Temperature Fiber-Optic Sensor with ZnO ALD Coating †

Abstract

:1. Introduction

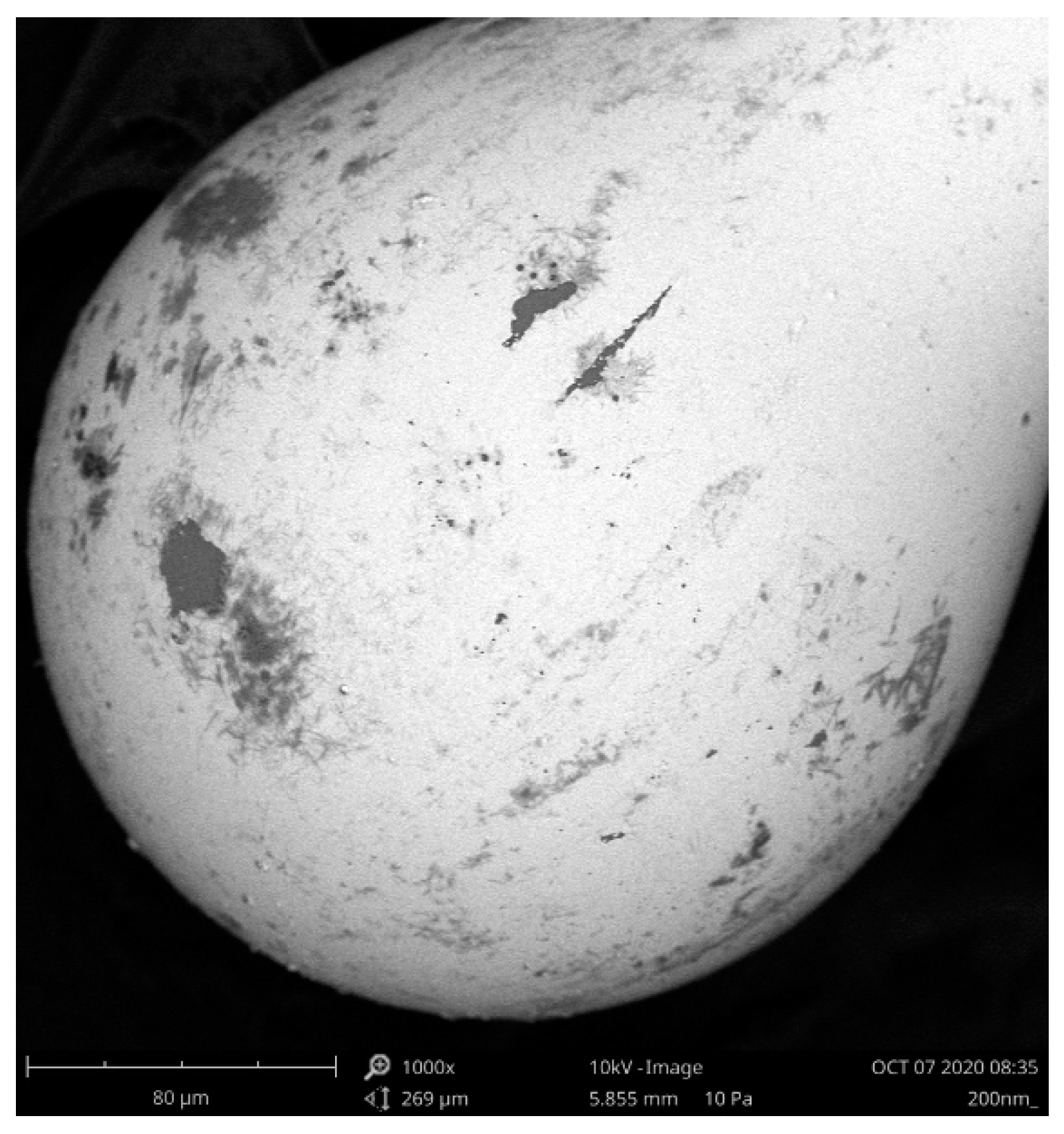

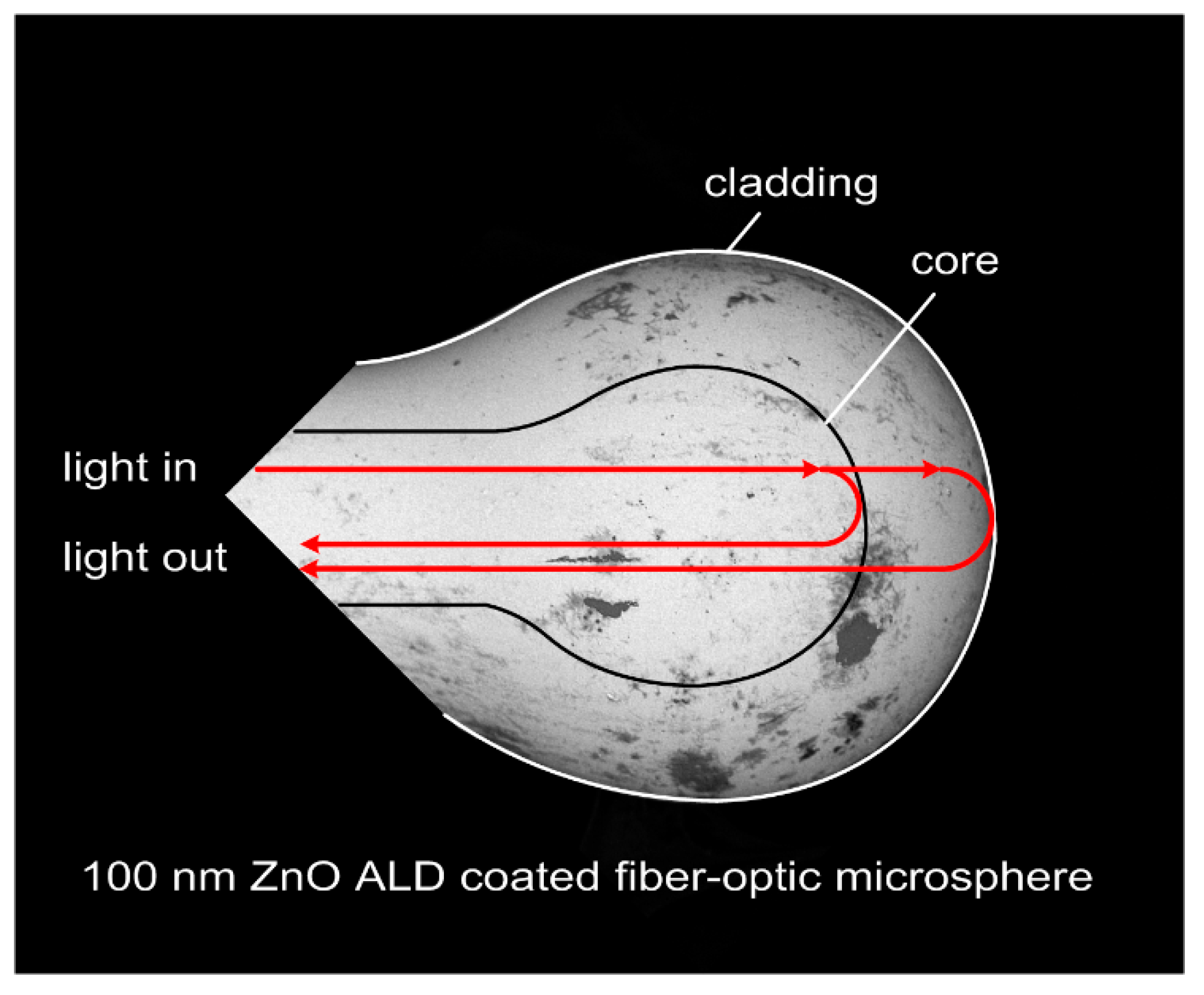

2. Materials and Methods

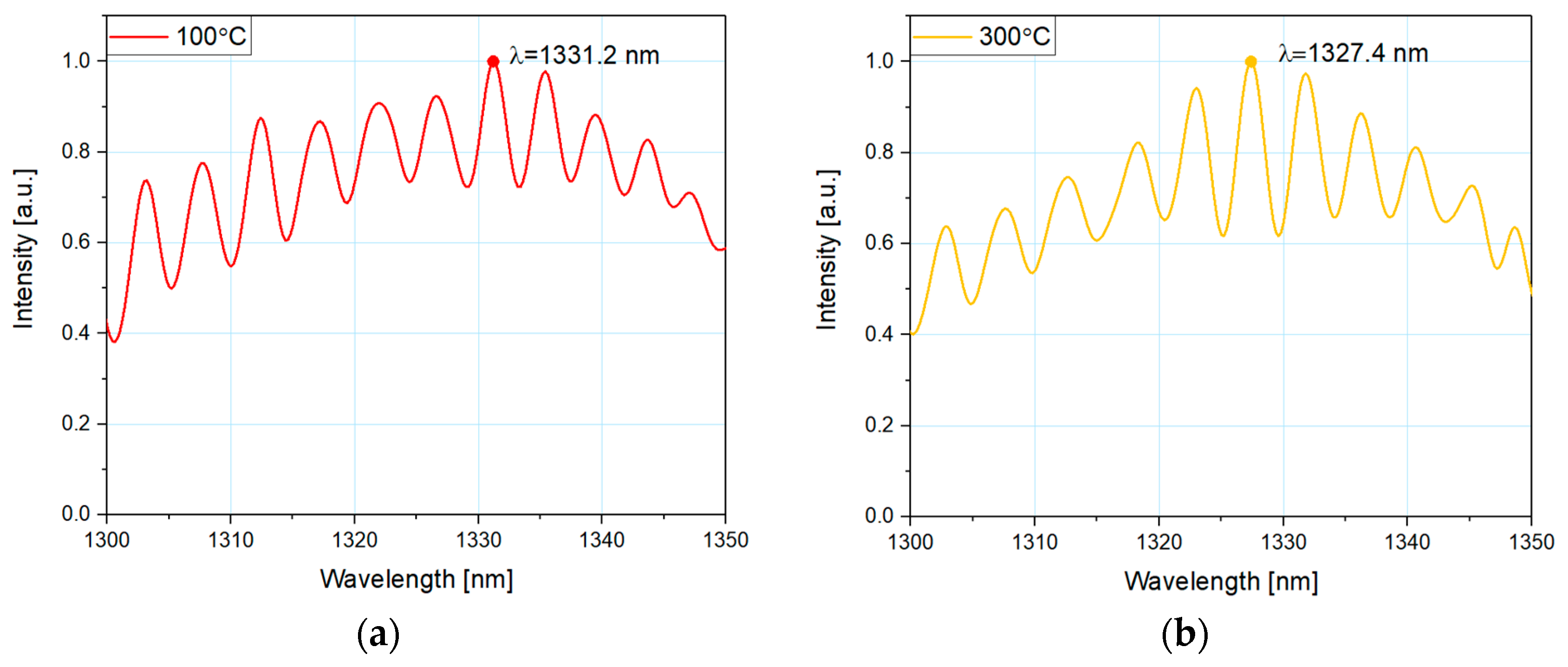

3. Results and Discussion

4. Conclusions

Funding

Conflicts of Interest

References

- Xiong, F.B.; Sisler, D. Determination of low-level water content in ethanol by fiber-optic evanescent absorption sensor. Opt. Commun. 2010, 283, 1326–1330. [Google Scholar] [CrossRef]

- Ramakrishnan, M.; Rajan, G.; Semenova, Y.; Farrell, G. Overview of Fiber Optic Sensor Technologies for Strain/Temperature Sensing Applications in Composite Materials. Sensors 2016, 16, 99. [Google Scholar] [CrossRef] [PubMed]

- Karpienko, K.; Wróbel, M.S.; Jedrzejewska-Szczerska, M. Determination of refractive index dispersion using fiber-optic low-coherence Fabry–Perot interferometer: Implementation and validation. Opt. Eng. 2014, 53, 077103. [Google Scholar] [CrossRef]

- Witt, J.; Narbonneau, F.; Schukar, M.; Krebber, K.; De Jonckheere, J.; Jeanne, M.; Kinet, D.; Paquet, B.; Depre, A.; D’Angelo, L.T.; et al. Medical Textiles with Embedded Fiber Optic Sensors for Monitoring of Respiratory Movement. IEEE Sens. J. 2012, 12, 246–254. [Google Scholar] [CrossRef]

- Arif, M.F.H.; Ahmed, K.; Asaduzzaman, S.; Azad, M.A.K. Design and optimization of photonic crystal fiber for liquid sensing applications. Photonic Sens. 2016, 6, 279–288. [Google Scholar] [CrossRef]

- Van Newkirk, A.; Antonio-Lopez, E.; Salceda-Delgado, G.; Amezcua-Correa, R.; Schülzgen, A. Optimization of multicore fiber for high-temperature sensing. Opt. Lett. 2014, 39, 4812. [Google Scholar] [CrossRef] [PubMed]

- Wierzba, P.; Jędrzejewska-Szczerska, M. Optimization of a Fabry-Perot Sensing Interferometer Design for an Optical Fiber Sensor of Hematocrit Level. Acta Phys. Pol. A 2013, 124, 586–588. [Google Scholar] [CrossRef]

- Wang, Q.; Wei, W.; Guo, M.; Zhao, Y. Optimization of cascaded fiber tapered Mach–Zehnder interferometer and refractive index sensing technology. Sens. Actuators B Chem. 2016, 222, 159–165. [Google Scholar] [CrossRef]

- Azad, S.; Sadeghi, E.; Parvizi, R.; Mazaheri, A.; Yousefi, M. Sensitivity optimization of ZnO clad-modified optical fiber humidity sensor by means of tuning the optical fiber waist diameter. Opt. Laser Technol. 2017, 90, 96–101. [Google Scholar] [CrossRef]

- Mishra, A.K.; Mishra, S.K.; Gupta, B.D. SPR based fiber optic sensor for refractive index sensing with enhanced detection accuracy and figure of merit in visible region. Opt. Commun. 2015, 344, 86–91. [Google Scholar] [CrossRef]

- Song, N.; Cai, W.; Song, J.; Jin, J.; Wu, C. Structure optimization of small-diameter polarization-maintaining photonic crystal fiber for mini coil of spaceborne miniature fiber-optic gyroscope. Appl. Opt. 2015, 54, 9831. [Google Scholar] [CrossRef] [PubMed]

- Tu, M.H.; Sun, T.; Grattan, K.T.V. Optimization of gold-nanoparticle-based optical fibre surface plasmon resonance (SPR)-based sensors. Sens. Actuators B Chem. 2012, 164, 43–53. [Google Scholar] [CrossRef]

- Listewnik, P.; Hirsch, M.; Struk, P.; Weber, M.; Bechelany, M.; Jędrzejewska-Szczerska, M. Preparation and Characterization of Microsphere ZnO ALD Coating Dedicated for the Fiber-Optic Refractive Index Sensor. Nanomaterials 2019, 9, 306. [Google Scholar] [CrossRef] [PubMed]

- Hirsch, M.; Listewnik, P.; Struk, P.; Weber, M.; Bechelany, M.; Szczerska, M. ZnO coated fiber optic microsphere sensor for the enhanced refractive index sensing. Sens. Actuators A Phys. 2019, 298, 111594. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Listewnik, P. Temperature Fiber-Optic Sensor with ZnO ALD Coating. Eng. Proc. 2020, 2, 99. https://doi.org/10.3390/engproc2020002099

Listewnik P. Temperature Fiber-Optic Sensor with ZnO ALD Coating. Engineering Proceedings. 2020; 2(1):99. https://doi.org/10.3390/engproc2020002099

Chicago/Turabian StyleListewnik, Paulina. 2020. "Temperature Fiber-Optic Sensor with ZnO ALD Coating" Engineering Proceedings 2, no. 1: 99. https://doi.org/10.3390/engproc2020002099

APA StyleListewnik, P. (2020). Temperature Fiber-Optic Sensor with ZnO ALD Coating. Engineering Proceedings, 2(1), 99. https://doi.org/10.3390/engproc2020002099