1. Introduction

Moisture in the environment is one of the most significant natural factors affecting the integrity, durability, and maintenance requirements of buildings or metal structures. The term “moisture” primarily refers to the presence of water vapor in the air—known as relative humidity—but also includes direct contact with water in the form of rain, fog, damp soil, or marine aerosols. This presence of water, whether in gaseous or liquid form, can interact with metals, triggering chemical and electrochemical reactions, most notably oxidation [

1,

2]. Moisture is one of the main enemies of plaster in buildings, as it directly affects both its appearance and structural integrity. When moisture penetrates the walls, it can lead to issues such as detachment of the plaster, swelling, cracks, and peeling [

3]. White salt deposits (known as efflorescence) often appear on the surface, caused by the evaporation of water that carries soluble salts from inside the wall. Additionally, in damp and poorly ventilated areas, mold can develop, which not only damages the building material but also poses health risks to occupants [

4,

5]. Over time, constant exposure to moisture weakens the cohesion of the plaster, making it brittle and ineffective as a protective layer [

6,

7]. Moisture can originate from several sources, such as water infiltration through exterior walls, rising damp from the ground, leaking pipes, or condensation in areas with inadequate ventilation. Protecting plaster requires proper wall insulation, the use of appropriate water-repellent materials, regular ventilation of indoor spaces, and timely repair of cracks or damage [

8]. In cases of extensive deterioration, complete removal and replacement of the plaster may be necessary, using specialized mortars designed for humid or challenging conditions [

9]. In metal surfaces that are constantly or periodically exposed to humid conditions, moisture creates an ideal environment for the development of corrosion, which over time reduces the strength of the metal, degrades its appearance, and may even lead to complete structural failure [

10,

11]. Therefore, understanding the role of moisture and implementing preventive measures is of critical importance for the protection and long-term viability of any metallic structure.

Moisture is one of the most serious factors contributing to the deterioration of monuments, regardless of their construction material. Whether made of stone or metal, the presence of moisture—especially when combined with air pollution, temperature fluctuations, and biological agents—accelerates decay, degrades aesthetics, and can cause significant structural damage over time.

In stone-built monuments, moisture penetrates the porous structure of the stone, leading to disintegration, surface flaking, and cracking [

12]. In climates with temperature variations, freeze–thaw cycles exacerbate the damage, as water expands when frozen, gradually breaking apart the stone [

13]. Additionally, moisture transports dissolved salts into the stone, which crystallize on the surface or inside its pores, causing efflorescence and internal stress. Biological growth, such as moss, lichens, and mold, also thrives in damp conditions, further accelerating stone erosion through biochemical activity [

14,

15].

In metal monuments or decorative elements (e.g., statues, railings, plaques), moisture promotes oxidation and corrosion. This is especially severe in marine or industrial environments, where airborne salts or pollutants (such as sulfur dioxide) react with the metal surface [

16]. Over time, these reactions can lead to rusting, green patina on bronze, and surface degradation, potentially compromising the structural integrity of the metallic components.

Preserving such monuments requires systematic monitoring of moisture levels, the use of appropriate conservation techniques, water-repellent protective coatings (when compatible with the materials), and carefully controlled interventions by skilled conservators [

17,

18]. Moisture, while a natural environmental element, acts as a silent threat to cultural heritage, making its management essential for the long-term protection and preservation of historic monuments.

The low-cost raindrop sensor [

19] can be used to some extent for detecting increased moisture in the environment, such as early morning dew, but not with precision. Its operation is based on the conductivity of its surface, which changes when it comes into contact with water droplets. It consists of a metallic surface with conductive lines and an amplifier/power supply circuit. When water droplets land on the sensor plate, the conductivity changes, and this is translated into an electrical signal. Therefore, if dew droplets form on the sensor, it can indicate that the surface is wet, even if no rainfall has occurred. However, if there is not enough moisture accumulation on the surface, it will not detect anything—even if the relative humidity of the air is very high.

A hygrometer is an instrument that measures the relative humidity of the air, meaning the percentage of moisture in the atmosphere relative to the maximum amount it can hold at a specific temperature. Electronic humidity sensors, such as the DHT22 [

20] or BME280 [

21], are commonly used; they provide accurate data on relative humidity and temperature and are compatible with microcontrollers like Arduino. These instruments are useful in applications such as weather stations, agriculture, storage facilities, and climate control systems.

Regarding dew, a hygrometer does not detect it directly—that is, it does not sense water droplets—but it can help identify the conditions that favor its formation. Dew forms when the relative humidity reaches 100% and the temperature drops near the dew point. Therefore, if the hygrometer shows very high humidity (e.g., above 95%) and low temperature, it is highly likely that dew will form. Thus, the hygrometer can indirectly assist in predicting the presence of dew, especially when combined with temperature measurements.

In many cases, the use of low-cost sensors is an important selection criterion, mainly due to their affordability and ease of integration into various projects and applications. Low-cost raindrop sensors can be used effectively, provided that some improvements or adjustments are made to increase their sensitivity. This can be achieved, for example, by modifying their surface to better retain moisture or droplets, enhancing the electronic circuitry for improved detection of small changes in conductivity, or by combining them with other sensors (e.g., humidity or temperature sensors) to improve the reliability of the measurements.

To enhance the sensitivity of the Arduino rain sensor module, several approaches can be implemented based on existing literature that focuses on sensor modules and their calibration. One significant method to increase the sensitivity of rain sensors involves using calibration techniques combined with advanced algorithms. For instance, Antonini et al. discuss the development and calibration of a low-cost piezoelectric rainfall sensor, applying machine learning to refine the relationship between the voltage signals produced by raindrop impacts and rainfall intensity [

22]. In another work, [

23] described a weather monitoring system that integrates multiple sensors, including a rain sensor connected to an Arduino. This setup processes various environmental inputs, improving the accuracy and responsiveness of weather-related data such as rainfall detection. Alternative procedures for improving sensitivity involve a combination of raindrop sensors with complementary lighting and moisture sensors are presented. Specifically, the work [

24] presents an automatic clothesline using raindrop sensors and light-dependent resistors (LDRs) exemplifies how integrating multiple sensor types can optimize the response to varied environmental conditions, essentially improving detection thresholds for rainfall. At the same way, the research work [

25] showcased a flood monitoring system where integrating ultrasonic sensors with rain sensors enabled enhanced data accuracy for flood detection, suggesting that multi-sensor systems can offer better sensitivity through collaborative data processing. The development of enhanced sensitivity in Arduino-based rain sensors through the use of suction or absorption membranes is an emerging area of research.

Recent literature explores the incorporation of membranes that increase the surface area exposed to rain. The work [

26] describes a rain detection system designed for clothing protection, validating the relationship between rain detection and effective response mechanisms, although it does not specifically address membrane technologies. The work [

27] emphasizes integrating various sensor types to enhance the responsiveness of rain detection systems, indicating possible adaptations to boost sensitivity through membrane applications. One research effort discusses a rain detection system that integrates the Arduino platform with a rain sensor. The authors emphasize that improvements in sensor technology can enhance rainfall detection performance, allowing the system to respond more quickly to rainfall variability. This capability is critical for protecting agricultural practices and urban infrastructure from flooding [

24,

28]. Additionally, the adaptation of certain materials can improve moisture absorption, which is crucial for converting rain signals into measurable electrical signals [

29,

30]. Research indicates that the integration of porous silicon (PS) in pressure sensors has been effective in enhancing their sensitivity. Porous silicon membranes exhibit properties that lead to a lower Young’s modulus, which contributes to increased sensitivity as porosity increases [

31]. This characteristic could analogously apply to Arduino rain sensors, where utilizing a porous medium for water detection may facilitate faster and more responsive measurements of rainwater, similar to the sensitivity benefits observed in PS membranes. Another research work [

32] discusses automatic clothes drying system that integrates rain sensors. It employs a mechanism where such sensor technologies can capture and respond to rain droplets more effectively. The work [

33] highlights that increasing the area of suspended membranes and optimizing membrane materials with lower elastic moduli can bolster sensor sensitivity in pressure sensing applications. This underscores the potential for similar methodologies to be applied when enhancing the sensitivity of rain sensors, as the operational principles can overlap significantly. The work [

34] refers to the sensitivity of rain sensors potentially being elevated through adaptations, such as incorporating an absorption membrane that increases the effective area of interaction with raindrops. This concept aligns with proposals that explore design and enhancements in rain detection systems aimed at optimizing functionality through improved sensor responsiveness.

The monitoring of various parameters that are detrimental to both human health and the environment is a daily scientific field of research. In particular, in fields such as environmental monitoring [

35,

36], air quality assessment [

37,

38], and rainwater quality analysis [

39,

40], measurements are often based on low-cost sensors. In general, low-cost devices provide an affordable solution, as low-cost sensors can yield satisfactory results when combined with appropriate correction factors. Additionally, data transmission can be carried out using widely adopted communication methods such as Wi-Fi, LoRa, and others [

41,

42]. It should be mentioned that the monitoring of environmental conditions (temperature, humidity, relative humidity, and acid rain) can also be used for the observation of monuments [

43,

44], both for prevention purposes and for how they can affect them in the long term.

In this paper, an alternative method for modifying a low-cost rain droplet sensor is described, aiming the sensor after modification to have the ability to detect small droplets such as morning dew during autumn days. The application to the surface of the sensor of a nylon mesh, in the case of the study a sock was used, has the effect of creating a fine braid in which the micro-droplets grow. As the nylon mesh is in contact with the sensor, the microdroplets are distributed through the mesh to the copper paths, which means that when a droplet with a diameter smaller than the distance between two copper lines spreads, on the mesh, the conductivity of the sensor changes, thus enabling the sensor to detect smaller droplets, such as dewdrops. The innovation of the proposed system is based on two axes: first, the use of a very fine nylon mesh instead of a porous material and, second, the very low cost of configuration.

The contribution of this work to the scientific community is shown through the results of the application to the development of moisture-sensitive dust sensors. In many cases, and particularly in monuments made of stone, iron, wood, moisture must be monitored as it is an aggravating factor for these structures and their viability is an integral part of the culture of our society.

The article is structured as follows:

Section 2 presents the Materials and Methods;

Section 3 includes the Results and Discussion; and

Section 4 covers the Conclusions.

2. Materials and Methods

For the purposes of the experiment, two raindrop sensors and one Arduino were used. The Rain Drops Module DSK sensor (Shenzhen Yixinyuan, Shenzhen, China) [

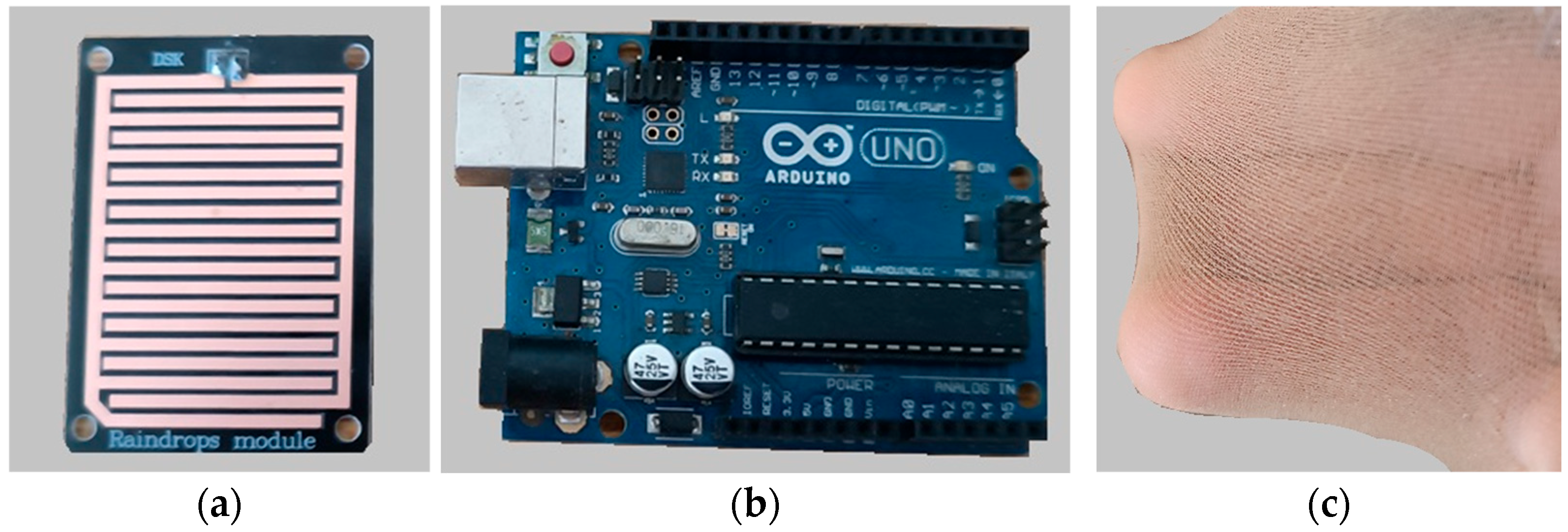

19] is shown in

Figure 1a, while the Arduino UNO board [

45] used for the measurements is shown in

Figure 1b. A typical photo of the nylon stocking is presented in

Figure 1c. A simple code written in Arduino IDE [

46] uses the Analog.Read function for analog ports A0 and A1, which correspond to the parameterized sensor and the non-parameterized sensor.

All components were connected together, and the experiment was conducted at a common location. One of the sensors was left in its original form, as provided by the manufacturer. The second sensor was modified by covering it with a nylon mesh stocking, as described in the introduction, and measurements were taken at the same time intervals for both sensors. During the experiment, a standard water spray bottle was used to apply droplets of approximately the same size and quantity to both sensors simultaneously.

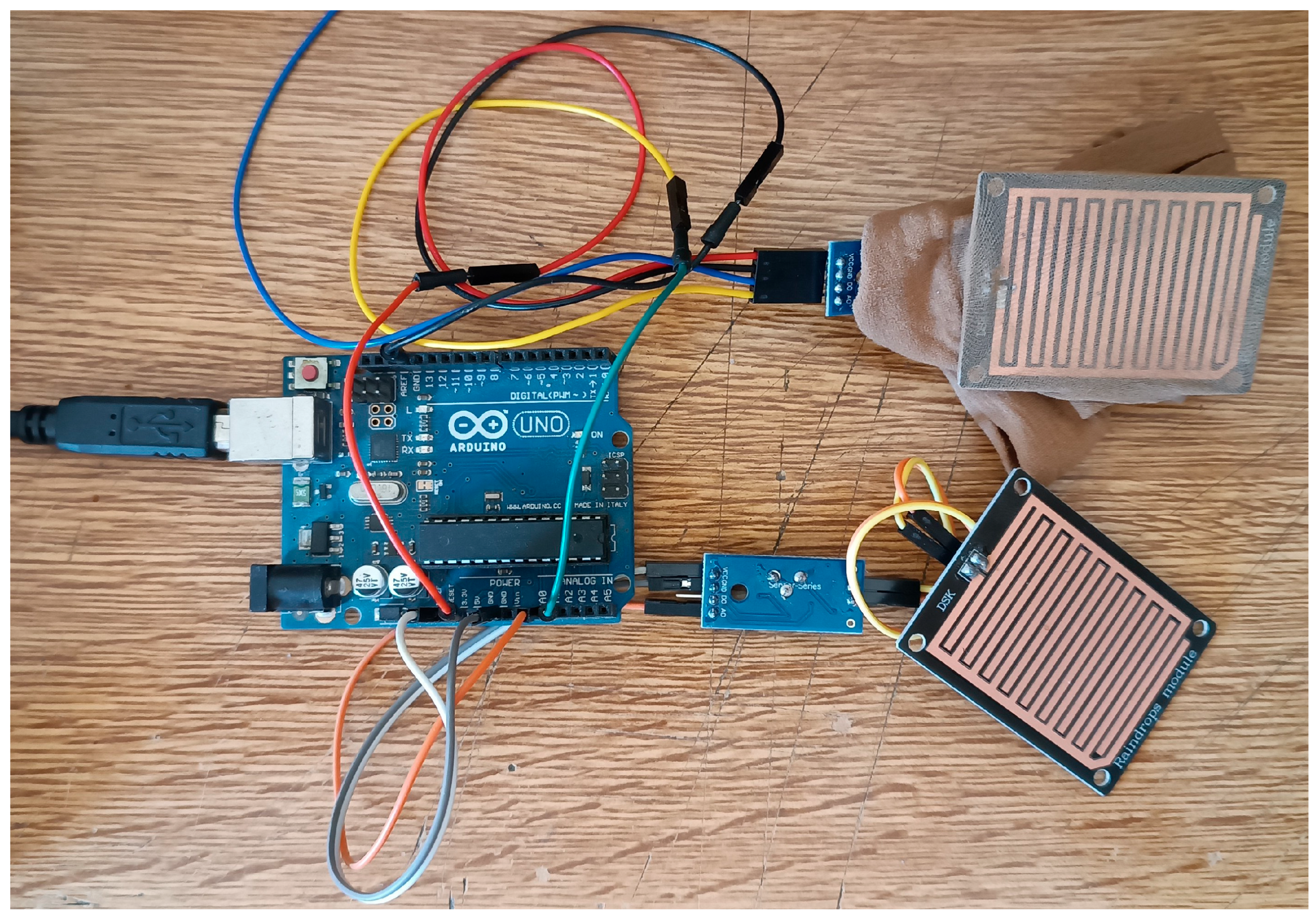

Figure 2 shows the setup with the Arduino and the two raindrop sensors—one in its original factory form, and the other covered with a fine nylon mesh (BIC, Castel Goffredo, Italy) (stocking) as a modification. The Arduino (Ivrea, Italy) is used for the visualization and collection of measurements from each sensor. Each sensor is connected through its power supply and signal lines, with the signal being received on a separate analog input pin for each sensor.

The raindrop sensor operates based on the principle of electrical conductivity. It consists of a flat surface with conductive lines (usually made of copper) and an electronic circuit that detects changes in electrical resistance. When there are no water droplets on the surface, the resistance between the lines is high, and no current flows. However, when water droplets fall on the surface, they act as conductive bridges between the lines, reducing the resistance and allowing electric current to flow. This change in conductivity is detected by the circuit and converted into an electrical signal, which can be read as an analog value by a microcontroller such as Arduino.

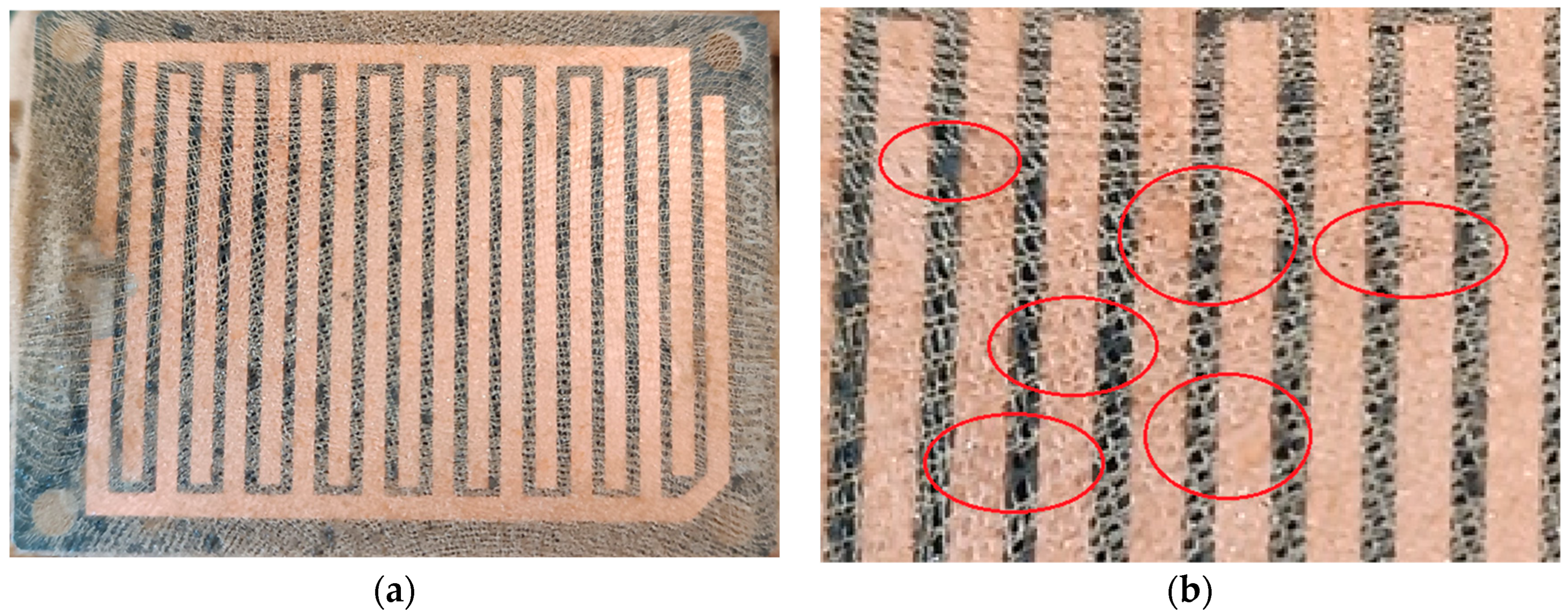

Figure 3a shows the surface of the sensor without water droplets (high resistance), while

Figure 3b shows the surface of the sensor with droplets present (low resistance).

The operation of the sensor in terms of output voltage, which is proportional to the conductivity on its surface—that is, the number of water droplets present—is based on the principle of a voltage divider. In a typical voltage divider circuit, there are two resistors, R1 and R2. In this case, R2 represents the resistance of the sensor surface, which varies depending on the amount of moisture or water droplets. As the number of droplets increases, the resistance R2 decreases, thus altering the voltage at the output.

The output voltage is calculated using the standard voltage divider relationship, as shown in Equation (1).

where

is the output voltage of sensor, Vcc is the supply voltage, R

1 is a fixed resistor, R

2 is the variable resistance of the sensor’s surface.

Arduino uses specific ports to read analog signals from special pins labeled with the prefix “A” (such as A0, A1, etc.). An analog signal is usually a continuously varying voltage, like the one produced by a light sensor, a potentiometer, or another sensor that changes its output based on some physical parameter (e.g., light, temperature, pressure).

Arduino includes an internal Analog-to-Digital Converter (ADC) that converts the input voltage into an integer value. This conversion is based on a 10-bit resolution, which means the output value ranges from 0 to 1023. A value of 0 corresponds to 0 V, while a value of 1023 corresponds to the maximum allowable reference voltage, which is typically 5 V (or 3.3 V on some boards). The intermediate values represent voltages proportionally between these limits. These intermediate values are also referred to as the step resolution.

The voltage Vout from Equation (1) does not appear directly in the experiments of this study. Instead, the steps resolution was chosen to be displayed. This was done to make even the smallest change in the sensors’ resistance noticeable. In order to calculate the value of Vout, Equation (2) must be applied.

where

is the value returned (ranging from 0 to 1023), 1023 is the maximum value of the 10-bit ADC (

),

is the reference voltage of the Arduino, typically 5 V for most boards, or 3.3 V for others.

Due to the construction of the sensor, the distance between the copper lines—that is, the gap between them—is approximately 1 mm, as shown in

Figure 4.

This 1 mm gap between the copper traces results in poor sensitivity to small droplets. As shown in

Figure 5, the observed droplets are very small and often do not make contact with both copper traces simultaneously—instead, they touch only one trace or fall into the gap between them. As a result, even though small droplets are present, the sensor fails to detect them (the image corresponds to a single spray from a handheld sprayer).

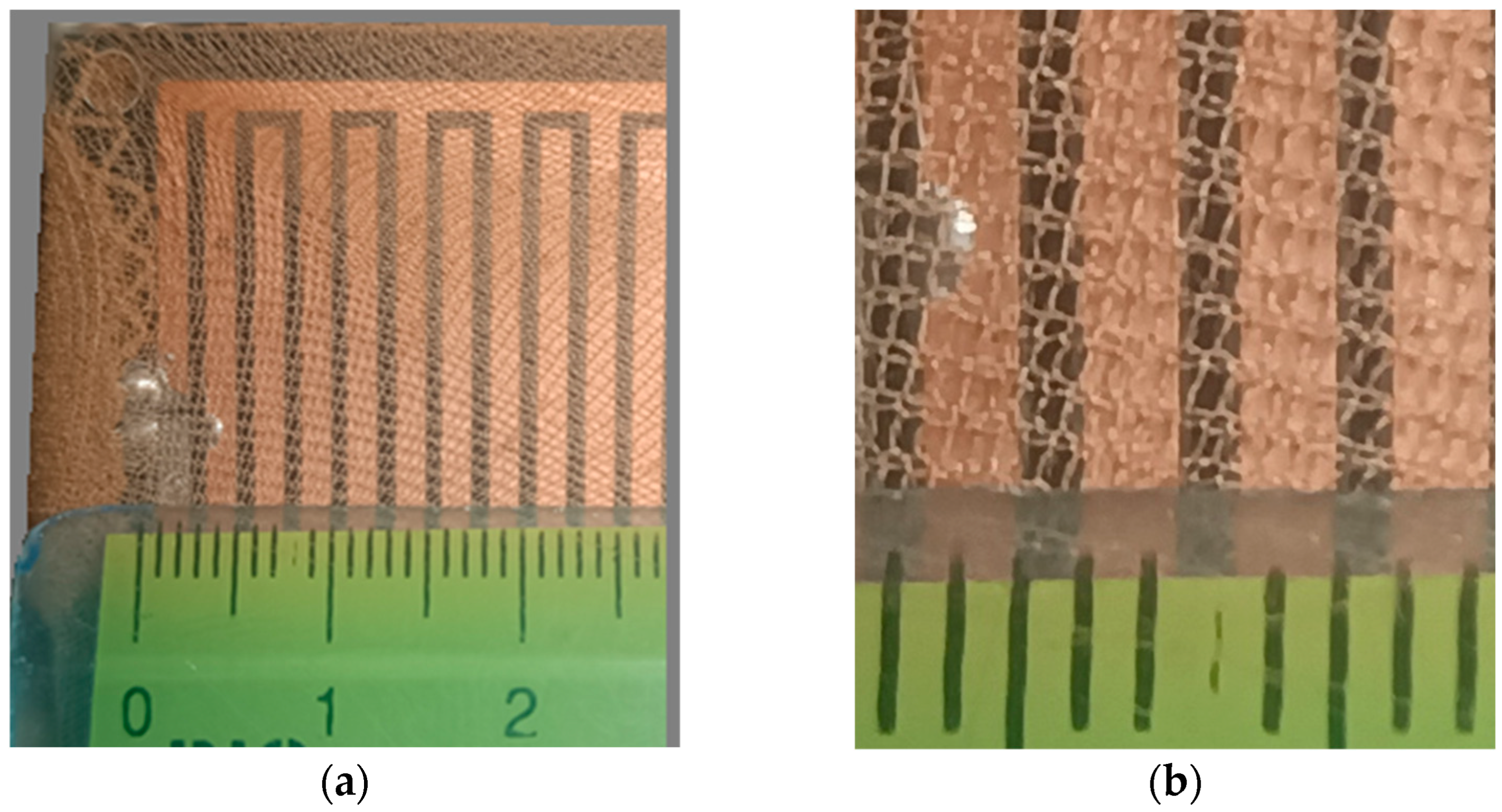

Figure 6 shows the sensor covered with the fine nylon mesh.

Figure 6a displays the sensor in its final form, where the nylon mesh is in close contact with the sensor’s surface and copper traces.

Figure 6b illustrates the water droplets deposited on the mesh, which spread across it and come into contact with both copper surfaces. This enables the sensor to detect smaller droplets more easily, improving its sensitivity to lower amounts of moisture (the image corresponds to a single spray from a handheld sprayer).

As is well known, nylon is not a good conductor of electricity. Therefore, stretching the nylon over the sensor does not directly affect conductivity, but since the thread is stretched over the sensor, the drops are distributed along the entire length of the thread. This results in the size of a small drop being distributed over the thread, so that it spreads more quickly over a greater distance between the copper paths. As the drop touches the copper paths through the thread, the result is that the conductivity changes with a smaller drop size. In this way, the conductivity of the sensor does not change, but it contributes significantly to the sensor’s detection mechanism, especially for smaller droplets. The degree of tension of the nylon mesh significantly affects the performance of the sensor. The nylon mesh must be stretched over the surface of the sensor. During the experiments, it was found that, as the mesh is stretched, the gap between the copper tracks must be covered by two to four lines of nylon.

Figure 7a shows the nylon mesh stretched over the surface of the sensor.

Figure 7b shows the number of threads in the gap between the copper tracks.

3. Results and Discussion

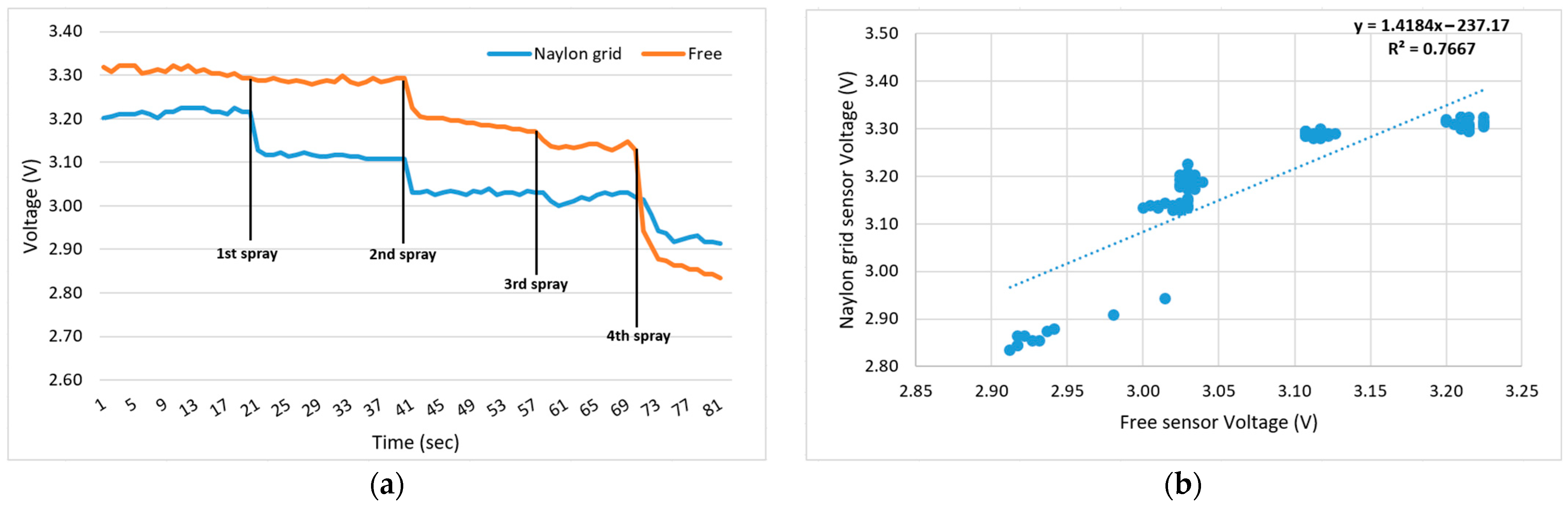

The measurements were conducted in a laboratory setting [

47] following a specific procedure. The sensors, both the one with the nylon mesh coating and the other without coating, as sold by the manufacturer, were placed very close together. During the measurement procedure, at regular intervals (approximately every 20 s), the sensors were sprayed four times with water from a hand sprayer at a distance of 40 cm. After weighing on a precision scale, each spray had a weight of 0.5 g (or 0.5 mL, given that the specific weight of water is equal to 1).

It should be noted that the nylon mesh must be placed tightly stretched over the sensor, as if it is not properly fitted, you will notice that the sensor performs even worse than its factory condition.

Figure 8 shows the result of incorrect placement of the nylon mesh. The result is that it initially detects moisture, but then fails to detect it. This happens because water droplets accumulate in the space between the nylon mesh and the sensor surface.

The results were obtained from the serial plotter and serial monitor functions using Arduino IDE software (v.1.8.19). For the interpretation of the results, the parameterized sensor is referred to as A0-alt, while the non-parameterized sensor is referred to as A1-Free.

The experiment was performed several times with similar results. Two experimental measurements related to the proposed methodology are presented.

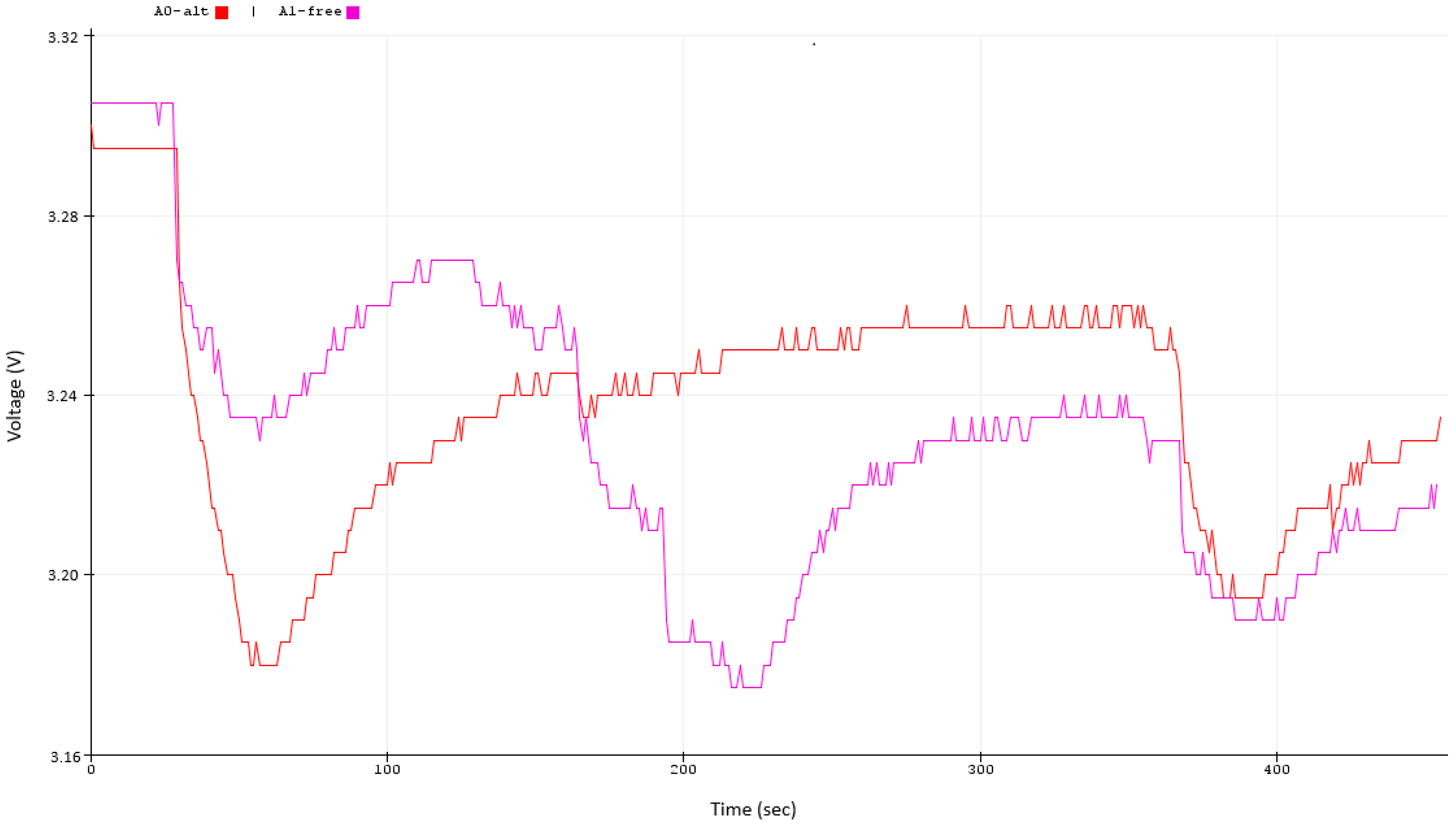

Figure 9 shows the response of the sensors at two different experiments. It should be noted that after each set of steps (visible steps), it is clear that the response changes, as does the meaning of the parameterized sensor (A0-alt) is clearly distinct from the signal of the uncalibrated sensor (A1-Free).

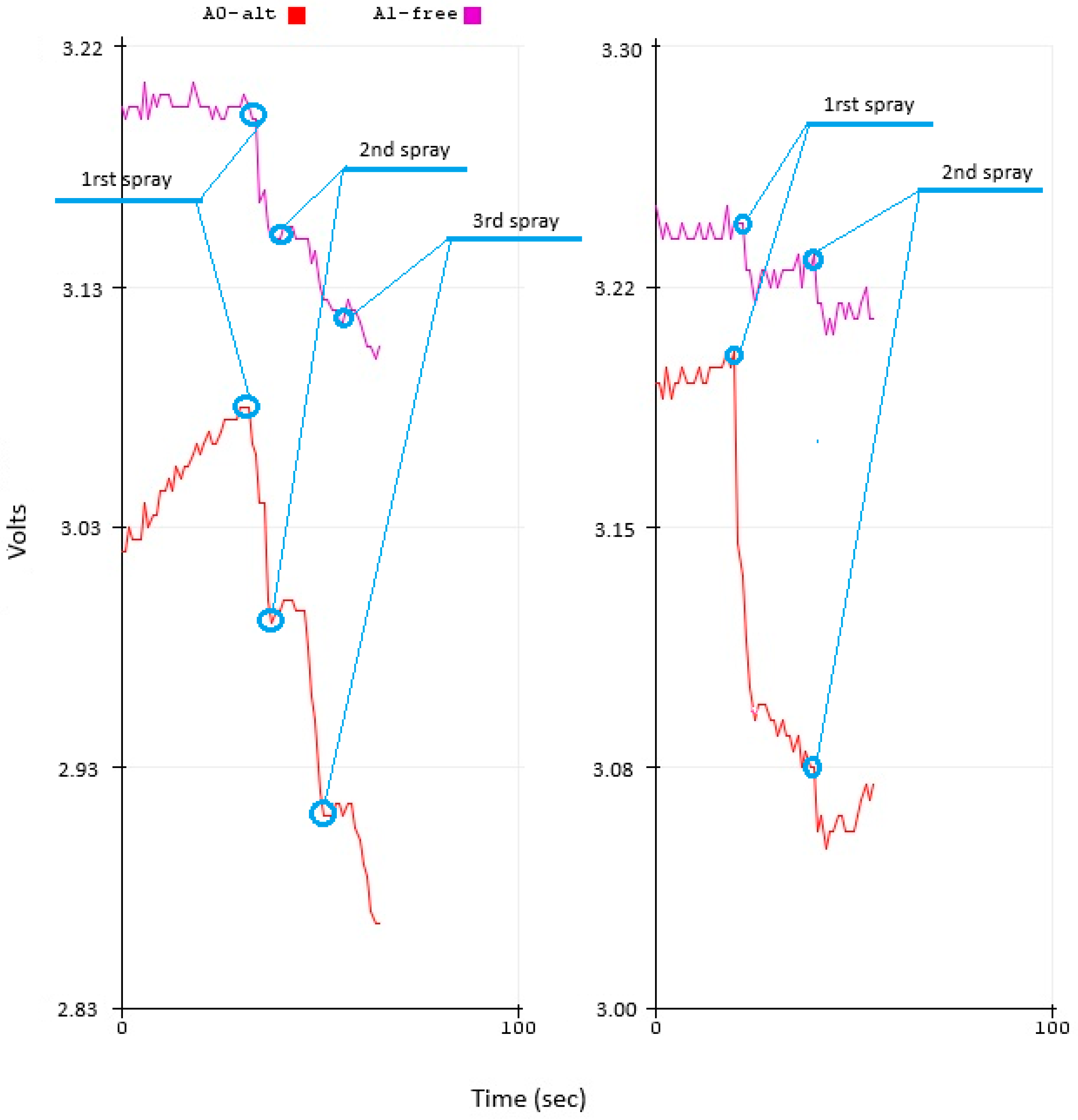

For research purposes, based on further analysis, two other sets of measurements are presented below, which examine how far ahead the parameterized sensor is and to what extent there is a correlation between the two sensors.

More specifically,

Figure 10 and

Figure 11 show two sets of measurements.

Figure 10a and

Figure 11a present the time series of the analysis steps and measurement readings, while

Figure 10b and

Figure 11b show the scatter plot and the coefficient of determination between the analysis steps and measurement readings for both sensors.

Figure 10 and

Figure 11 show that, based on the time series graphs, the parameterized sensor exhibits a better response. On the other hand, based on the scatter plot, the coefficient of determination shows a very satisfactory degree (R

2 = 0.76), which means that the parameterized sensor follows the measurements and has similar behavior in relation to the non-parameterized one.

This helps us understand that the parameterized sensor has the ability to perceive more than the non-parameterized sensor, i.e., sensitivity is increased in some way. The result of all of the above is that such a sensor can detect small droplets of moisture.

An extensive study was conducted on the reproducibility of the results. For this reason, a series of ten measurement experiments was conducted on two identical sensors, to which nylon mesh with the same degree of tension was applied.

The Coefficient of Variation (CV) is often used to compare reproducibility or stability between different conditions or sensors. The reproducibility of the measurements was quantified using the Coefficient of Variation (CV), which is defined as the ratio of the standard deviation (SD) to the mean value, expressed as a percentage by Equation (3).

where the SD is the standard deviation and the Mean is the mean value of the measurements.

Table 1 presents the mean value, standard deviation, and coefficient of variation for the ten experiments conducted on the two sets of sensors.

According to

Table 1, the coefficient of variation (CV) obtained for the Nylon mesh condition (3.67%) was slightly higher than that of the Free condition (3.38%). Nevertheless, both values are below 5%, indicating that the reproducibility of the Nylon mesh measurements is satisfactory and comparable to that of the Free condition.

In general, after a series of experiments, it appears that the proposed methodology can work, as it produces valuable results. The proposed method does not increase the sensitivity of the sensor, but by applying this technique, it is possible to spread the droplets over the surface of the sensor, which ultimately results in the droplet coming into direct contact with the sensors (copper track) and being detected by the sensor even when it is small in size.

4. Conclusions

The experimental results clearly show that the parameterized raindrop sensor, modified with a fine nylon mesh such as a stocking, is capable of detecting smaller moisture droplets than the original unmodified sensor. This improvement in detection is achieved not by altering the sensor’s electrical components, but by enhancing how water droplets are retained and spread across the sensor’s surface. The nylon mesh helps micro-droplets, like morning dew or light mist, to bridge the gaps between the copper conductive tracks, thereby changing the conductivity and allowing the sensor to respond to even very small amounts of moisture.

Repeated experiments demonstrated that the modified sensor consistently gave off stronger and earlier signals in the presence of moisture compared to the factory sensor. This shows a clear enhancement in sensitivity and detection capability. Even when both sensors were exposed to the same controlled spray of water droplets, the parameterized sensor was more effective at registering the moisture. The quality of the work performed was very good, with the results being highly satisfactory and reliable, confirming the validity of the proposed modification method.

The proposed method is low-cost, simple, and easy to implement, making it very practical for many applications. The nylon mesh must be applied tightly and correctly on the sensor surface; otherwise, the sensor’s performance can worsen due to water pooling between the mesh and sensor, which prevents accurate detection. When properly installed, this system offers a novel and practical solution for enhancing moisture detection in low-cost sensors.

The results of the study indicate that the work performed was successful and meaningful. The sensor modification method reliably improves moisture detection, making it a valuable contribution to both sensor technology and cultural heritage preservation. The approach balances cost-efficiency with enhanced functionality, addressing a critical need for practical humidity monitoring solutions in various fields.

Importantly, this makes the solution particularly suitable for applications involving the monitoring of humidity in sensitive cultural heritage structures—such as monuments made of stone, marble, or iron. In such environments, even small amounts of moisture can accelerate degradation processes. The use of a cost-effective, enhanced-sensitivity sensor can provide early warnings and support timely conservation interventions, helping to preserve materials and structures that are essential to cultural identity and history.