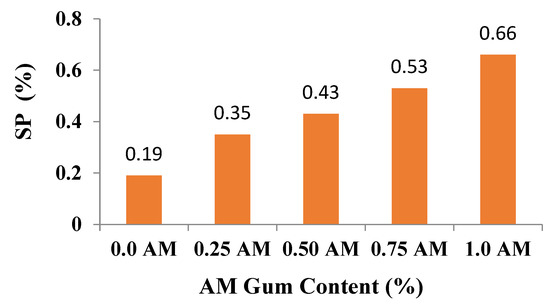

3.1. SP Demand of SCPs Containing AM Gum Powder

The result of the superplasticizer (SP) demand of various SCP formulations containing AM gum powder is shown in Figure 1. From these results, it can be concluded that super-plasticizer demands of the SCPs containing AM gum powder increases with the increase in content of the AM gum due to increased internal friction, irregular and rough external surface. Secondly, it might be increased due to the anionic polysaccharides present in acacia gums [22]. The calcium ions (Ca2+) present in the cement paste or H+ ions present in mixing water may get adsorbed on the polysaccharides through ionic attraction, causing an increased attraction between the cement grains and AM gum powder resulting in an enhanced viscosity. It is an indication that AM gum powder can be used as viscosity-modifying agent in SCPs.

Figure 1.

SP Demands of SCPs.

3.2. Viscosity of SCPs Containing AM Gum Powder

To explore the possible utilization of AM gum powder as viscosity-modifying agent in SCPs, two types of tests are performed and analyzed.

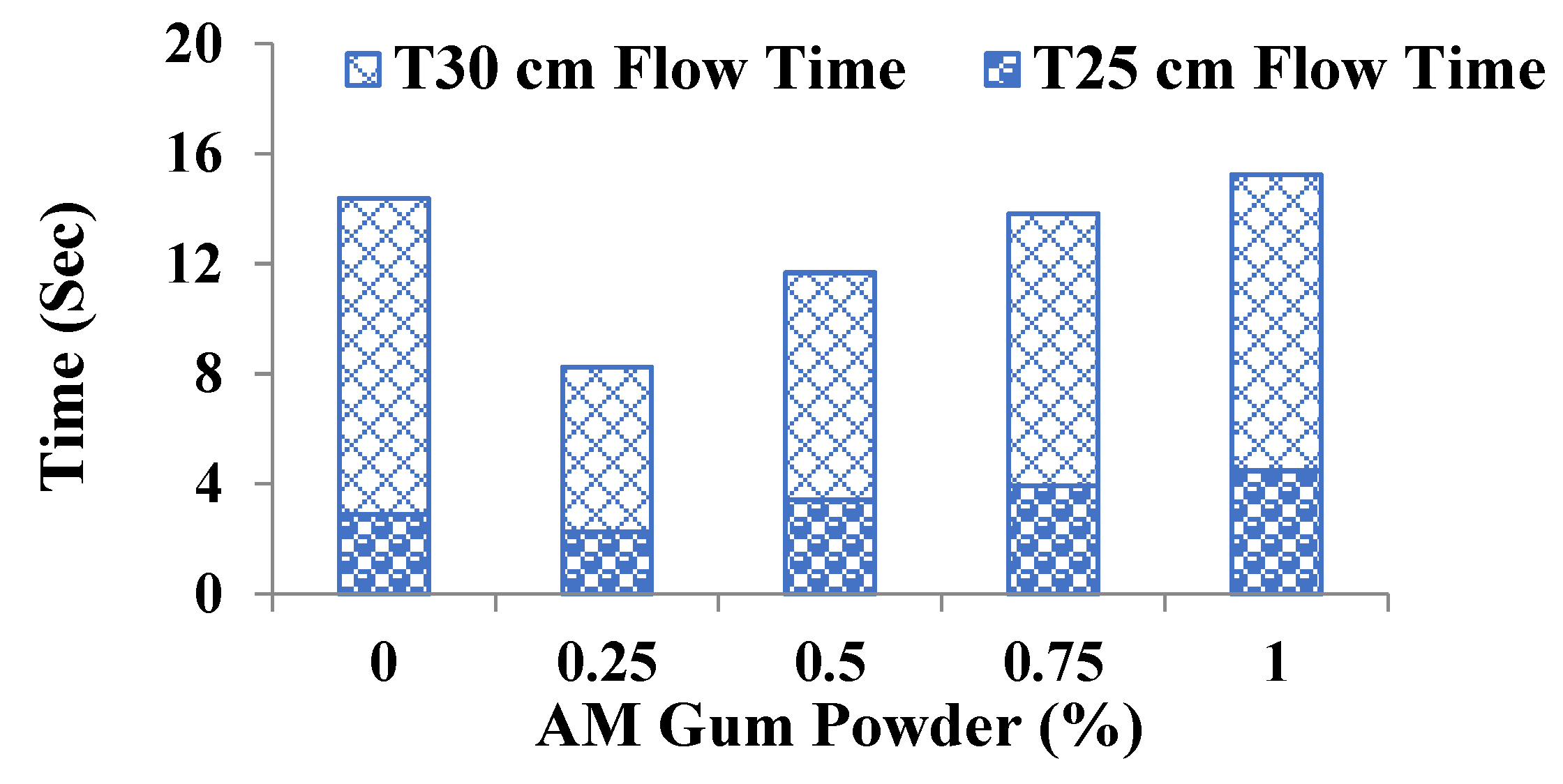

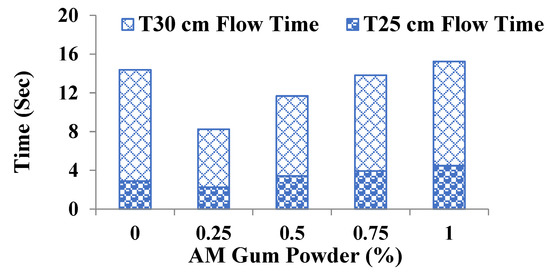

3.2.1. Viscosity Using Hagerman’s Mini-Cone Flow Test

T25 cm flow time, in a Hagerman’s mini-cone flow test, is a measure of viscosity of the system while T30 cm flow time is a function of yield stress of SCP systems. Figure 2 depicts the T25 cm and T30 cm flow times of SCPs containing different dosages of AM gum powder. With the increase in AM gum content, the time required (T25 and T30) to reach the specific flow value (30 ± 1 cm) increased, indicating that the qualitative plastic viscosity and qualitative yield stress of the respective SCP system becomes higher with the incorporation of AM gum in SCP systems. This further strengthens the postulate that acacia gum acts as a viscosity-enhancing agent.

Figure 2.

Viscosity and yield stress of SCPs.

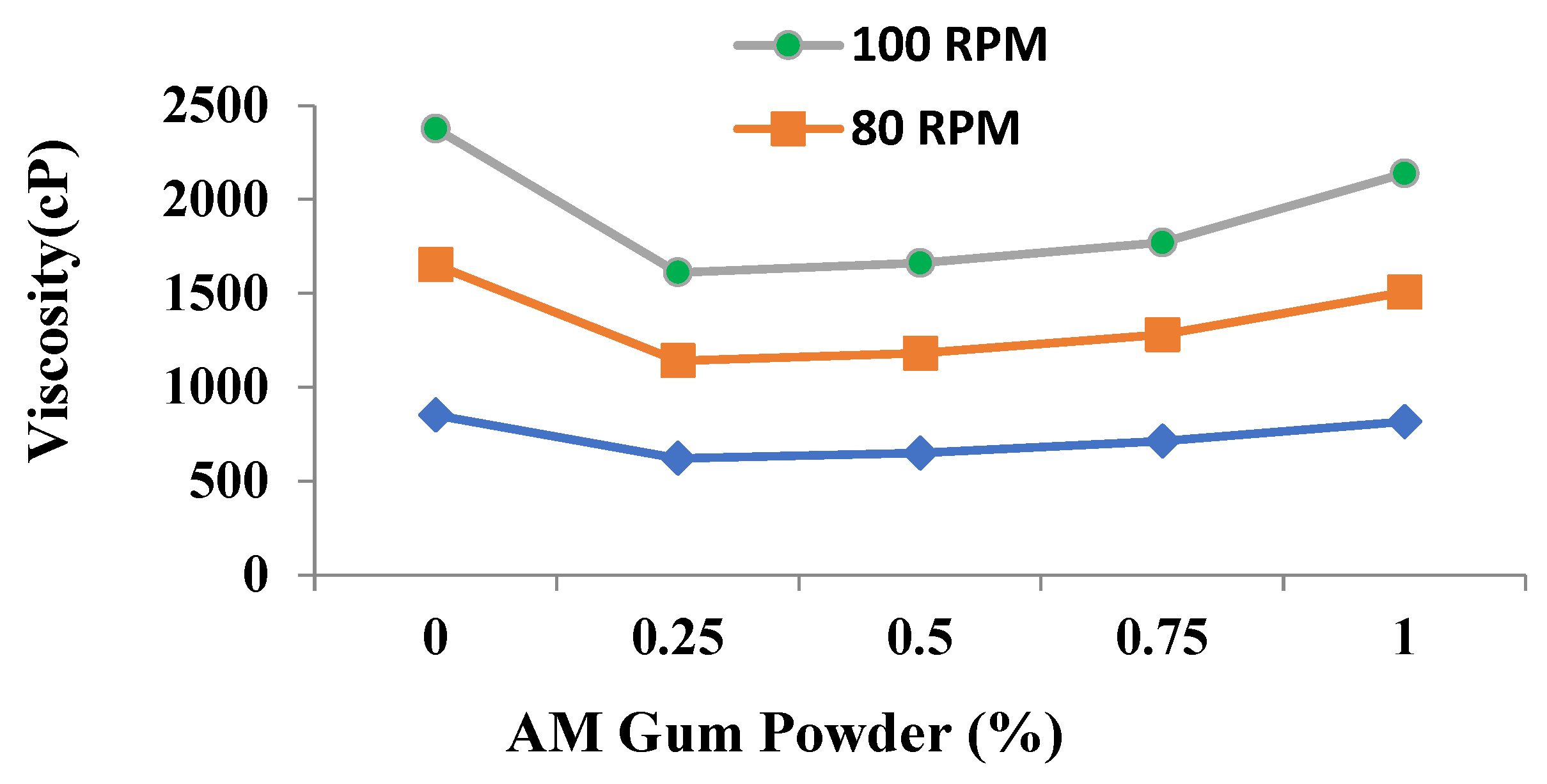

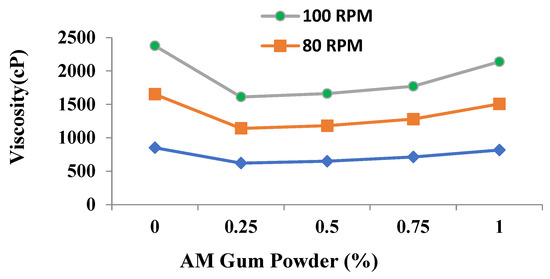

3.2.2. Apparent Viscosity using Rheometer

Apparent viscosity of the SCPs is measured using a rheometer to carry out the rheometric investigations. Viscosities are measured for 2 min at shear rates of 20.4 s−1, 27.2 s−1, and 34 s−1 corresponding to 60 rpm, 80 rpm, and 100 rpm, respectively. The shear rates selected are the same through which concrete passes during the processes of mixing, placing, and casting [23]. From Figure 3, it can be seen that the apparent viscosity of the SCP systems increases with the increase in AM gum content. This could be due to adsorption, association or intertwining [15,24,25]. This property is known as shear thinning and is more prominent for formulations containing higher dosages of AM gum powder. Moreover, the results obtained through rheometric investigation compliment the viscosity and yield stress results obtained indirectly through the mini-cone slump flow test by measuring T25 cm and T30 cm times.

Figure 3.

Apparent viscosities of SCPs.

3.3. Fresh Properties of SCPs Containing AM Gum Powder

To study the effect of utilization of AM gum powder as viscosity-modifying agent in SCPs in the fresh state, two types of tests (air content and fresh density) are performed and analyzed.

3.3.1. Air Content

Air content of SCP formulations is measured in the fresh state. Results shown in Table 2 (column 2) indicate that the air content of the SCP formulations increases with the increase in the amount of AM gum powder. This is mainly due to the nature of the gum as most polysaccharide gums entrain air [26]. These air voids might be entrained during mixing in a Hobart mixer and might be responsible for the reduction in the compressive strength of SCPs containing AM gum powder.

Table 2.

Air content, Fresh and Hardened Densities of SCPs.

3.3.2. Fresh Density

The fresh paste densities measured for various SCPs are shown in Table 2 (column 3). Generally, the fresh density of the SCPs containing AM gum powder decreases with the increase in the amount of the AM gum powder. A maximum fresh paste density of 2.36 g/cm3 is attained with 0.25% AM gum powder while a minimum fresh paste density of 2.23 g/cm3 is noted when 1% AM gum powder is added in SCPs. The entrainment of air content might result in the reduction of densities (both fresh and hardened) with the increase in the AM gum content.

3.4. Hardness Properties of SCPs Containing AM Gum Powder

To study the applicability of addition of AM gum powder as viscosity-modifying agent in SCPs, the properties of SCPs are studied in the hardened state as well. The following two tests (hardened density and compressive strength) are studied in this respect.

3.4.1. Hardened Density

The results of the hardened densities measured before testing prisms for 28 days in compressive strength tests are shown in Table 2 (column 4). Just like fresh densities, hardened densities of the SCPs containing AM gum powder also decrease with the increase in the amount of the AM gum powder. A maximum hardened density of 2.13 g/cm3 is attained with 0.25% AM gum powder while a minimum hardened density of 2.02 g/cm3 is noted when 1% AM gum powder is added in SCPs. This is possibly due to the property that the acacia gums entrain air, which ultimately resulted in the reduction of the hardened densities leading to the reduction in the compressive strengths of SCPs containing AM gum powder. It can be inferred that as the fresh and hardened densities decrease, the corresponding compressive strength values also decrease and maximum strength is attained when the fresh and hardened densities are maximum.

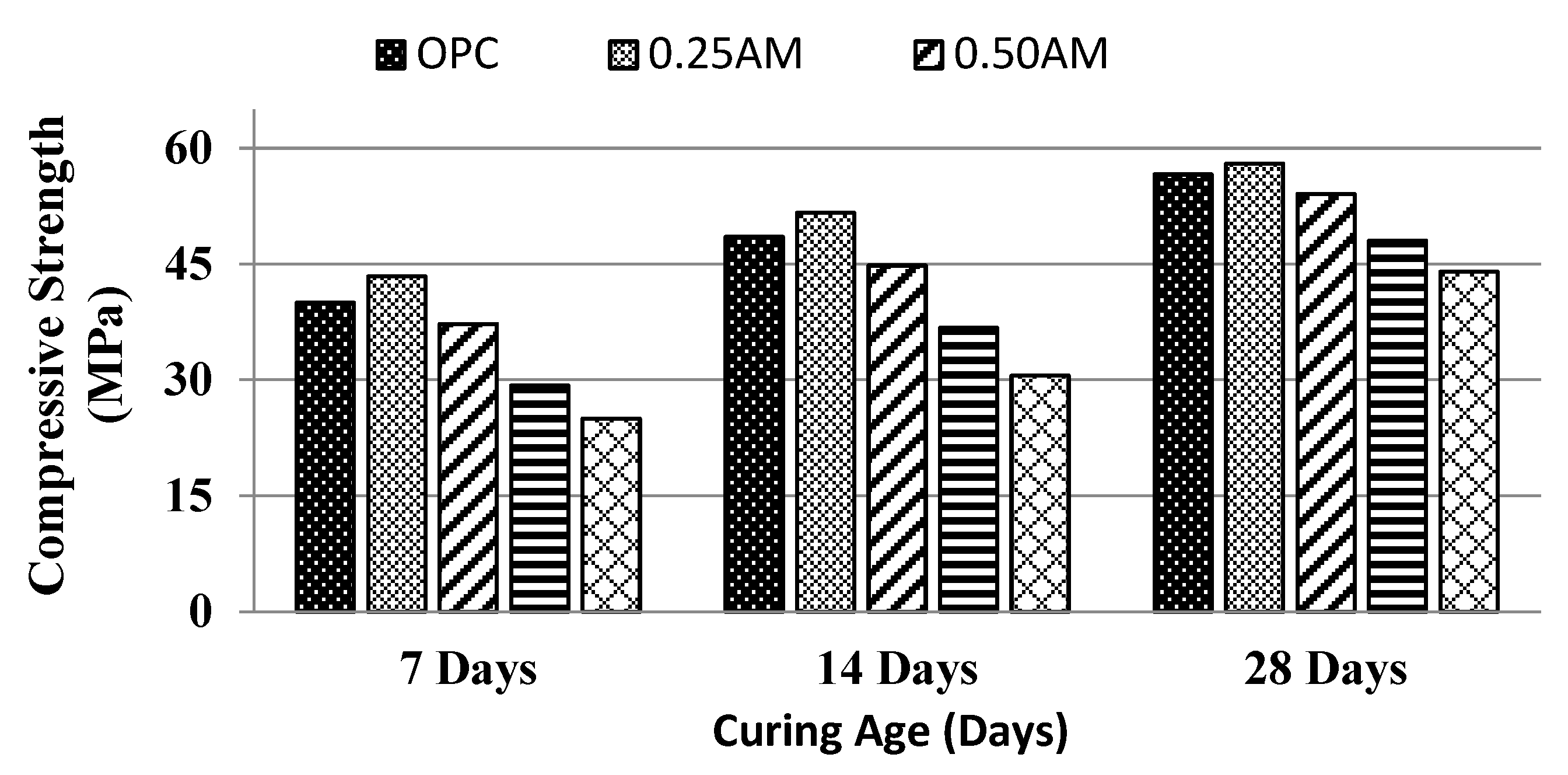

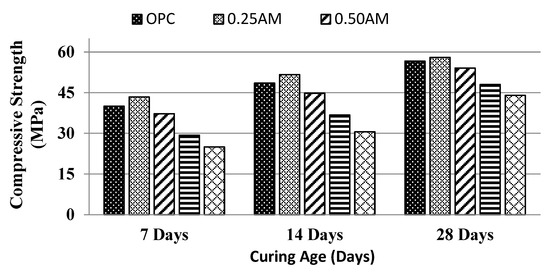

3.4.2. Compressive Strength

The results of the compressive strength test conducted using a universal testing machine are shown in Figure 4. From the results, it can be inferred that the compressive strength decreases as the AM gum content increases which is in accordance with the literature reporting that AM gum reduces the strength of SCPs [3,4,5,27]. This reduction can be associated with the air content which increases with the increase in AM gum dosage, resulting in weaker SCP matrix by enhancing the porosity of the system. It can also be inferred that as the fresh and hardened densities decrease, the corresponding compressive strength values also decrease and the maximum strength is attained when the fresh and harden densities are maximum. Moreover, compressive strength with 0.25% AM gum content at the age of 28 days exceeds by about 2.5% as compared to OPC. So, the strength degradation caused due to addition of AM gum powder can be mitigated using a smaller average particle size of AM gum powder.

Figure 4.

Compressive strength of SCPs.

4. Practical Implementations

On the basis of the findings of this research work, it is suggested to use AM gum powder less than 0.50% by weight of the cement in the construction industry to prepare sustainable and environmentally friendly SCC. Through this, AM gum powder, apart from increasing the viscosity of the matrix, will also help in offsetting the strength reduction of SCPs (as indicated in Figure 4). Strength reduction can be further countered by using an average particle size of AM gum powder close to the average particle size of OPC; however, this aspect needs to be first investigated. Moreover, AM gum powder has the tendency to adsorb water, the incorporation of an air-curing regime might give higher compressive strengths without compromising the viscosity and flow of the matrix.

5. Conclusions

Acacia Modesta (AM) gum powder is an organic ooze-out of acacia modesta trees and has the tendency to affect the fresh and hardness properties of SCPs to a great extent. The following conclusions can be drawn from this study:

- Super-plasticizer demand of the SCPs containing AM gum powder increases with the increase in the amount of AM gum powder due to nature (rough texture) and chemical composition of AM gum powder.

- Viscosity of the SCPs increases with the increase in the amount of AM gum powder, indicating that it has the potential to act as viscosity-modifying agent.

- Fresh tests of SCPs containing AM gum powder indicate that AM gum powder has the potential to act as air-entraining agent as the air content increases and fresh density decreases with the increase in the amount of the AM gum powder.

- Hardness tests of SCPs containing AM gum powder indicate that it degrades the compressive strength; however, this strength degradation can be mitigated by using the average particle sizes closer to the size of the cement. About 2.5% improvement in compressive strength with 0.25% AM gum content is a clear indication of this aspect as it improves the fresh paste and hardens the densities of SCPs.

Author Contributions

Conceptualization, visualization, methodology and supervision, S.A.R.; analysis, investigation, writing—original draft preparation, writing—review and editing, M.W.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research was partially funded by NUST institute of Civil Engineering (NICE), NUST, Islamabad.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All reported results are incorporated in the paper. There isn’t any hidden data.

Conflicts of Interest

There is no conflict of interest between the authors.

References

- Mebrouki, A.; Belas, N.; Bouhamou, N.-e. Experimental plans method to formulate a self-compacting cement paste. Mater. Technol. 2010, 44, 13–20. [Google Scholar]

- Revilla-Cuesta, V.; Faleschini, F.; Skaf, M.; Ortega-López, V.; Manso, J.M. Balancing sustainability, workability, and hardened behavior in the mix design of self-compacting concrete. In Handbook of Sustainable Concrete and Industrial Waste Management; Woodhead Publishing: Duxford, UK, 2022; pp. 333–358. [Google Scholar] [CrossRef]

- Rizwan, S.A.; Gul, S.; Bier, T.A. Self-Consolidating Paste Systems Containing Acacia Nilotica Gum Powder. ACI Mater. J. 2019, 116, 5–14. [Google Scholar] [CrossRef]

- Rizwan, S.A.; Mahmood, N.; Mahmood, U.; Bier, T.A. Response of self-compacting paste (SCP) systems containing Acacia Modesta gum. Constr. Build. Mater. 2018, 161, 398–406. [Google Scholar] [CrossRef]

- Rizwan, S.A.; Latif, W.; Bier, T.A. Response of self-consolidating cement paste systems containing Acacia Nilotica Gum as an organic admixture. Constr. Build. Mater. 2016, 126, 768–776. [Google Scholar] [CrossRef]

- Montenegro, M.A.; Boiero, M.L.; Valle, L.; Borsarelli, C.D. Gum Arabic: More than an edible emulsifier. Prod. Appl. Biopolym. 2012, 51, 953–978. [Google Scholar]

- Obaid, S.S. The medical uses of Gum Acacia-Gum Arabic (GA) in human. Acad. J. Res. Sci. Publ. 2020, 1, 1–11. [Google Scholar]

- Jamila, N.; Khan, N.; Hwang, I.M.; Saba, M.; Khan, F.; Amin, F.; Khan, S.N.; Atlas, A.; Javed, F.; Minhaz, A. Characterization of natural gums via elemental and chemometric analyses, synthesis of silver nanoparticles, and biological and catalytic applications. Int. J. Biol. Macromol. 2020, 147, 853–866. [Google Scholar] [CrossRef]

- Massey, S.; MacNaughtan, W.; Williams, H.E.; Wolf, B.; Iqbal, M.S. A structural study of Acacia nilotica and Acacia modesta gums. Carbohydr. Polym. 2017, 175, 207–215. [Google Scholar] [CrossRef]

- Bahmani, H.; Mostofinejad, D. Microstructure of ultra-high-performance concrete (UHPC)—A review study. J. Build. Eng. 2022, 50, 104118. [Google Scholar] [CrossRef]

- Rizwan, S.A. High-Performance Mortars and Concrete Using Secondary Raw Materials. Ph.D. Thesis, TU Bergakademie Freiberg, Freiberg, Germany, 2006. [Google Scholar]

- Pang, L.; Liu, Z.; Wang, D.; An, M. Review on the Application of Supplementary Cementitious Materials in Self-Compacting Concrete. Crystals 2022, 12, 180. [Google Scholar] [CrossRef]

- Usman, M.; Khan, A.Y.; Farooq, S.H.; Hanif, A.; Tang, S.; Khushnood, R.A.; Rizwan, S.A. Eco-friendly self-compacting cement pastes incorporating wood waste as cement replacement: A feasibility study. J. Clean. Prod. 2018, 190, 679–688. [Google Scholar] [CrossRef]

- Navarrete, I.; Kurama, Y.; Escalona, N.; Brevis, W.; Lopez, M. Effect of supplementary cementitious materials on viscosity of cement-based pastes. Cem. Concr. Res. 2021, 151, 106635. [Google Scholar] [CrossRef]

- Khayat, K.H. Viscosity-enhancing admixtures for cement-based materials—An overview. Cem. Concr. Compos. 1998, 20, 171–188. [Google Scholar] [CrossRef]

- ACI 318-14; Building Code Requirements for Structural Concrete (ACI 318-14): An ACI Standard; Commentary on Building Code Requirements for Structural Concrete (ACI 318R-14). American Concrete Institute: Farmington Hills, MI, USA, 2014.

- Mehta, P.K.; Monteiro, P.J. Concrete Microstructure, Properties and Materials, 4th ed.; McGraw Hill: New York, NY, USA, 2017. [Google Scholar]

- Bessaies-Bey, H.; Khayat, K.H.; Palacios, M.; Schmidt, W.; Roussel, N. Viscosity modifying agents: Key components of advanced cement-based materials with adapted rheology. Cem. Concr. Res. 2021, 152, 106646. [Google Scholar] [CrossRef]

- de Matos, P.R.; Sakata, R.D.; Gleize, P.J.P.; de Brito, J.; Repette, W.L. Eco-friendly ultra-high performance cement pastes produced with quarry wastes as alternative fillers. J. Clean. Prod. 2020, 269, 122308. [Google Scholar] [CrossRef]

- ASTM C150; Standard Specification for Portland Cement. ASTM International: West Conshohocken, PA, USA, 2022. [CrossRef]

- Fares, G.; Al-Negheimish, A.; Alhozaimy, A.M.; Khan, M.I. Polycarboxylate superplasticizer and viscosity modifying agent: Mode of addition and its effect on cement paste rheology using image analysis. J. Build. Eng. 2022, 48, 103946. [Google Scholar] [CrossRef]

- Pei, R.; Liu, J.; Wang, S. Use of bacterial cell walls as a viscosity-modifying admixture of concrete. Cem. Concr. Compos. 2015, 55, 186–195. [Google Scholar] [CrossRef]

- Saak, A.W.; Jennings, H.M.; Shah, S.P. New methodology for designing self-compacting concrete. Mater. J. 2001, 98, 429–439. [Google Scholar]

- Chang, Y.; Hu, Y.; McClements, D.J. Competitive adsorption and displacement of anionic polysaccharides (fucoidan and gum arabic) on the surface of protein-coated lipid droplets. Food Hydrocoll. 2015, 52, 820–826. [Google Scholar] [CrossRef]

- Huang, F.; Li, H.; Yi, Z.; Wang, Z.; Xie, Y. The rheological properties of self-compacting concrete containing superplasticizer and air-entraining agent. Constr. Build. Mater. 2018, 166, 833–838. [Google Scholar] [CrossRef]

- Elinwa, A.U.; Abdulbasir, G.; Abdulkadir, G. Gum Arabic as an admixture for cement concrete production. Constr. Build. Mater. 2018, 176, 201–212. [Google Scholar] [CrossRef]

- Mbugua, R.; Salim, R.; Ndambuki, J. Effect of Gum Arabic karroo as a Water-Reducing Admixture in Concrete. Materials 2016, 9, 80. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).