IOT Based Fault Detection and Protection of Power Transformer in the Smart Grid †

Abstract

:1. Introduction

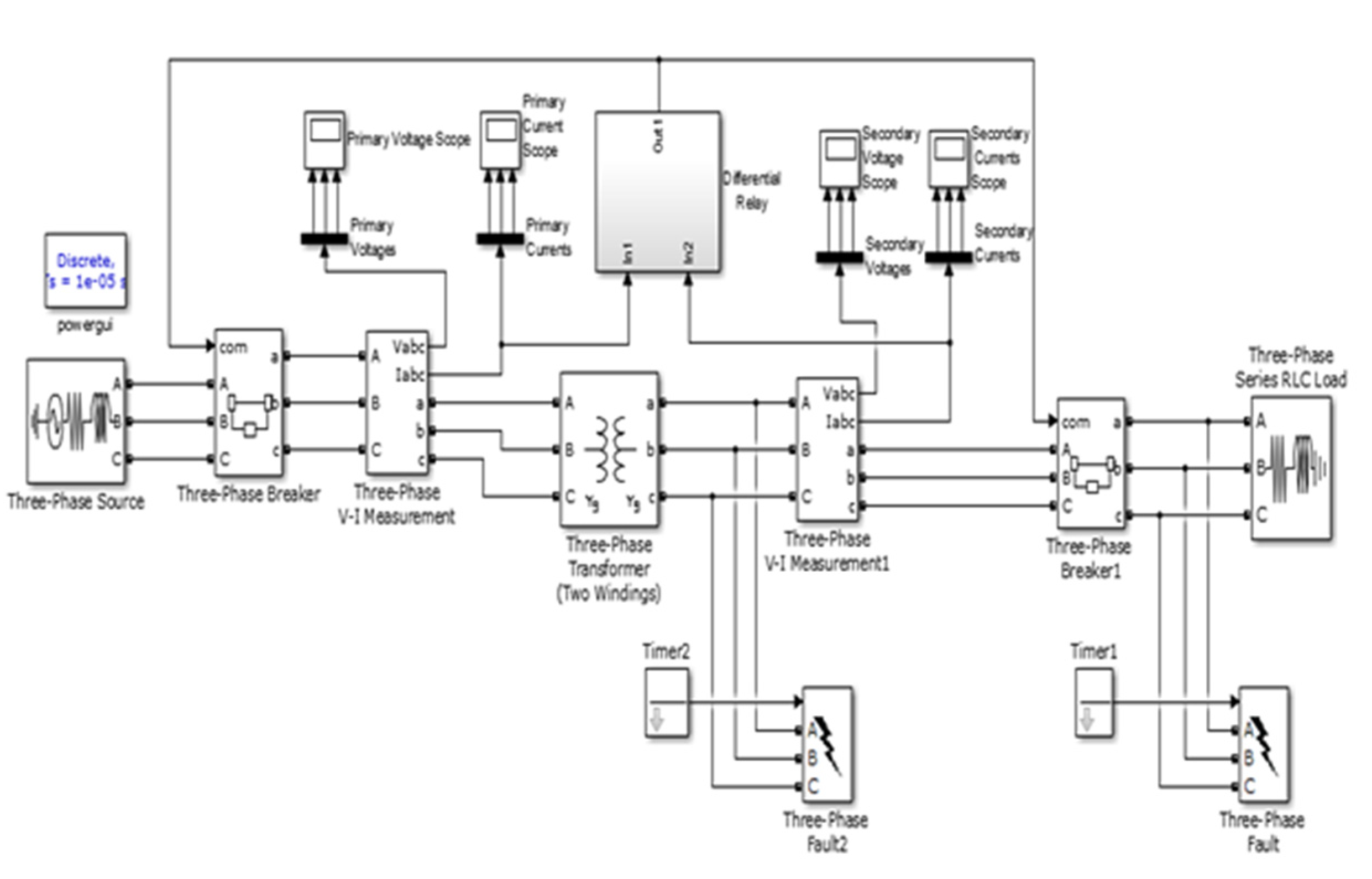

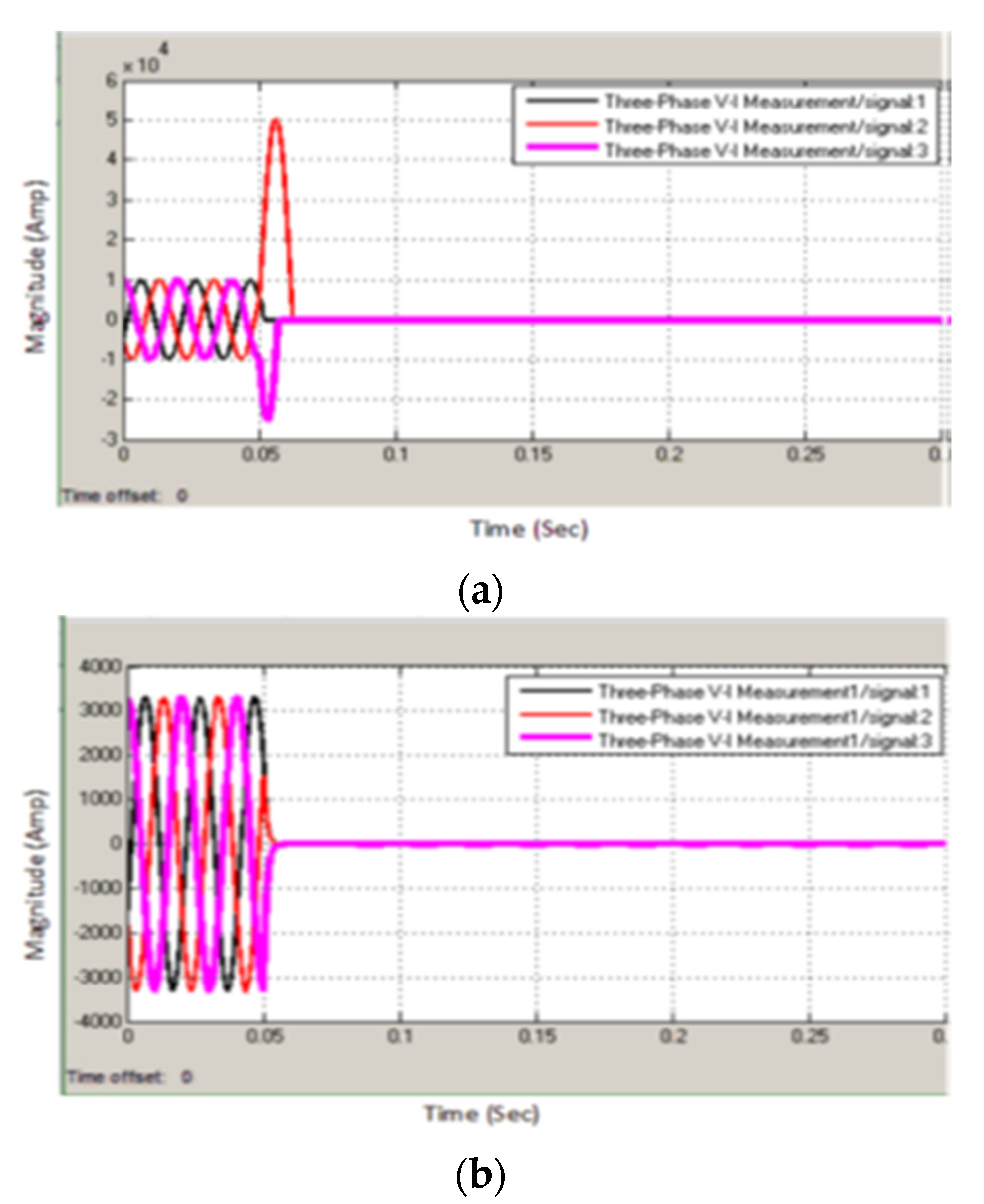

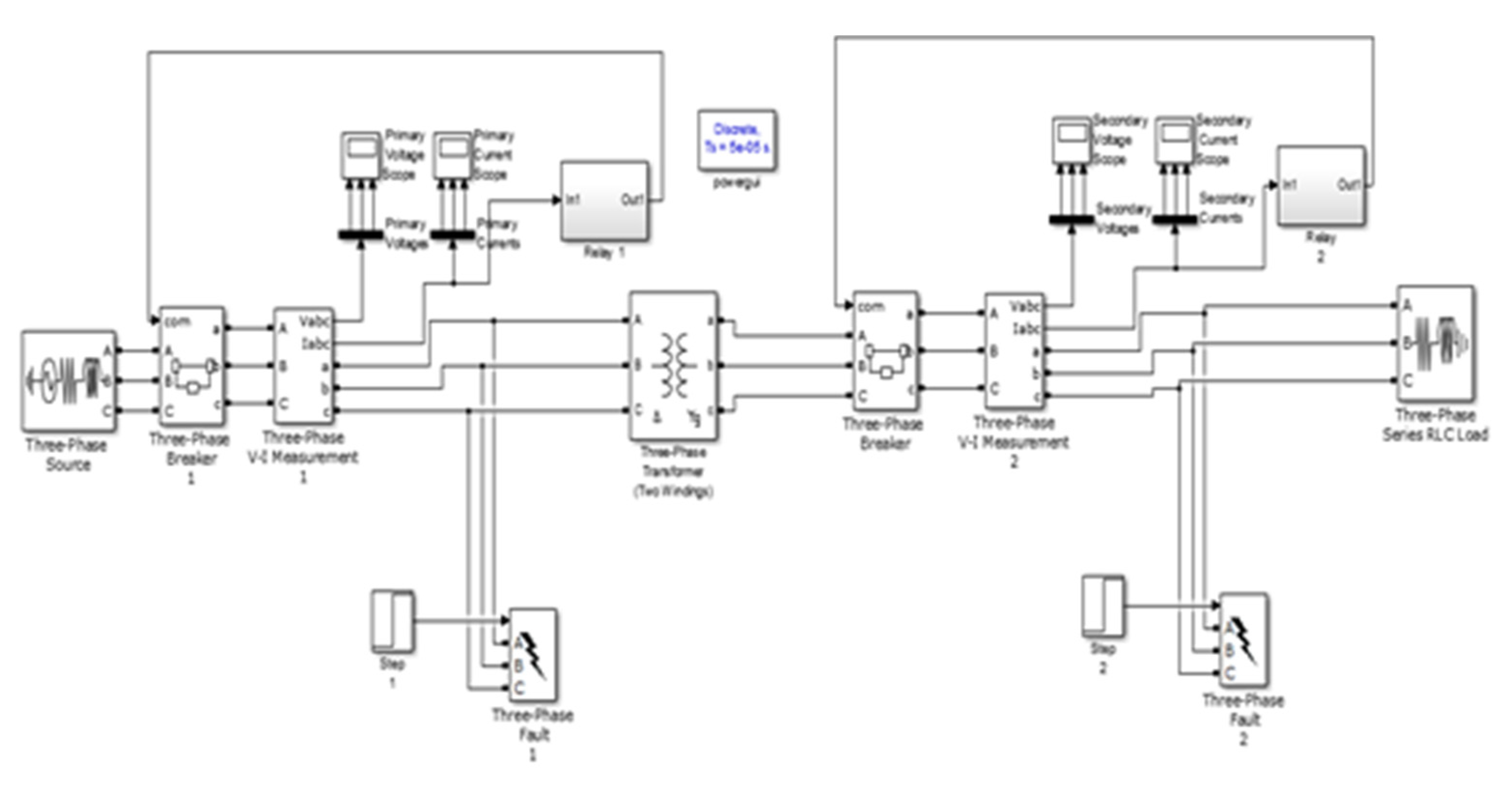

2. Proposed IoT-Based Protection Scheme for Power Transformers

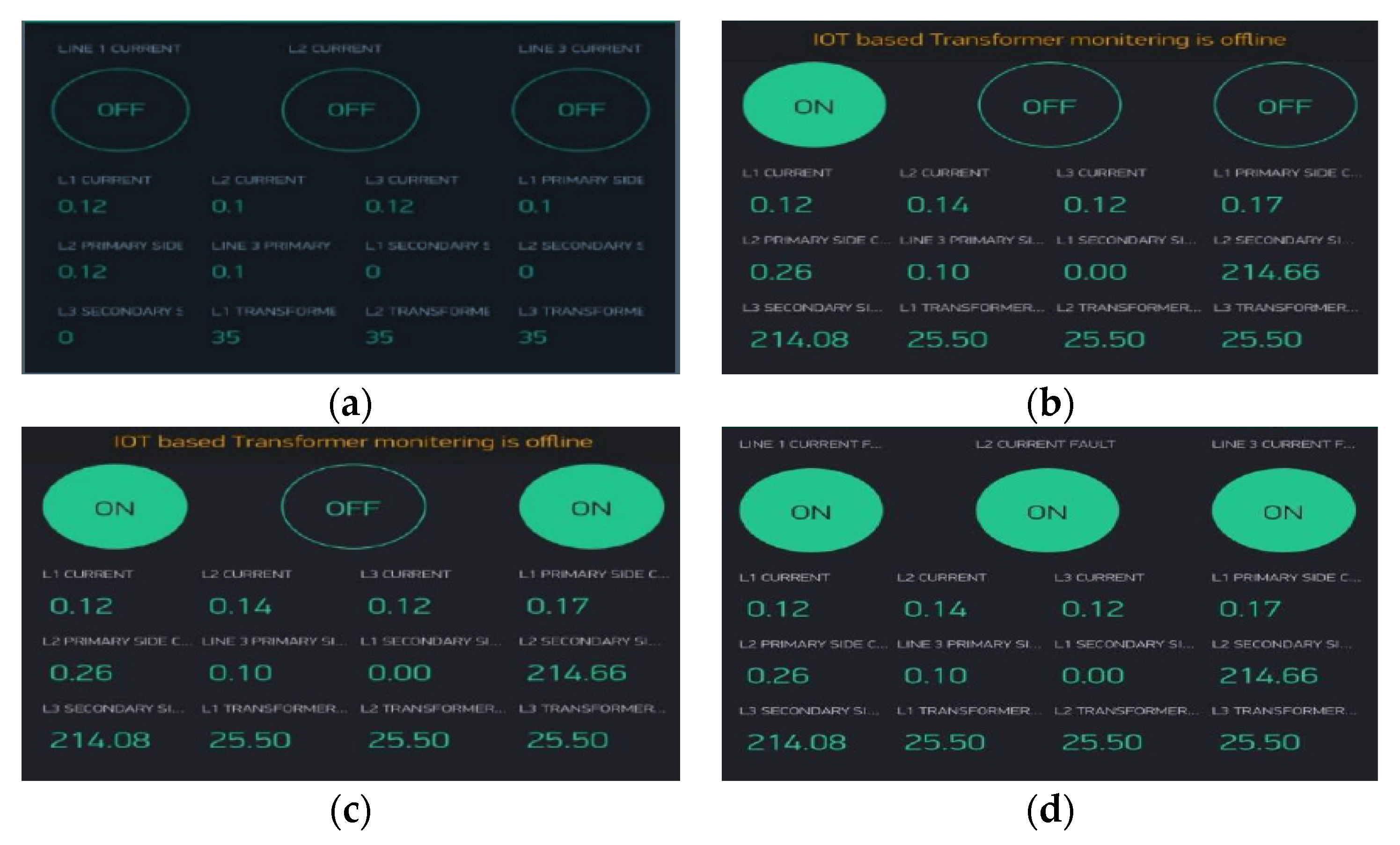

2.1. Outputs on Blynk App on a PC or Mobile Phone

2.2. Comparison with Other Relays

3. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rizwan, M.; Hong, L.; Waseem, M.; Shu, W. Sustainable protection coordination in presence of distributed generation with distributed network. Int. Trans. Electr. Energy Syst. 2020, 30, e12217. [Google Scholar] [CrossRef]

- Tajdinian, M.; Allahbakhshi, M.; Bagheri, A.; Samet, H.; Dehghanian, P.; Malik, O.P. An enhanced sub-cycle statistical algorithm for inrush and fault currents classification in differential protection schemes. Int. J. Electr. Power Energy Syst. 2020, 119, 105939. [Google Scholar] [CrossRef]

- Jamal, H.; Waseem, M.; Sajjad, I.A.; Anjum, A.; Khan, M.S. Low-Cost Feedback Control Thermal Protection System for 3-Phase Distribution Transformer Using Microcontroller. In Proceedings of the 2018 IEEE International Conference on Smart Energy Grid Engineering (SEGE), Oshawa, ON, Canada, 12–15 August 2018; pp. 200–204. [Google Scholar]

- Rizwan, M.; Hong, L.; Waseem, M.; Ahmad, S.; Sharaf, M.; Shafiq, M. A Robust Adaptive Overcurrent Relay Coordination Scheme for Wind-Farm-Integrated Power Systems Based on Forecasting the Wind Dynamics for Smart Energy Systems. Appl. Sci. 2020, 10, 6318. [Google Scholar] [CrossRef]

- Iqbal, M.M.; Waseem, M.; Manan, A.; Liaqat, R.; Muqeet, A.; Wasaya, A. IoT-Enabled Smart Home Energy Management Strategy for DR Actions in Smart Grid Paradigm. In Proceedings of the 2021 International Bhurban Conference on Applied Sciences and Technologies (IBCAST), Islamabad, Pakistan, 12–16 January 2021; pp. 352–357. [Google Scholar]

- Waseem, M.; Lin, Z.; Liu, S.; Sajjad, I.A.; Aziz, T. Optimal GWCSO-based home appliances scheduling for demand response considering end-users comfort. Electr. Power Syst. Res. 2020, 187, 106477. [Google Scholar] [CrossRef]

- Aziz, T.; Lin, Z.; Waseem, M.; Liu, S. Review on optimization methodologies in transmission network reconfiguration of power systems for grid resilience. Int. Trans. Electr. Energy Syst. 2021, 31, e12704. [Google Scholar] [CrossRef]

- Iqbal, M.M.; Sajjad, I.A.; Manan, A.; Waseem, M.; Ali, A.; Sohail, A. Towards an Optimal Residential Home Energy Management in Presence of PV Generation, Energy Storage and Home to Grid Energy Exchange Framework. In Proceedings of the 2020 3rd International Conference on Computing, Mathematics and Engineering Technologies (iCoMET), Islamabad, Pakistan, 29–30 January 2020; pp. 1–7. [Google Scholar]

- Waseem, M.; Sajjad, I.A.; Chicco, G. Seasonal Effect on the Flexibility Assessment of Electrical Demand. In Proceedings of the 2018 53rd International Universities Power Engineering Conference (UPEC), Glasgow, UK, 4–7 September 2018; pp. 1–6. [Google Scholar]

- Wilcher, D. Learn Electronics with Arduino; Knowledge Rapid Series; Apress: New York, NY, USA, 2012. [Google Scholar]

- Usman, M.; Waseem, M.; Khan, D.; Manan, A.; Ullah, S.; Iqbal, M.M.; Faheem, Z.B. PD Based Cost Effective and Accurate Calorimeter Temperature Control and Measurement System. In Proceedings of the 2020 IEEE International Conference on Sustainable Engineering and Creative Computing (ICSECC), Cikarang, Indonesia, 16–17 December 2020; pp. 189–193. [Google Scholar]

- Naseem, A.; Alam, N. Protection of distribution transformer using Arduino platform. Sci. Int. 2015, 27, 403–406. [Google Scholar]

- Fayyaz, S.; Sattar, M.K.; Waseem, M.; Ashraf, M.U.; Ahmad, A.; Hussain, H.A.; Alsubhi, K. Solution of Combined Economic Emission Dispatch Problem Using Improved and Chaotic Population-Based Polar Bear Optimization Algorithm. IEEE Access 2021, 9, 56152–56167. [Google Scholar] [CrossRef]

| Sr. No. | Temperature (°C) | Output Voltage | Fan Status |

|---|---|---|---|

| 1 | 25 | 0.25 V | Off |

| 2 | 30 | 0.30 V | Off |

| 3 | 35 | 0.35 V | On |

| 4 | 40 | 0.40 V | On & system trips |

| Fault Types | Percentage Differential Relay | Buchholzs Relay | IDMT | Our Scheme |

|---|---|---|---|---|

| Over voltage | ● | ● | ● | ✓ |

| Over current | ● | ● | ✓ | ✓ |

| Differential | ✓ | ● | ● | ✓ |

| Thermal | ● | ✓ | ● | ✓ |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sattar, M.K.; Waseem, M.; Fayyaz, S.; Kalsoom, R.; Hussain, H.A.; Saddique, M.S. IOT Based Fault Detection and Protection of Power Transformer in the Smart Grid. Eng. Proc. 2021, 12, 7. https://doi.org/10.3390/engproc2021012007

Sattar MK, Waseem M, Fayyaz S, Kalsoom R, Hussain HA, Saddique MS. IOT Based Fault Detection and Protection of Power Transformer in the Smart Grid. Engineering Proceedings. 2021; 12(1):7. https://doi.org/10.3390/engproc2021012007

Chicago/Turabian StyleSattar, Muhammad Kashif, Muhammad Waseem, Saqib Fayyaz, Riffat Kalsoom, Hafiz Ashiq Hussain, and Muhammad Shahzar Saddique. 2021. "IOT Based Fault Detection and Protection of Power Transformer in the Smart Grid" Engineering Proceedings 12, no. 1: 7. https://doi.org/10.3390/engproc2021012007

APA StyleSattar, M. K., Waseem, M., Fayyaz, S., Kalsoom, R., Hussain, H. A., & Saddique, M. S. (2021). IOT Based Fault Detection and Protection of Power Transformer in the Smart Grid. Engineering Proceedings, 12(1), 7. https://doi.org/10.3390/engproc2021012007