Experimental Study on the Particle Flow and Validation of the Results Using TIS Model in a Continuously Operated Horizontal Fluidized Bed †

Abstract

:1. Introduction

2. Experimental Procedure

3. Results and Discussion

3.1. Effect of Solid Feed Rate on Dispersion Coefficient and Bodenstein Number

3.2. Effect of Baffle Gap Height on Dispersion Coefficient and Bodenstein Number

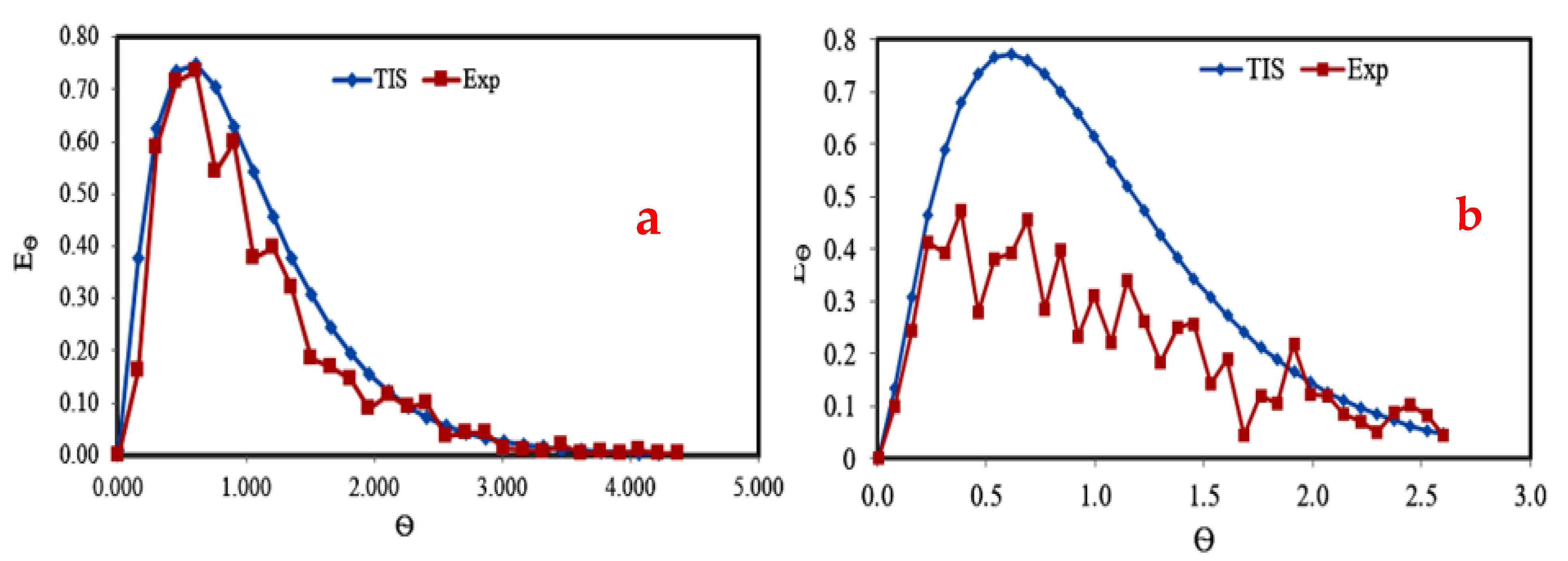

4. Analysis with Tank in Series Model

5. Conclusions

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hua, L.; Wang, J. Residence time distribution of particles in circulating fluidized bed risers. Chem. Eng. Sci. 2018, 186, 168–190. [Google Scholar] [CrossRef]

- Bachmann, P.; Tsotsas, E. Analysis of residence time distribution data in horizontal fluidized beds. Procedia Eng. 2015, 102, 790–798. [Google Scholar] [CrossRef] [Green Version]

- Srinivasakannan, C.; Al Shoaibi, A.; Balasubramanian, N. Continuous fluidized bed drying with and without internals: Kinetic model. Chem. Biochem. Eng. Q. 2012, 26, 97–104. [Google Scholar]

- Khanali, M.; Rafiee, S.; Jafari, A.; Banisharif, A. Study of residence time distribution of rough rice in a plug flow fluid bed dryer. Int. J. Adv. Sci. Technol. 2012, 48, 103–114. [Google Scholar]

- Avidan, A.; Yerushalmi, J. Solids mixing in an expanded top fluid bed. AIChE J. 1985, 31, 835–841. [Google Scholar] [CrossRef]

- Borodulya, V.; Epanov, Y.G.; Teplitskii, Y.S. Horizontal particle mixing in a free fluidized bed. J. Eng. Phys. 1982, 42, 528–533. [Google Scholar] [CrossRef]

- Levenspiel, O. Tracer Technology: Modeling the Flow of Fluids; Springer Science & Business Media: New York, NY, USA; Dordrecht, The Netherlands; Heidelberg, Germany; London, UK, 2011; Volume 96. [Google Scholar]

- Satija, S.; Zucker, I. Hydrodynamics of vibro-fluidized beds. Dry. Technol. 1986, 4, 19–43. [Google Scholar] [CrossRef]

| Run | F.R | G.H | Mpro | Mh | BO | D × 10−4 | N | |||

|---|---|---|---|---|---|---|---|---|---|---|

| kg/min | cm | kg | kg | s | s2 | - | - | m2/s | - | |

| 1 | 0.5 | 0.4 | 30.183 | 8.407 | 938 | 43,879,203 | 0.4986 | 2.56 | 4.149 | 2.0053 |

| 2 | 1.0 | 0.4 | 32.164 | 9.638 | 563 | 140,052.49 | 0.4415 | 3.15 | 5.62 | 2.2648 |

| 3 | 1.5 | 0.4 | 43.063 | 9.765 | 350 | 42,313.89 | 0.3455 | 4.53 | 6.30 | 2.8942 |

| 4 | 0.5 | 0.6 | 17.382 | 8.799 | 785 | 245,469.05 | 0.3981 | 3.709 | 3.434 | 2.5114 |

| 5 | 1.0 | 0.6 | 28.917 | 9.041 | 544 | 142,297.97 | 0.4870 | 2.679 | 6.906 | 2.053 |

| 6 | 1.5 | 0.6 | 44.068 | 9.933 | 398 | 70,424.91 | 0.4431 | 3.137 | 7.995 | 2.256 |

| 7 | 0.5 | 1.2 | 15.014 | 8.843 | 695.8 | 201,334.77 | 0.4157 | 3.47 | 4.14 | 2.405 |

| 8 | 1.0 | 1.2 | 30.285 | 9.556 | 463 | 130,478.44 | 0.6070 | 1.72 | 12.501 | 1.647 |

| 9 | 1.5 | 1.2 | 40.887 | 9.297 | 402 | 82,877.70 | 0.5117 | 2.458 | 10.11 | 1.953 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ali, A.; Abbas, G.; Ayub, K.S.; Imran, A.; Ali, L.; Zaid, M. Experimental Study on the Particle Flow and Validation of the Results Using TIS Model in a Continuously Operated Horizontal Fluidized Bed. Eng. Proc. 2021, 12, 80. https://doi.org/10.3390/engproc2021012080

Ali A, Abbas G, Ayub KS, Imran A, Ali L, Zaid M. Experimental Study on the Particle Flow and Validation of the Results Using TIS Model in a Continuously Operated Horizontal Fluidized Bed. Engineering Proceedings. 2021; 12(1):80. https://doi.org/10.3390/engproc2021012080

Chicago/Turabian StyleAli, Asad, Ghulam Abbas, Khurram Shahzad Ayub, Aiza Imran, Liaqat Ali, and Muhammad Zaid. 2021. "Experimental Study on the Particle Flow and Validation of the Results Using TIS Model in a Continuously Operated Horizontal Fluidized Bed" Engineering Proceedings 12, no. 1: 80. https://doi.org/10.3390/engproc2021012080

APA StyleAli, A., Abbas, G., Ayub, K. S., Imran, A., Ali, L., & Zaid, M. (2021). Experimental Study on the Particle Flow and Validation of the Results Using TIS Model in a Continuously Operated Horizontal Fluidized Bed. Engineering Proceedings, 12(1), 80. https://doi.org/10.3390/engproc2021012080