Evaluation of Innovative and Sustainable Fire Protection Systems for Reinforced Concrete Structures †

Abstract

1. Introduction

2. Materials and Methods

2.1. Specimen Configuration and Base Materials

- Batch #1 (used for evaluating System A under ramp-and-hold conditions): ≈ 21–22 MPa at 28 days. FRP-confined room-temperature compressive strength () ≈ 55.6 MPa (CFRP).

- Batch #2 (used for evaluating System B under initial ASTM E119 conditions and Systems A, B, and C under extended ASTM E119 conditions): ≈ 30 MPa (at 28 days). FRP-confined ≈ 86.1 MPa (CFRP).

- Batch #3 (used for evaluating the Sikacrete™ 213F system under ramp-and-hold conditions [9]): ≈ 42 MPa (at 28 days). FRP-confined varied with FRP type (e.g., ≈126.6 MPa for 2-ply CFRP).

2.2. Fire Protection Systems, Thermal Exposures, and Performance Metrics

- System A Key configuration: T3 (inner RS cloth + 2 Dymatherm™ layers + outer RS cloth) and T4 (inner RS + 4 Dymatherm™ layers + outer RS).

- System B key configurations: T1 (1 epoxy + 3 intumescent layers) and T2 (2 epoxy + 6 intumescent layers).

- Sikacrete™ 213F System: Applied at 15 mm and 30 mm thicknesses.

- System C (REARLOCK+FireSet60): REARLOCK primer with FireSet60 intumescent topcoat.

- Ramp-and-hold (used for the initial evaluation of System A): Heating at 2.5 °C/min to 200 °C or 400 °C, then 60 min hold.

- ASTM E119 standard fire (used for the initial evaluation of System B and comparative evaluation of Systems A, B, and C): Durations of 30 min (furnace peak ~821 °C), 60 min (furnace peak ~925 °C), and 4 h (240 min, furnace peak ~1090 °C).

- Ramp-and-hold (used for the evaluation of the Sikacrete™ 213F system): Specimens heated in furnace at 400 °C or 700 °C for 90 or 180 min.

- Strength Retention Ratio (SRR): SRR = /, where is the post-exposure confined strength and is the room-temperature strength of an identical companion specimen from the same concrete batch, FRP configuration, and test series.

- FRP interface temperatures : Maximum recorded temperature () and temperature profiles.

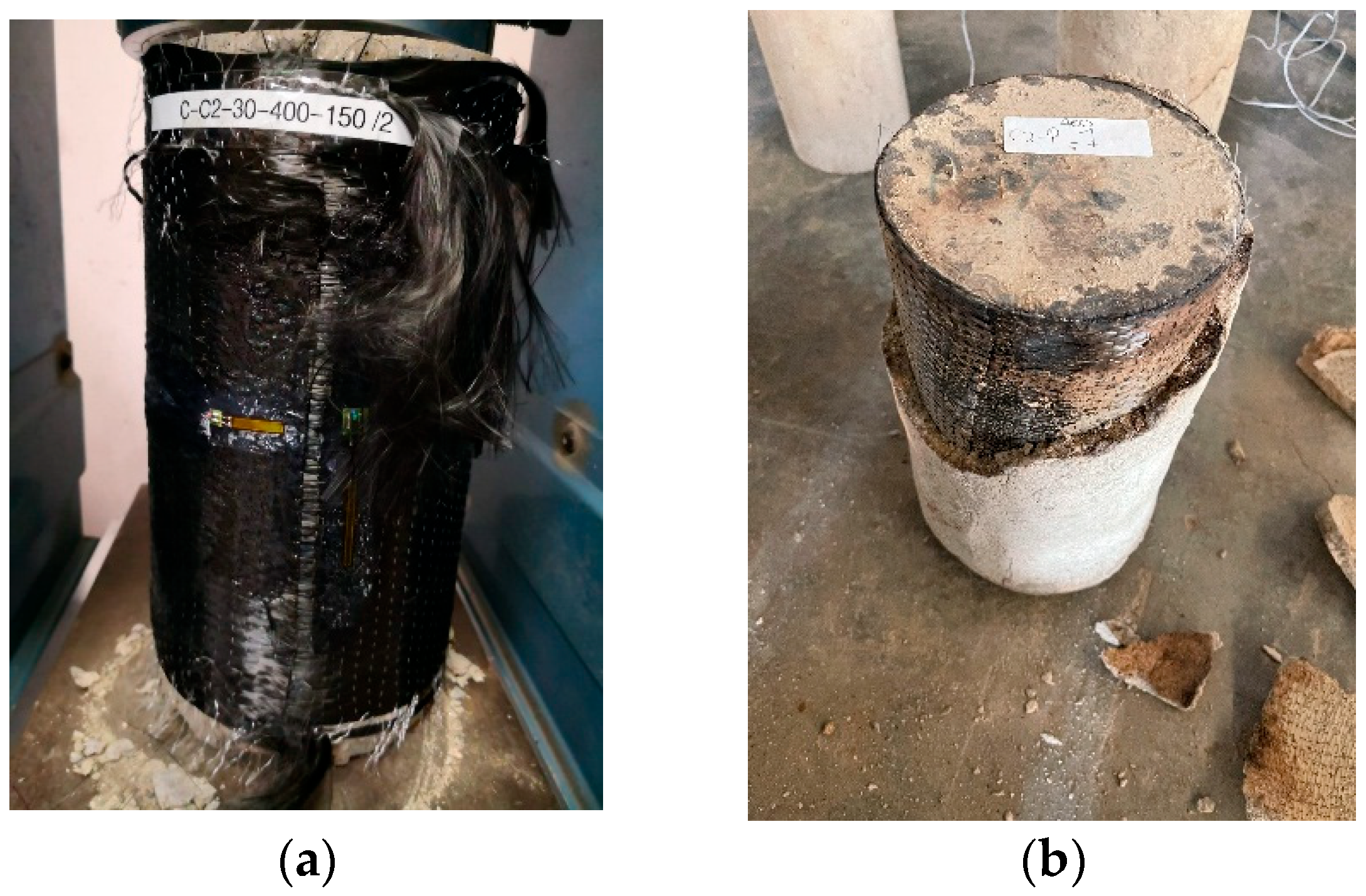

- Observed protection mechanisms: Inferred from visual state and thermal data (e.g., insulation, intumescence, sacrificial action; see Figure 1 for representative post-exposure conditions).

- Failure modes and physical integrity: Spalling, cracking, and debonding of PFP system; degradation and charring of FRP system; concrete conditions.

3. Results and Discussion

3.1. Baseline: Unprotected FRP-Confined Specimens

3.2. System A (Flexible Insulation Barrier—DYMAT™-RS/Dymatherm™)

3.3. System B (Intumescent/Epoxy Coating—FIRECOAT)

3.4. Sikacrete™ 213F System (Cementitious Mortar)

3.5. System C (REARLOCK+FireSet60)

3.6. Comparative Discussion: Mechanisms, Failure Modes, and Protocol Influence

4. Conclusions

- System A (DYMAT™-RS cloth and Dymatherm™ blanket) provides effective thermal insulation and maintains good physical integrity. Its T4 configuration achieved SRR ≈ 0.79 (CFRP, 400 °C ramp-and-hold, ≈ 90–95 °C) and SRR ≈ 0.36 (CFRP, 4 h ASTM E119, ≈ 320–350 °C).

- System B (FIRECOAT) relies on char formation. It demonstrated high initial performance (SRR ≈ 0.88 for CFRP T2, 30 min ASTM E119) but suffered PFP cracking and spalling in longer/more severe fires, leading to very low SRRs (e.g., ≈0.08 for T1, 4 h ASTM E119).

- Sikacrete™ 213F (cementitious mortar) offers robust thermal mass and insulation, achieving excellent SRRs such as 0.74 (CFRP, 15mm, compared to 0.52 for unprotected) and 0.98 (C2G2, 30 mm, compared to 0.57 for unprotected) after 400 °C (180 min) exposure and maintaining good resilience even under more extreme conditions (e.g., SRR ≈ 0.41 for hybrid C2G2 FRP with 30 mm protection after 180 min at 700 °C).

- All PFP systems improved performance over unprotected FRP. However, efficacy and failure modes are highly dependent on the PFP nature and, critically, thermal exposure characteristics. The varied protocols highlight that simple system ranking is inappropriate; evaluations must be relevant to specific fire scenarios. Understanding how a PFP system behaves and fails under different fire conditions is essential for reliable design.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| PFP | Passive Fire Protection |

| SRR | Strength Retention Ratio |

| FRP | Fiber-Reinforced Polymer |

| CFRP | Carbon Fiber-Reinforced Polymer |

| Glass Transition Temperature | |

| Room Temperature-Confined Compressive Strength |

References

- Mosallam, A.S.; Bayraktar, A.; Elmikawi, M.; Pul, S.; Adanur, S. Polymer Composites in Construction: An Overview. SOJ Mater. Sci. Eng. 2014, 2, 25. [Google Scholar] [CrossRef]

- Sheikh, S.; Yau, G. Seismic behavior of concrete columns confined with steel and fiber-reinforced polymers. ACI Struct. J. 2002, 99, 72–80. [Google Scholar] [CrossRef] [PubMed]

- Firmo, J.P.; Correia, J.R.; Bisby, L.A. Fire behaviour of FRP-strengthened reinforced concrete structural elements: A state-of-the-art review. Compos. Part B Eng. 2015, 80, 198–216. [Google Scholar] [CrossRef]

- Firmo, J.P.; Correia, J.R.; França, P. Fire behaviour of reinforced concrete beams strengthened with CFRP laminates: Protection systems with insulation of the anchorage zones. Compos. Part B Eng. 2012, 43, 1545–1556. [Google Scholar] [CrossRef]

- Campbell, R.A.; Pickett, B.M.; La Saponara, V.; Dierdorf, D. Thermal characterization and flammability of structural epoxy adhesive and carbon/epoxy composite with environmental and chemical degradation. J. Adhes. Sci. Technol. 2012, 26, 889–910. [Google Scholar] [CrossRef]

- ACI Committee 440. ACI 440.2R-17: Guide for the Design and Construction of Externally Bonded FRP Systems for Strengthening Concrete Structures; American Concrete Institute: Farmington Hills, MI, USA, 2017. [Google Scholar]

- Kodur, V.R.; Bisby, L.A.; Williams, B.K.; Green, M.; Chowdhury, E.U. Fire Performance of FRP Systems for Infrastructure: A State-of-the-Art Report; National Research Council of Canada: Ottawa, ON, Canada, 2005. [Google Scholar]

- ASTM E119-20; Standard Test Methods for Fire Tests of Building Construction and Materials. ASTM International: West Conshohocken, PA, USA, 2020.

- Wafa, L.F.F. Assessment of Post-Fire Performance of FRP-Confined RC Columns. Ph.D. Thesis, University of California, Irvine, CA, USA, 2022. [Google Scholar]

| System | Materials | Nominal Specimen Size (s) | Primary Experimental Context |

|---|---|---|---|

| System A | DYMAT™-RS cloth and Dymatherm™ blanket | Ø200 × 450 | Ramp-and-hold at 200/400 °C; ASTM E119 standard fire for 30–240 min |

| System B | FIRECOAT: DYMAT™ DCF-D epoxy and FireFree 88 intumescent | Ø200 × 450 | ASTM E119 standard fire for 30–240 min |

| Sikacrete™ 213F | Cement-based insulative mortar (15 mm, 30 mm thicknesses) | Ø100 × 200, Ø150 × 300 | Ramp-and-hold at 400/700 °C for 90–180 min |

| System | FRP Type | Insulation Config. | Thermal Exposure | SRR | Unprotected SRR |

|---|---|---|---|---|---|

| System A | CFRP | T4 (4-layer blanket) | 400 °C (60 min) | 0.79 | 0.50 |

| CFRP | T4 (4-layer blanket) | 4 h ASTM E119 | 0.36 | 0.08 | |

| System B | CFRP | T2 (2 epoxy + 6 FireFree88) | 30 min ASTM E119 | 0.88 | 0.40 |

| CFRP | T1 (1 epoxy + 3 FireFree88) | 4 h ASTM E119 | 0.08 | 0.08 | |

| Sikacrete™ 213F | CFRP | 15 mm | 400 °C (180 min) | 0.74 | 0.52 1 |

| C2G2 | 30 mm | 400 °C (180 min) | 0.98 | 0.57 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wafa, L.; Mosallam, A.; Mostafa, A.A.-E. Evaluation of Innovative and Sustainable Fire Protection Systems for Reinforced Concrete Structures. Eng. Proc. 2025, 112, 62. https://doi.org/10.3390/engproc2025112062

Wafa L, Mosallam A, Mostafa AA-E. Evaluation of Innovative and Sustainable Fire Protection Systems for Reinforced Concrete Structures. Engineering Proceedings. 2025; 112(1):62. https://doi.org/10.3390/engproc2025112062

Chicago/Turabian StyleWafa, Louai, Ayman Mosallam, and Ashraf Abed-Elkhalek Mostafa. 2025. "Evaluation of Innovative and Sustainable Fire Protection Systems for Reinforced Concrete Structures" Engineering Proceedings 112, no. 1: 62. https://doi.org/10.3390/engproc2025112062

APA StyleWafa, L., Mosallam, A., & Mostafa, A. A.-E. (2025). Evaluation of Innovative and Sustainable Fire Protection Systems for Reinforced Concrete Structures. Engineering Proceedings, 112(1), 62. https://doi.org/10.3390/engproc2025112062