Fast and Accurate Determination of Minute Ochratoxin A Levels in Cereal Flours: Towards Application at the Field †

Abstract

:1. Introduction

2. Materials and Methods

2.1. Reagents and Instrumentation

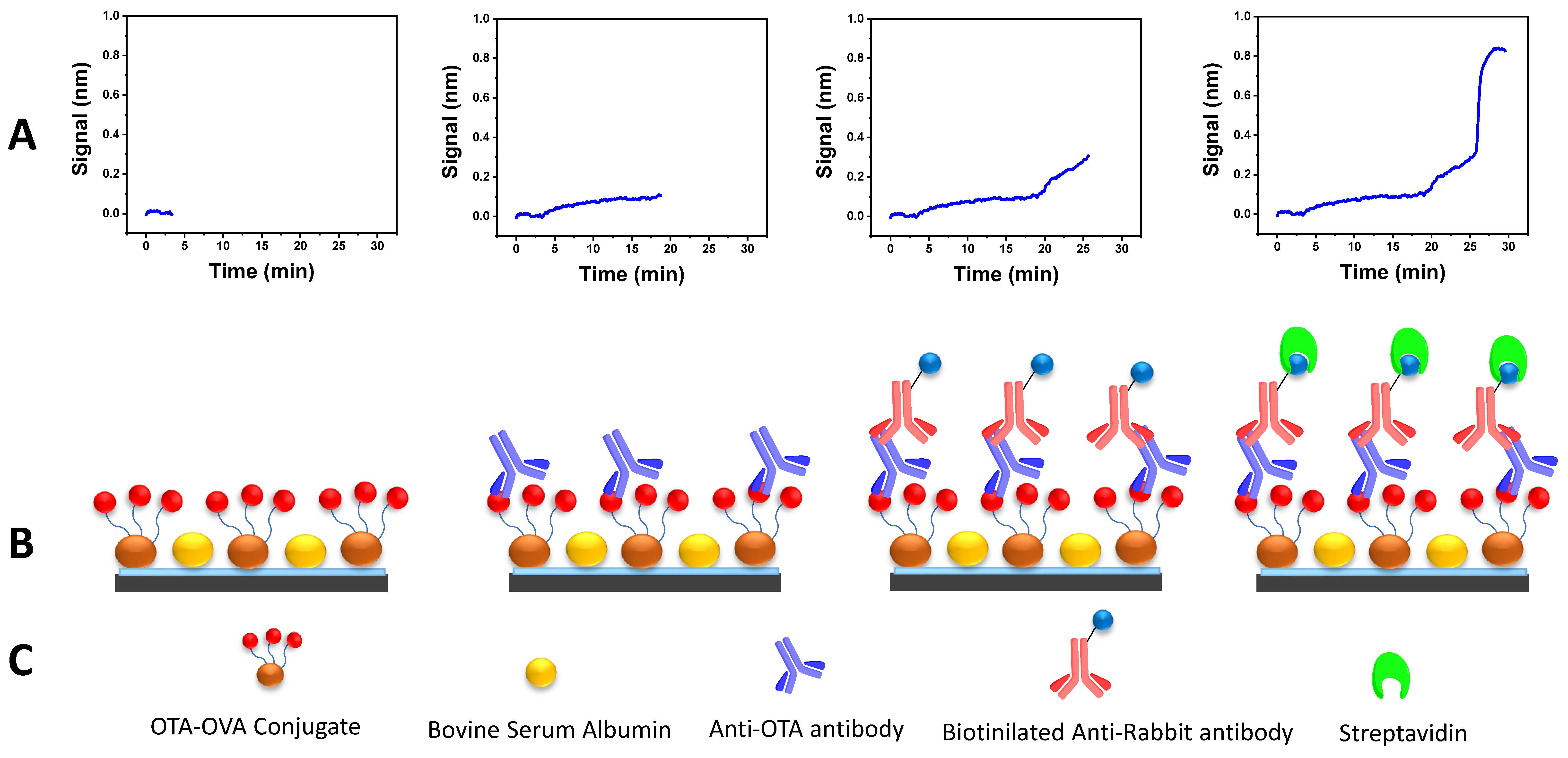

2.2. Chip Biofunctionalization and Assay Protocol

3. Results and Discussion

3.1. WLRS Assay Optimization

3.2. WLRS Assay Characteristics

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Weidenbörner, M. Encyclopedia of Food Mycotoxins, 1st ed.; Springer: Berlin/Heidelberg, Germany, 2001. [Google Scholar]

- Jørgensen, K. Occurrence of ochratoxin A in commodities and processed food—A review of EU occurrence data. Food Addit. Contam. 2005, 22 (Suppl. 1), 26–30. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ostry, V.; Malir, F.; Toman, J.; Grosse, Y. Mycotoxins as human carcinogens-the IARC Monographs classification. Mycotoxin Res. 2017, 33, 65–73. [Google Scholar] [CrossRef] [PubMed]

- Commission Regulation (EC) No. 1881/2006 setting maximum levels for certain contaminants in foodstuffs. Off. J. Eur. Union 2006, L 364/5, 5–24.

- Skarkova, J.; Ostry, V.; Malir, F.; Roubal, T. Determination of Ochratoxin A in Food by High Performance Liquid Chromatography. Anal. Lett. 2013, 46, 1495–1504. [Google Scholar] [CrossRef]

- Li, P.; Zhang, Z.; Hu, X.; Zhang, Q. Advanced hyphenated chromatographic-mass spectrometry in mycotoxin determination: Current status and prospects. Mass Spectrom. Rev. 2013, 32, 420–452. [Google Scholar] [CrossRef] [PubMed]

- Srinivasan, B.; Tung, S. Development and Applications of Portable Biosensors. J. Lab. Autom. 2015, 20, 365–389. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tsougeni, K.; Ellinas, K.; Koukouvinos, G.; Petrou, P.S.; Tserepi, A.; Kakabakos, S.E.; Gogolides, E. Three-dimensional (3D) plasma micro-nanotextured slides for high performance biomolecule microarrays: Comparison with epoxy-silane coated glass slides. Colloids Surf. B Biointerfaces 2018, 165, 270–277. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Karachaliou, C.-E.; Koukouvinos, G.; Pissaridi, K.; Ladikos, D.; Goustouridis, D.; Raptis, I.; Livaniou, E.; Kakabakos, S.; Petrou, P. Fast and Accurate Determination of Minute Ochratoxin A Levels in Cereal Flours: Towards Application at the Field. Eng. Proc. 2022, 16, 14. https://doi.org/10.3390/IECB2022-12270

Karachaliou C-E, Koukouvinos G, Pissaridi K, Ladikos D, Goustouridis D, Raptis I, Livaniou E, Kakabakos S, Petrou P. Fast and Accurate Determination of Minute Ochratoxin A Levels in Cereal Flours: Towards Application at the Field. Engineering Proceedings. 2022; 16(1):14. https://doi.org/10.3390/IECB2022-12270

Chicago/Turabian StyleKarachaliou, Chrysoula-Evangelia, Georgios Koukouvinos, Katerina Pissaridi, Dimitris Ladikos, Dimitris Goustouridis, Ioannis Raptis, Evangelia Livaniou, Sotirios Kakabakos, and Panagiota Petrou. 2022. "Fast and Accurate Determination of Minute Ochratoxin A Levels in Cereal Flours: Towards Application at the Field" Engineering Proceedings 16, no. 1: 14. https://doi.org/10.3390/IECB2022-12270

APA StyleKarachaliou, C.-E., Koukouvinos, G., Pissaridi, K., Ladikos, D., Goustouridis, D., Raptis, I., Livaniou, E., Kakabakos, S., & Petrou, P. (2022). Fast and Accurate Determination of Minute Ochratoxin A Levels in Cereal Flours: Towards Application at the Field. Engineering Proceedings, 16(1), 14. https://doi.org/10.3390/IECB2022-12270