IoT System for Monitoring and Controlling Microclimates in a Fruit Fly Breeding Chamber †

Abstract

1. Introduction

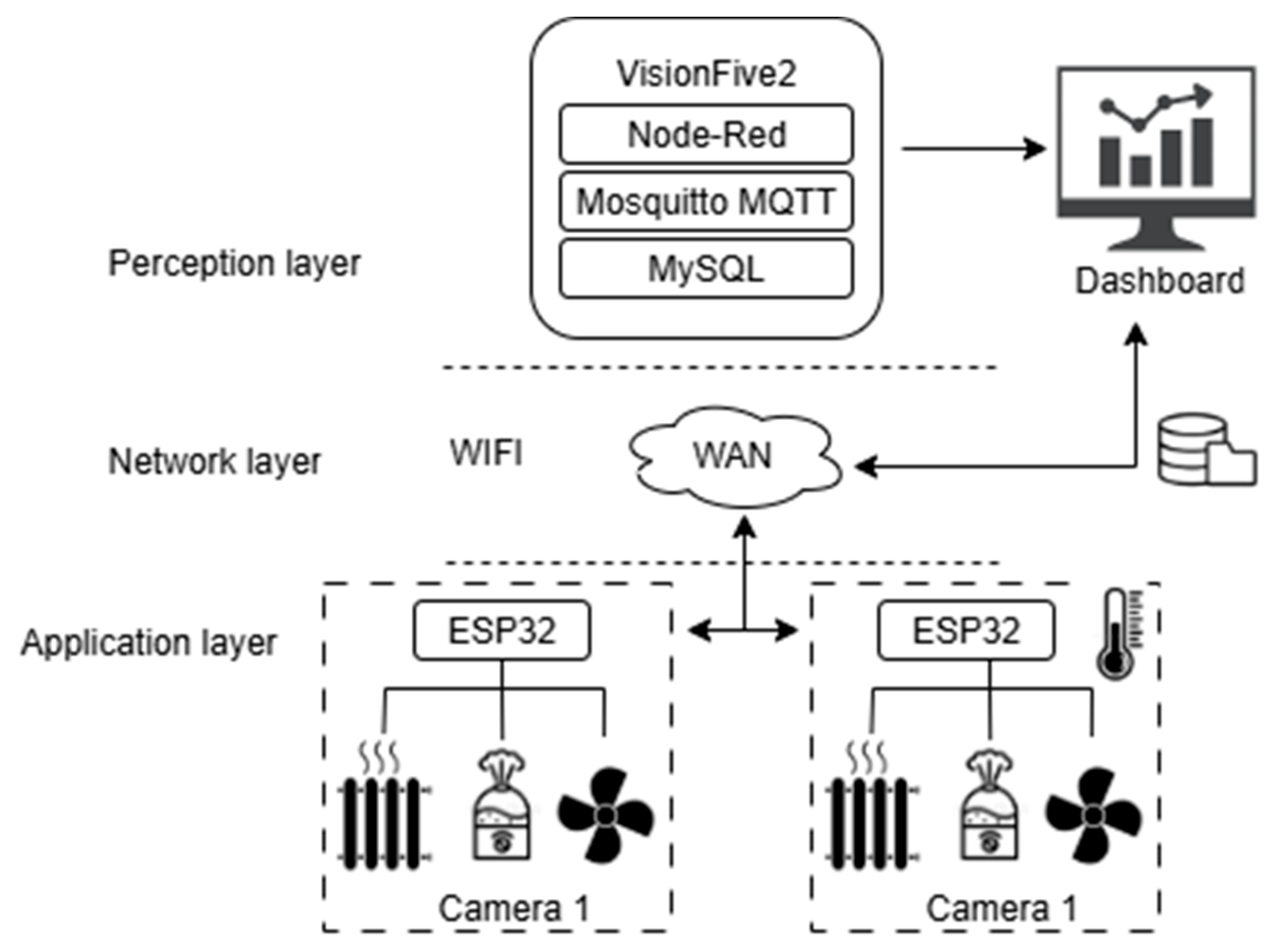

2. System Design

2.1. Perception Layer (Edge)

2.2. Network Layer

2.3. Application Layer

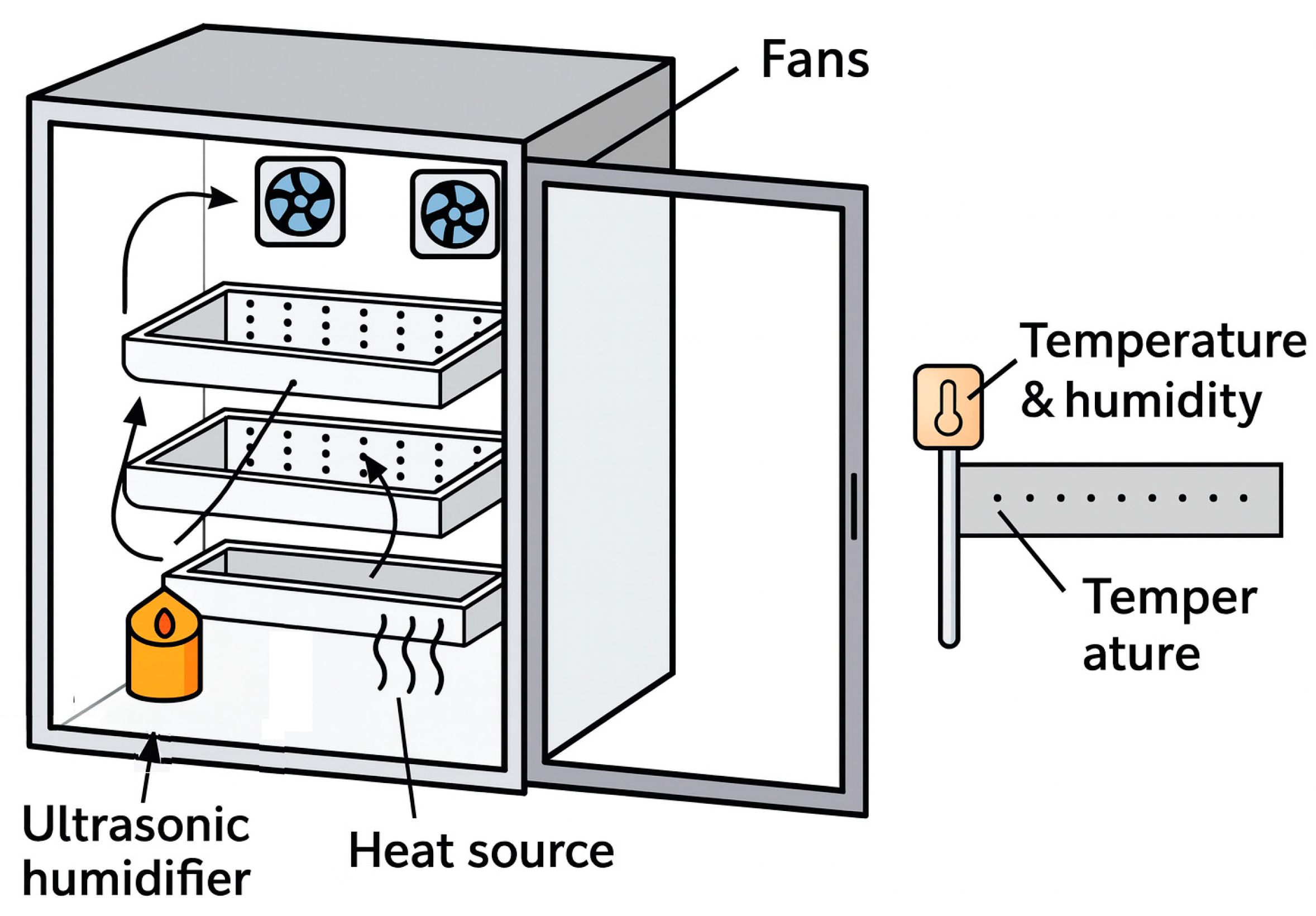

2.4. Experimental Environment

2.5. Control System

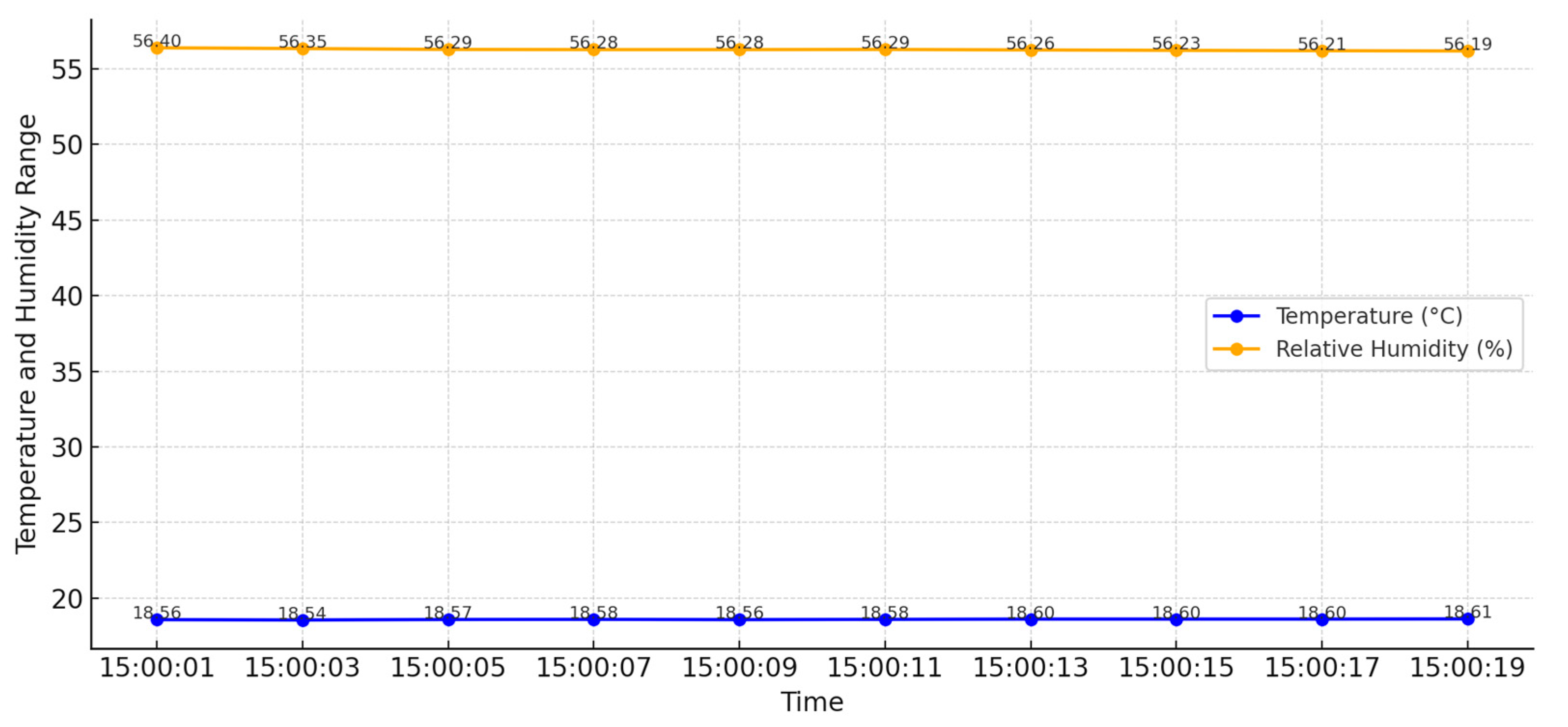

3. Results

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Lovett, G.M.; Burns, D.A.; Driscoll, C.T.; Jenkins, J.C.; Mitchell, M.J.; Rustad, L.; Shanley, J.B.; Likens, G.E.; Haeuber, R. Who needs environmental monitoring? Front. Ecol. Environ. 2007, 5, 253–260. [Google Scholar] [CrossRef]

- Kirkhorn, S.R.; Schenker, M.B. Current Health Effects of Agricultural Work: Respiratory Disease, Cancer, Reproductive Effects, Musculoskeletal Injuries, and Pesticide–Related Illnesses. J. Agric. Saf. Health 2002, 8, 16. [Google Scholar] [CrossRef]

- Jacome, E.; Jácome, C.J.; Bayancela, S.; Freire, L.O. Technological Reconversion of a Climatic Chamber for the Artificial Rearing of Fruit Flies of the Species (Anastrepha striata). Smart Innov. Syst. Technol. 2024, 372, 573–580. [Google Scholar] [CrossRef]

- Pamula, A.S.P.; Ravilla, A.; Madiraju, S.V.H. Applications of the Internet of Things (IoT) in Real-Time Monitoring of Contaminants in the Air, Water, and Soil. Eng. Proc. 2022, 27, 26. [Google Scholar] [CrossRef]

- Al-Fuqaha, A.; Guizani, M.; Aledhari, M.; Ayyash, M. Internet of Things: A Survey on Enabling Technologies, Protocols, and Applications. IEEE Commun. Surv. Tutor. 2015, 17, 2347–2376. [Google Scholar] [CrossRef]

- Hosny, K.M.; Magdi, A.; Salah, A.; El-Komy, O.; Lashin, N.A. Internet of Things Applications Using Raspberry-Pi: A Survey. Int. J. Electr. Comput. Eng. 2023, 13, 902–910. [Google Scholar] [CrossRef]

- Mohiuddin, M.; Islam, M.S.; Shanjida, S. Internet of Things (IoT)-Based Smart Agriculture Irrigation and Monitoring System Using Ubidots Server. Eng. Proc. 2024, 82, 99. [Google Scholar] [CrossRef]

- Behera, T.M.; Mohapatra, S.K.; Samal, U.C.; Khan, M.S.; Daneshmand, M.; Gandomi, A.H. I-SEP: An Improved Routing Protocol for Heterogeneous WSN for IoT-Based Environmental Monitoring. IEEE Internet Things J. 2019, 7, 710–717. [Google Scholar] [CrossRef]

- Rajalakshmi, P.; Mahalakshmi, S.D. IOT Based Crop-Field Monitoring and Irrigation Automation. In Proceedings of the 10th International Conference on Intelligent Systems and Control (ISCO), Coimbatore, India, 7–8 January 2016; pp. 1–6. [Google Scholar]

- Jo, R.S.; Lu, M.; Raman, V.; Then, P.H.H. Design and Implementation of IoT-enabled Compost Monitoring System. In Proceedings of the IEEE 9th Symposium on Computer Applications & Industrial Electronics (ISCAIE), Kota Kinabalu, Malaysia, 27–28 April 2019; pp. 27–28. [Google Scholar] [CrossRef]

- de Melo, G.C.G.; Torres, I.C.; de Araújo, Í.B.Q.; Brito, D.B.; Barboza, E.A. A Low-Cost IoT System for Real-Time Monitoring of Climatic Variables and Photovoltaic Generation for Smart Grid Application. Sensors 2021, 21, 3293. [Google Scholar] [CrossRef]

- Vacacela, S.G.; Freire, L.O. Implementation of a Network of Wireless Weather Stations Using a Protocol Stack. In Intelligent Manufacturing and Energy Sustainability; Smart Innovation, Systems and Technologies (SIST); Springer: Singapore, 2021; Volume 213. [Google Scholar] [CrossRef]

- Mulyono, A.; Suriadikusumah, A.; Harriyanto, R.; Djuwansah, M.R. Soil Quality under Agroforestry Trees Pattern in Upper Citarum Watershed, Indonesia. J. Ecol. Eng. 2019, 20, 203–213. [Google Scholar] [CrossRef]

- Chandra, A.A.; Jannif, N.I.; Prakash, S.; Padiachy, V. Cloud Based Real-time Monitoring and Control of Diesel Generator using the IoT Technology. In Proceedings of the 20th International Conference on Electrical Machines and Systems (ICEMS), Sydney, Australia, 11–14 August 2017. [Google Scholar] [CrossRef]

- Memon, G.S.; Jaffer, S.S.; Zaidi, S.; Sheikh, M.M.; Jabbar, M.U.; Ahad, A. An IOT-Enabled Generator for Power Monitoring and Load Management with Power Factor Improvement. Eng. Proc. 2021, 12, 33. [Google Scholar] [CrossRef]

- Khan, M.A.; Waqas, A.; Khand, Q.U.; Khan, S. Context Aware Fuel Monitoring System for Cellular Sites. Int. J. Adv. Comput. Sci. Appl. 2017, 8, 281–285. [Google Scholar] [CrossRef]

- Mhaned, A.; Mouatassim, S.; Haji, M.E.; Benhra, J. Low-Cost Smart Irrigation System Based on Internet of Things and Fuzzy Logic. In Smart Applications and Data Analysis; Communications in Computer and Information Science; Springer: Cham, Switzerland, 2022; pp. 78–89. [Google Scholar] [CrossRef]

- Mhaned, A.; Salma, M.; Mounia, E.H.; Jamal, B. Contribution to Smart Irrigation Based on Internet of Things and Artificial Intelligence. In Proceedings of the 6th International Conference on Big Data and Internet of Things, Tangier, Morocco, 25–27 October 2022; Lecture Notes in Networks and Systems. pp. 537–549. [Google Scholar] [CrossRef]

- Castillo, J.N.; Carrillo, G.G.; Freire, L.O.; Culqui, J. Fusion of Data and Modeling Techniques in Power Quality Compensation Using SAPF. Fusion Pract. Appl. 2024, 16, 8–21. [Google Scholar]

- Al Noman, A.; Baidya, P.; Hossain, M.A.; Dev, P.; Saha, K.; Hossain, M.L. Design and Implementation IoT-Driven Distribution Transformer Health Monitoring System for the Smart Power Grid. Eng. Proc. 2025, 87, 27. [Google Scholar] [CrossRef]

- Nie, X.; Fan, T.; Wang, B.; Li, Z.; Shankar, A.; Manickam, A. Big Data Analytics and IoT in Operation Safety Management in Under Water Management. Comput. Commun. 2020, 154, 188–196. [Google Scholar] [CrossRef]

- Safara, F.; Souri, A.; Baker, T.; Al Ridhawi, I.; Aloqaily, M. PriNergy: A Priority-Based Energy-Efficient Routing Method for IoT Systems. J. Supercomput. 2020, 76, 8609–8626. [Google Scholar] [CrossRef]

- Aleesha, M.; Laseena, C.A. MQTT Protocol for Resource Constrained IoT Applications: A Review. In Proceedings of the International Conference on Systems, Energy and Environment 2022 (ICSEE 2022), Kerala, India, 5–6 August 2022; SSRN Electronic Journal: Rochester, NY, USA, 2022. [Google Scholar] [CrossRef]

- Bormann, C.; Castellani, A.P.; Shelby, Z. CoAP: An Application Protocol for Billions of Tiny Internet Nodes. IEEE Internet Comput. 2012, 16, 62–67. [Google Scholar] [CrossRef]

- Naik, N. Choice of Effective Messaging Protocols for IoT Systems: MQTT, CoAP, AMQP and HTTP. In Proceedings of the 2017 IEEE International Symposium on Systems Engineering (ISSE), Vienna, Austria, 11–13 October 2017. [Google Scholar] [CrossRef]

- Gupta, P.; Indhra, M. A Survey of Application Layer Protocols for Internet of Things. In Proceedings of the International Conference on Communication, Information and Computing Technology (ICCICT), Mumbai, India, 25–27 June 2021. [Google Scholar] [CrossRef]

- Fouguira, S.; Ammar, E.; Haji, M.E.; Benhra, J. Internet of Things and Predictive Artificial Intelligence for SmartComposting Process in the Context of Circular Economy. Eng. Proc. 2025, 97, 16. [Google Scholar] [CrossRef]

- Han, Y.; Du, Z.; Hu, X.; Li, Y.; Cai, D.; Fan, J.; Geng, Z. Production Prediction Modeling of Food Waste Anaerobic Digestion for Resources Saving Based on SMOTE-LSTM. Appl. Energy 2023, 352, 122024. [Google Scholar] [CrossRef]

- Porras, J.; Navarrete, L.; Castillo, J.N.; Freire, L.O. Pressure Control of a Compressed Air System Based on Hardware in the Loop. In Digital Technologies and Applications; Lecture Notes in Networks and Systems (LNNS); Springer: Cham, Switzerland, 2023; Volume 669. [Google Scholar] [CrossRef]

- Wojcieszak, D.; Zaborowicz, M.; Przybyl, J.; Boniecki, P.; Jedrus, A. Assessment of the Content of Dry Matter and Dry Organic Matter in Compost with Neural Modelling Methods. Agriculture 2021, 11, 307. [Google Scholar] [CrossRef]

- Fouguira, S.; Benhra, J.; El Haji, M.; Ammar, E. Optimization of Olive Oil Extraction Wastes Co-Composting Procedure Based on Bioprocessing Parameters. Heliyon 2023, 181, e107040. [Google Scholar] [CrossRef] [PubMed]

- Meng, X.; Liu, B.; Zhang, H.; Wu, J.; Yuan, X.; Cui, Z. Co-composting of the Biogas Residues and Spent Mushroom Substrate: Physicochemical Properties and Maturity Assessment. Bioresour. Technol. 2019, 276, 281–287. [Google Scholar] [CrossRef] [PubMed]

- Parra, L.; Sendra, S.; García, L.; Lloret, J. Design and Deployment of Low-Cost Sensors for Monitoring the Water Quality and Fish Behavior in Aquaculture Tanks during the Feeding Process. Sensors 2018, 18, 750. [Google Scholar] [CrossRef] [PubMed]

| Set Point °C | Thermohygrometer °C | Sensor SHT32 °C |

|---|---|---|

| 3 | 3.5 | 3.4/3.2 |

| 5 | 5.5 | 5.4/5.24 |

| 10 | 10.5 | 10.4/10.29 |

| 15 | 15.5 | 15.38/15.27 |

| 20 | 20.5 | 20.37/20.25 |

| 25 | 25.5 | 24.36/22.4 |

| 30 | 30.5 | 30.45/30.17 |

| Set Point °C | Thermohygrometer °C | Sensor SHT32 °C |

|---|---|---|

| 40 | 39.2 | 39.5 |

| 50 | 49.2 | 49.5 |

| 60 | 59.2 | 59.5 |

| 70 | 69.2 | 69.5 |

| 80 | 79.2 | 79.5 |

| 90 | 89.2 | 89.5 |

| 100 | 99.2 | 99.5 |

| Variable | Average Value | Standard Deviation | Range | Unit |

|---|---|---|---|---|

| MQTT response time | 180 | 25 | 150–220 | ms |

| Total energy consumption | 12.4 | 0.6 | 11.8–13.2 | Wh |

| Wi-Fi reconnection time | 3.5 | 0.8 | 2.1–4.7 | s |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Freire, L.O.; Castillo, J.N.; Robalino, E.F.; Flores, L.A.; Trujillo, D.F. IoT System for Monitoring and Controlling Microclimates in a Fruit Fly Breeding Chamber. Eng. Proc. 2025, 115, 2. https://doi.org/10.3390/engproc2025115002

Freire LO, Castillo JN, Robalino EF, Flores LA, Trujillo DF. IoT System for Monitoring and Controlling Microclimates in a Fruit Fly Breeding Chamber. Engineering Proceedings. 2025; 115(1):2. https://doi.org/10.3390/engproc2025115002

Chicago/Turabian StyleFreire, Luigi O., Jessica N. Castillo, E. Freddy Robalino, Luis Antonio Flores, and Danilo Fabricio Trujillo. 2025. "IoT System for Monitoring and Controlling Microclimates in a Fruit Fly Breeding Chamber" Engineering Proceedings 115, no. 1: 2. https://doi.org/10.3390/engproc2025115002

APA StyleFreire, L. O., Castillo, J. N., Robalino, E. F., Flores, L. A., & Trujillo, D. F. (2025). IoT System for Monitoring and Controlling Microclimates in a Fruit Fly Breeding Chamber. Engineering Proceedings, 115(1), 2. https://doi.org/10.3390/engproc2025115002