Flexural Strength Investigation of Flat-Oriented PLA Filament 3D Printing Parts Under Different Infill Styles and Printing Conditions †

Abstract

1. Introduction

2. Experimental Section

2.1. Materials and Methods

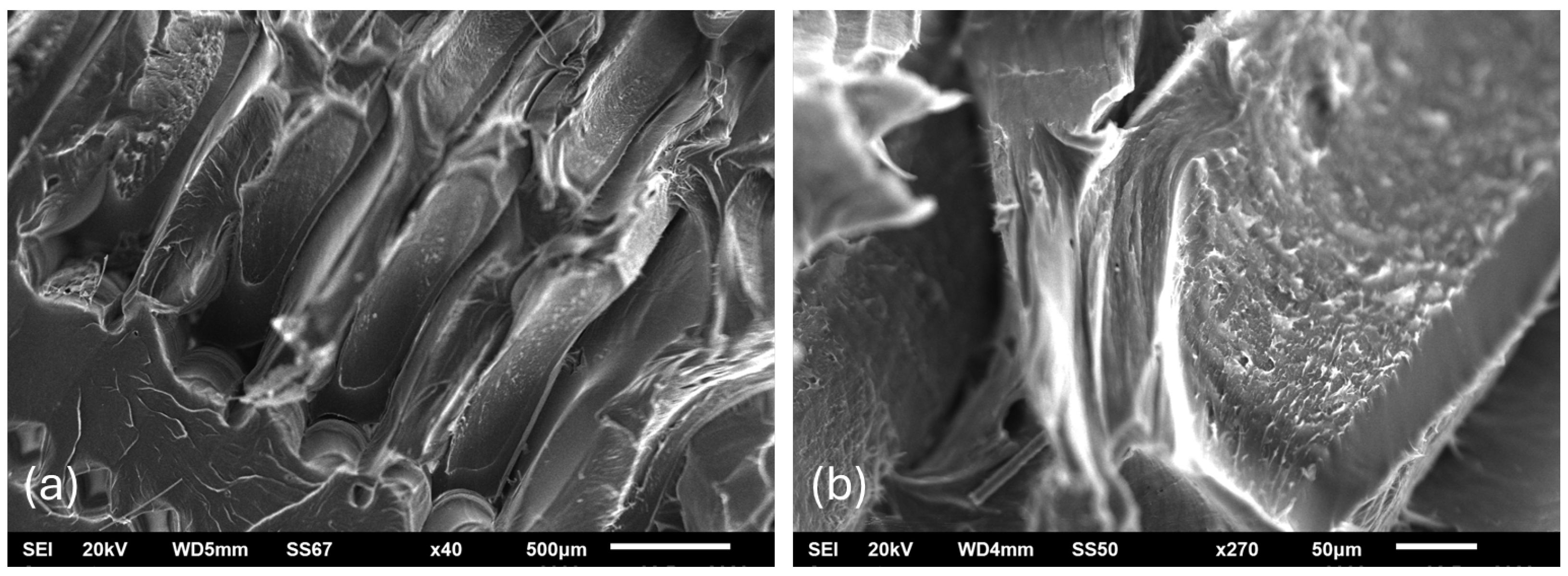

2.2. Fracture Analysis and Failure Modes

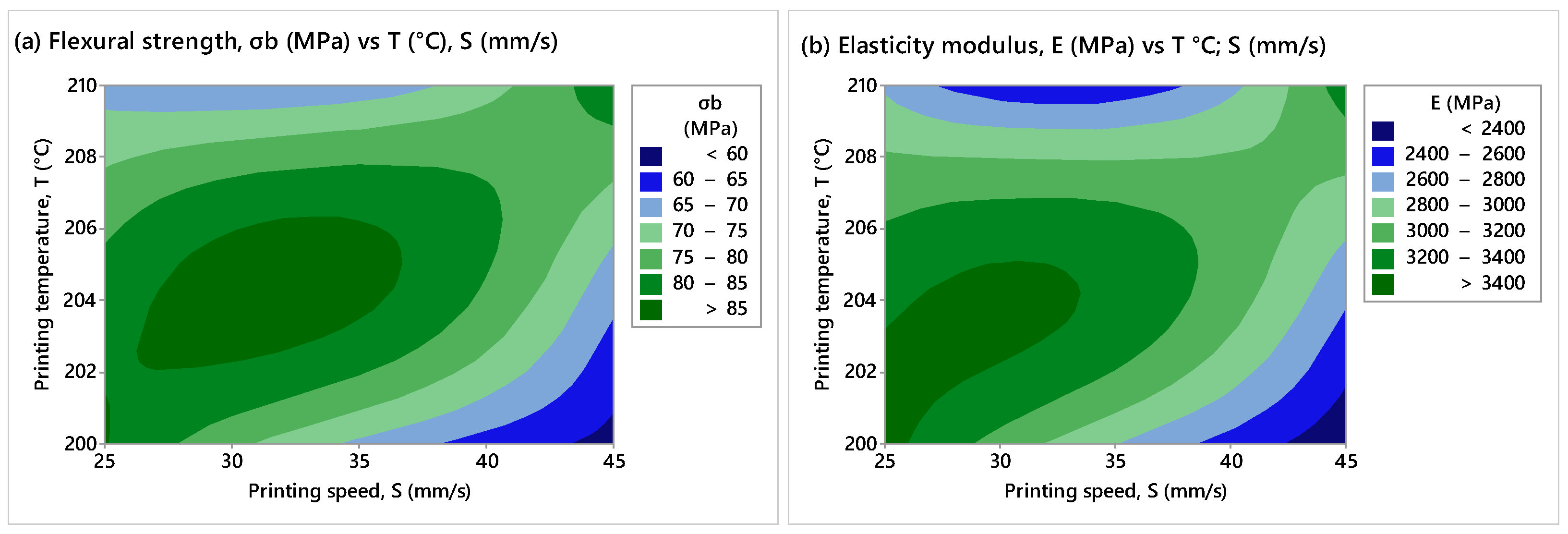

3. Statistical Analysis and Regression Model Generation

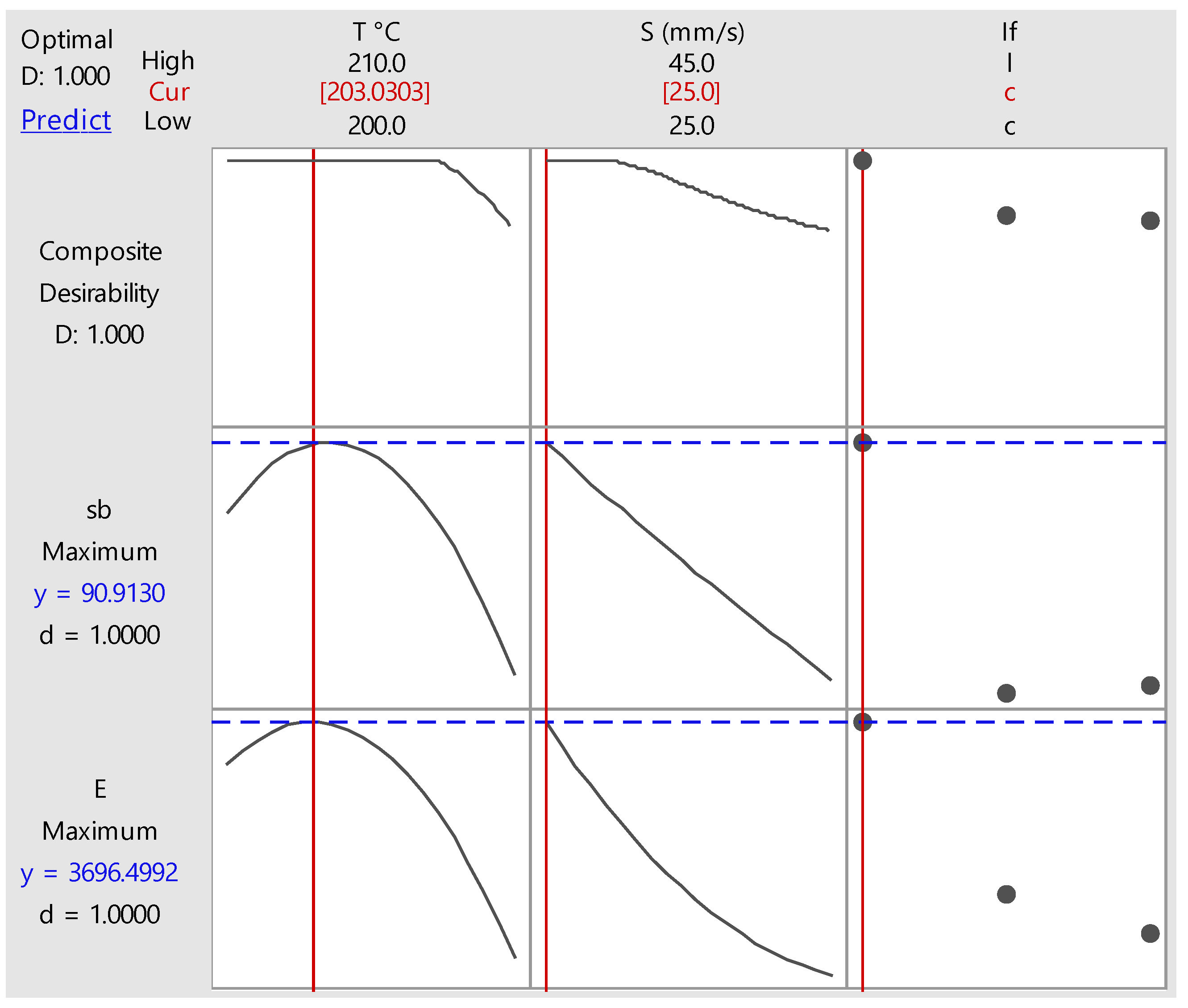

4. Parameter Optimization Using Desirability Function (DF)

5. Conclusions and Future Perspectives

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ANOVA | Analysis of variance |

| DF | Desirability function |

| FFF | Fused filament fabrication |

| FDM | Fused deposition modeling |

| PLA | Poly-lactic acid |

| σb | Flexural strength |

| SEM | Scanning electron microscope |

References

- Tao, Y.; Kong, F.; Li, Z.; Zhang, J.; Zhao, X.; Yin, Q.; Xing, D.; Li, P. A review on voids of 3D printed parts by fused filament fabrication. J. Mater. Res. Technol. 2021, 15, 4860–4879. [Google Scholar] [CrossRef]

- Khosravani, M.R.; Soltani, P.; Reinicke, T. Failure and fracture in adhesively bonded 3D-printed joints: An overview on the current trends. Eng. Fail. Anal. 2023, 105, 107574. [Google Scholar] [CrossRef]

- Alsoufi, M.S.; Alhazmi, M.W.; Suker, D.K.; Yunus, M.; Malibari, R.O. From 3D models to FDM 3D prints: Experimental study of chemical treatment to reduce stairs-stepping of semi-sphere profile. AIMS Mater. Sci. 2019, 6, 1086–1106. [Google Scholar] [CrossRef]

- Zaldivar, R.J.; Mclouth, T.D.; Ferrelli, G.L.; Patel, D.N.; Hopkins, A.R.; Witkin, D. Effect of initial filament moisture content on the microstructure and mechanical performance of ULTEM® 9085 3D printed parts. Addit. Manuf. 2018, 24, 457–466. [Google Scholar] [CrossRef]

- Kim, T.; Kim, M.-K.; Fang, Y.; Suhr, J. Moisture Effects on Qualities and Properties of Laser Powder Bed Fusion (LPBF) Additive Manufacturing of As-Built 17-4PH Stainless Steel Parts. Metals 2023, 13, 1550. [Google Scholar] [CrossRef]

- Kechagias, J.; Chaidas, D.; Vidakis, N.; Salonitis, K.; Vaxevanidis, N.M. Key parameters controlling surface quality and dimensional accuracy: A critical review of FFF process. Mater. Manuf. Process. 2022, 37, 963–984. [Google Scholar] [CrossRef]

- Ahmed, S.W.; Hussain, G.; Altaf, K.; Ali, S.; Alkahtani, M.; Abidi, M.H.; Alzabidi, A. On the Effects of Process Parameters and Optimization of Interlaminate Bond Strength in 3D Printed ABS/CF-PLA Composite. Polymers 2020, 12, 2155. [Google Scholar] [CrossRef] [PubMed]

- Asadi-Eydivand, M.; Solati-Hashjin, M.; Farzad, A.; Abu Osman, N.A. Effect of technical parameters on porous structure and strength of 3D printed calcium sulfate prototypes. Robot. Comput. Integr. Manuf. 2016, 37, 57–67. [Google Scholar] [CrossRef]

- Markiz, N.; Horváth, E.; Ficzere, P. Influence of printing direction on 3D printed ABS specimens. Prod. Eng. Arch. 2020, 26, 27–130. [Google Scholar] [CrossRef]

- Ouhsti, M.; El Haddadi, B.; Belhouideg, S. Effect of printing parameters on the mechanical properties of parts fabricated with open-source 3D printers in PLA by fused deposition modeling. Mech. Mech. Eng. 2018, 22, 895–908. [Google Scholar] [CrossRef]

- Cantrell, J.T.; Rohde, S.; Damiani, D.; Gurnani, R.; DiSandro, L.; Anton, J.; Young, A.; Jerez, A.; Steinbach, D.; Kroese, C.; et al. Experimental characterization of the mechanical properties of 3D-printed ABS and polycarbonate parts. Rapid Prototyp. J. 2017, 23, 811–824. [Google Scholar] [CrossRef]

- ASTM D790-17; Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. ASTM International: West Conshohocken, PA, USA, 2017.

- ISO R291:1977; Plastics—Standard Atmospheres for Conditioning and Testing. ISO: Geneva, Switzerland, 1977.

| 3D Printing Parameters | Levels | ||

|---|---|---|---|

| 1 | 2 | 3 | |

| Infill style, If | C | G | L |

| Printing temperature, T (°C) | 200 | 205 | 210 |

| Printing speed, S (mm/s) | 25 | 35 | 45 |

| Exp. | If | T (°C) | S (mm/s) | σb (MPa) | E (MPa) |

|---|---|---|---|---|---|

| 1 | C | 200 | 25 | 85.3 | 3472 |

| 2 | C | 205 | 35 | 86.4 | 3345 |

| 3 | C | 210 | 45 | 84.0 | 3317 |

| 4 | G | 200 | 35 | 68.9 | 2805 |

| 5 | G | 205 | 45 | 68.5 | 2724 |

| 6 | G | 210 | 25 | 67.7 | 2763 |

| 7 | L | 200 | 45 | 58.7 | 2268 |

| 8 | L | 205 | 25 | 81.0 | 3294 |

| 9 | L | 210 | 35 | 66.6 | 2458 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fountas, N.A.; Kechagias, J.D.; Zaoutsos, S.; Vaxevanidis, N.M. Flexural Strength Investigation of Flat-Oriented PLA Filament 3D Printing Parts Under Different Infill Styles and Printing Conditions. Eng. Proc. 2025, 119, 18. https://doi.org/10.3390/engproc2025119018

Fountas NA, Kechagias JD, Zaoutsos S, Vaxevanidis NM. Flexural Strength Investigation of Flat-Oriented PLA Filament 3D Printing Parts Under Different Infill Styles and Printing Conditions. Engineering Proceedings. 2025; 119(1):18. https://doi.org/10.3390/engproc2025119018

Chicago/Turabian StyleFountas, Nikolaos A., John D. Kechagias, Stefanos Zaoutsos, and Nikolaos M. Vaxevanidis. 2025. "Flexural Strength Investigation of Flat-Oriented PLA Filament 3D Printing Parts Under Different Infill Styles and Printing Conditions" Engineering Proceedings 119, no. 1: 18. https://doi.org/10.3390/engproc2025119018

APA StyleFountas, N. A., Kechagias, J. D., Zaoutsos, S., & Vaxevanidis, N. M. (2025). Flexural Strength Investigation of Flat-Oriented PLA Filament 3D Printing Parts Under Different Infill Styles and Printing Conditions. Engineering Proceedings, 119(1), 18. https://doi.org/10.3390/engproc2025119018

_Kechagias.jpg)