Real Application For A Data Acquisition System From Sensors Based On Embedded Systems †

Abstract

:1. Introduction

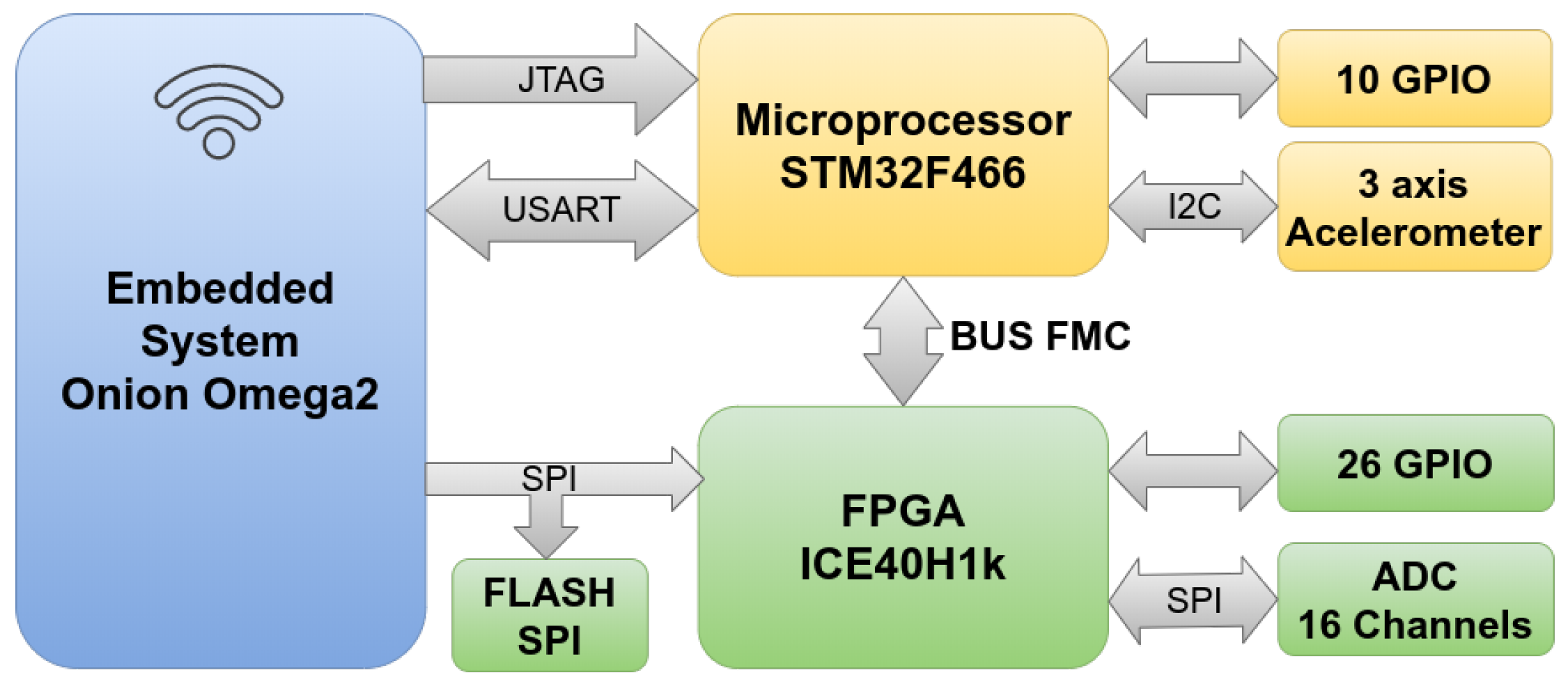

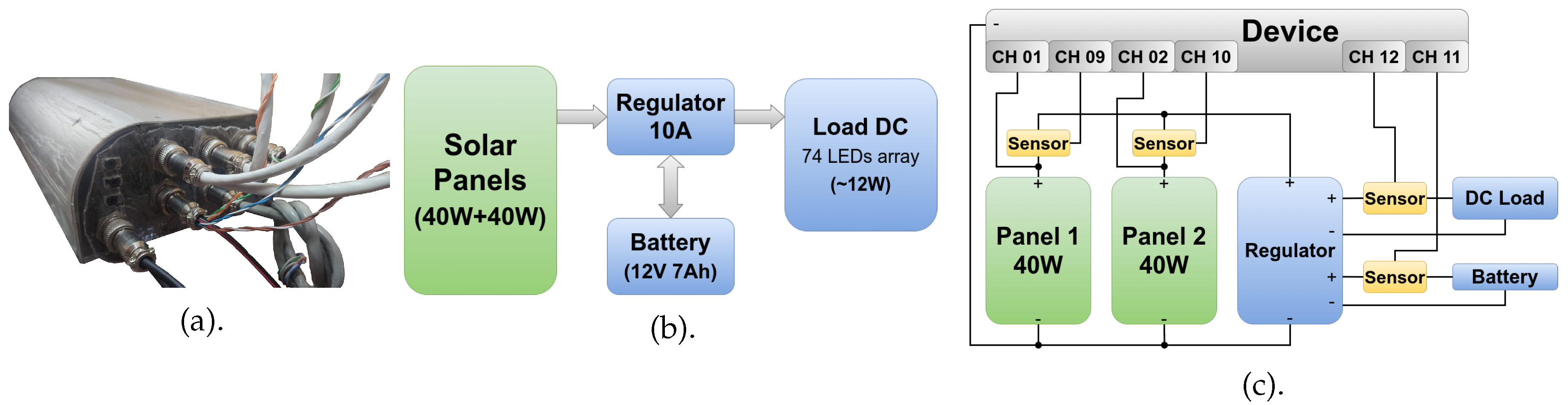

2. Materials and Methods

2.1. Tests Performed

2.1.1. Number of Messages Sent in 24 h

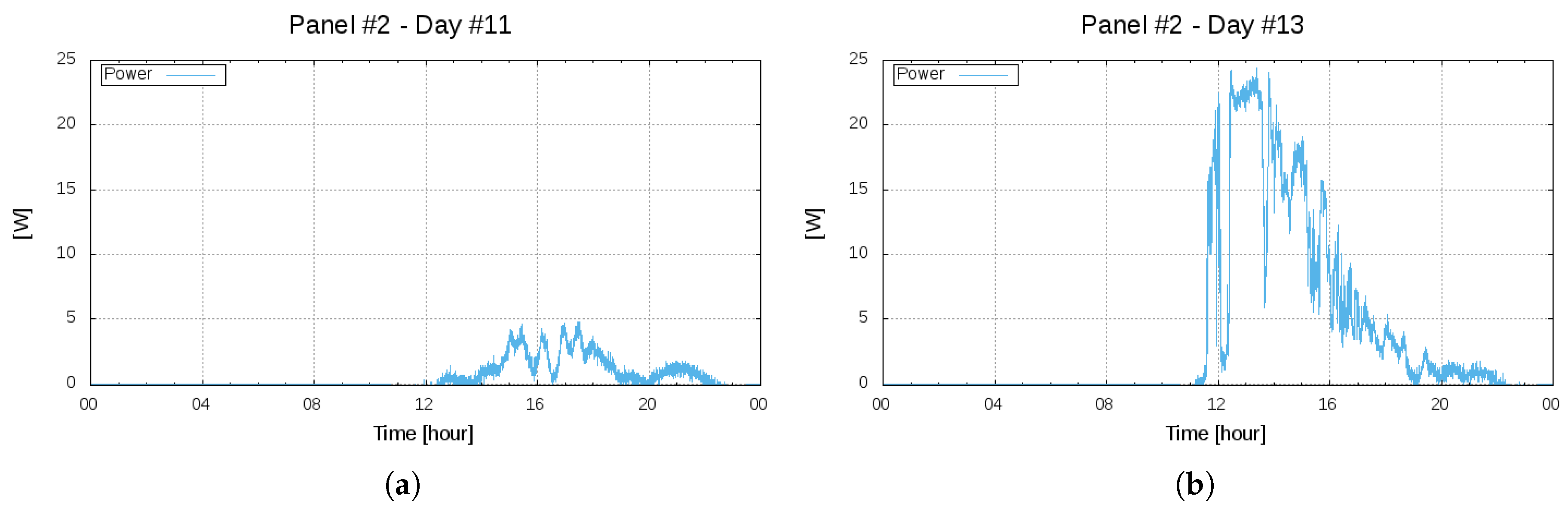

2.1.2. Difference between Cloudy Day and Sunny Day

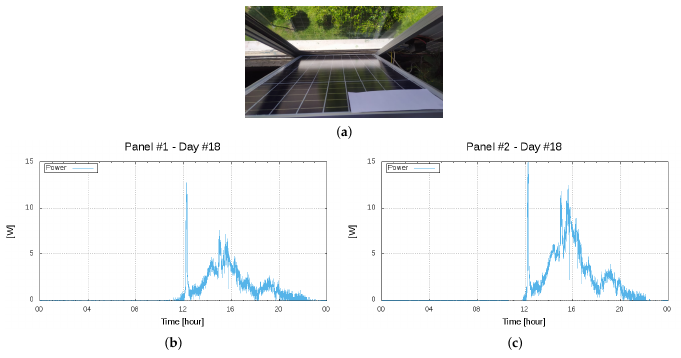

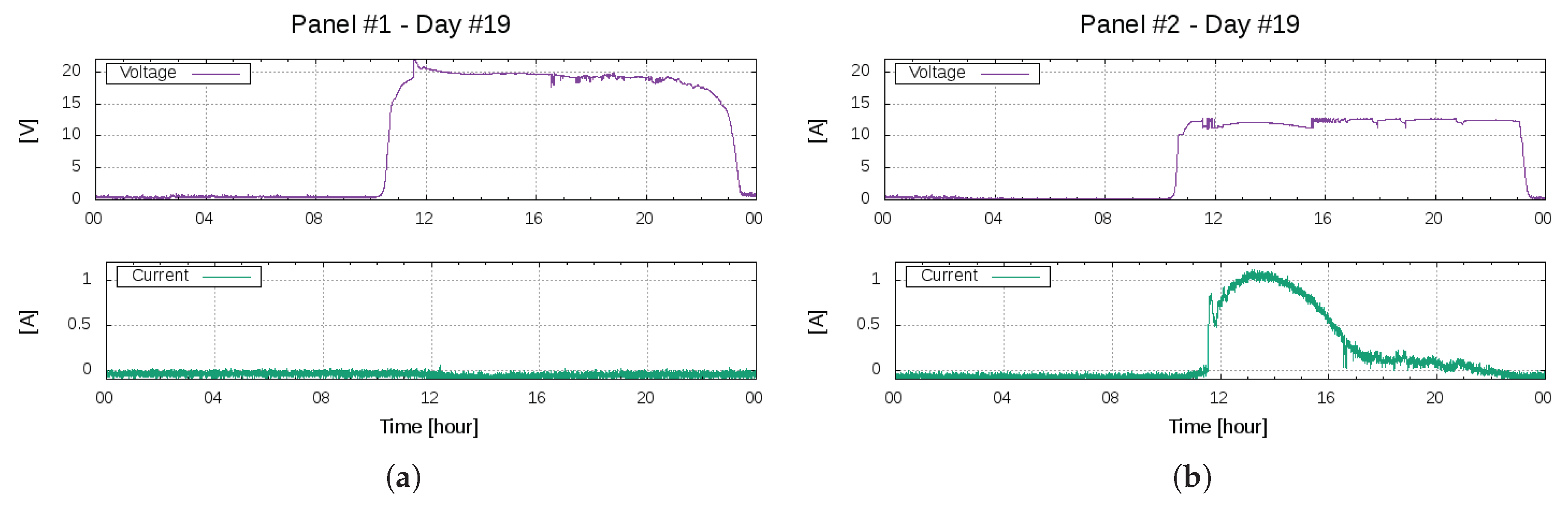

2.1.3. Partial Covering of Panel 1

2.1.4. Emulating an Open Circuit

3. Results

3.1. Amount of Messages Sent in 24 h

3.2. Difference between Cloudy Day and Sunny Day

3.3. Partial Covering of Panel 1

3.4. Emulating an Open Circuit

4. Conclusions

Conflicts of Interest

References

- Camacho-Olarte, J. Uso de Herramientas Libres para dise nar un Sistema de Monitoreo de Variables físicas de Bajo Costo Basado en Sistemas Embebidos; Universidad Nacional de Colombia: Bogotá, Colombia, 2020; p. 149. [Google Scholar]

- Sharma, S.; Jain, K.K.; Sharma, A. Solar Cells: In Research and Applications—A Review. Mater. Sci. Appl. 2015, 6, 1145–1155. [Google Scholar] [CrossRef]

- Raja Paul, M.M.; Mahalakshmi, R.; Karuppasamypandiyan, M.; Bhuvanesh, A.; Ganesh, R.J. Classification and Detection of Faults in Grid Connected Photovoltaic System. Int. J. Sci. Eng. Res. 2016, 7, 149–154. [Google Scholar]

- Bedi, G.; Venayagamoorthy, G.K.; Singh, R.; Brooks, R.R.; Wang, K. Review of Internet of Things (IoT) in Electric Power and Energy Systems. IEEE Internet Things J. 2018, 5, 847–870. [Google Scholar] [CrossRef]

- Shafique, K.; Khawaja, B.A.; Sabir, F.; Qazi, S.; Mustaqim, M. Internet of Things (IoT) for Next-Generation Smart Systems: A Review of Current Challenges, Future Trends and Prospects for Emerging 5G-IoT Scenarios. IEEE Access 2020, 8, 23022–23040. [Google Scholar] [CrossRef]

- Chernyshev, M.; Baig, Z.; Bello, O.; Zeadally, S. Internet of Things (IoT): Research, Simulators, and Testbeds. IEEE Internet Things J. 2018, 5, 1637–1647. [Google Scholar] [CrossRef]

- Acellent. Smarter Structures, Safer World. 2018. Available online: http://www.acellent.com/en/hardware/ (accessed on 2 October 2020).

- Mageba. Monitoreo Estructural. 2018. Available online: https://www.mageba-group.com/sk/data/docs/en_SK/2584/PROSPECT-ROBO-CONTROL-sytems-overview-ch-en.pdf?v=1.1 (accessed on 2 October 2020).

- Digitexx. Digitexx Software for Structural Health Monitoring. 2017. Available online: http://digitexx.website2.me/semi-permanent-to-permanent (accessed on 2 October 2020).

- Anand, A.; Krishna, A.; Tiwari, R.; Sharma, R. Comparative Analysis between Proprietary Software VS. In Open-Source Software VS. Free Software. In Proceedings of the 2018 Fifth International Conference on Parallel, Distributed and Grid Computing (PDGC), Solan Himachal Pradesh, India, 20–22 December 2018; pp. 144–147. [Google Scholar]

- Wang, Y.J. A Summary of Research on the Linux Operating System. In Advanced Materials Research; MEMS and Mechanics; Trans Tech Publications Ltd.: Stafa-Zurich, Switzerland, 2013; Volume 705, pp. 565–568. [Google Scholar] [CrossRef]

- Wolf, C.; Lasser, M. Project IceStorm. 2019. Available online: http://www.clifford.at/icestorm/ (accessed on 2 October 2020).

- Shah, D.; Hung, E.; Wolf, C.; Bazanski, S.; Gisselquist, D.; Milanovic, M. Yosys+nextpnr: An Open Source Framework from Verilog to Bitstream for Commercial FPGAs. In Proceedings of the 2019 IEEE 27th Annual International Symposium on Field-Programmable Custom Computing Machines (FCCM), San Diego, CA, USA, 28 April–1 May 2019; pp. 1–4. [Google Scholar] [CrossRef]

- Rath, D. Design and Implementation of an On-Chip Debug Solution for Embedded Target Systems Based on the ARM7 and ARM9 Family. Ph.D. Thesis, University of Applied Sciences Augsburg, Augsburg, Germany, 2005. [Google Scholar]

| Day | Received | Missing | Rate |

|---|---|---|---|

| 1 | 8196 | 12 | 99.85% |

| 3 | 8208 | 0 | 100% |

| 6 | 8128 | 80 | 99.03% |

| 9 | 8061 | 147 | 98.21% |

| 14 | 8205 | 3 | 99.96% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Camacho-Olarte, J.; Burgos, D.A.T. Real Application For A Data Acquisition System From Sensors Based On Embedded Systems. Eng. Proc. 2020, 2, 25. https://doi.org/10.3390/ecsa-7-08275

Camacho-Olarte J, Burgos DAT. Real Application For A Data Acquisition System From Sensors Based On Embedded Systems. Engineering Proceedings. 2020; 2(1):25. https://doi.org/10.3390/ecsa-7-08275

Chicago/Turabian StyleCamacho-Olarte, Jaiber, and Diego Alexander Tibaduiza Burgos. 2020. "Real Application For A Data Acquisition System From Sensors Based On Embedded Systems" Engineering Proceedings 2, no. 1: 25. https://doi.org/10.3390/ecsa-7-08275

APA StyleCamacho-Olarte, J., & Burgos, D. A. T. (2020). Real Application For A Data Acquisition System From Sensors Based On Embedded Systems. Engineering Proceedings, 2(1), 25. https://doi.org/10.3390/ecsa-7-08275