1. Introduction

In Pakistan, there is an annual increase of around 2% in solid waste generation, followed by an increase in the rate of industrialization (67.6%), urbanization (37.17%), and population growth (2%) [

1]. Based on the lack of waste management practices in Pakistan, its ever-increasing complexity has stimulated extensive research across this domain. While developed countries have matured the process, the lack of knowledge, planning, and action in developing countries have resulted in socio-economic losses. Until the start of the 21st century, municipal solid waste was dumped in landfills or left open even in the developed economies, which led to serious environmental hazards, such as land, air, and water pollution, land infertility, and an increasing profile of GHG emissions. However, with the advancement in technologies, this liability can be treated and recovered as a potential source for addressing the energy needs of the country [

2].

Despite an agriculture-based economy, commercial facilities of bioenergy treatment in Pakistan are non-existent. Biomass is rarely used for any energy purpose, other than co-generation in some sugar plants [

3]. Even in the literature, the technical, economical or environmental assessment of biomass in Pakistan is very limited. Therefore, this study performs an economic assessment based on the levelized cost of energy (LCOE) for various technologies that are commercially available in Pakistan. These technologies range from thermal processes, such as incineration or gasification in different turbines to biochemical processes, such as anaerobic digestion. Based on the extensive literature, bioenergy can serve as a sustainable alternative for Pakistan, but data on the techno-economic assessment of waste-to-energy technologies are very limited [

4,

5]. Most of the studies conducted in Pakistan simply consider the economic assessment of other countries with similar demographics. Without proper access to accurate and reliable information, technology feasibility cannot be studied for a particular area. This study fulfills the significant gap in the cost and performance of bioenergy technologies in Pakistan. The LCOE based assessment is carried out through different bioenergy conversion technologies using datasets of Pakistan, which in return, will provide additionally better insights for policies and decision making.

2. Methodology and Model Development

The model development in this study requires extensive data collection under three domains, i.e., characteristics of WTE technologies, economic parameters, and feedstocks. Data for technologies were the most critical since they have a wide classification even on a commercial scale, ranging from thermal to chemical processes. Each technology can only treat a particular set of biomass feedstock. Data for technologies that are currently operating in Pakistan were taken from respective power plants (mainly JDW sugar mills), while data for technologies that are present but not commercially deployed have been taken from countries with similar demographics, i.e., China, India, and Bangladesh. However, these data before use have also been compared with the statistics provided in “Renewable Energy Technologies: Cost Analysis Series” and “Cost competitiveness of Renewable Energy” [

6] of the International Renewable Energy Agency (IRENA). For biomass feedstocks, both data regarding feedstock availability and prices are taken from the Economic Survey of Pakistan and respective Agriculture departments [

7]. The feedstock composition and their prices in Pakistan are shown in

Table 1.

Similar to biomass feedstock, the processing costs through the use of proper technologies also pose a significant challenge for bioenergy. These technologies require high investments and consequently, a trade-off has to be made between energy requirements and cost parameters. The technology cost is also highly dependent on the plant scale, as scaling up the capacity reduces the net cost of production. Cost predictions for technologies and processes are taken from the National Electric and Power Regulatory Authority (NEPRA) [

8]. Equipment costs have been collected/calculated for both the simple and combined heat and power plants (CHPs).

Followed by data collection, the levelized cost of electricity (LCOE) is calculated for each technology using the equation provided below.

Here, CRF represents the capital recovery factor, which is calculated through , where n represents the number of years.

Similarly, data for the technical parameters of all technologies have been collected. To verify the results, the NREL LCOE calculator has been used, which uses similar input parameters for calculations.

3. Results and Discussion

The range of technology and feedstock cost has resulted in a very broad range of LCOE for WTE technologies. Even for a single technology, some ranges are significantly wide due to the different configurations of sub-equipment. Then, waste classification disturbs the total cost.

Figure 1 below represents the LCOE results for different technologies.

Considering all of the technologies, the LCOE of Pakistan may vary from as low as USD 0.06/kWh to as high as USD 0.315/kWh. Combustion technologies (stoker boiler and CFB) are the technologies with the least economic cost with LCOE ranging from USD 0.06–0.22/kWh. It should be identified that although the LCOE of CHP plants is larger, these plants operate with high efficiency and result in generating both heat and power. Revenues that are generated by supplying heat to other facilities or using it in the same boiler have not been accounted for in this calculation since they are very case-specific.

The range of LCOE for gasifiers is comparatively very wide due to a range of feedstock costs (pre-treated feedstock is used). More importantly, this is due to the fact that gasification in Pakistan is not a commercially mature technology and the sub-equipment can vary substantially. Therefore, the economic feasibility of bioenergy is highly dependent on the supply chain process. At low feedstock prices, bioenergy can be a market competitive for generating electricity. However, with a comparatively higher capital cost and feedstock prices, bioenergy will not be able to match other generating sources without subsidies and incentives. As a result, for bioenergy utilization, it is essential that a working competitive supply chain is first established on a large scale.

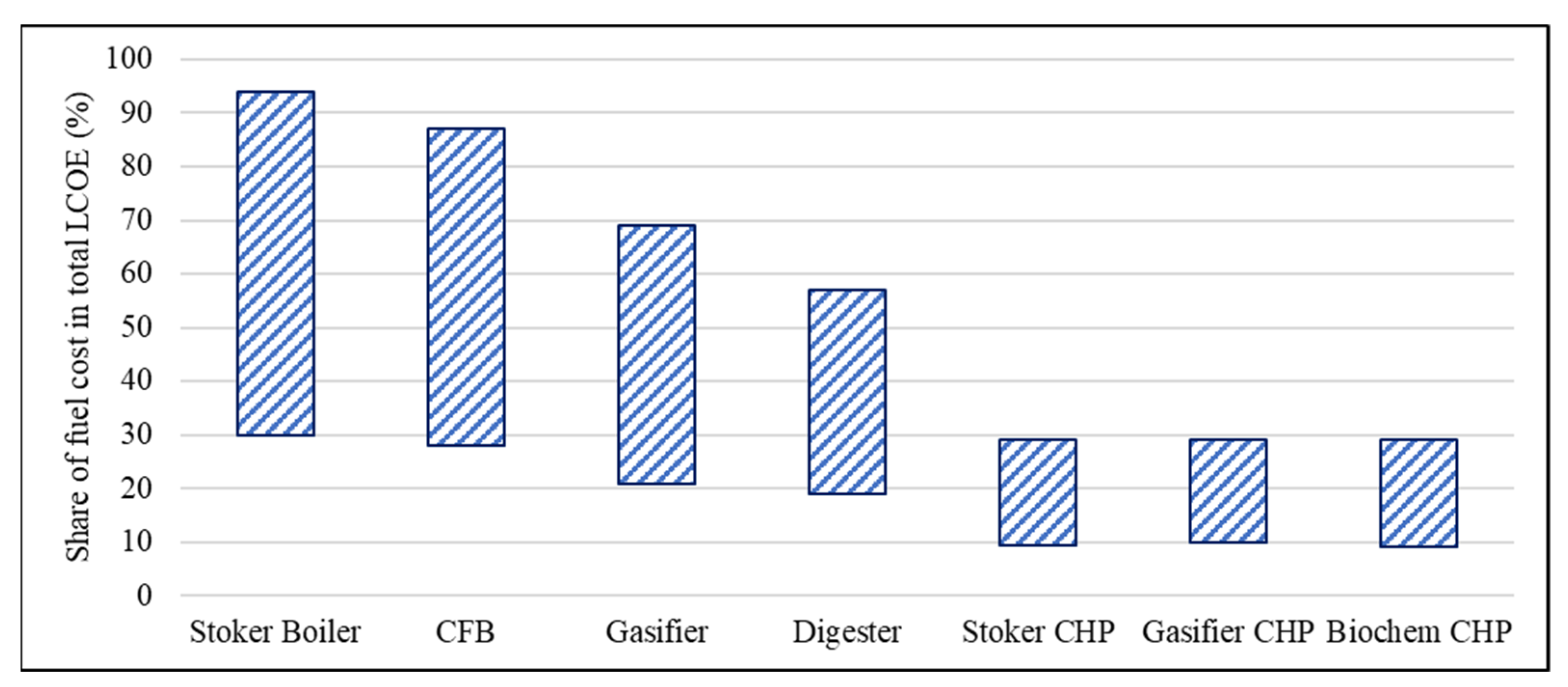

An in-depth analysis of LCOE can be further carried out through its breakdown process. This represents that a major share of LCOE is driven by the feedstock price as depicted in

Figure 2. These values are also significantly close to the values observed in other studies. Even as per the international studies, the share of feedstock cost may go as high as 60% in some cases. However, one difference that this study has reported as compared to other countries is the effect of fuel imports. The share of feedstock cost may be even higher for countries that have to import biomass or feedstock. However, since Pakistan is an agriculture-based economy, feedstock availability for use as an energy source is not as big of a problem.

The LCOE of the stoker boiler varies from USD 0.06–0.2/kWh. In addition, on average, slightly less than half of it accounted for fuel cost, while 30–35% accounted for investment cost. For instance, since bagasse is a cheap residue that is available in Pakistan, a stoker boiler fired with bagasse will be near the lower end of the spectrum. In this case, the larger portion of LCOE will be due to the equipment or CAPEX cost. The same applies to other combustion technologies and an anaerobic digestor. However, for CHP plants, the share of feedstock in overall LCOE is comparatively lower. This is due to the comparatively higher investment in equipment and maintenance. Moreover, the results indicate that LCOE is a function of the size of a biomass plant. Plants with a larger size result in a comparatively lower LCOE.

The economic assessment performed above has clearly described that bioenergy will have large prospects if it is deployed on a commercial scale in Pakistan. The resulting LCOE is market-competitive and provides additional benefits in terms of social and environmental sustainability.