Development of CNC-Based Automated Soldering Machine †

Abstract

:1. Introduction

2. Materials and Methodology

2.1. Soldering

2.1.1. Measurement of Resistance at the Heating Element

- Remove the nut tip, enclosure tip, and nipple.

- Push the cord assembly in the direction of the tip and remove the terminal board from the handle.

- Remove the grounding spring from the D-sleeve.

- Measure the resistance values at the sensor and heating element of the terminal board in normal conditions.

2.1.2. Replacement of the Heating Element

- De-solder the heating element leads, and sensor leads.

- Remove the old heating element and replace it with a new one.

- Solder the new heating element lead to the terminal board then cut the extra lead.

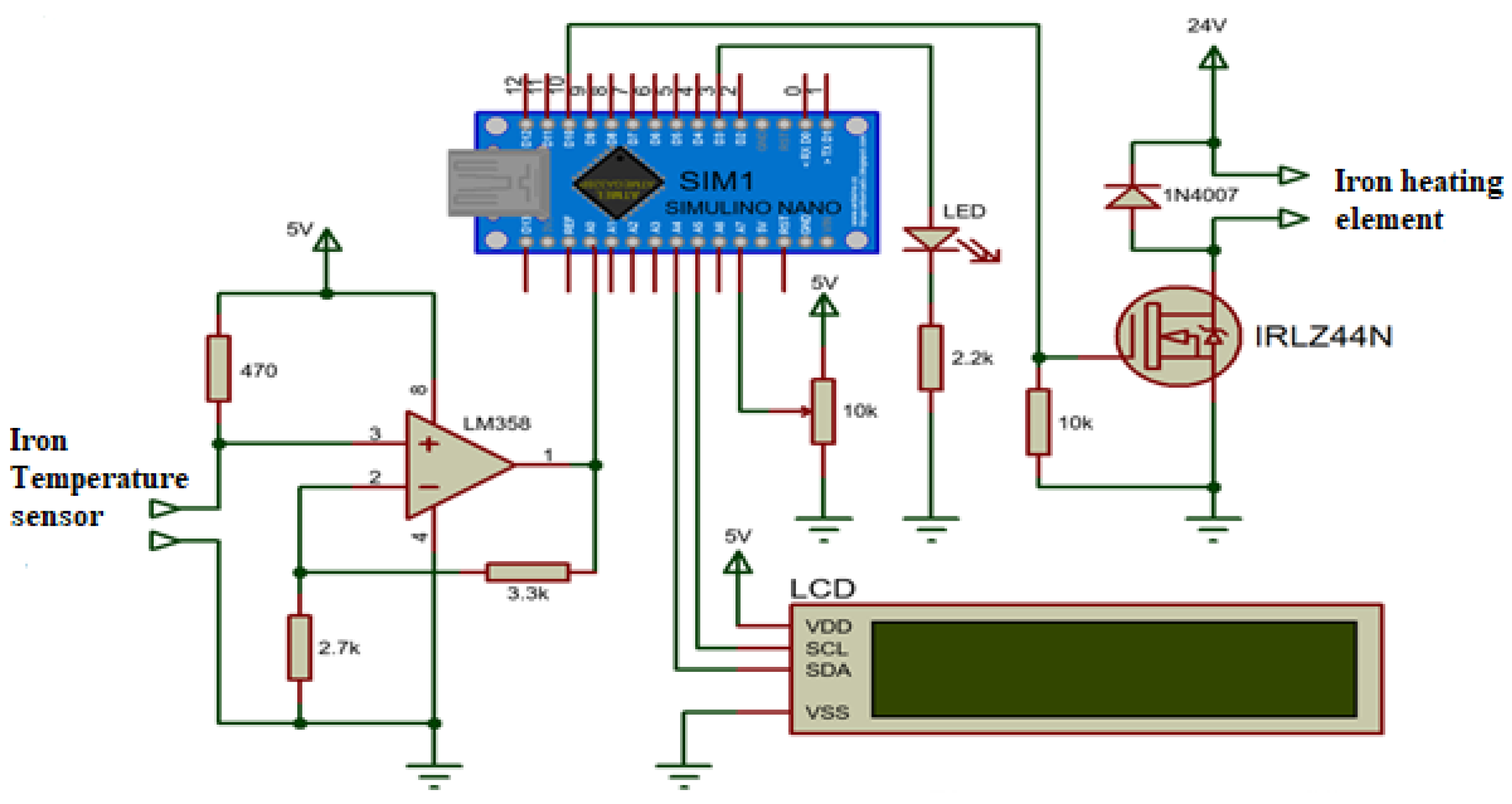

2.2. Digital Soldering Station

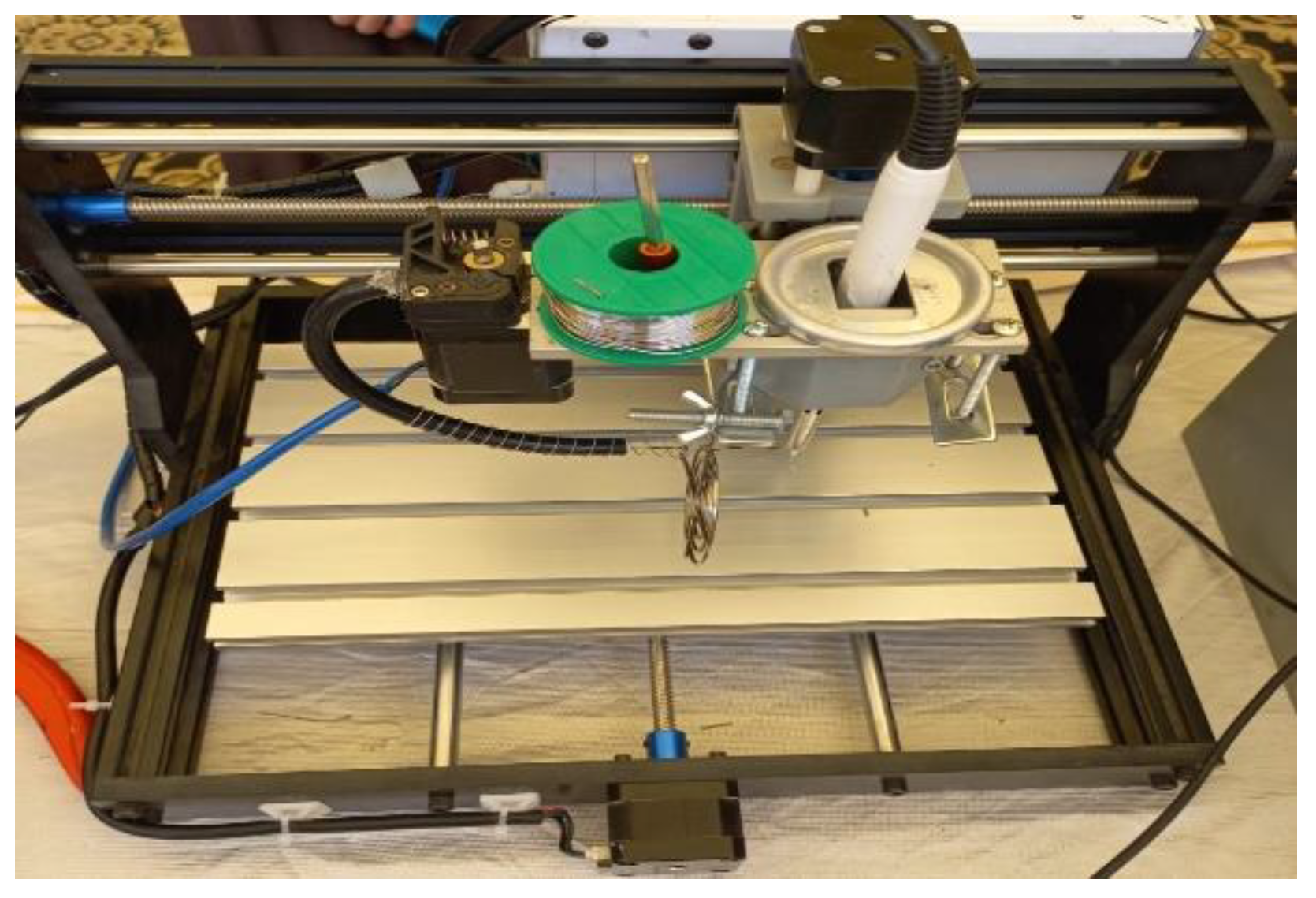

2.3. Manufacturing of CNC (Computer Numeric Control)

2.3.1. Electromechanical Components

- Five-phase stepper motor,

- Flexible couplings,

- Bearings,

- Lead screw,

- Limit switch.

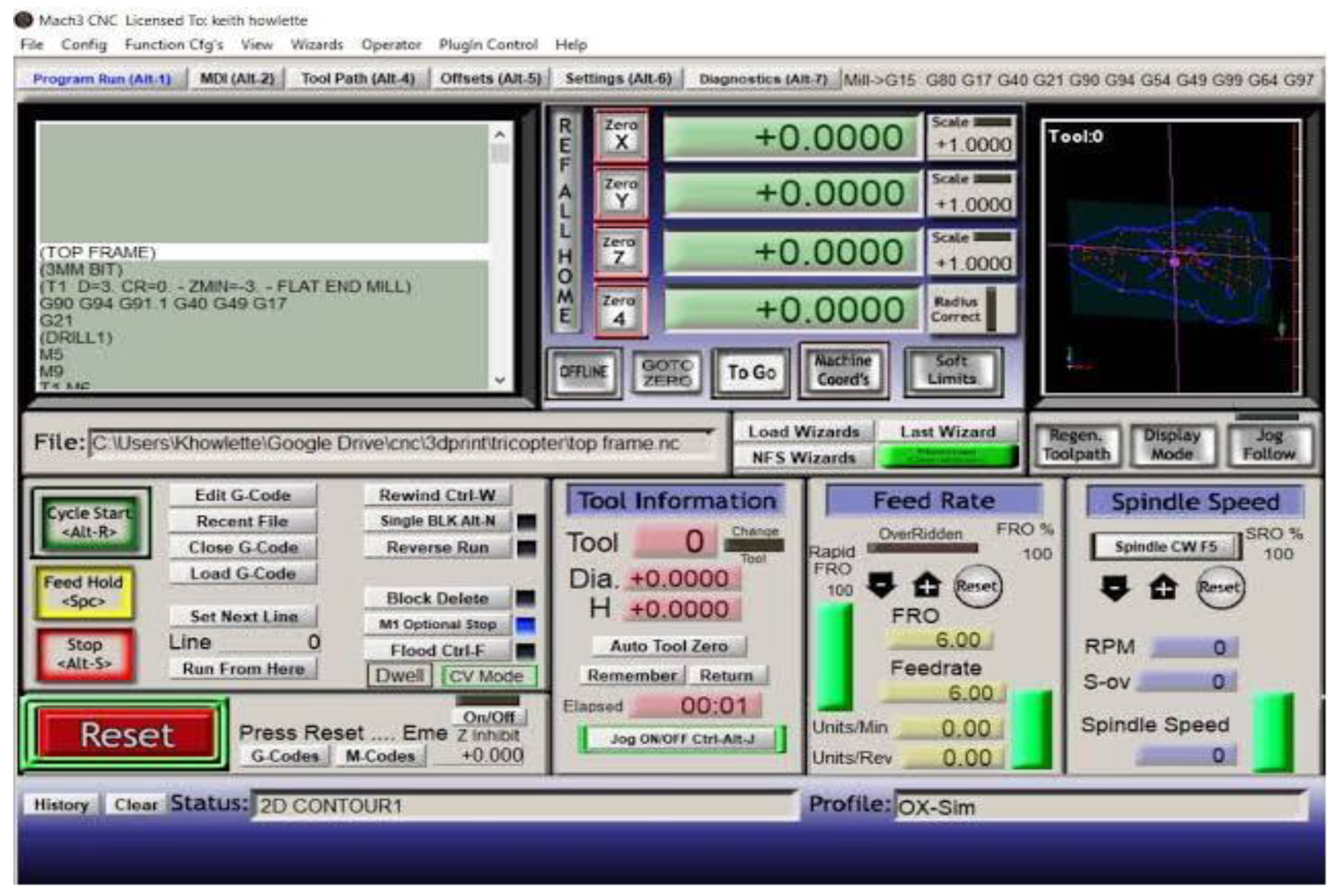

2.3.2. CNC Control Software

2.4. Techniques and Fabrication

3. Discussion and Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Santiago, S.B.; Almeida, E.L.O.; Dias, J.O. Automatic welding process: A study case of Soldering Machine. In Proceedings of the International Conference on Industrial Engineering and Operations Management, Toronto, ON, Canada, 23–25 October 2019. [Google Scholar]

- Thandapral, J.J.; Mugelan, R.K. Solderbot: Automated Soldering using Robot Arm. Int. J. Sci. Res. (IJSR) 2021, 10, 48–52. [Google Scholar]

- McKerrow, R. Optimization of Robotic Soldering Process: A Focus on Solder Spread and Spattering. In Proceedings of the SMTA International Conference, Virtual, 28 September–23 October 2020. [Google Scholar]

- Mamilla, V.R.; Srinivasulu, M.; Mani, P.N. Study on computer numerical control (CNC) machines. Int. J. Adv. Sci. Res. (IJASR) 2016, 1, 21–25. [Google Scholar]

- Misra, A.S.; Singh, G.; Kumar, A.; Rastogi, V. Design and Development of a Low-Cost CNC Alternative SCARA Robotic Arm. In Proceedings of the Third International Conference on Computing and Network Communications (CoCoNet’19), Trivandrum, India, 18–21 December 2019. [Google Scholar]

- Patel, N. Study on computer numerical control (CNC) technology. Int. Res. J. Eng. Technol. (IRJET) 2020, 7, 2883–2887. [Google Scholar]

- Cecil, J.V.D.; Powell, D. A review of gripping and manipulation techniques for micro-assembly applications. Int. J. Sci. Res. (IJSR) 2005, 43, 819–828. [Google Scholar] [CrossRef]

- Zhou, Y.; Nelson, B.J. The effect of material properties and gripping force on micro grasping. In Proceedings of the IEEE International Conference on Robotics and Automation (ICRA), San Francisco, CA, USA, 24–28 April 2000. [Google Scholar]

- Cappelleri, D.P.; Fink, J.; Gavrea, B.; Kumar, V. Automated assembly for meso-scale parts. IEEE Trans. Autom. Sci. Eng. 2011, 8, 598–613. [Google Scholar] [CrossRef]

- Das, A.M.R.; Popa, D.; Stephanou, H. A multiscale assembly and packaging system for manufacturing of complex micro-nano devices. IEEE Trans. Autom. Sci. Eng. 2011, 9, 160–170. [Google Scholar] [CrossRef]

- Smid, S. CNC Programming Handbook, 2nd ed.; Industrial Press: New York, NY, USA, 2002. [Google Scholar]

- Khandpur, R.S. Printed Circuit Board Design, Fabrication Assembly and Testing; Tata Publisher McgrawHill Education: Delhi, India, 2005. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wahid, H.; Hashmi, H.; Baig, M.U.; Raza, N.A.; Sheikh, M.F.; Bhutto, M.Y. Development of CNC-Based Automated Soldering Machine. Eng. Proc. 2022, 20, 17. https://doi.org/10.3390/engproc2022020017

Wahid H, Hashmi H, Baig MU, Raza NA, Sheikh MF, Bhutto MY. Development of CNC-Based Automated Soldering Machine. Engineering Proceedings. 2022; 20(1):17. https://doi.org/10.3390/engproc2022020017

Chicago/Turabian StyleWahid, Hafsa, Hufsa Hashmi, Muhammad Umer Baig, Nawab Ahmed Raza, Muhammad Faizan Sheikh, and Muhammad Yousif Bhutto. 2022. "Development of CNC-Based Automated Soldering Machine" Engineering Proceedings 20, no. 1: 17. https://doi.org/10.3390/engproc2022020017

APA StyleWahid, H., Hashmi, H., Baig, M. U., Raza, N. A., Sheikh, M. F., & Bhutto, M. Y. (2022). Development of CNC-Based Automated Soldering Machine. Engineering Proceedings, 20(1), 17. https://doi.org/10.3390/engproc2022020017