Abstract

The rise of Industry 4.0 has made digital transformation a critical element of modern supply chain management, offering organizations a pathway to competitive advantage. While the prior literature has examined aspects of digitalization, few studies present a comprehensive view of the transformation process through to its practical application. This study proposes and aims to validate a digital transformation model developed by the author, based on a systematic literature review of 284 articles from Scopus and Web of Science. The model outlines a progression from data management to the integration of enabling technologies, culminating in enhanced supply chain decision-making. It introduces three key metrics—readiness, adoption, and Digital Maturity—to guide companies through distinct stages of transformation. Validation will be conducted using a mixed-methods approach, combining expert interviews and a quantitative survey with SCM professionals. This study offers both a theoretical framework and practical roadmap to support organizations in evolving their digital transformation strategies.

1. Introduction

Organizations are currently moving their competitive position to the digital realm, where the supply chain (SC) capabilities and visibility are positively impacted by its development [1]. Top management allocates its resources and investment toward dynamic digitalization initiatives, with the aim of strengthening entire value chains to implement Industry 4.0 advancement for their businesses. This direction has systematically shaped the digitalization landscape [2]. However, the transformative journey proves to entail complex and highly demanding management as well as execution to catch up with the global evolution pace. The previous research paper titled “The Evolution of Digitalization Transformation and Industry 4.0 in Supply Chain Management: A Systematic Literature Review” (SLR) by the author affirmed the profound impact of embracing this evolution throughout the systematic literature review of a database of 284 articles from Scopus and Web of Science sources [3]. The author built up a digitalization transformation model that was generalized based on empirical cases and a literature review of practices applied to SCM and operations.

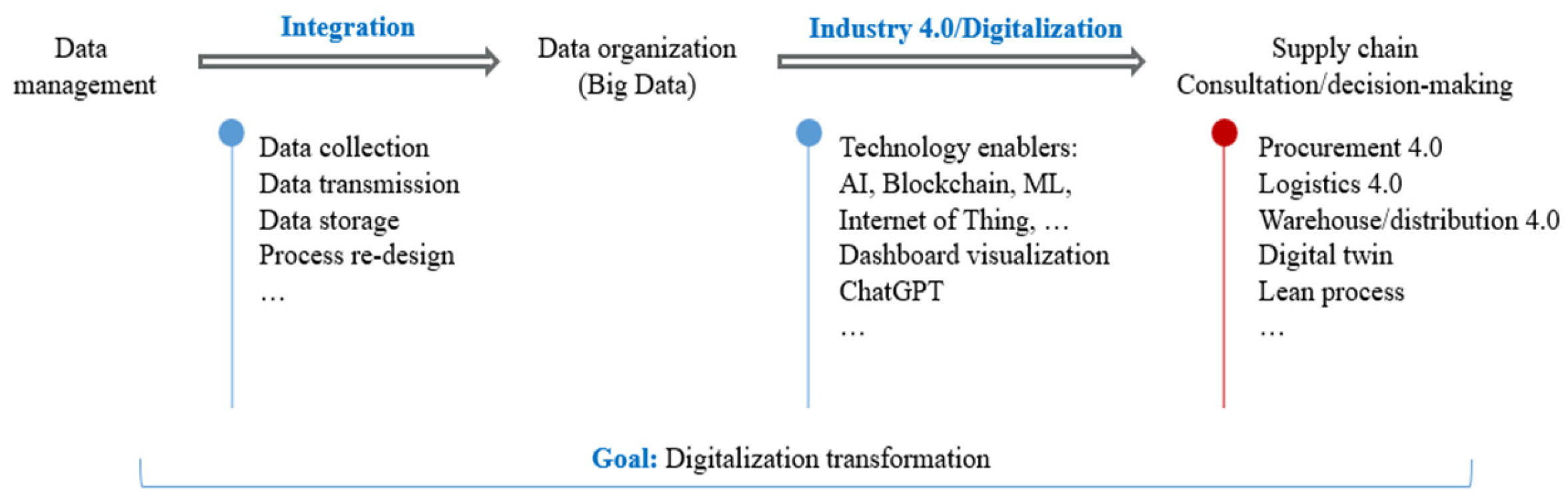

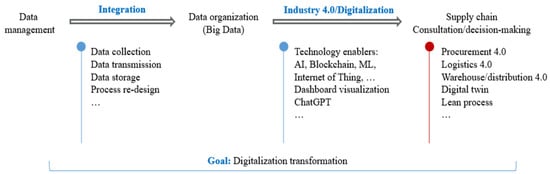

As shown in Figure 1, the model covered the process of digital projects specifically to enhance the SC consultation and decision-making function. Concurrently, researchers and practitioners delved into the research area of the emergence and embedment of Artificial Intelligence (AI), Machine Learning (ML), Cloud service, Internet of Things (IoT), Blockchain, and other technology enablers [4], which all come from data management [5]. Against this backdrop, several innovative concepts are being evolved within the “factory of the future” framework. Most of them insist on integrating new technologies to address the industrial problem promptly by employing decision-aided tools, robots, algorithms from AI/ML, automation, etc. [6]. The first step is managing the whole-value-chain data and organizing them in the Big Data Lake, followed by integrating them into selected technology advancements, and ultimately streamlining them for the decision-making process within SCM.

Figure 1.

Digitalization transformation conceptual model proposed by author.

This paper aims to design a conceptual model to validate the author’s self-proposed process and navigate a company’s digitalization transformation journey.

Two research questions (RQs) are developed from this article’s objective:

RQ1: How does the self-proposed model represent the current practices in digitalization transformation?

RQ2: What key metrics can be used to assess the transformation of a digital SCM project?

The paper will conduct a comprehensive model review to assess the digitalization transformation process in five sections. The relevant literature is reviewed in Section 2, and the research methodology is presented in Section 3, with a detailed explanation of how the author plans to achieve the research aim. Discussion is conducted in Section 4. Section 5 concludes the paper and gives a future direction for fellow researchers.

2. Literature Review

2.1. Model-Related Works

In this section, the author provides a comparison among models developed by prior scholars and researchers, showing how the digital world is immersed in SCM and operation activities.

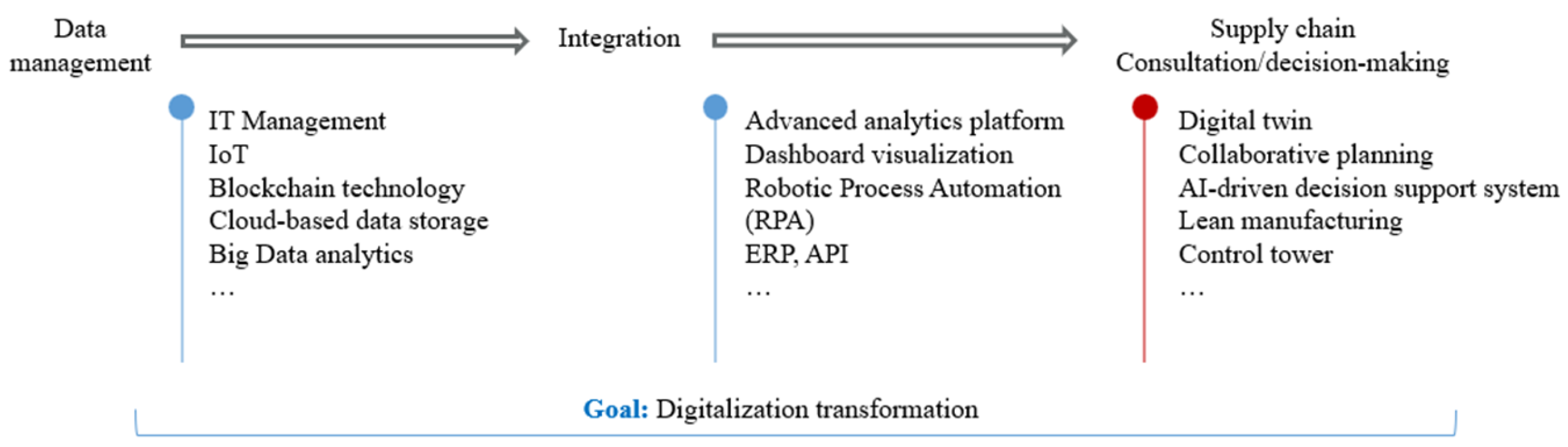

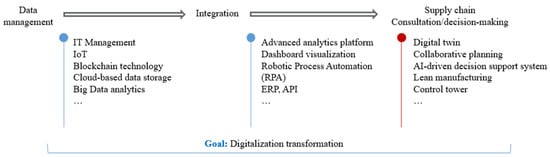

The list of model reviews in Table 1 introduces different approaches to digitalization transformation by researchers. From the highlighted dimensions in every model, the key themes are data, decision-making, and digital technologies. While these dimensions are consistent, the application and objective of each model moderately vary. Notably, the “Reconfigurability using Industry 4.0 principles” of [7]’s model analyzed full aspects of SCM facilitated by various technology enablers. The digital resource arrangement process model by [8] is the most closely aligned with the author’s model, and their perspective on the digital transformation mechanism is true for the rest of the models. Through a synthesis of existing models, the author refines the self-proposed process to a new one illustrated below in Figure 2. Data organization is considered as part of data management, and integration is the second main stage of the transformation. So, technology enablers will not only appear in the second stage but also depend on the operational and strategic demands of the digital environment shaping the SC activities.

Table 1.

Existing digitalization transformation models.

Figure 2.

Improved digitalization transformation conceptual model proposed by author.

2.2. Model Structure

Following the dimension formulation, the author derived a concept relevant to the model structure and assessed its theoretical and practical implications. To facilitate different analyses of Industry 4.0, ref. [13] developed a Digital Maturity model with 62 items covered by nine dimensions. The evaluation process involved transparent calculation based on individual items and obtained the transformation level of one dimension. Regarding the author’s model, the conceptual framework acquires a similar structure, assessing the model from the general dimension down to specific items. Below, the existing literature for items in Table 2 briefly indicates the targeted functions within one dimension, though it may overlook the potential cross-dimensional contributions of these enablers.

Table 2.

Dimensions and exemplary items of digitalization transformation model.

2.3. Model Assessment

Most of the papers on models mentioned their application and function among the dimensions; however, few researchers assessed the digital transformation level after developing them. Of the 284 articles in the SLR, there are 49 papers that discussed the adoption of technology in SCM, while 10 explored the industry’s readiness and only 5 investigated the maturity of the transformation. The author will validate the proposed model in Figure 2 by assessing the digitalization transformation in three process dimensions.

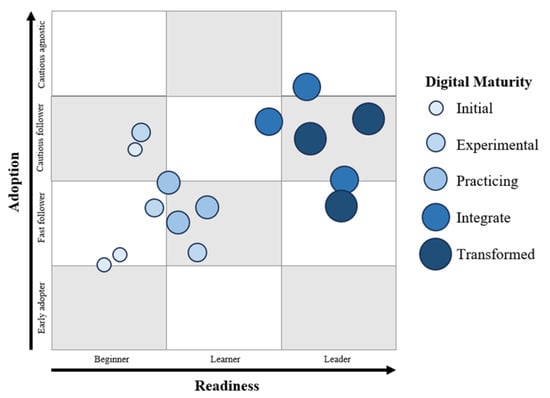

Adoption refers to a metric that assesses the adoption level of innovative technologies or digital approaches. The adoption scale [14] visualizes their differences based on potential gains or losses and the adoption timeline. Early adopters are defined as the pioneers in exploring a project that may face the highest uncertainty due to a lack of historical experiments, while the latest adopter is a cautious agnostic who needs more reassurance for their adoption decision. Readiness refers to a metric that measures the company’s readiness to start using the technology and become a leader in that area. The hierarchy of readiness level goes from knowing nothing—an outsider—to a leading position—a top performer [15]. Digital Maturity refers to a metric that assesses the maturity of a digital activity, including five levels: Initial–Experimental–Practicing–Integrate–Transformed. Level 1 stands for “companies lack attributes that support concepts of Industry 4.0”, and level 5 is “companies can meet all requirements of Industry 4.0” [16].

The difference between readiness and maturity models can be explained by there being five levels of readiness to clarify whether the organization is ready to start the development process or not, while there are five levels of maturity targets to illustrate which level the organization has transformed to. Navigating a company’s digitalization performance in the readiness model can encourage it to make a move for its digital environment, and assessing progress by a maturity model can create a motivation to reach an advanced level of maturity. Therefore, using two metrics to evaluate a company’s digitalization transformation is essential for a comprehensive assessment [15].

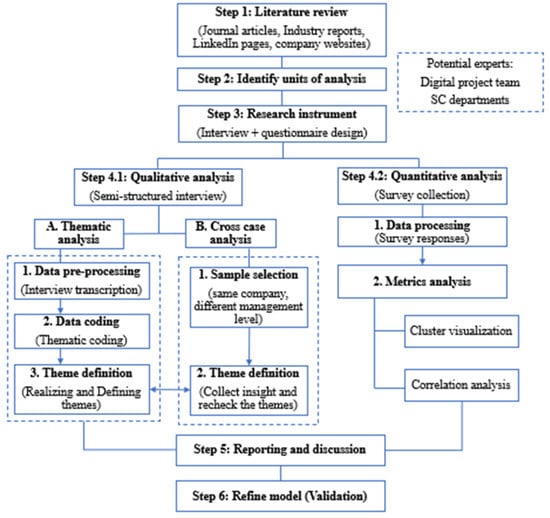

3. Research Methodology

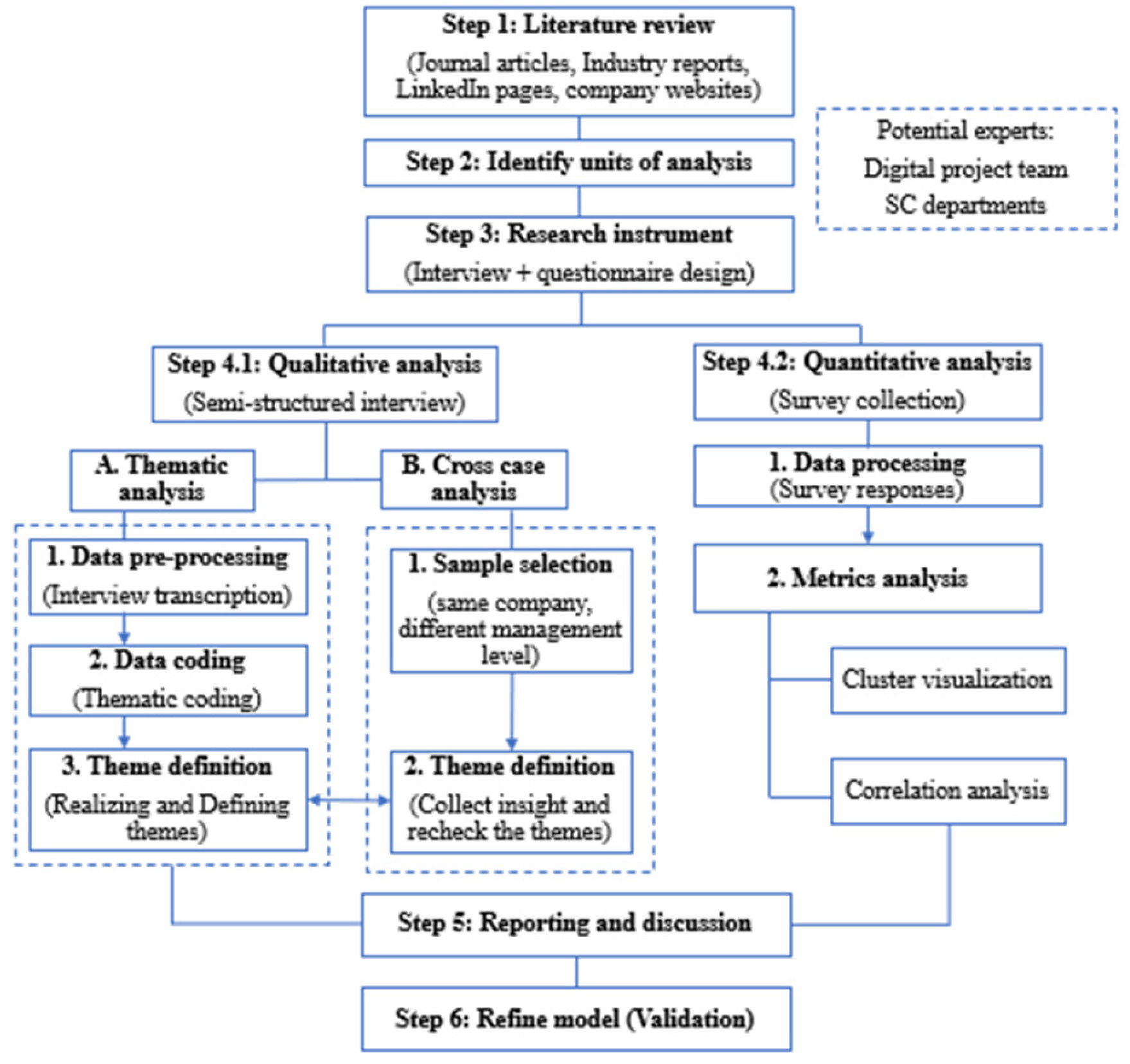

In this article, a comprehensive model review is carried out to validate the self-proposed process of digitalization transformation. Figure 3, shown below, demonstrates the research design and the steps followed by the author to conduct this paper.

Figure 3.

Research methodology process.

To answer the RQs, a mixed method is conducted on both qualitative and quantitative analysis, with the aim of gaining a broad-based assessment. This paper primarily focuses on potential experts who are either related to digital projects or working in SC operations. With this filtering, the author can obtain insightful viewpoints, while the respondents have an overall understanding or familiarity with the topic’s terms and definitions.

3.1. Qualitative Analysis

The thematic analysis in this study is divided into two projects: one follows Braun and Clarke’s guidelines [17] (using thematic analysis in psychology), and one is based on cross-case analysis. The proposed case involved two pairs of managers and executive staff in one digital project to examine the digitalization process from two points of view, with one pair managing the SC digital strategy, and one pair executing the digital action steps. The analysis derived from the cross-case method will be a tool for rechecking the defined theme in the first thematic results, helping reconfirm the paper’s theme.

3.2. Quantitative Analysis

The survey is conducted by a quantitative ranking method applied among individual items. Each dimension is examined by one similar question about the importance level of all items within the dimension. All questions in the survey require one answer on the Likert scale. For adoption result analysis, the respondent is asked to self-assess the adoption level best indicated by their organization for the mentioned technology [18]. To determine the adoption level of one dimension, the author selects the level with the highest coverage within the items of that dimension. In the readiness result analysis of ref. [19], the respondent is asked to evaluate each item’s readiness level, and the dimension’s readiness level will be the lowest level of all fields in one dimension, since it measures how well a company meets a minimum requirement for a dimension. The readiness score is used for evaluation, under the following formula: Readiness score = Readiness level × Important points. In Digital Maturity result analysis, the response to the maturity question is converted and put in the following factors: maturity level, weighting factor, and number of maturity items.

In this equation, M is maturity, D is dimension, I is item, g is weighting factor, and n is number of maturity items.

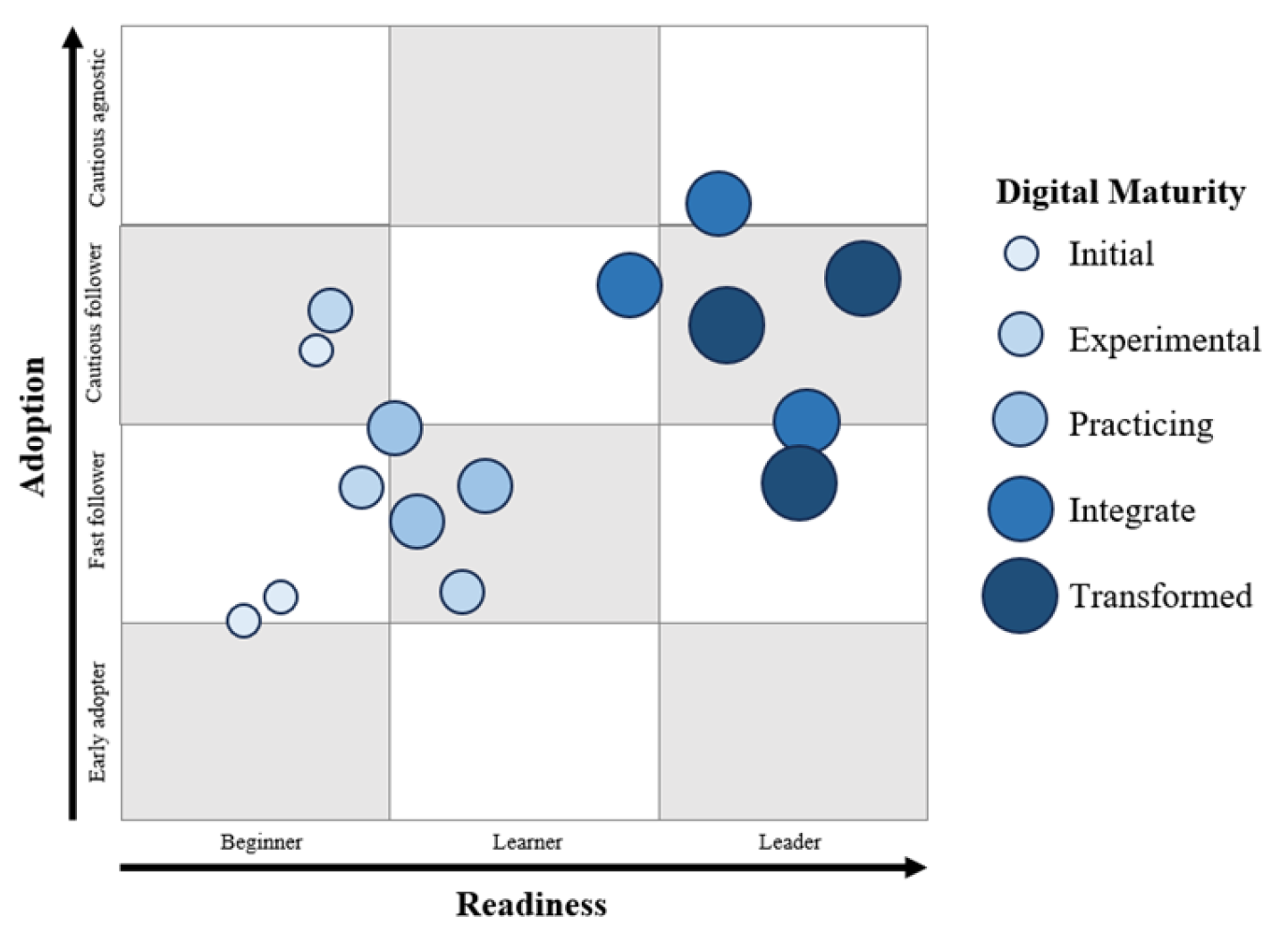

3.3. Result Presentation

Figure 4 provides an example of how the results of the survey will be presented. From this visualization, the author expects to gain some insight from the metrics and the dimensions’ patterns, and the cluster can be formulated with enough respondents.

Figure 4.

Cluster visualization for three metrics of digitalization measurement.

After that, the Pearson Correlation Coefficient (r) method will be carried out to explore the connection among the three metrics, three dimensions, and their coefficient relationship altogether. Python 3.10 will mainly be used to interpret databases and visualize the correlation.

4. Discussion

4.1. Realization of Author’s Improved Model

Based on the addendum literature review, the author generated an improved version of the digitalization transformation model. The former version included three stages—data management, data organization, and SC consultation/decision-making—while the latter version adjusted the second stage to digital integration and incorporated data organization as part of data management. Additionally, the list of items per dimension also changed to align with the findings of other researchers’ models. The author’s initial model elaborated dimensions based on the function of each stage. As can be seen from the author’s first model, the author defined it as how one digital process can be applied in SCM, starting with data management, deploying the technology enablers by available big data sets, and finally building up a digital SC. The original model is a technology-centric transformation approach. However, with the comparative analysis of diversified digital integration and transformation models in Table 1, technology enablers could be integrated at any stage to fulfill distinct functions for that specific dimension. Subsequently, enterprises can decide the strategy to adopt multiple digital enablers for their operation and management, all leading to one common goal of making decisions for their SC. By completing the process and achieving the SC goals, businesses can transform from a conventional SC to comprehensive Industry 4.0 or digitalized SCM. Thus, the improved model is a digitalization transformation process-based approach.

4.2. Recommendation from Measuring Metrics

The digital models reviewed in Table 1 focused on the examination of digital processes, value delivery at different stages, or enterprises’ capabilities during digitalization. With either a process-based or technology-centric approach, firms also face challenges related to execution, management, and effectiveness and efficiency of what they have invested in. So, a structured approach to digitalization transformation requires measuring metrics as guidance for being on the right track of any model [20]. Therefore, the author designs a concept to reach the same goal of model validation, applying three metrics to measure the digital context within SCM including adoption level, readiness score, and Digital Maturity level. This is because maturity model frameworks are significantly important to evaluate organizations [15]. Likewise, the author’s metrics can be utilized to assess whether the organization can be ready for technology integration, be mature enough to achieve the transformation, and be agile enough to adapt to the evolution speed. By examining these three metrics, the author probably gains insights from SC departments or, rather, digital project teams regarding how they are immersed in the digital environment for their operation and management.

4.3. Future Research Direction

Firstly, with the validation methodology for the author’s proposed model, the actual primary data is the top priority for examining both the methodology and the proposed digitalization transformation model—qualitative and quantitative. Secondly, the list of items within each dimension is influenced by the previous literature and the author’s perspectives. With an understanding of the mechanism, fellows can enlarge the list of items for testing their own models based on the author’s research methodology.

5. Conclusions

In conclusion, this paper aims to design a conceptual model to validate the author’s self-proposed process and navigate a company’s digitalization transformation journey. The previous SLR of 284 articles served as a robust foundation for the subsequent literature review.

Theoretical contribution: This study contributes to the scientific area of a mixed-analysis method for model validation, which offers several important theoretical contributions. Firstly, it presents a methodology to examine the model, and secondly, it outlines an analysis approach for synthesis of measuring metrics. Recalling the RQs given in the Introduction, the author came up with some closing results:

RQ1: How does the self-proposed model represent the current practices in digitalization transformation? This question can be addressed by the current models in the market, investigated by researchers, and then answered by the author’s own model. The finding is that most of the digitalization transformations position themselves either in the digitalization process or as a technology enabler, and a selection would depend on the company’s transformational context.

RQ2: What key metrics can be used to assess the transformation of a digital SCM project? The context mentioned in RQ1’s answer could be measured by three metrics: adoption, readiness, and maturity. These metrics altogether synthesize and represent a logical path for digital processes in several business fields including many levels of transformation.

Managerial contribution: This study contributes tools for checking an SC department’s Digital Maturity, and summarizes steps for adopting, integrating, and transforming. The key objective for managers is achieving the goal of SCM consultation or decision-making based on digital integration and organization data. Thus, SCM can evolve to a higher digital level.

In summary, this comprehensive review emphasizes the methodology for validating a digitalization transformation model. By integrating technology from scratch, firms can position themselves as leaders of the digital era and drive their sustainable growth. Fellow scholars can leverage this paper to conduct in-depth analyses of the transformative era.

Author Contributions

Conceptualization, N.Q.T.N. and L.B.; methodology, N.Q.T.N. and L.B.; software, N.Q.T.N.; resources, N.Q.T.N.; writing—original draft preparation N.Q.T.N.; writing—review and editing, L.B.; visualization, N.Q.T.N. supervision, L.B.; project administration, L.B. All authors have read and agreed to the published version of the manuscript.

Funding

The publication was created in the framework of the Széchenyi István University’s VHFO/416/2023-EM_SZERZ project entitled “Preparation of digital and self-driving environmental infrastructure developments and related research to reduce carbon emissions and environmental impact” (Green Traffic Cloud).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Huang, K.; Wang, K.; Lee, P.K.C.; Yeung, A.C.L. The impact of Industry 4.0 on supply chain capability and supply chain resilience: A dynamic resource-based view. Int. J. Prod. Econ. 2023, 262, 108913. [Google Scholar] [CrossRef]

- Pérez-Moure, H.; Lampón, J.F.; Cabanelas, P. Mobility business models toward a digital tomorrow: Challenges for automotive manufacturers. Futures 2024, 156, 103309. [Google Scholar] [CrossRef]

- Nguyen, T.N.Q.; Buics, L. The evolution of digitalization transformation and Industry 4.0 in supply chain management: A systematic literature review. Eng. Proc. 2024, 79, 65. [Google Scholar] [CrossRef]

- Malik, M.; Gahlawat, V.K.; Mor, R.S. Digital interoperability and transformation using Industry 4.0 technologies in the dairy industry: An SLR and bibliometric analysis. Logforum 2023, 19, 461–479. [Google Scholar] [CrossRef]

- Hsu, C.-H.; He, X.; Zhang, T.-Y.; Chang, A.-Y.; Liu, W.-L.; Lin, Z.-Q. Enhancing supply chain agility with Industry 4.0 enablers to mitigate ripple effects based on integrated QFD-MCDM: An empirical study of new energy materials manufacturers. Mathematics 2022, 10, 1635. [Google Scholar] [CrossRef]

- Dossou, P.-E. Development of a new framework for implementing Industry 4.0 in companies. Procedia Manuf. 2019, 38, 573–580. [Google Scholar] [CrossRef]

- Mantravadi, S.; Srai, J.S.; Møller, C. Application of MES/MOM for Industry 4.0 supply chains: A cross-case analysis. Comput. Ind. 2023, 148, 103907. [Google Scholar] [CrossRef]

- Zhang, X.; Xiao, G. Enterprise digital transformation mechanism from the perspective of resource arrangement. Front. Artif. Intell. Appl. 2023, 367, 311–318. [Google Scholar] [CrossRef]

- Herold, D.; Ćwiklicki, M.; Pilch, K.; Mikl, J. The emergence and adoption of digitalization in the logistics and supply chain industry: An institutional perspective. J. Enterp. Inf. Manag. 2021, 34, 1917–1938. [Google Scholar] [CrossRef]

- Wang, W.M.; Preidel, M.; Fachbach, B.; Stark, R. Towards a reference model for knowledge driven data provision processes. In Proceedings of the International Conference on Product Lifecycle Management, Valencia, Spain, 23–25 November 2020; pp. 123–132. [Google Scholar] [CrossRef]

- Liu, L.; Song, W.; Liu, Y. Leveraging digital capabilities toward a circular economy: Reinforcing sustainable supply chain management with Industry 4.0 technologies. Comput. Ind. Eng. 2023, 178, 109113. [Google Scholar] [CrossRef]

- Chavez, Z.; Gopalakrishnan, M.; Nilsson, V.; Westbroek, A. Exploring data-driven decision-making for enhanced sustainability. In Advances in Transdisciplinary Engineering; IOS Press: Amsterdam, The Netherlands, 2022; pp. 392–403. [Google Scholar] [CrossRef]

- Schumacher, A.; Erol, S.; Sihn, W. A maturity model for assessing Industry 4.0 readiness and maturity of manufacturing enterprises. Procedia CIRP 2016, 52, 161–166. [Google Scholar] [CrossRef]

- Nguyen, S.; Chen, P.S.-L.; Du, Y. Blockchain adoption in container shipping: An empirical study on barriers, approaches, and recommendations. Mar. Policy 2023, 155, 105724. [Google Scholar] [CrossRef]

- Akdil, K.Y.; Ustundag, A.; Cevikcan, E. Maturity and readiness model for Industry 4.0 strategy. In Springer Series in Advanced Manufacturing; Springer Nature: Cham, Switzerland, 2018; pp. 61–94. [Google Scholar] [CrossRef]

- Sonntag, M.; Mehmann, S.; Mehmann, J.; Teuteberg, F. Development and evaluation of a maturity model for AI deployment capability of manufacturing companies. Inf. Syst. Manag. 2024, 42, 37–67. [Google Scholar] [CrossRef]

- Clarke, V.; Braun, V. Successful Qualitative Research: A Practical Guide for Beginners; SAGE Publications: London, UK, 2013. [Google Scholar]

- White, A.; Msc, B.; Frsa, E.; Beng, M.J.; Miee, E.; Wilson, H. RFID in the supply chain: Lessons from European early adopters. Int. J. Phys. Distrib. Logist. Manag. 2008, 38, 88–107. [Google Scholar] [CrossRef]

- Grufman, N.; Lyons, S.; Sneiders, E. Exploring readiness of SMEs for Industry 4.0. Complex Syst. Inform. Model. Q. 2020, 25, 54–86. [Google Scholar] [CrossRef]

- Horváth, Z.C.; Buics, L.; Földesi, P.; Balassa, B.E. The Role of Hungarian Traffic Rules Education and Examination System—A Quality Function Deployment Approach. Acta Polytech. Hung. 2022, 19, 7–26. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).