Smart IoT-Enabled Embedded Platform for Real-Time Energy Efficiency Assessment in Heat Pumps †

Abstract

1. Introduction

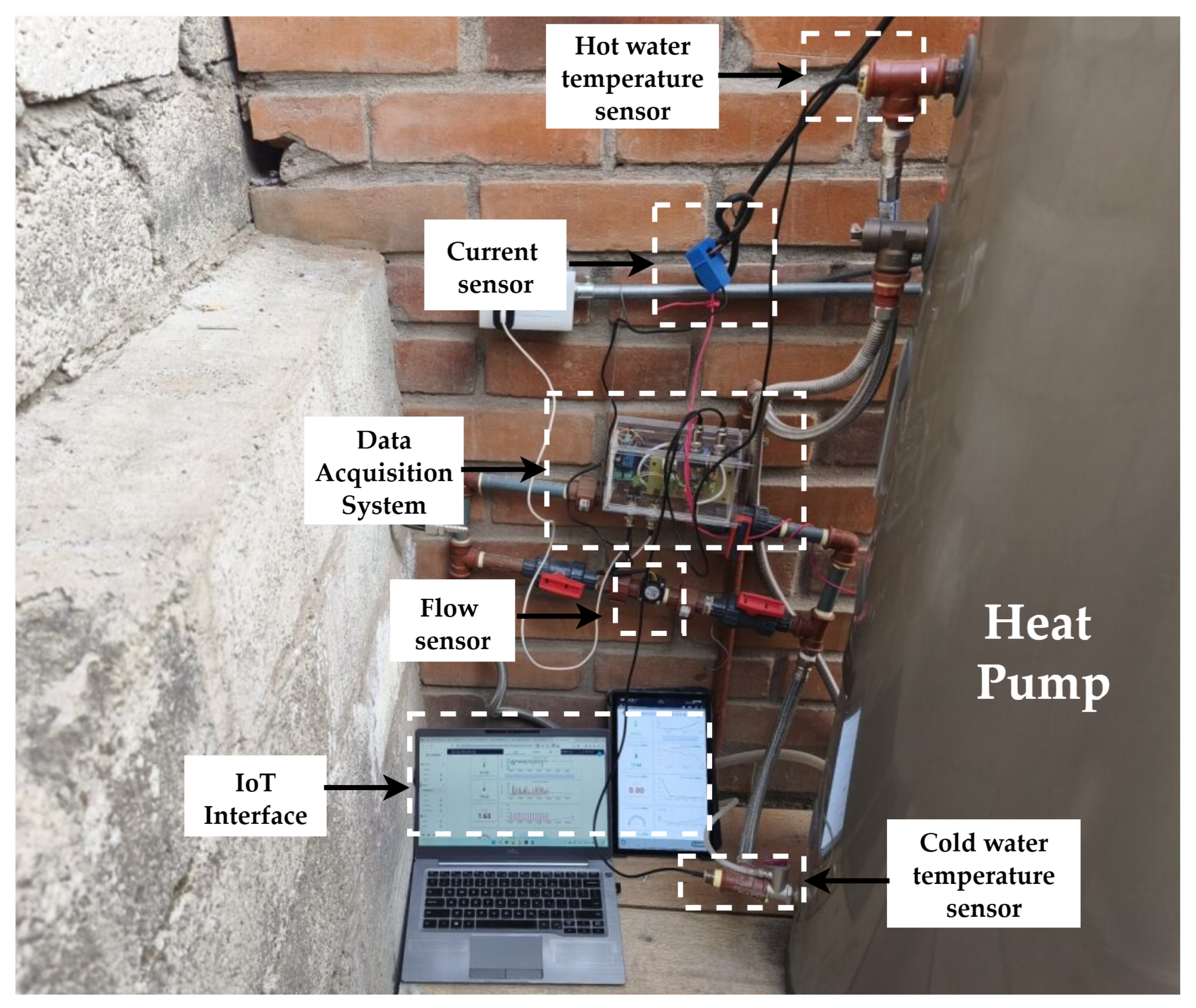

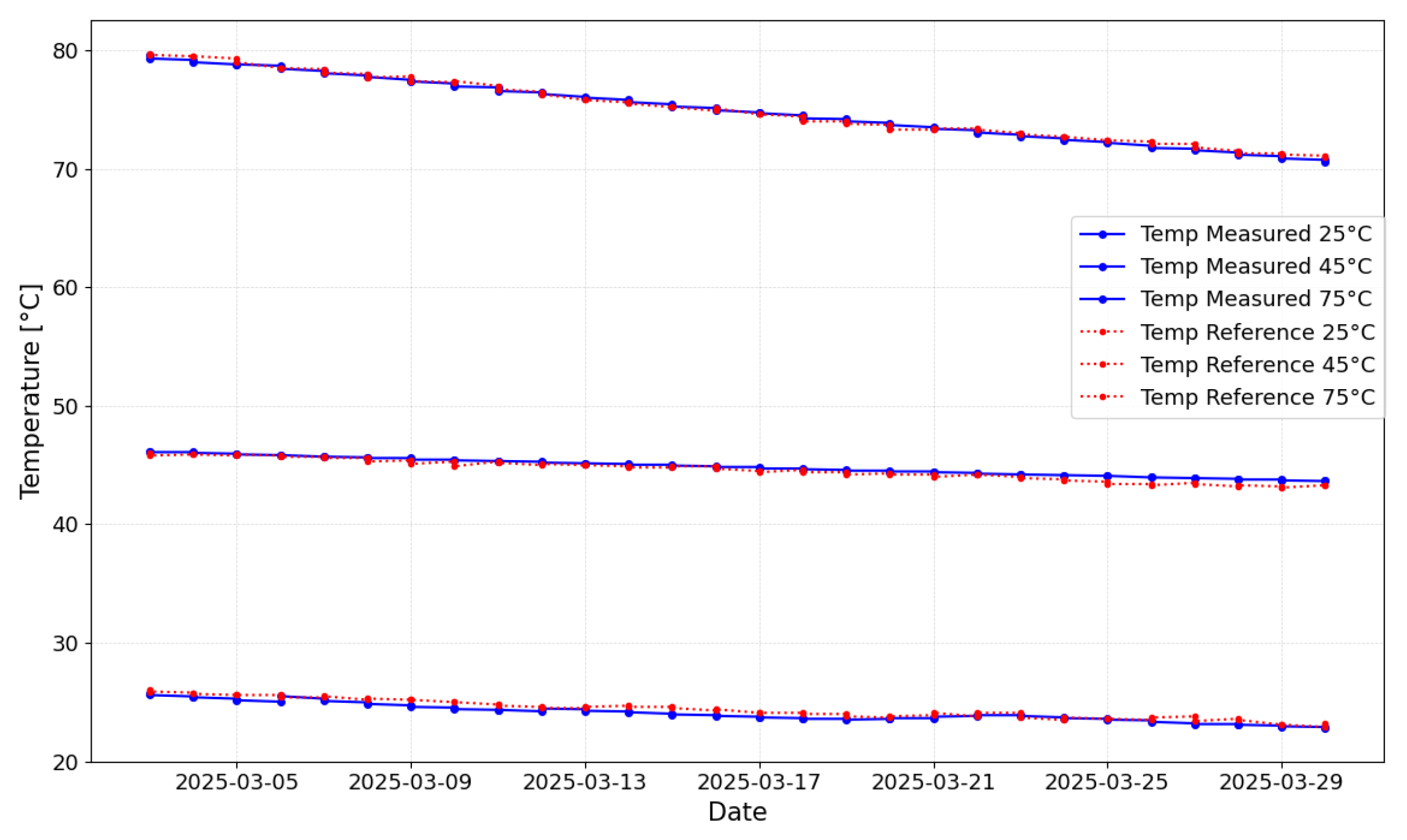

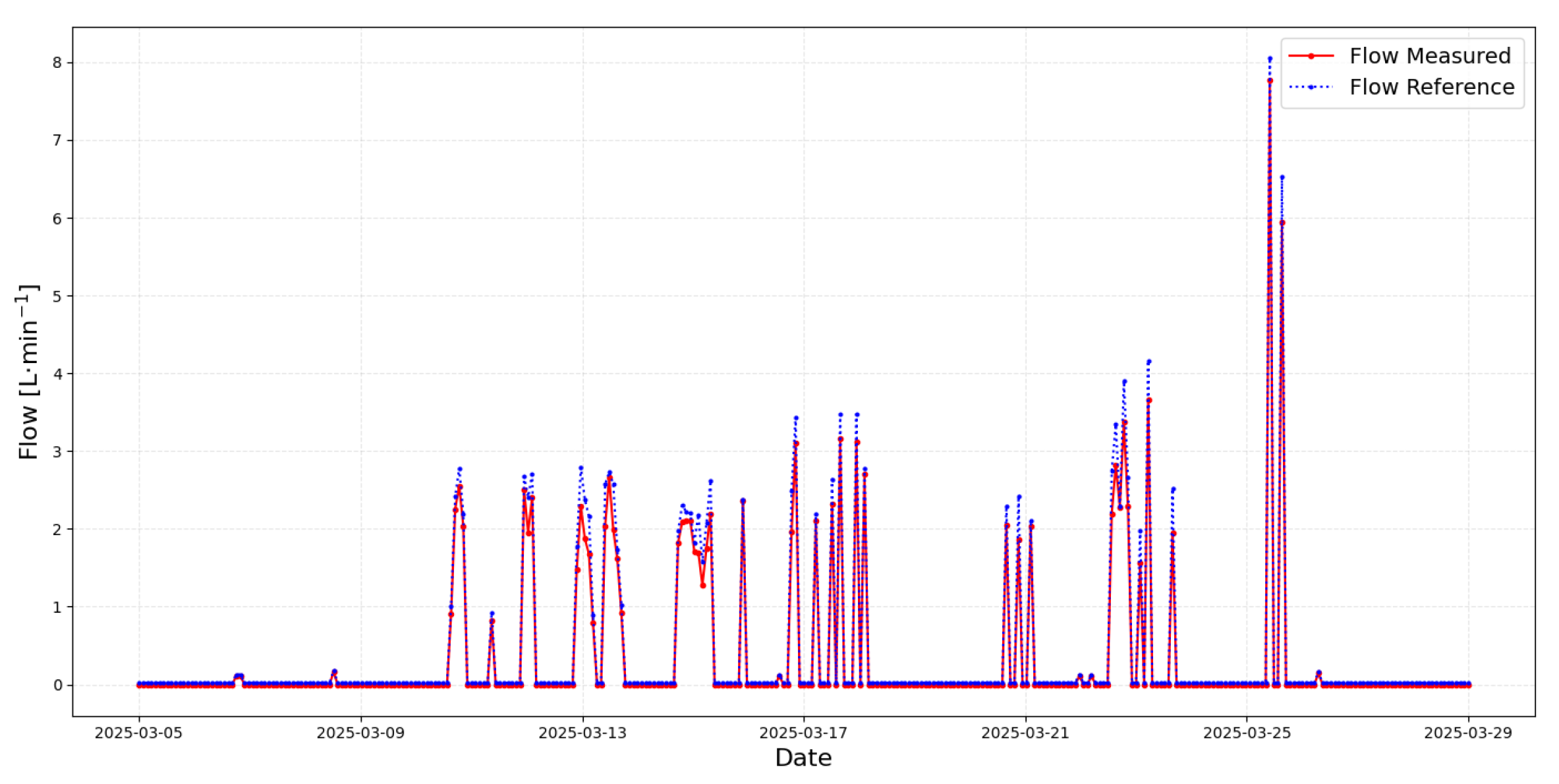

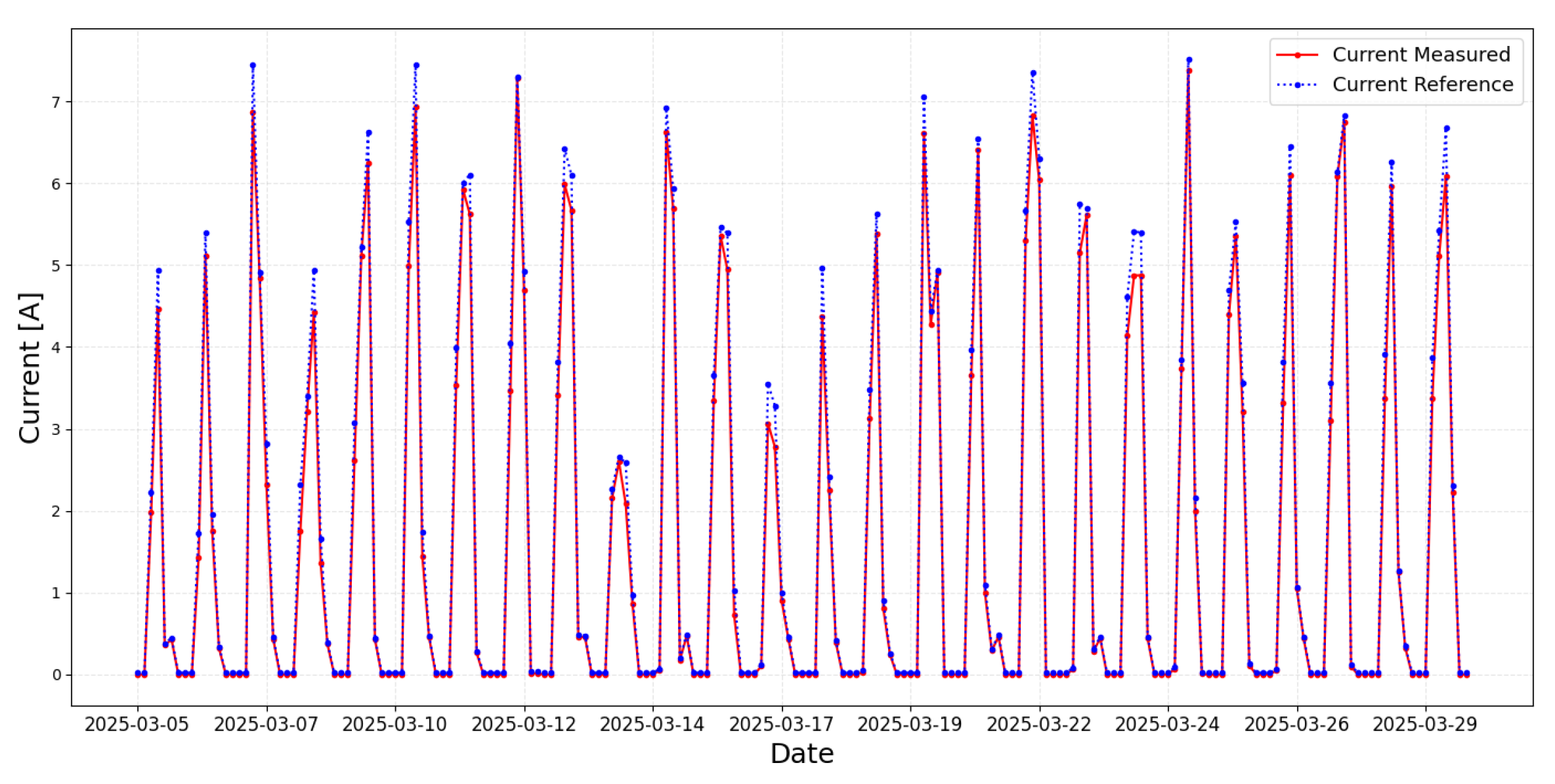

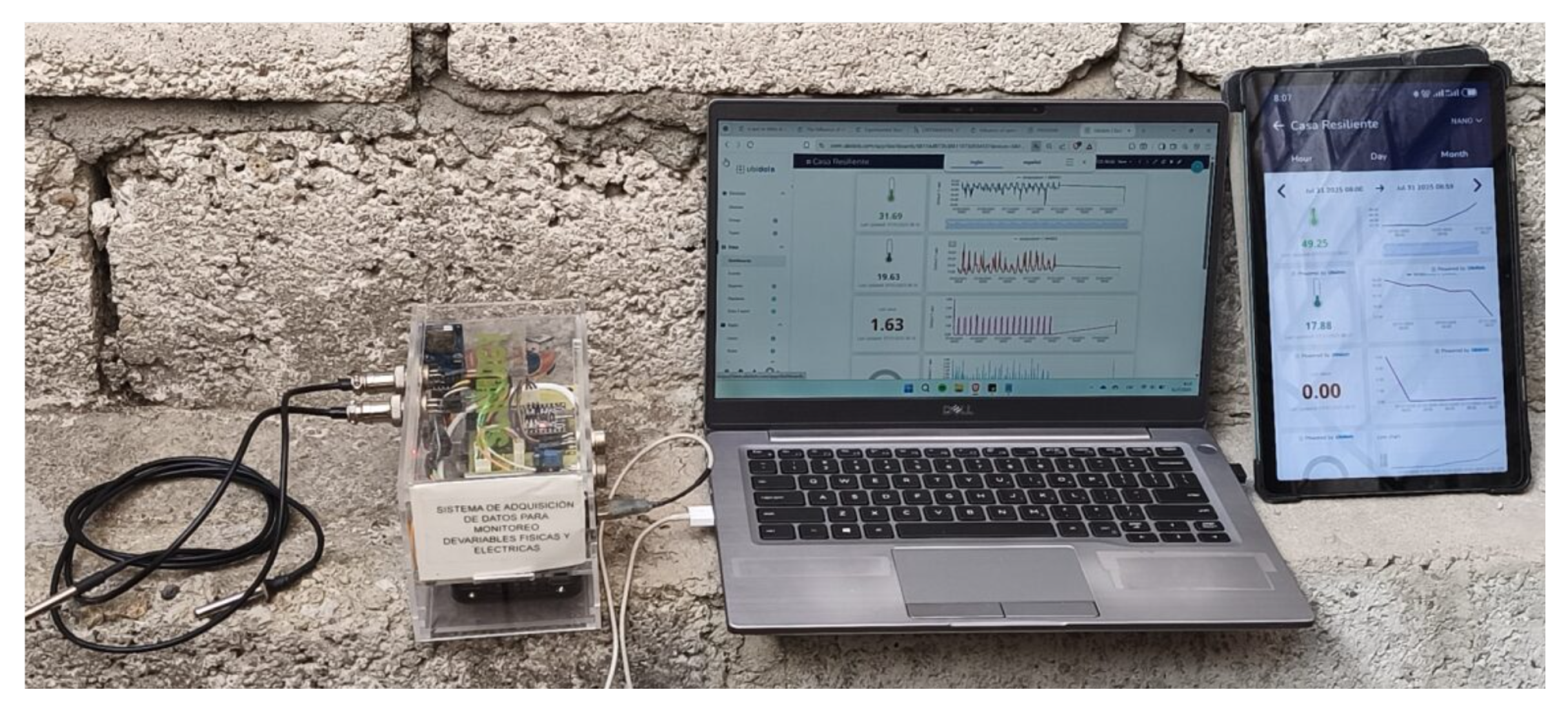

- A low-cost, portable acquisition system integrating calibrated temperature (DS18B20, Maxim Integrated, San José, CA, USA), flow-rate (YF-S201, Foshan Shunde Zhongjiang Energy Saving Electronics, Foshan, China), and current (SCT-013-030, Beijing YaoHuaDechang Electronic Co., Ltd., Beijing, China) sensing with on-device filtering, delivering sub-degree/≤0.01 /∼0.1 accuracy, and flexible deployment (autonomous microSD + RTC, Wi-Fi telemetry).

- A dual data-management strategy—local microSD logging with reliable time-stamping and real-time cloud transmission—that provides redundancy, auditability, and remote diagnostics.

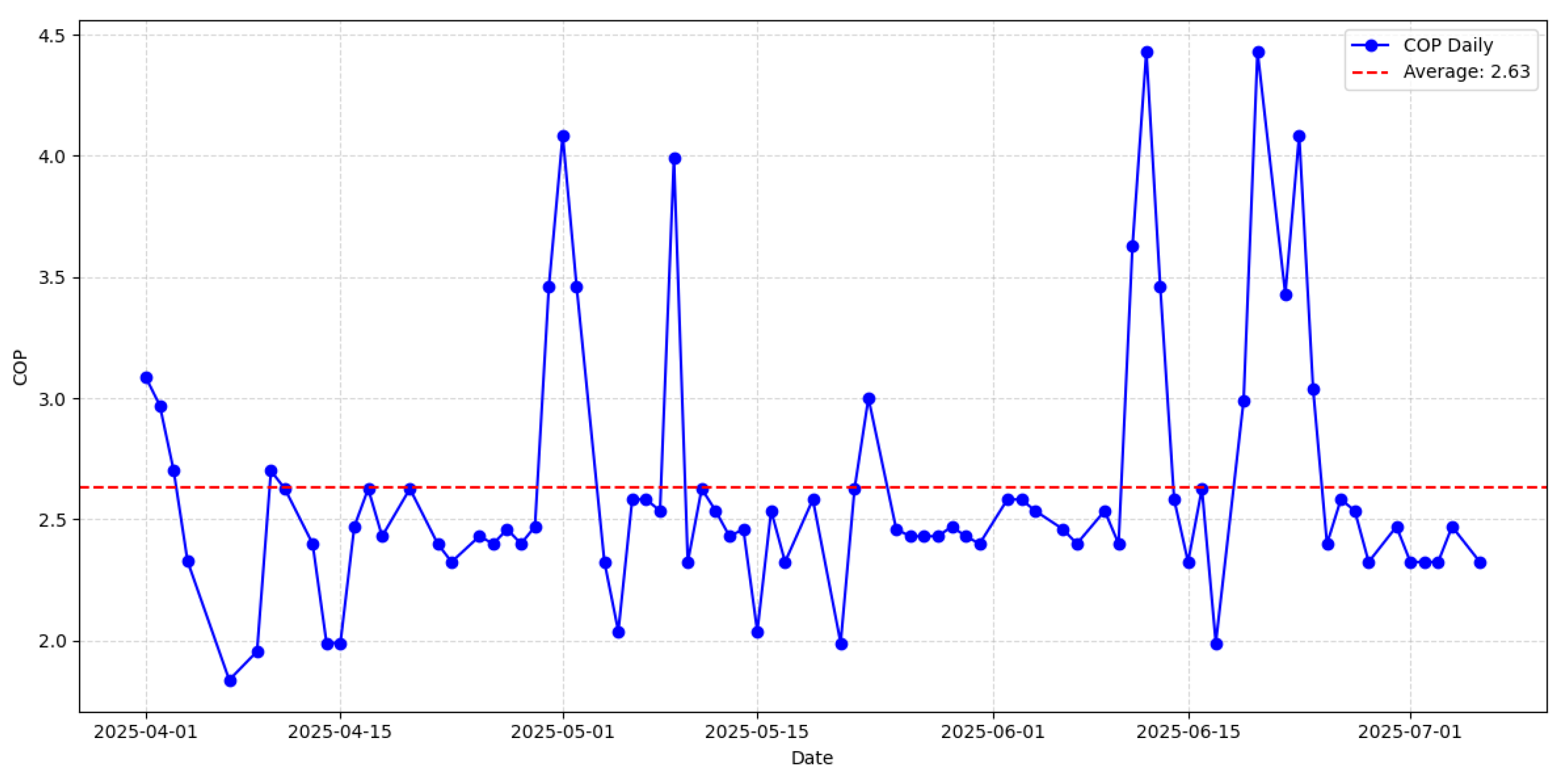

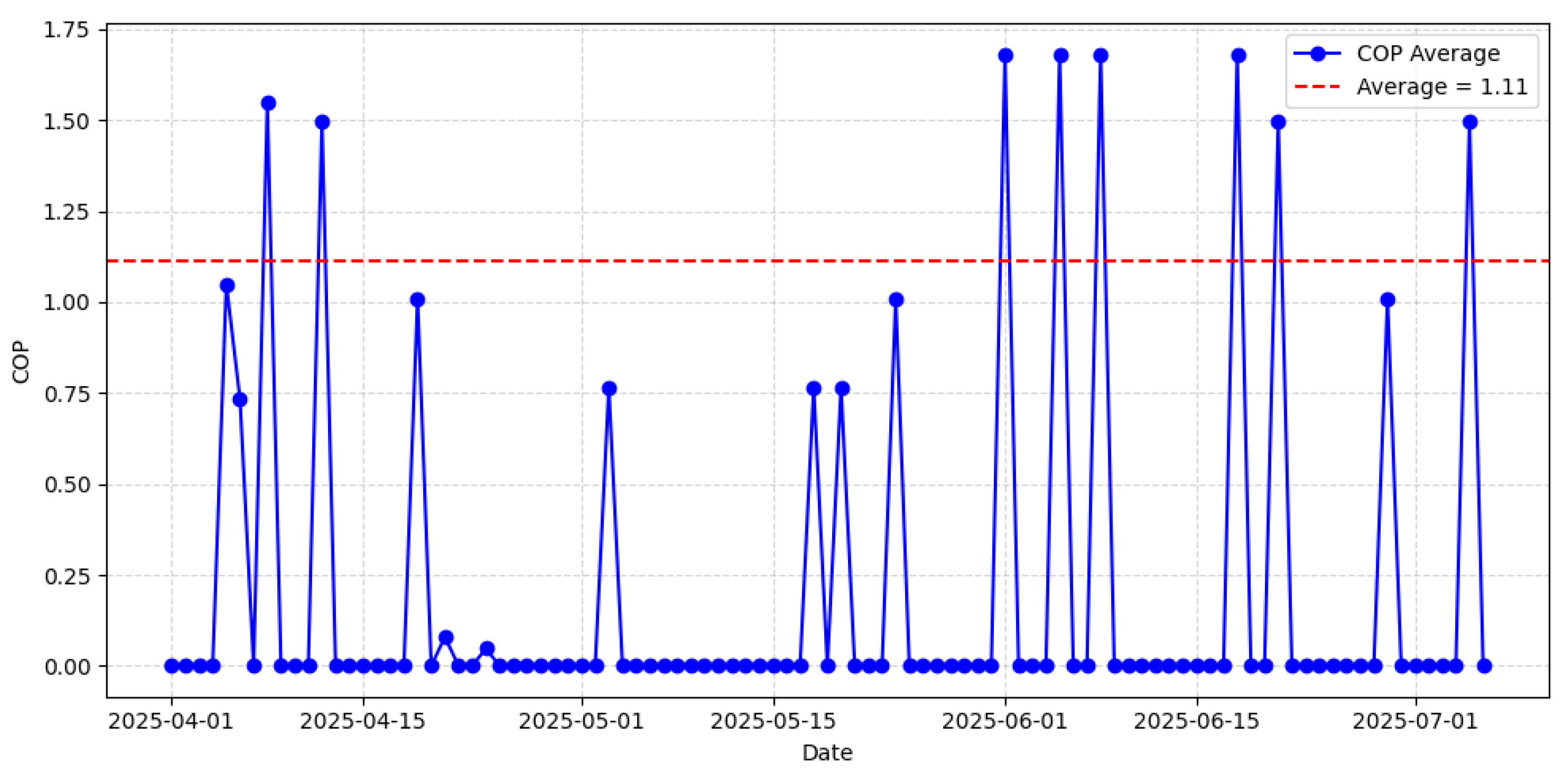

- A three-month in situ deployment on a working heat pump, reporting accuracy against certified references and analyzing daily COP under steady-state and transient conditions, thereby linking engineering implementation with scientific assessment.

2. Methodology

2.1. System Overview

2.2. Measurement and Data Flow

2.3. Calibration and Experimental Setup

3. Results and Discussion

3.1. Sensor Accuracy and System Stability

3.2. COP Analysis and Energy Performance

3.3. System Usability and Deployment Potential

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Parameshwaran, R.; Kalaiselvam, S.; Harikrishnan, S.; Elayaperumal, A. Sustainable Thermal Energy Storage Technologies for Buildings: A Review. Renew. Sustain. Energy Rev. 2012, 16, 2394–2433. [Google Scholar] [CrossRef]

- Kharchenko, V.; Sychov, A.; De Angelis, P.L.; Fiore, U. Monitoring System of a Heat Pump Installation for Heating a Rural House Using Low-Grade Heat from a Surface Watercourse. J. Sens. Actuator Netw. 2020, 9, 11. [Google Scholar] [CrossRef]

- Li, H.; Xu, Z.; Yang, Q.; Wang, Z.; Shao, S.; Xu, C.; Yang, Y.; Li, J. Efficiency Assessment of Variable Speed Air Source Heat Pump Heating Systems: A Hybrid Data-Driven and Theoretical Approach. J. Build. Eng. 2024, 87, 109018. [Google Scholar] [CrossRef]

- Chesser, M.; Lyons, P.; O’Reilly, P.; Carroll, P. Air Source Heat Pump In-Situ Performance. Energy Build. 2021, 251, 111365. [Google Scholar] [CrossRef]

- Carroll, P.; Chesser, M.; Lyons, P. Air Source Heat Pumps Field Studies: A Systematic Literature Review. Renew. Sustain. Energy Rev. 2020, 134, 110275. [Google Scholar] [CrossRef]

- Osterman, E.; Stritih, U. Review on Compression Heat Pump Systems with Thermal Energy Storage for Heating and Cooling of Buildings. J. Energy Storage 2021, 39, 102569. [Google Scholar] [CrossRef]

- Xu, J.; Liu, C.; Liu, X.; Sun, X.; Li, Y. Simulation and Optimization Study on an Energy Efficiency Improvement Strategy of an Air Source Heat Pump under Australian Standards. Energies 2025, 18, 1392. [Google Scholar] [CrossRef]

- Nardi, I.; Lavinia, C.; Iatauro, D.; Calabrese, N. Field Study on Heat Pump Monitoring: Challenges and Opportunities. In E3S Web of Conferences; EDP Sciences: Les Ulis, France, 2021; Volume 312, p. 04002. [Google Scholar] [CrossRef]

- Heat Pump Centre. Heat Pumping Technologies Magazine No 2—Control and Monitoring of Heat Pump Systems. HPT Magazine, 1 September 2022. [CrossRef]

- Melo, G.C.G.; Torres, I.C.; Araújo, Í.B.Q.; Brito, D.B.; Barboza, E.A. A Low-Cost IoT System for Real-Time Monitoring of Climatic Variables and Photovoltaic Generation for Smart Grid Application. Sensors 2021, 21, 3293. [Google Scholar] [CrossRef]

- Ivanov, V.; Smolentsev, S.; Filyakov, A. Microprocessor Temperature Control Device for a Thermal Object. In E3S Web of Conferences; EDP Sciences: Les Ulis, France, 2022; Volume 363, p. 01027. [Google Scholar] [CrossRef]

- Widayaka, P.D.; Jauhari, L. Prototype of Water Pipe Leakage Detector Using Flowmeter Sensor Based on Arduino Uno. Best J. Appl. Electr. Sci. Technol. 2020, 2, 34–38. [Google Scholar] [CrossRef]

- Saputra, D.B.; Pradana, A.; Togatorop, J.F.; Jasa, L.; Hartati, R.S. Rancang Bangun Purwarupa Monitoring Arus Bocor Pada Kabel Grounding Trafo Incoming 20 KV di Gardu Induk Nusa Dua Berbasis Internet of Things. INFORMATIKA 2024, 12, 390–403. [Google Scholar] [CrossRef]

- Haroon, A.L.; Shafiulla, M.; Naveed, S.M.; Ahmed, S.; Nawaz, S.M.; Kumar, U. Home Automation Using Wi-Fi: ESP32-Based System for Remote Control and Environmental Monitoring. In Proceedings of the 2024 Third International Conference on Distributed Computing and Electrical Circuits and Electronics (ICDCECE), Ballari, India, 26–27 April 2024; IEEE: Piscataway, NJ, USA, 2024; pp. 189–193. [Google Scholar] [CrossRef]

- Asenov, S.M.; Tokmakov, D.M. Power Optimization of LoRaWAN Wireless End Sensor Node. In Proceedings of the 2020 XXIX International Scientific Conference Electronics (ET), Sozopol, Bulgaria, 16–18 September 2020; IEEE: Piscataway, NJ, USA, 2020. [Google Scholar] [CrossRef]

- Chanapromma, W.; Wongdocmai, W. Calibration Based on Polynomial Function for Low-Cost Sensors: A Case Study of Air Purifier Filter. In Proceedings of the 2024 12th International Electrical Engineering Congress (iEECON), Pattaya, Thailand, 6–8 March 2024; IEEE: Piscataway, NJ, USA, 2024; pp. 1–4. [Google Scholar] [CrossRef]

- Tirta, I.D.; Wisaksono, A.; Ahfas, A.; Jamaaluddin, J. Home Surveillance Monitoring with ESP32-CAM and SD Card for Data Storage. J. Comput. Netw. Archit. High Perform. Comput. 2024, 6, 419–429. [Google Scholar] [CrossRef]

- Mohiuddin, M.; Islam, M.S.; Shanjida, S. Internet of Things (IoT)-Based Smart Agriculture Irrigation and Monitoring System Using Ubidots Server. Eng. Proc. 2024, 82, 99. [Google Scholar] [CrossRef]

- Arif, R.H.; Musthofa, A.N. Design and Development of Voltage, Current and Frequency Monitoring on 3-Phase Electrical Panel Boxes for Audio Sound Systems Using ESP32-Based Ubidots. BEST J. Appl. Electr. Sci. Technol. 2024, 6, 29–36. [Google Scholar] [CrossRef]

- Feng, H.; Chen, L.; Sun, F. Heating Load and COP Optimizations for a Class of Generalized Irreversible Universal Steady-Flow Variable-Temperature Heat Reservoir Heat Pump Cycle Model. Int. J. Low-Carbon Technol. 2010, 5, 210–222. [Google Scholar] [CrossRef]

- Yin, X.; Wang, A.; Fang, J.; Cao, F.; Wang, X. Investigations on the Dynamic Characteristic and Its Influence Factors of a Transcritical CO2 Automobile Heat Pump. Sci. Technol. Built Environ. 2021, 27, 533–543. [Google Scholar] [CrossRef]

- Ion, V.; Gheorghe, A.; Diaconu, E. Electrical Characteristics Measuring Device for Security Systems. Sci. Bull. Electr. Eng. Fac. 2021, 21, 60–63. [Google Scholar] [CrossRef]

- Sanap, V.C. Design and Implementation of Real Time Clock Using RTC DS3231 and Arduino Uno. Int. J. Res. Appl. Sci. Eng. Technol. 2025, 13, 1545–1551. [Google Scholar] [CrossRef]

- Robeson, S.M.; Willmott, C.J. Decomposition of the Mean Absolute Error (MAE) into Systematic and Unsystematic Components. PLoS ONE 2023, 18, e0279774. [Google Scholar] [CrossRef]

- de Myttenaere, A.; Golden, B.; Le Grand, B.; Rossi, F. Mean Absolute Percentage Error for Regression Models. Neurocomputing 2016, 192, 38–48. [Google Scholar] [CrossRef]

- Chi, J.; Xiao, L.; Wu, Z.; Xu, J.; Yang, Y.; Hu, Y.; Zhang, L.; Hu, J.; Luo, E. A High-Efficiency Gas–Liquid Coupled Heat-Driven Thermoacoustic Heat Pump. Int. J. Refrig. 2023, 155, 296–304. [Google Scholar] [CrossRef]

- Ceviz, M.A.; Afshari, F.; Ceylan, M.; Muratçobanoğlu, B.; Mandev, E.; Gelen, G. Experimental Study to Evaluate Effect of Source Temperature on COP and Compressor Status in Water-to-Air Heat Pumps. Heat Transf. Res. 2023, 54, 51–66. [Google Scholar] [CrossRef]

| Compute Core | BoM (USD) | Energy (Wh/day) | Notes |

|---|---|---|---|

| ESP32 (this work) | USD 49 | 12 | Wi-Fi on-board; microSD + RTC |

| 8-bit MCU + ESP8266 Wi-Fi | USD 60 | 10 | External Wi-Fi; lower compute headroom |

| Single-board computer (SBC) | USD 75 | 36 | Higher power; OS maintenance |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Paguay, J.; Cuenca-Sánchez, A.; Proaño, P. Smart IoT-Enabled Embedded Platform for Real-Time Energy Efficiency Assessment in Heat Pumps. Eng. Proc. 2025, 115, 14. https://doi.org/10.3390/engproc2025115014

Paguay J, Cuenca-Sánchez A, Proaño P. Smart IoT-Enabled Embedded Platform for Real-Time Energy Efficiency Assessment in Heat Pumps. Engineering Proceedings. 2025; 115(1):14. https://doi.org/10.3390/engproc2025115014

Chicago/Turabian StylePaguay, Jefferson, Alan Cuenca-Sánchez, and Pablo Proaño. 2025. "Smart IoT-Enabled Embedded Platform for Real-Time Energy Efficiency Assessment in Heat Pumps" Engineering Proceedings 115, no. 1: 14. https://doi.org/10.3390/engproc2025115014

APA StylePaguay, J., Cuenca-Sánchez, A., & Proaño, P. (2025). Smart IoT-Enabled Embedded Platform for Real-Time Energy Efficiency Assessment in Heat Pumps. Engineering Proceedings, 115(1), 14. https://doi.org/10.3390/engproc2025115014