Energy Assessment of a Combined Cycle Power Plant through Empirical and Computational Approaches: A Case Study †

Abstract

:1. Introduction

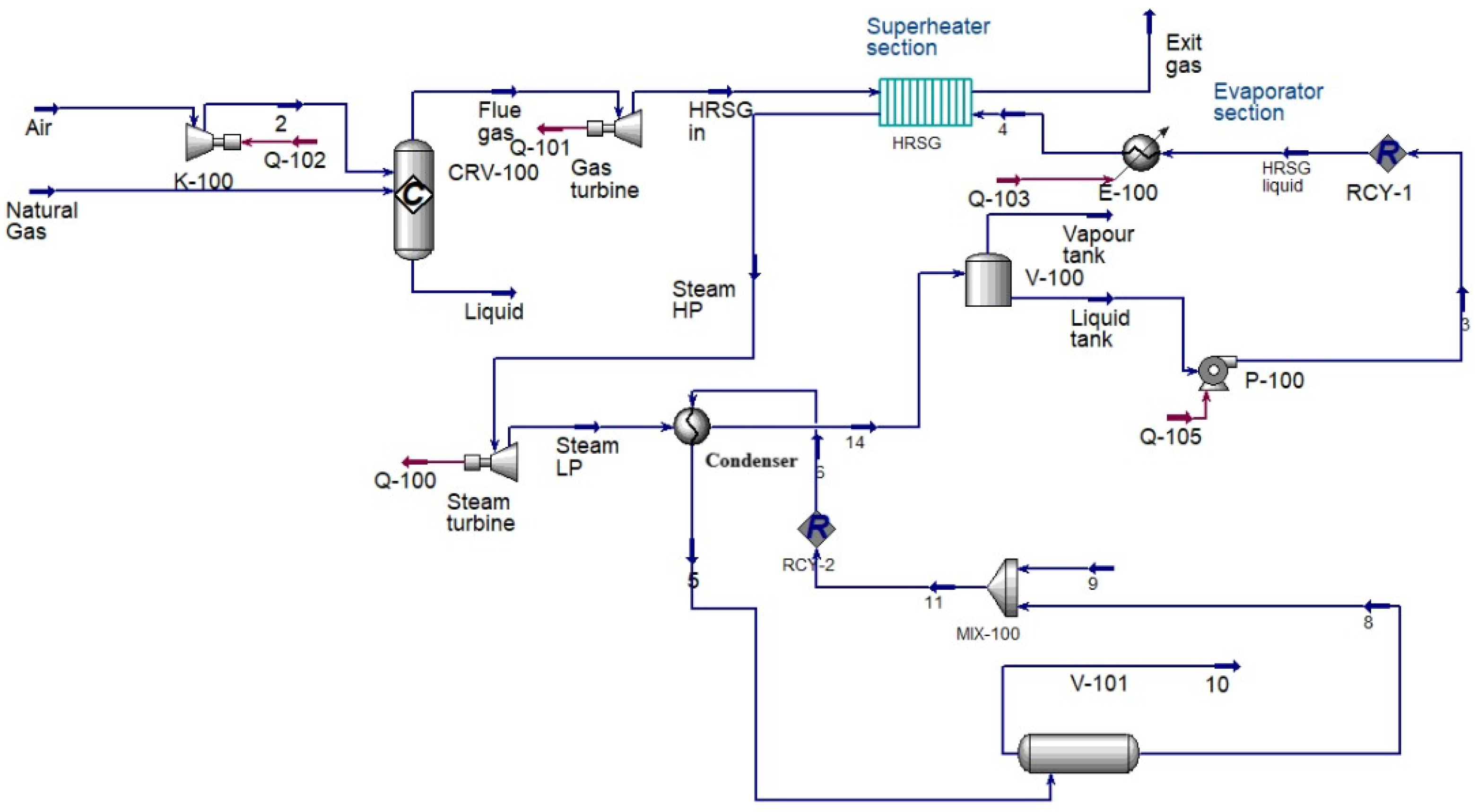

2. Methodology

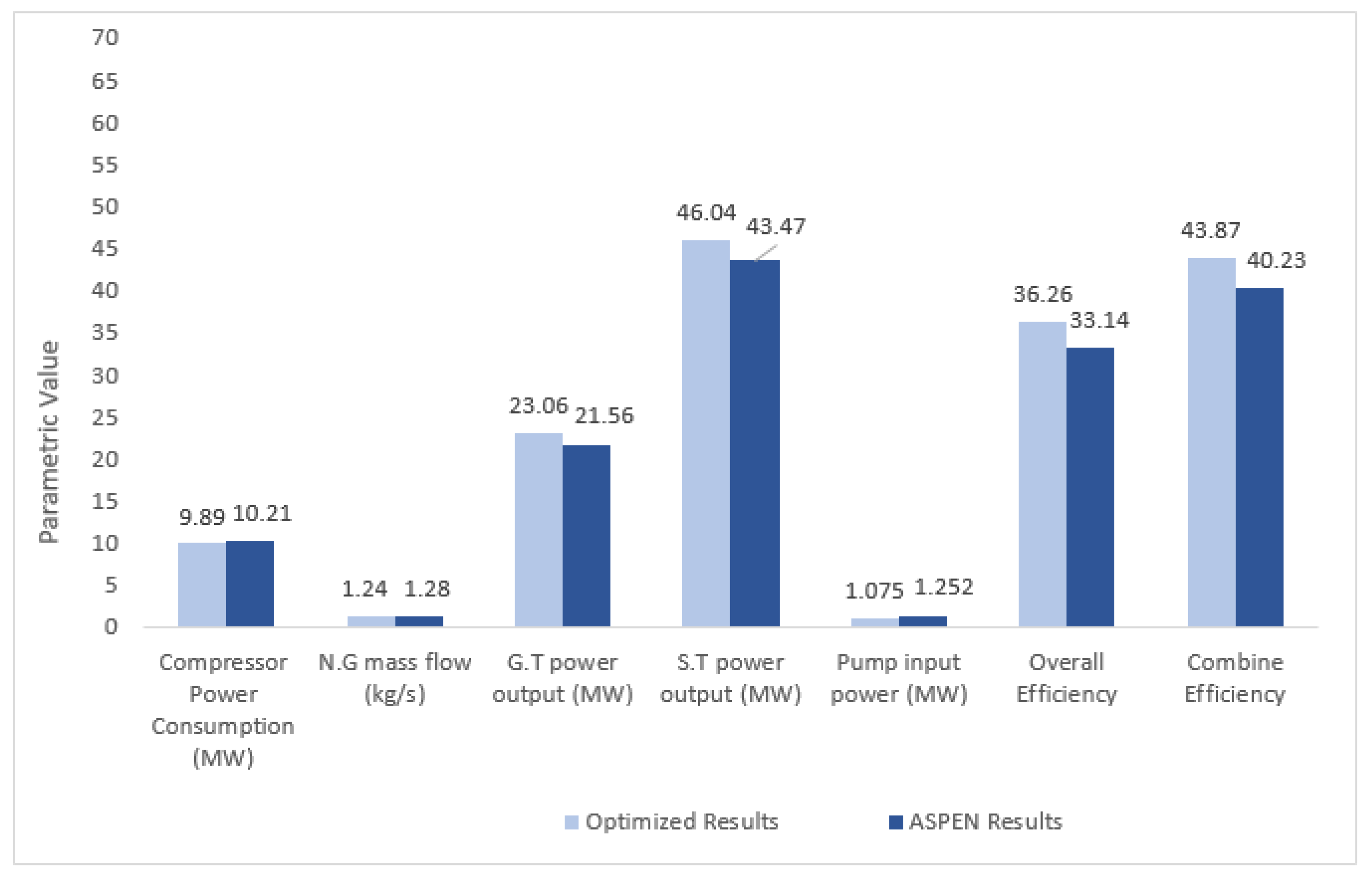

3. Results and Discussion

4. Conclusions

Acknowledgments

Conflicts of Interest

References

- Abbi, Y.P. Energy Audit: Thermal Power, Combined Cycle, and Cogeneration Plants; The Energy and Resources Institute (TERI): New Delhi, India, 2012; ISBN 8179933113. [Google Scholar]

- Kumbhar, N.R.; Joshi, R.R. An industrial energy auditing: Basic approach. Int. J. Mod. Eng. Res. 2012, 2, 313–315. [Google Scholar]

- Pourbeik, P. Modeling of Gas Turbines and Steam Turbines in Combined Cycle Power Plants. 2003. Available online: https://e-cigre.org/publication/238-modeling-of-gas-turbines-and-steam-turbines-in-combined-cycle-power-plants (accessed on 15 November 2021).

- Aminov, Z.; Nakagoshi, N.; Xuan, T.D.; Higashi, O.; Alikulov, K. Evaluation of the energy efficiency of combined cycle gas turbine. Case study of Tashkent thermal power plant. Uzbekistan Appl. Therm. Eng. 2016, 103, 501–509. [Google Scholar] [CrossRef]

- Saidur, R.; Ahamed, J.U.; Masjuki, S.S. Energy, Exergy and Economic Analysis of Industrial Boilers. Energy Policy 2010, 38, 2188–2197. [Google Scholar] [CrossRef]

| Parameters | Parameter Symbol | Unit | Optimized Results | ASPEN Results | Audit Results |

|---|---|---|---|---|---|

| Exhaust flue gases move toward HRSG | Mass flow | Ton/h | 180.2 | 180.2 | 171 |

| Pressure | Bar | 8.021 | 8.53 | 9.625 | |

| Temperature | C | 830.21 | 867.54 | 924.34 | |

| HRSG | Duty | MW | 25.87 | 33.15 | 42.87 |

| Steam Stream | Temperature | C | 500 | 505 | 513 |

| - | Pressure | Bar | 47.92 | 43.7 | 39.5 |

| Turbine | Isentropic efficiency | % | 75 | 75 | 73.6 |

| Polytropic efficiency | % | 75 | 72.64 | 69.76 | |

| Power output | MW | 46.04 | 43.47 | 40 | |

| Condenser | Duty | MW | 95.7 | 103 | 110 |

| Pump | Pressure difference | 50 | 50.1 | 51.4 | |

| Duty | MW | 1.075 | 1.252 | 1.5 | |

| Adiabatic efficiency | % | 75 | 75 | 75 | |

| Overall efficiency | - | % | 32.26 | 33.14 | 30.4 |

| Combined efficiency | - | % | 43.87 | 40.23 | 38.93 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Amjad, W.; Shahid, M.; Munir, A.; Asghar, F.; Manzoor, O. Energy Assessment of a Combined Cycle Power Plant through Empirical and Computational Approaches: A Case Study. Eng. Proc. 2021, 12, 25. https://doi.org/10.3390/engproc2021012025

Amjad W, Shahid M, Munir A, Asghar F, Manzoor O. Energy Assessment of a Combined Cycle Power Plant through Empirical and Computational Approaches: A Case Study. Engineering Proceedings. 2021; 12(1):25. https://doi.org/10.3390/engproc2021012025

Chicago/Turabian StyleAmjad, Waseem, Mubeen Shahid, Anjum Munir, Furqan Asghar, and Owais Manzoor. 2021. "Energy Assessment of a Combined Cycle Power Plant through Empirical and Computational Approaches: A Case Study" Engineering Proceedings 12, no. 1: 25. https://doi.org/10.3390/engproc2021012025

APA StyleAmjad, W., Shahid, M., Munir, A., Asghar, F., & Manzoor, O. (2021). Energy Assessment of a Combined Cycle Power Plant through Empirical and Computational Approaches: A Case Study. Engineering Proceedings, 12(1), 25. https://doi.org/10.3390/engproc2021012025