1. Introduction

Ref. [

1] Solar energy has gained a lot of importance in this eco-friendly, sustainable environment and energy demand for its users is increasing day by day. This energy can be used to power up the refrigerator. Frequent and long-term power disruption can cause difficulties in developing countries to maintain and preserve blood banks, vaccines and perishable food. Locations that are very far away from the supply grids can be affected immensely.

In refrigeration, the temperature of the components is being lowered below the immediate temperature to reserve or make them suitable for future use. The growth of microorganisms is greatly reduced when food is stored in the refrigerator at temperatures below freezing. Ref. [

2] In this regard, complete failure of cells and fiber in nutrition is prevented. Additionally, the fluid loss and rate of rust through evaporation is reduced. With a constant temperature range, the refrigerator provides significant injection strength and blood quality [

3,

4].

The objective of this article is to demonstrate the importance of combining renewable energy sources to power up the refrigerator system, which are of low cost and high efficiency. This was achieved using a DC compressor that also runs directly on the demarcated voltage through the battery or the charge controller through the sun, thus eliminating the components of the inverter. Microprocessor-based control and monitoring systems provide energy savings and flexible use of the refrigerator [

5,

6].

The remaining parts of the paper are as follows: The required Methods and Materials are presented in

Section 2. In

Section 3, the purpose of content size is calculated and presented. The results are presented in

Section 4, and

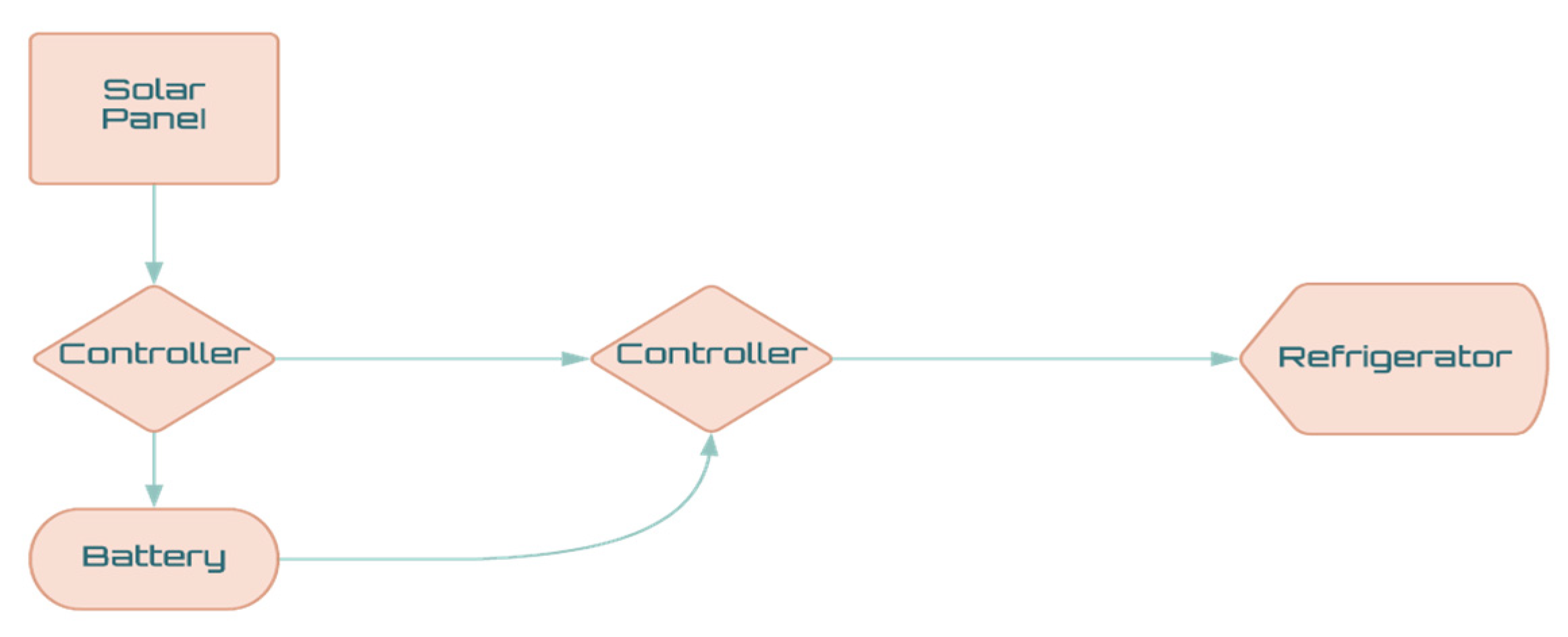

Section 5 covers the endings and definitions of the solar refrigerator system of the solar panel that collects the solar energy. Solar panels consist of photovoltaic cells that convert solar light into electrical energy and this energy is stored in batteries. The electricity is supplied directly through the solar panel in normal conditions, the excess power is supplied by the battery when the output power of the solar panels decreases. The battery recharges when more electricity is generated from solar panels. The 12V DC is applied as output supply from batteries and solar panels. A total of 300 W or 600 W of electricity is produced by a typical solar panel, and it depends upon the size of the refrigerator required [

7]. The compressor is connected to a voltage regulator battery to convert a low voltage DC supply to a high voltage AC supply. It is effective and beneficial to utilize the AC supply compressor as it can also run-on household power supply. Few of the solar refrigerators use compressors that can operate on DC voltage directly. This research work is related to the different renewable energy resources where people are also focusing on developing the applications that use renewable energy [

8]. This work is used to generate electricity for cooling; therefore, this is achievable work. This research project is cost effective and provides benefits for future applications.

2. Methods and Materials

It has a simple refrigerant (Ra134) with flat plate pre-compressor having a maximum temperature of 120 °C. Heat is packed in this collector and contains copper vessels that have refrigerant. The refrigerant is compressed by heat packed in a flat plate collector. To flow the refrigeration in one direction, a small 1/8 HP 12 V DC compressor is used which is energized by a 100-watt PV system. The greater the solar radiation is outside in the environment, the greater its cooling will be. A 150-watts solar refrigerator will approximately provide a temperature of 2 °C. Materials specifications are:

Flat plate 1.64 ft3

Evaporator temperature = 2 °C

Evaporator Size = 1.64 ft3

DC compressor 1/10th HP

Refrigerant: R134a, PV = 150 Watt

This project totally works on solar energy and have a battery backup.

Figure 1 shows the simple block diagram in which a solar panel, battery and controller are used for this work.

The procedure is divided into five stages: preparation, research, examination, designing and implementation. The planning phase is the basic process of understanding why a system should be built and deciding where to build it. This step will ensure that all activities will be on time as the system develops. The research phase is where all the relevant information for this project is to be gathered. The study includes a feasibility study on solar geometry, solar energy, feasibility of using solar energy for cooling, steam cooler systems, heat sources and cooling load. Analysis is where many factors/ideas are considered before implementing the system. This phase includes a description of the input and output process, cooling load analysis, device size analysis and equipment space analysis. The design phase determines how the system will work. All the mechanisms required for a steam powered solar cooler system must be stated. The design should be analyzed for best performance with low rate and low power.

3. Solar PV System Sizing

3.1. Determine Power Consumption Demands

The first step in designing a solar PV system is to find out the total power and energy consumption of all loads that need to be supplied by the solar PV system as follows:

where Ced is the hourly energy demand and hr is the number of hours.

3.2. Calculate Total Watt-Hours per Day for Each Appliance Used

Add the Watt-hours needed for all appliances together to get the total Watt-hours per day which must be delivered to the appliances:

3.3. Calculate Total Watt-Hours per Day Needed from the PV Modules

Multiply the total appliance’s Watt-hours per day times 1.3 (the energy lost in the system) to get the total Watt-hours per day which must be provided by the panels:

3.4. Battery Sizing

To find out the size of battery, calculate as follows:

where Daut is the number of days of sovereignty (i.e., the number of days the battery bank should supply without charging).

Nonviolent energy stored:

The number of modules in series is given by (7) and the number of modules in parallel is given by:

4. Results and Discussion

The result of the first test carried out determines the time taken for water to freeze:

Realistic view of the refrigerator with a solar panel, charge controller and battery. Power sterilization to operate the refrigerator depends on its actual temperature and the set value of the temperature to be stored.

Table 1 shows the results on testing the refrigerator on a typical day, after charging the battery volt is 12.77 at about 7:00 a.m., on switching ON the refrigerator the starting current is about 5.30 A and the power consumed was 67.16 W that was measured by multimeter. This reading was measured when the refrigeration early temperature was about 26 °C and the predetermined temperature is 9 °C as programmed into the Microprocessor. As time goes on at night, the battery voltage drops because the sun was no longer there to charge. It has also been observed that as the temperature drops, the power consumption also decreases while the default temperature is maintained to a considerable extent. The battery starts to charge as soon as the sun rises the next day. The results show that, once the default temperature is reached, the power consumption is quite stable, and when the battery is fully charged, the system can be continued overnight.

5. Conclusions

To reduce costs, renewable energy can be used for DC refrigerators and this article shows this applicability. In this work, losses are minimized, and power consumption is reduced as an average of 30.21 W. The operation of the system is enhanced and made efficient by using monitoring and control of the refrigerator. Power supply to the refrigerator was disconnected whenever the open, empty unit or overload was detected. The devices used in homes, workplaces, hospitals, etc., can be directly powered with low power using DC sources. DC power refrigerators should be promoted in rural areas and in hospitals. The cooling effect is not good in this work because casing is not airtight, and it does not give an ideal system. To remove this issue, a new approach is advised to make better casing.

Author Contributions

Conceptualization, M.H.N. and M.W.J.; methodology, M.H.N. and U.R.; validation, M.H.N., T.R., U.R.; formal analysis, M.W.J.; investigation, M.H.N.; data curation, T.R., U.R.; writing—original draft preparation, M.H.N., M.W.J.; writing—review and editing, A.M., M.W.J.; supervision, M.W.J. All authors have read and agreed to the published version of manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- American Society for Heating: Fundamental Handbook, Refrigeration and Air Conditioning for Engineers; Ashrae Publishing: Peachtree Corners, GA, USA, 1977; p. 272.

- Anderson, O.E. Refrigeration in America; Princeton University Press: Princeton, NJ, USA, 2015. [Google Scholar]

- Aprea, C.; Mastrullo, R.; De Rossi, F. Behaviour and performances of R502 alternative working fluids in refrigerating plants. Int. J. Refrig. 1996, 19, 257–263. [Google Scholar] [CrossRef]

- Wilson, D.P.; Basu, R.S. Thermodynamic properties of a new stratospherically safe working fluid-refrigerant 134a. ASHRAE Trans. 1988, 94, 2095–2118. [Google Scholar]

- Ungar, M.P. Fresh: A Perishable History; Harvard University Press: Cambridge, MA, USA, 2010; pp. 300–302. [Google Scholar]

- Neuburger, A. The Technical Arts and Science of the Ancients; Kegan Paul: London, UK, 2003; p. 122. [Google Scholar]

- Rajput, R.K. A Textbook of Engineering Thermodynamics; Laxmi Publications: New Delhi, India, 2005. [Google Scholar]

- Deshmukh, S.D.; Kalbande, S.R. Performance evaluation of photovoltaic system designed for DC refrigerator. Int. J. Sci. Res. 2015, 4, 18–23. [Google Scholar]

| Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).