Abstract

Nowadays, the implementation of automated manufacturing processes within a wide variety of industrial environments is not understood without the Industry 4.0 concept and the context-aware possibilities given by the Industrial Internet of Things (IIoT). In this sense, Wireless Sensor Networks (WSN) play a key role due to their inherent mobility, ease of deployment and maintenance, scalability and low power consumption, among others. This work proposes the deployment and optimization of a WSN in the facilities of the Galeo Enrollables Company, located in Navarre (Spain), in order to optimize the manufacturing processes of technical curtains. For that purpose, radio propagation measurements as well as 3D Ray Launching simulations have been performed in order to characterize the wireless channel of this harsh industrial environment. Then, low cost sensors and actuators have been selected to prepare different wireless motes in order to deploy them on different machines/workstations present within the scenario. The information gathered by the motes is then transmitted to a central node, which conditions the data for input into the Enterprise Resource Planning (ERP) system.

1. Introduction

In this modern era of technology, Industry 4.0 will allow companies to implement innovative manufacturing techniques by acquiring real-time data using a large number of interconnected smart devices, thanks mainly to the Industrial Internet of Things (IIoT) [1]. A Wireless Sensor Network (WSN) may be necessary for the manufacturing process due to its monitoring capacity, flexibility and scalability leading to an optimization of operating costs. In order to do that, it is necessary to carry out a precise analysis of the wireless channel due to the noise caused by the surrounding machinery, the harsh industrial environment (metallic objects) and the dynamic channel that causes strong multipath components [2]. In the literature, a survey analyzes a WSN reliability in industrial automation and control systems in order to replace wired solutions in factory applications [3]. In [4], a wireless time-synchronous network that allows machine-to-machine (M2M) data sharing is presented. References [5,6] focus on communication among nodes and real-time data gathering challenges in industrial environments.

Following these trends, this work proposes the deployment and optimization of a WSN in the facilities of the Galeo Enrollables Company located in Navarre (Spain). The company designs and manufactures technical and solar protection curtains. Due to the current state of lack of control on manufacturing times and administrative tasks, the company wants to integrate an Enterprise Resource Planning (ERP) system in order to carry out the effective management of the entire manufacturing plant, with the aim of controlling and optimizing all their resources and processes. In this sense, the proposed and deployed WSN acquires real-time data from different machinery and workstations within the workshop in order to supply them to the ERP system.

The paper is organized as follows: Section 2 describes the workshop of the Galeo Enrollables Company as well as the deployment of the monitoring WSN. The performed radio propagation analysis prior the WSN deployment and the obtained system results are presented in Section 3. Finally, Section 4 is devoted to discussing the obtained results and future work.

2. Workshop Description

The Galeo Enrollables Company was founded in 2008 and during these years it has specialized in the manufacturing, design and innovation of technical and solar protection curtains for different types of windows and glass enclosures, from large glazing and facades to indoor solutions (dormers, skylights, etc.). The wide variety of products they manufacture (such as roller blinds, vertical curtains, Japanese panels, pleated curtains, night and day blinds, nautical curtains, outdoor curtains, etc.) leads to the necessity of very specific machinery. In this sense, the workshop where the WSN was deployed contains different automatic and semi-automatic cutters based on crush cutting, laser, ultrasounds and blades, thermal and ultrasound-based welding machines and automatic machinery for the manufacture of slats, among others. Figure 1 shows different areas of the workshop.

Figure 1.

Pictures of different workstations and areas of the workshop under study.

The company is in the process of integrating a new Enterprise Resource Planning (ERP) system to control and monitor manufacturing times, the stock of the warehouse and administrative tasks, leading to the calculation of operating costs. In this way, the company is interested in deploying a WSN in order to acquire real-time data provided by the workshop machinery with the aim of including it in the new ERP system. Next subsection presents the employed low-cost hardware for the construction of the wireless nodes and how they have been deployed.

Wireless Sensor Network Deployment

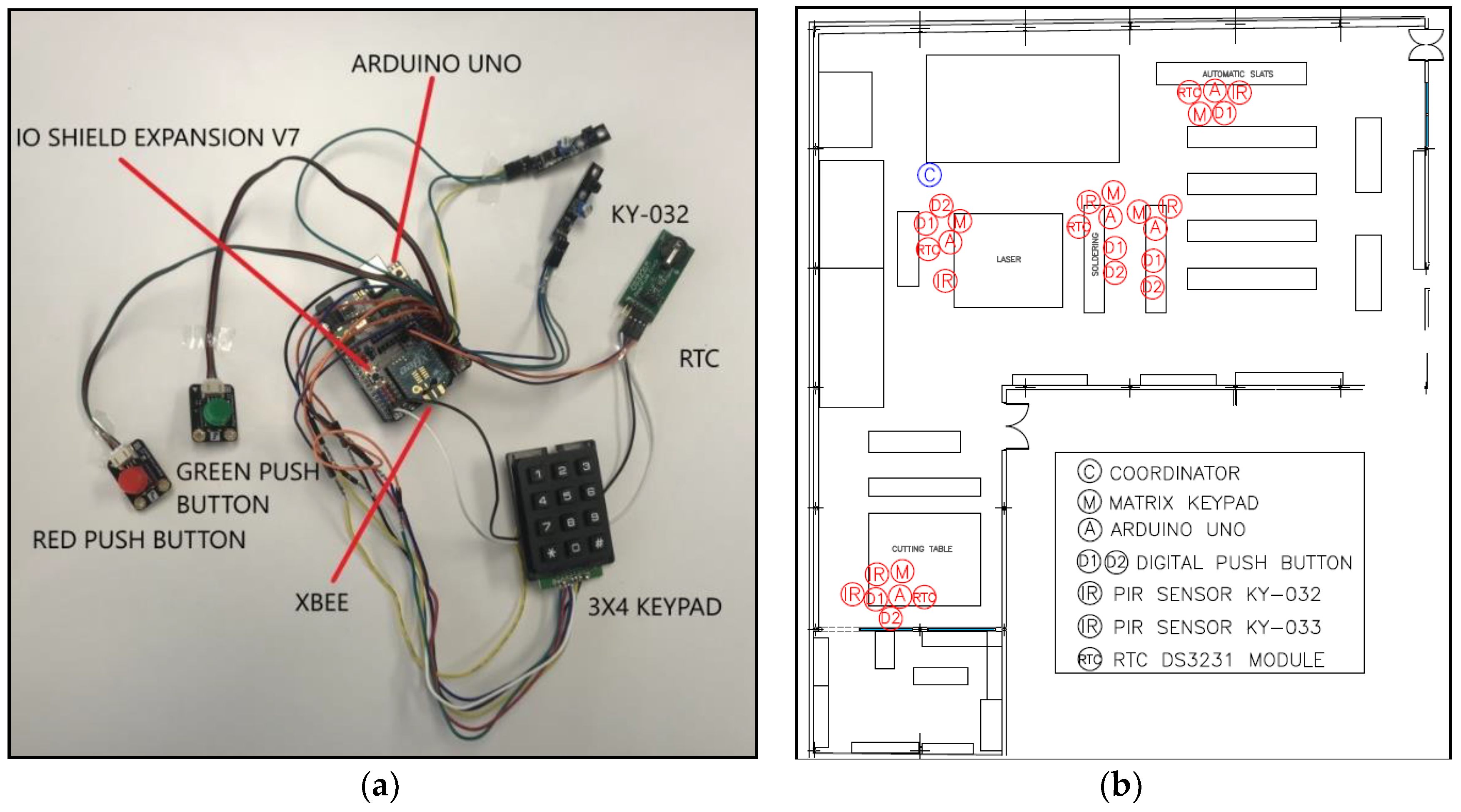

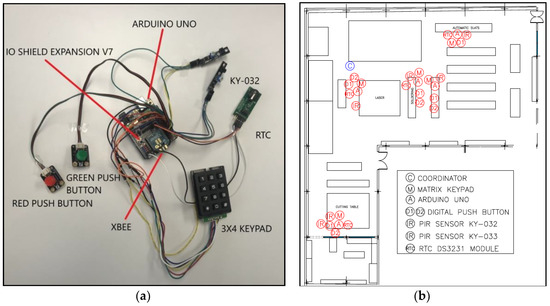

Figure 2a presents the employed hardware for the WSN nodes. Depending on the requirements of each workstation, the nodes components differ, but in general, they consist on an Arduino UNO board, an IO Shield expansion, digital push buttons, a matrix keypad, KY-032 Passive Infrared (PIR) sensors from Joy-IT (Neukirchen-Vluyn, Germany), Real-Time Clock (RTC) modules for synchronization and an XBee s2c module for the ZigBee-based wireless communications. Figure 2b shows the schematic view of the ZigBee-based WSN deployment, including the location of the network coordinator. The sensors and actuators deployed on each workstation are indicated by red circles.

Figure 2.

(a) Hardware employed for the construction of the Wireless Sensor Networks (WSN) nodes; (b) Schematic view of the WSN deployment within the workshop.

3. Results

Once the desired WSN has been deployed, different measurement campaigns have been carried out. First, radio propagation measurements at 2.4 GHz have been taken in order to assess the radio channel at 2.4 GHz within the workshop (see Section 3.1). On the other hand, the overall system performance has been studied in terms of Packet Error Rate (PER) (Section 3.2).

3.1. Radio Channel Assessment wihitn the Workshop

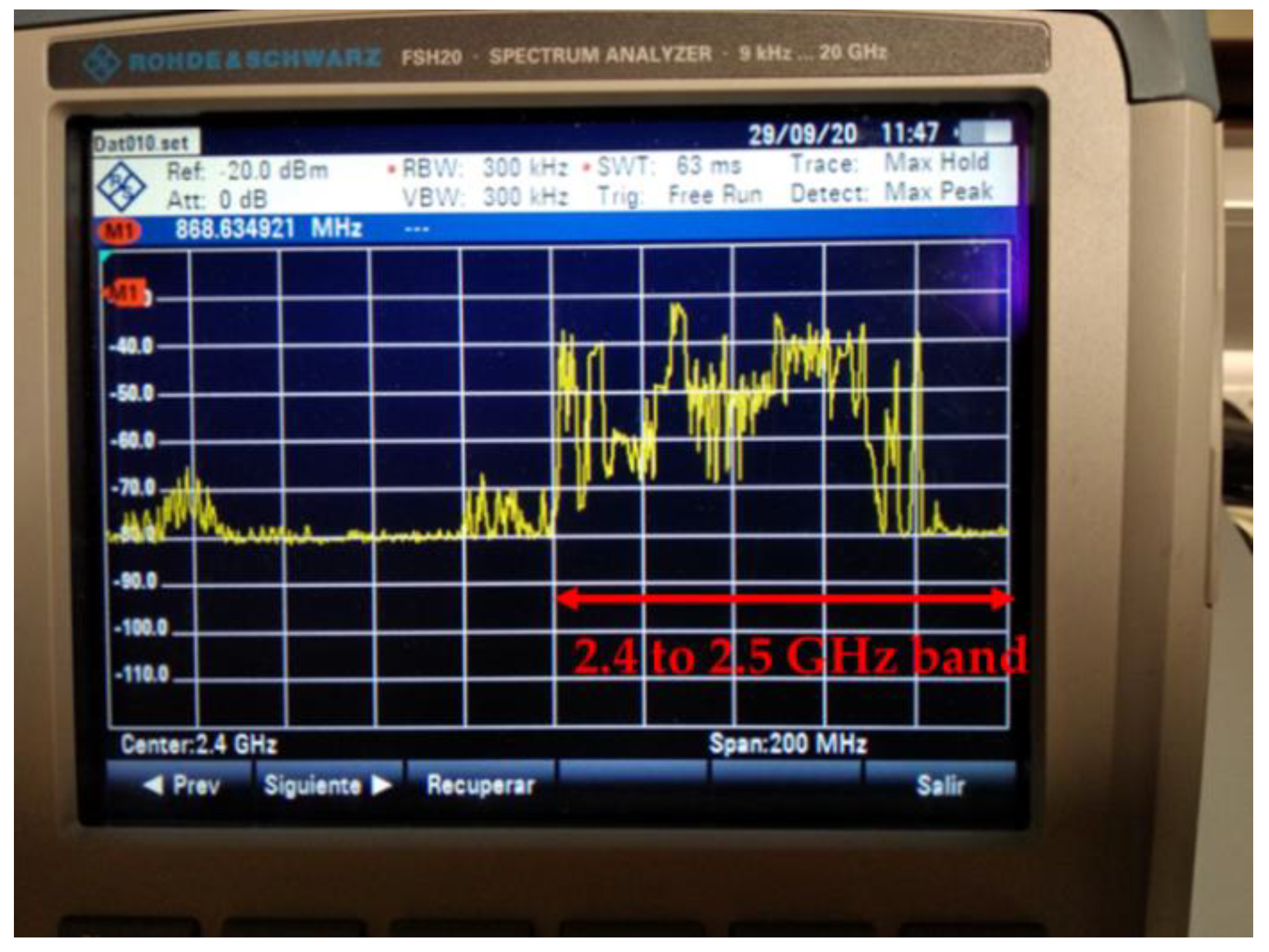

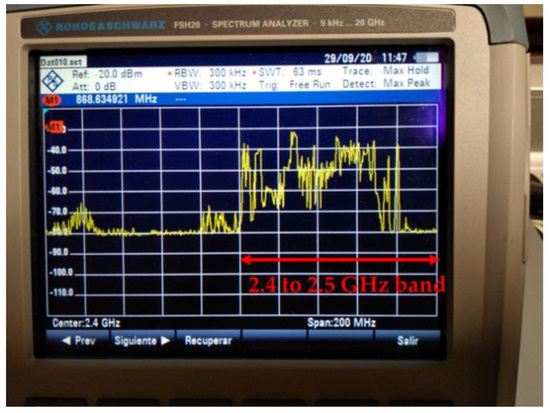

Before the deployment of the WSN, potential interference sources (including specific machinery such as laser or soldering machines) on the wireless radio channel have been measured by the aid of a Rohde & Schwarz (Munich, Germany) FSH20 portable spectrum analyzer. As can be seen in Figure 3, the band from 2.4 to 2.5 GHz presents RF (Radio Frequency) signals/noise due mainly to the Wi-Fi access points present in the workshop. Even so, there are some free bands near 2.5 GHz. In addition, the ZigBee protocol automatically chose the best operation frequency band at the specific scenario, and since it is well-known that ZigBee systems are very robust in terms of losing packets when coexisting with Wi-Fi signals, no potential problems have been detected for the deployment of our ZigBee-based WSN.

Figure 3.

RF signals present within the workshop prior deploying the ZigBee-based WSN.

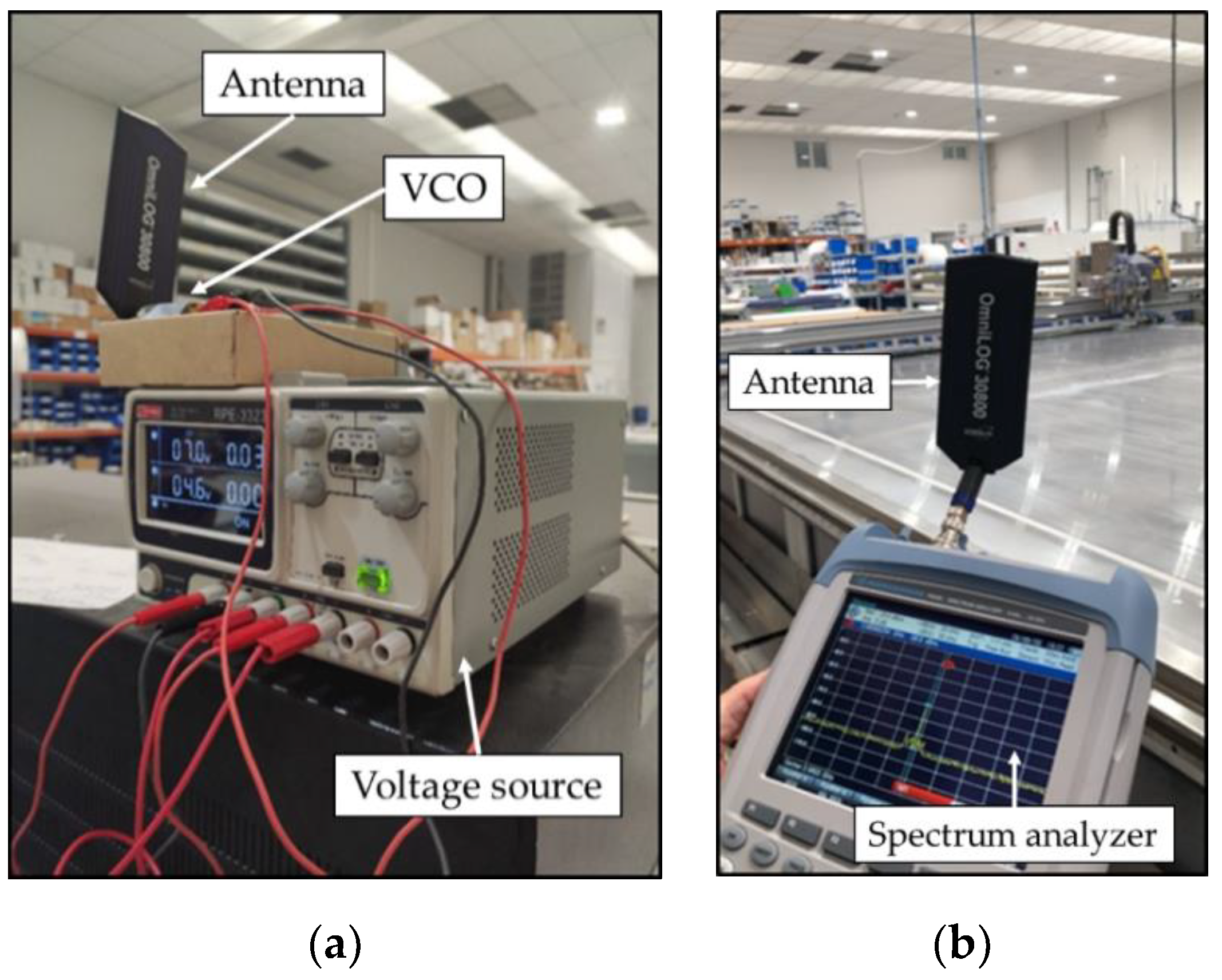

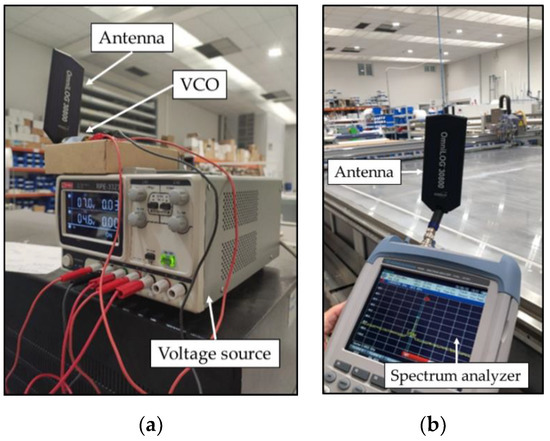

However, in complex industrial scenarios where a lot of obstacles as well as metallic objects are present, the radio propagation of the deployed system can be severely affected. Therefore, RF propagation measurements have been taken at 2.4 GHz in order to study radio propagation within the environment under analysis. For that purpose, a Voltage Controlled Oscillator (VCO) ZX95-2500+ from Mini-Circuits (operation frequency range from 1600 to 2500 MHz with a transmitted power level of 7.5 dBm) has been employed as a transmitter (see Figure 4a). As a receiver, the same portable spectrum analyzer has been used (see Figure 4b). For both transmitter and receiver, the same Omni-directional Broadband Antenna OmniLOG® 30,800 (frequency range: 300 MHz–8 GHz) from Aaronia (Euscheid, Germany) has been used.

Figure 4.

Employed transmitter and receiver for the radio channel assessment: (a) transmitter; (b) receiver.

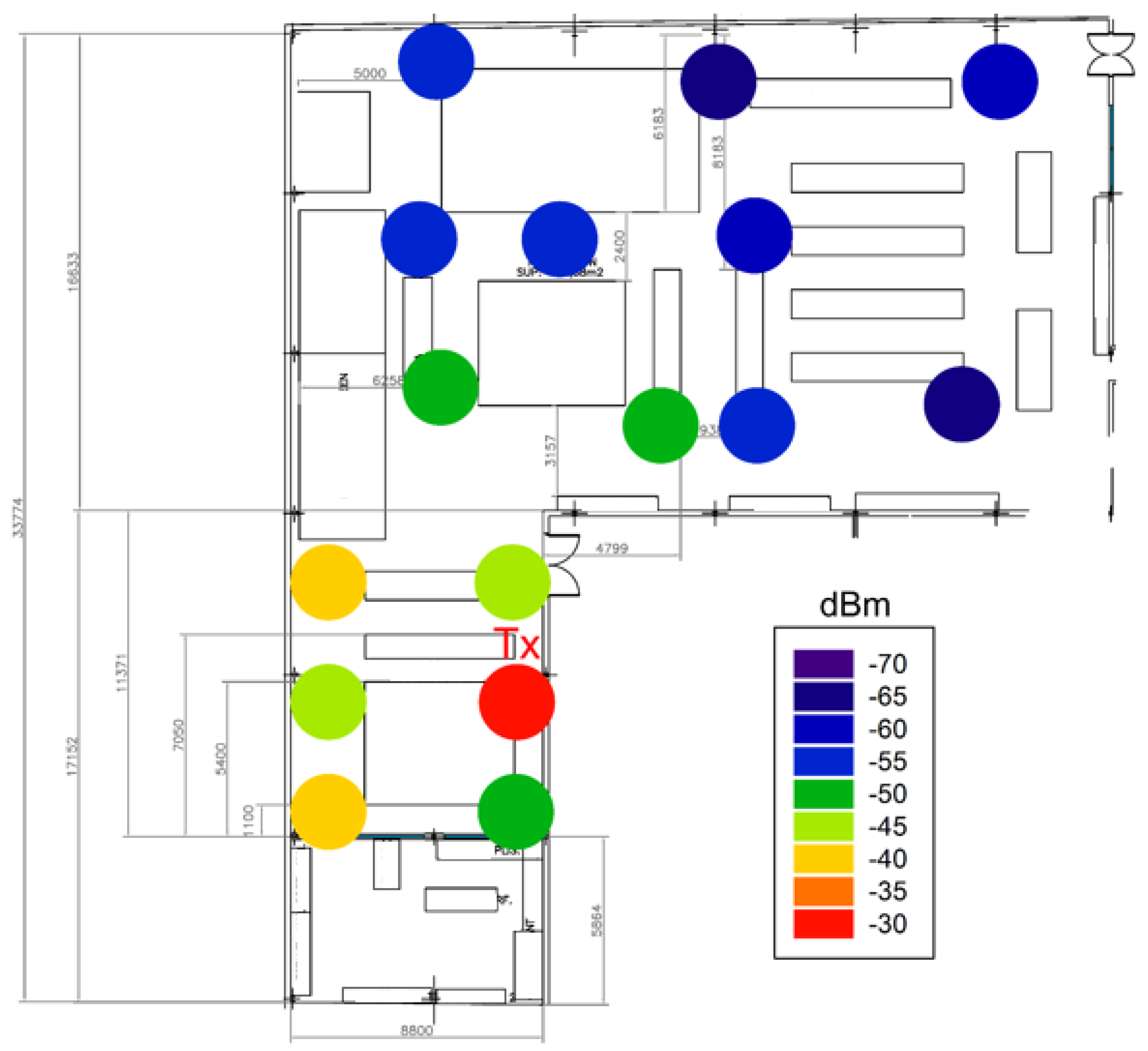

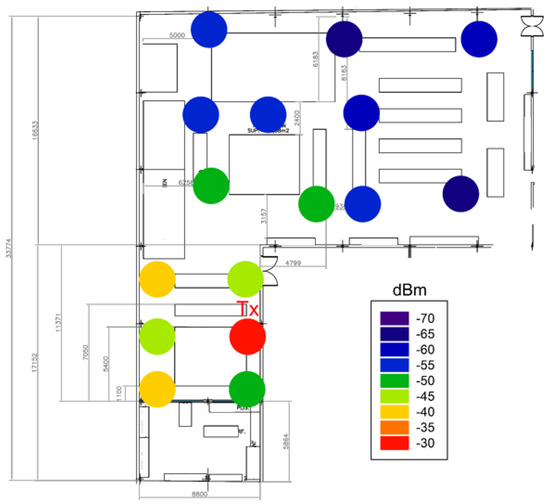

The location of the transmitter for these measurements can be seen in Figure 5, marked as “Tx”. It is important to note that the location of the transmitter has been chosen in order to study different areas with Line of Sight (LoS) and Non Line of Sight (NLoS) conditions. The measurement points are represented as colored circles, distributed throughout the workshop, covering its whole surface. As expected, the points nearer to the transmitter received higher RF power level, and the NLoS zones the lowest. Even so, the received power level at every point is significantly higher than the sensitivity values of the employed ZigBee nodes (i.e., −100 dBm). Therefore, no problems are expected for the connectivity between the WSN nodes.

Figure 5.

RF power level measurements for the whole area (in meters) of the workshop.

3.2. System Performance

In order to assess the overall performance of the deployed ZigBee-based WSN within the workshop, each node has been programmed to send 10,000 in a time interval of 2 h. This measurement campaign has been performed for two different scenarios: during a high activity period of the workstations and during the rest period. Table 1 presents the correctly received packets by the coordinator from each WSN node. As it can be observed, no packet has been lost during the activity period, and only two packets in the rest period, obtaining a PER of 0.00% for the activity period and a PER of 0.005% for the rest period. These results confirm the lack of problems expected from the preliminary radio planning tasks presented in Section 3.1.

Table 1.

Correctly received packets by the coordinator from each WSN node (from 10,000 transmitted packets).

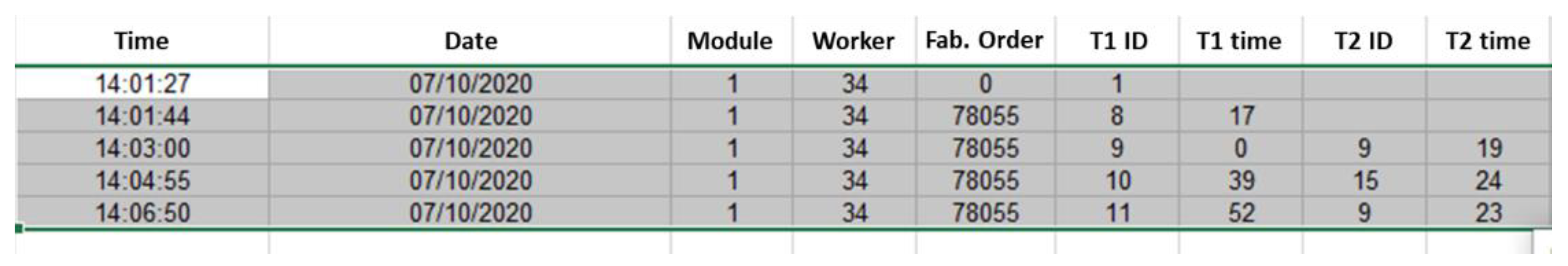

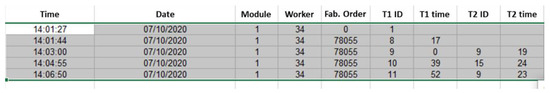

As an illustrative example of the packets transmitted by the WSN nodes, Figure 6 shows a macro of part of the information included in the packets, in this case, related to the time related to specific tasks on a workstation. As can be observed, the date and time (in seconds) are shown, but also is the workstation number, the worker ID and the fabrication order. These data will help the company to adjust their working fluxes for a more efficient performance in a future.

Figure 6.

Screenshot of a macro with part of the information sent in the packets.

4. Discussion

Galeo Enrollables Company has bet on Industry 4.0 paradigm, and it is installing a new ERP system in order to improve the quality of the products as well as to optimize the manufacturing processes and reduction of cost. For that purpose, the company needs to deploy a WSN within the workshop. Taking into account the workshop’s morphology and size, ZigBee wireless communication technology has been chosen. The drawback of this technology could be the relative high-power consumption of the wireless nodes, but in this specific application all the nodes are connected to the corresponding workstation and no extra energy supply is needed. Furthermore, due to its versatility (mesh topology, ease of adding new nodes to the network) and low cost (Arduino compatible devices operating at free 2.4 GHz ISM band), the prepared nodes satisfied the company’s expectations. As can be seen in the obtained results, the performance of the deployed WSN has been very satisfactory. For future work, the company is working on the integration of the data collected by the WSN into the new ERP system and their analysis via Big Data techniques for the predictive optimization of the manufacture processes.

Author Contributions

Conceptualization, F.F., A.B.S. and A.B.; methodology, F.F. and P.L.-I.; software, A.B.; validation, I.P., H.K. and A.B.; formal analysis, A.V.A.; investigation, A.V.A. and L.A.; resources, F.F.; data curation, A.B.; writing—original draft preparation, L.A., I.P. and A.B.; writing—review and editing, P.L.-I.; visualization, I.P. and H.K.; supervision, A.B.S. and P.L.-I. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Acknowledgments

We thank the Galeo Enrollables Company for all the received support.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

References

- Sisinni, E.; Saifullah, A.; Han, S.; Jennehag, U.; Gidlund, M. Industrial Internet of Things: Challenges, Opportunities, and Directions. IEEE Trans. Ind. Infor. 2018, 14, 4724–4734. [Google Scholar] [CrossRef]

- Ahmed, A.; Valtiner, D.; Thomos, C.; Dielacher, F. Wireless connectivity in Industrial sensor and control networks: Challenges and issues in a real implementation for a smart production use-case. In Proceedings of the 2020 25th IEEE International Conference on Emerging Technologies and Factory Automation (ETFA), Vienna, Austria, 8–11 September 2020; Volume 1, pp. 302–309. [Google Scholar]

- Islam, K.; Shen, W.; Wang, X. Wireless Sensor Network Reliability and Security in Factory Automation: A Survey. IEEE Trans. Syst. Man Cybern. Part C Appl. Rev. 2012, 42, 1243–1256. [Google Scholar] [CrossRef]

- Lu, X.; Kim, I.H.; Xhafa, A.; Zhou, J. WSN for Machine Area Network applications. In Proceedings of the 2016 46th European Solid-State Device Research Conference (ESSDERC), Lausanne, Switzerland, 12–15 September 2016; pp. 23–28. [Google Scholar]

- Ding, X.; Tian, Y.; Yu, Y. A Real-Time Big Data Gathering Algorithm Based on Indoor Wireless Sensor Networks for Risk Analysis of Industrial Operations. IEEE Trans. Ind. Infor. 2015, 12, 1232–1242. [Google Scholar] [CrossRef]

- Rani, S.; Ahmed, S.H.; Talwar, R.; Malhotra, J. Can Sensors Collect Big Data? An Energy-Efficient Big Data Gathering Algorithm for a WSN. IEEE Trans. Ind. Infor. 2017, 13, 1961–1968. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).