A Review of Concrete Strengthening Methods Using Synthetic and Natural Composites †

Abstract

1. Introduction

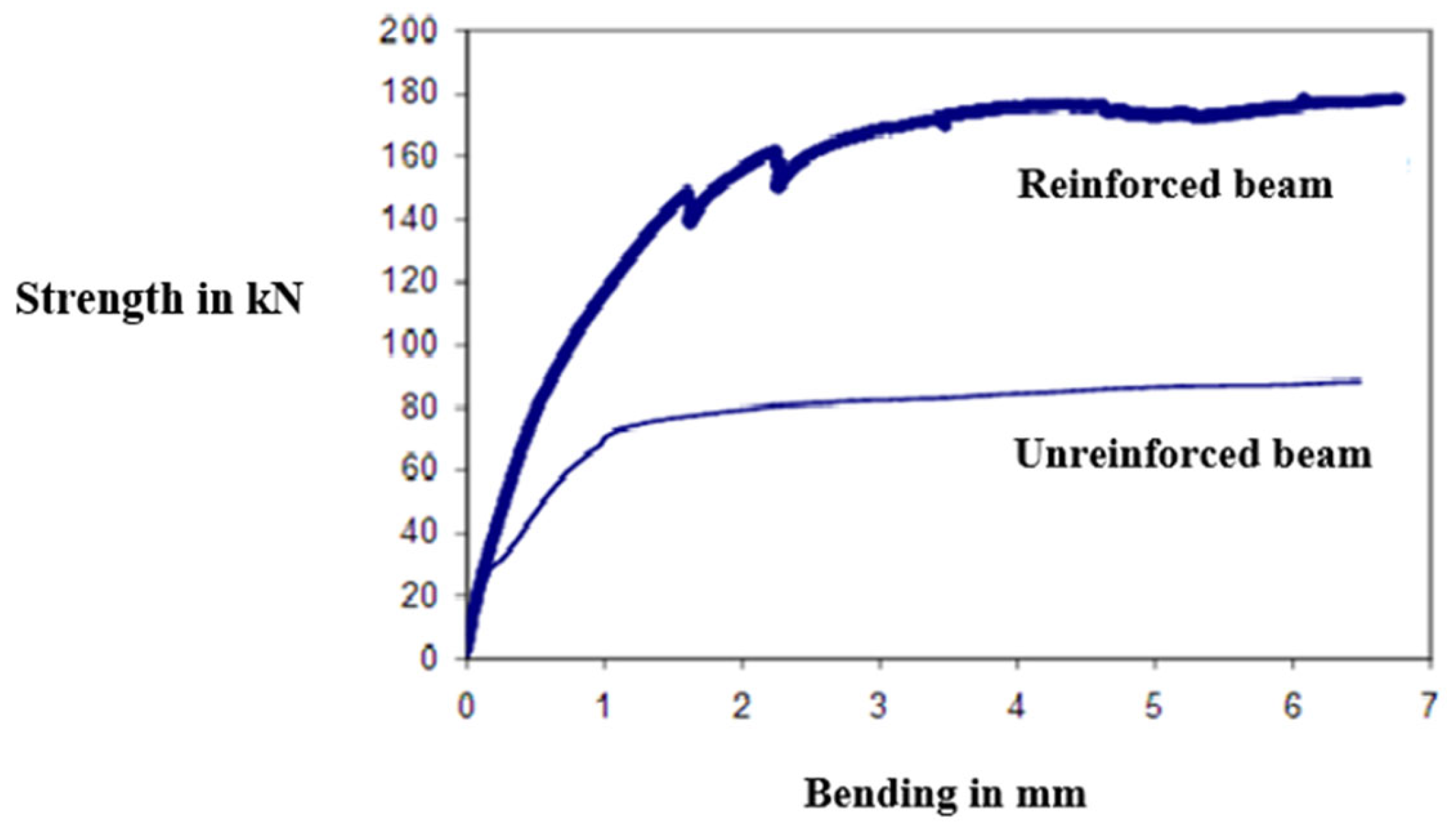

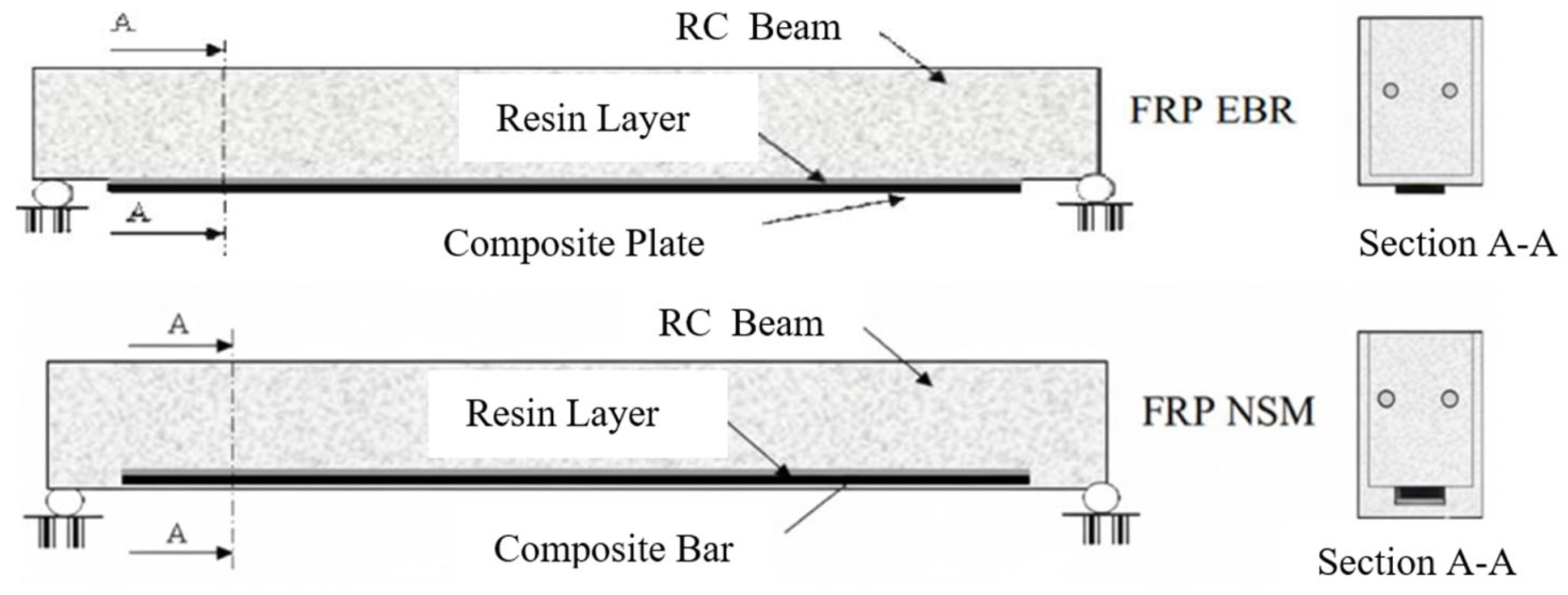

2. External Strengthening of RC Members with FRP Composites

- Ease of adaptation to various geometries;

- Ease of implementation;

- High resistance to fatigue;

- Enhanced durability;

- Minimum of maintenance.

3. Externally Bonded Reinforcement in Grooves (EBRIGI) Technique

4. Externally Bonded Reinforcement on Grooves (EBGOR) Technique

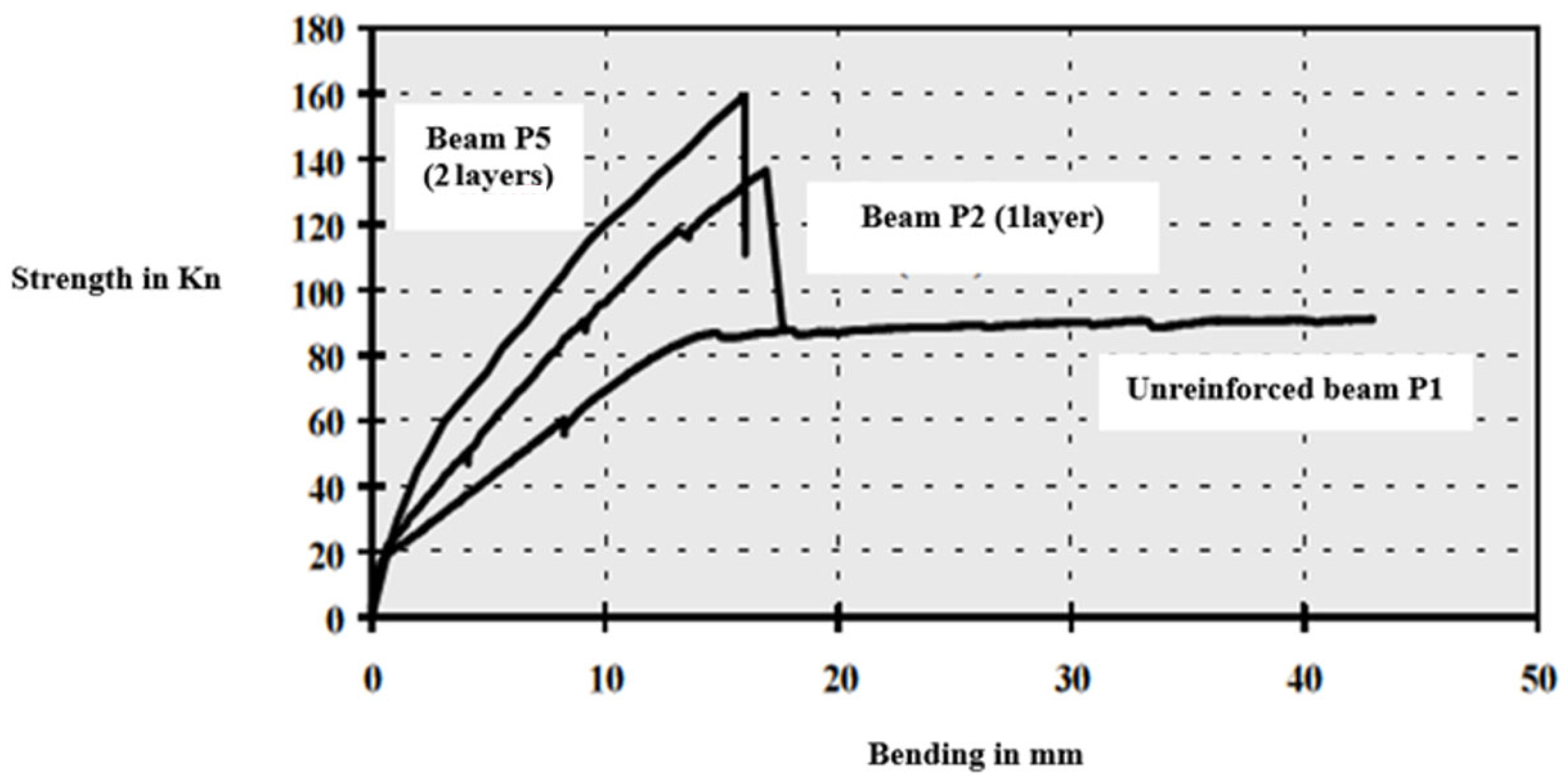

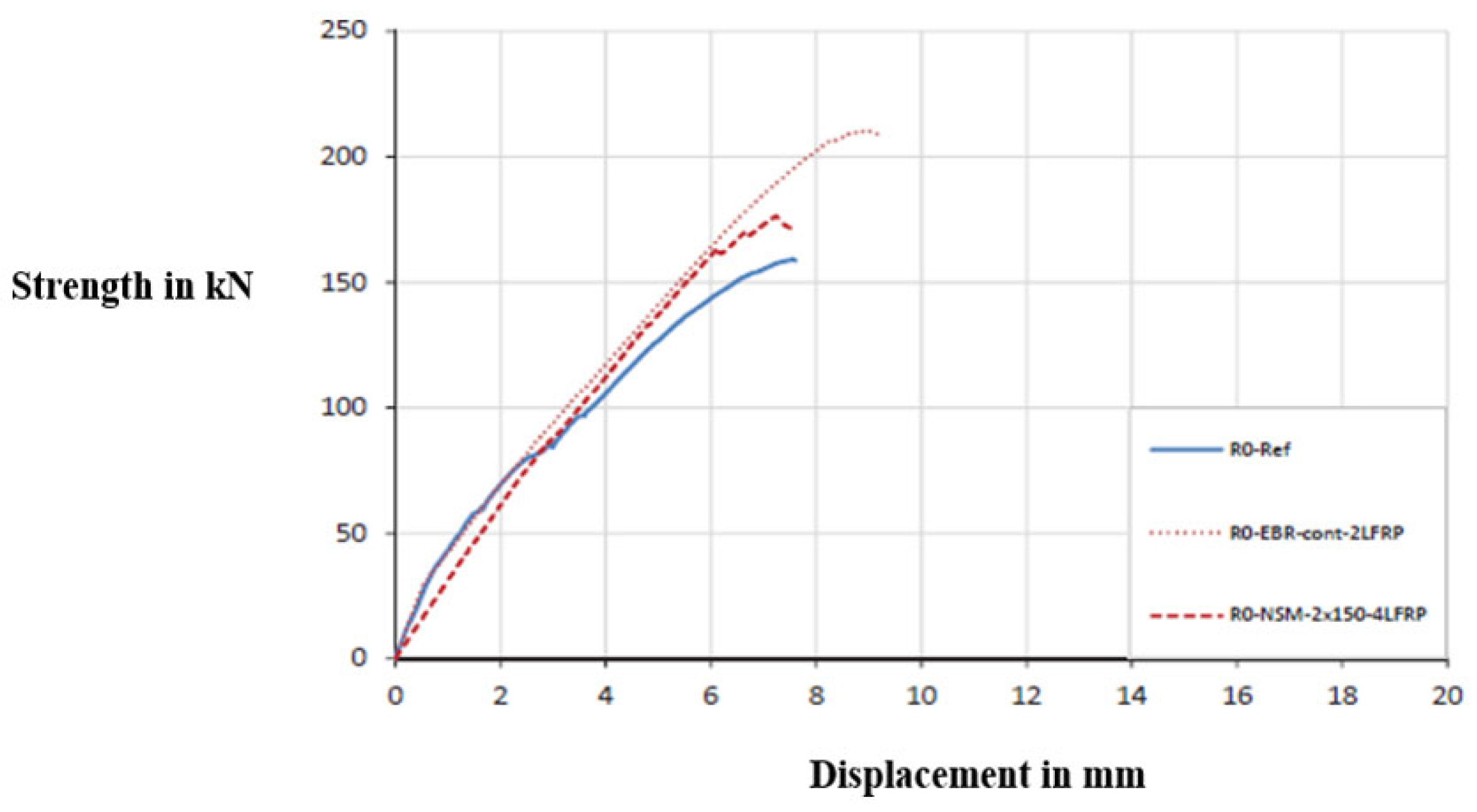

5. Near-Surface-Mounted (NSM) Technique

- Reduced surface preparation and, in some cases, even installation work can be minimized;

- FRP reinforcements can easily be anchored to the adjacent elements preventing delamination failures;

- The strengthening effective levels are higher, as FRP reinforcements are protected by the embedding concrete and are therefore less exposed to mechanical damage, fire, and vandalism;

- The visual appearance of the reinforced structure is virtually unchanged.

6. Strengthening Techniques of Embedded Through Section (ETS)

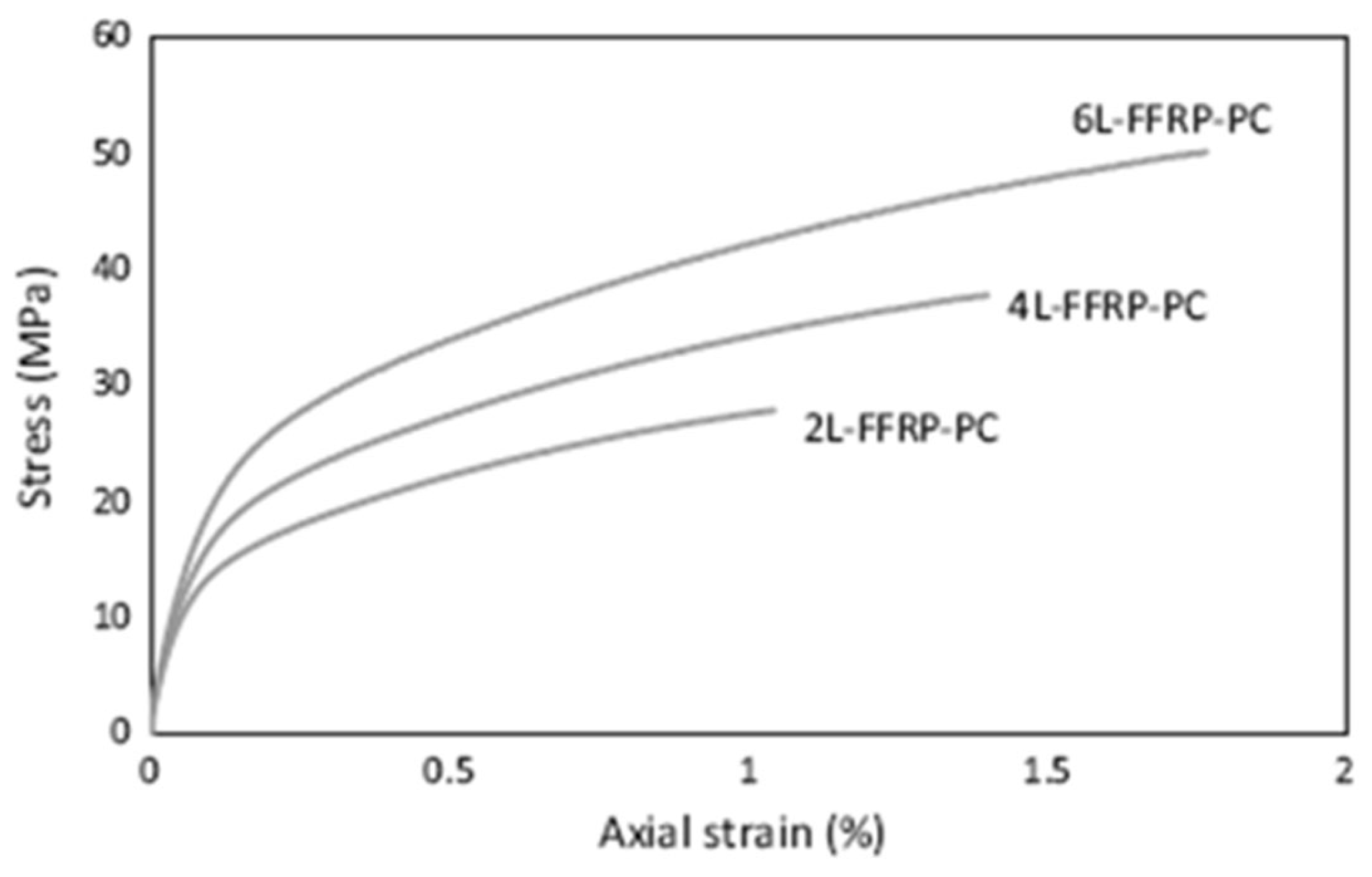

7. Reinforcement Using Natural Fibers

8. Conclusions

- Increased load-bearing capacity;

- Reduced deflection;

- Increased ductility;

- Increased stiffness.

9. Patent

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| FRP | Fiber-Reinforced Polymer |

| EBRIG | Externally Bonded Reinforcement In Grooves |

| EBROG | Externally Bonded Reinforcement On Grooves |

| ETS | Embedded Through-Section |

| NSM | Near-Surface Mounted |

| CFRP | Carbon Fiber-Reinforced Polymer |

| EBR | Externally Bonded Reinforcement |

| RC | Reinforced Concrete |

References

- Salama, A.S.D.; Hawileh, R.A.; Abdalla, J.A. Performance of externally strengthened RC beams with side-bonded CFRP sheets. Compos. Struct. 2019, 212, 281–290. [Google Scholar] [CrossRef]

- Hawileh, R.A.; Nawaz, W.; Abdalla, J.A.; Saqan, E.I. Effect of flexural CFRP sheets on shear resistance of reinforced concrete beams. Compos. Struct. 2015, 122, 468–476. [Google Scholar] [CrossRef]

- Wu, Z.Y. Etude Expérimentale du Comportement des Poutres Courtes en Béton Armé pré-Fissurées et Renforcées par Matériaux Composites sous Chargement Statique et de Fatigue. Ph.D. Thesis, École des Ponts ParisTech, Paris, France, November 2004.

- Correia, L.; Teixeira, T.; Michels, J.; Almeida, J.A.; Sena-Cruz, J. Flexural behaviour of RC slabs strengthened with prestressed CFRP strips using different anchorage systems. Compos. Part B Eng. 2015, 81, 158–170. [Google Scholar] [CrossRef]

- Mosallam, A.S.; Mosalam, K.M. Strengthening of two-way concrete slabs with FRP composite laminates. Constr. Build. Mater. 2003, 17, 43–54. [Google Scholar] [CrossRef]

- Wong, R.S.; Vecchio, F.J. Towards modeling of reinforced concrete members with externally bonded fiber-reinforced polymer composites. ACI Struct. J. 2003, 100, 47–55. [Google Scholar] [CrossRef]

- Davids, W.G. Nonlinear analysis of FRP-glulam-concrete beams with partial composite action. J. Struct. Eng. 2001, 127, 967–971. [Google Scholar] [CrossRef]

- Yinh, S.; Hussain, Q.; Joyklad, P.; Chaimahawan, P.; Rattanapitikon, W.; Limkatanyu, S.; Pimanmas, A. Strengthening effect of natural fiber reinforced polymer composites (NFRP) on concrete. Case Stud. Constr. Mater. 2021, 15, e00653. [Google Scholar] [CrossRef]

- Gholampour, A.; Ozbakkaloglu, T. A review of natural fiber composites: Properties, modification and processing techniques, characterization, applications. J. Mater. Sci. 2020, 55, 829–892. [Google Scholar] [CrossRef]

- Effiong, J.U.; Ede, A.N. Experimental Investigation on the Strengthening of Reinforced Concrete Beams Using Externally Bonded and Near-Surface Mounted Natural Fibre Reinforced Polymer Composites. Materials 2022, 15, 5848. [Google Scholar] [CrossRef]

- David, E.; Ragneau, E.; Buyle-Bodin, F. Experimental study and modeling of the flexural behavior of RC beams reinforced by composite bonding. Rev. Fr. Génie Civ. 2001, 5, 1181–1195. [Google Scholar] [CrossRef]

- Mostofinejad, D.; Shameli, S.M. Externally bonded reinforcement in grooves (EBRIG) technique to postpone debonding of FRP sheets in strengthened concrete beams. Constr. Build. Mater. 2013, 38, 751–758. [Google Scholar] [CrossRef]

- Hosseini, A.; Mostofinejad, D. Experimental investigation into bond behavior of CFRP sheets attached to concrete using EBR and EBROG techniques. Compos. Part B Eng. 2013, 51, 130–139. [Google Scholar] [CrossRef]

- Mostofinejad, D.; Hosseini, S.A.; Razavi, S.B. Influence of different bonding and wrapping techniques on performance of beams strengthened in shear using CFRP reinforcement. Constr. Build. Mater. 2016, 116, 310–320. [Google Scholar] [CrossRef]

- Hosseini, A.; Mostofinejad, D. Effect of groove characteristics on CFRP-to-concrete bond behavior of EBROG joints: Experimental study using particle image velocimetry (PIV). Constr. Build. Mater. 2013, 49, 364–373. [Google Scholar] [CrossRef]

- Merdas, A.; Fiorio, B.; Chikh, N.E. Adhérence de joncs et plats composites mis en place dans le béton selon la méthode NSM. In Proceedings of the 29th University Meeting of Civil Engineering, Tlemcen, Algeria, 29–31 May 2011. [Google Scholar]

- Capozucca, R. Static and dynamic response of damaged RC beams strengthened with NSM CFRP rods. Compos. Struct. 2009, 91, 237–248. [Google Scholar] [CrossRef]

- El-Hacha, R.; Rizkalla, S. Near-surface mounted fiber reinforced polymer reinforcement for flexural strengthening of concrete structures. ACI Struct. J. 2004, 101, 717–726. [Google Scholar]

- Szabò, Z.K.; Balazs, G.L. Near surface mounted FRP reinforcement for strengthening of concrete structures. Civ. Eng. 2007, 51, 33–38. [Google Scholar] [CrossRef]

- Mosallam, A.S.; Ghabban, N.; Mirnateghi, E.; Agwa, A.A.K. Nonlinear numerical simulation and experimental verification of bondline strength of CFRP strips embedded in concrete for NSM strengthening applications. Struct. Concr. 2022, 23, 1794–1815. [Google Scholar] [CrossRef]

- Mosallam, A.S.; Ghaban, N.; Mirnateghi, E.; Khalek, A.A.; Mahdy, I.; Xin, H. Structural evaluation of RC overhang cantilever slab strengthened with FRP near-surface mounted (NSM) composites for bridge applications. Struct. Concr. 2024, 25, 1105–1128. [Google Scholar] [CrossRef]

- Seo, S.; Yoon, S.; Kwon, Y.; Choi, K. Bond behavior between near surface-mounted fiber reinforced polymer plates and concrete in structural strengthening. J. Korea Concr. Inst. 2011, 23, 75–82. [Google Scholar]

- Bilotta, A.; Ceroni, F.; Barros, J.A.; Costa, I.; Palmieri, A.; Szabó, Z.K.; Nigro, E.; Matthys, S.; Balazs, G.L.; Pecce, M. Bond of NSM FRP-strengthened concrete: Round robin test initiative. J. Compos. Constr. 2016, 20, 04015026. [Google Scholar] [CrossRef]

- De Lorenzis, L.; Nanni, A. Shear strengthening of reinforced concrete beams with near-surface mounted fiber-reinforced polymer rods. ACI Struct. J. 2001, 98, 60–68. [Google Scholar]

- De Lorenzis, L.; Teng, J.G. Near-surface mounted FRP reinforcement: An emerging technique for strengthening structures. Compos. Part B Eng. 2007, 38, 119–143. [Google Scholar] [CrossRef]

- Sharaky, I.A.; Torres, L.; Baena, M.; Miàs, C. An experimental study of different factors affecting the bond of NSM FRP bars in concrete. Compos. Struct. 2013, 99, 350–365. [Google Scholar] [CrossRef]

- Khodja, A. Performance et caractérisation à l’arrachement des tiges en FRP de carbone utilisées pour renforcement au cisaillement par la méthode ETS. Master’s Thesis, ÉTS Higher Technology School, Montreal, QC, Canada, May 2012.

- Chaallal, O.; Mofidi, A.; Benmokrane, B.; Neale, K. Embedded through-section FRP rod method for shear strengthening of RC beams: Performance and comparison with existing techniques. J. Compos. Constr. 2011, 15, 374–383. [Google Scholar] [CrossRef]

- Yan, L.; Kasal, B.; Huang, L. A review of recent research on the use of cellulosic fibres, their fibre fabric reinforced cementitious, geo-polymer and polymer composites in civil engineering. Compos. Part B Eng. 2016, 92, 94–132. [Google Scholar] [CrossRef]

- Cervantes, I.; AungYong, L.; Chan, K.; Ko, Y.-F.; Mendez, S. Flexural retrofitting of reinforced concrete structures using Green Natural Fiber Reinforced Polymer plates. In Proceedings of the ICSI 2014: Creating Infrastructure for a Sustainable World, São Paulo, Brazil, 8–11 June 2014; pp. 1051–1062. [Google Scholar]

- Sen, T.; Reddy, H.J. Pretreatment of woven jute FRP composite and its use in strengthening of reinforced concrete beams in flexure. Adv. Mater. Sci. Eng. 2013, 2013, 128158. [Google Scholar] [CrossRef]

- Ed-Dariy, Y.; Lamdouar, N.; Cherradi, T.; Rotaru, A.; Barbuta, M.; Mihai, P. The Influence of the Curing Conditions on the Behavior of Jute Fibers Reinforced Concrete Cylinders. Period. Polytech. Civ. Eng. 2021, 65, 1162–1173. [Google Scholar] [CrossRef]

- Tan, H.; Yan, L.; Huang, L.; Wang, Y.; Li, H.; Chen, J.Y. Behavior of sisal fiber concrete cylinders externally wrapped with jute FRP. Polym. Compos. 2017, 38, 1910–1917. [Google Scholar] [CrossRef]

- Huang, L.; Yan, B.; Yan, L.; Xu, Q.; Tan, H.; Kasal, B. Reinforced concrete beams strengthened with externally bonded natural flax FRP plates. Compos. Part B Eng. 2016, 91, 569–578. [Google Scholar] [CrossRef]

- Tanvir, A.; El-Gawady, Y.H.; Al-Maadeed, M. Cellulose nanofibers to assist the release of healing agents in epoxy coatings. Prog. Org. Coat. 2017, 112, 127–132. [Google Scholar] [CrossRef]

- Ngo, M.D. Renforcement au Cisaillement des Poutres en Béton Armé par Matériaux Composites naturels (Fibre de Lin). Ph.D. Thesis, Université de Lyon, Lyon, France, September 2016.

- Ed-Dariy, Y.; Lamdour, N.; Cherradi, T.; Rotaru, A.; Barbuta, M.; Mihai, P.; Judele, L. The Behavior of Concrete Cylinders Confined by JFRP Composites: Effect of KOH Solution. In Proceedings of the 5th World Congress on Civil, Structural, and Environmental Engineering, Lisbon, Portugal, 18–20 October 2020. [Google Scholar]

- Ed-Dariy, Y.; Lamdour, N.; Cherradi, T.; Rotaru, A.; Barbuta, M.; Mihai, P. Effect of alkali treatment of Jute fibers on the compressive strength of normal-strength concrete members strengthened with JFRP composites. Tamkang J. Eng. Sci. 2020, 23, 677–685. [Google Scholar]

- Ed-Dariy, Y.; Lamdouar, N.; Cherradi, T.; Rotaru, A.; Barbuta, M.; Mihai, P.; Judele, L. Experimental investigation of the effects of NaOH and KOH solution on the behavior of concrete square columns reinforced by JFRP Composites. In Proceedings of the 5th World Congress on Civil, Structural, and Environmental Engineering, Lisbon, Portugal, 18–20 October 2020. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ed-Dariy, Y.; El Bhiri, B.; Deifalla, A. A Review of Concrete Strengthening Methods Using Synthetic and Natural Composites. Eng. Proc. 2025, 112, 35. https://doi.org/10.3390/engproc2025112035

Ed-Dariy Y, El Bhiri B, Deifalla A. A Review of Concrete Strengthening Methods Using Synthetic and Natural Composites. Engineering Proceedings. 2025; 112(1):35. https://doi.org/10.3390/engproc2025112035

Chicago/Turabian StyleEd-Dariy, Yasmina, Brahim El Bhiri, and Ahmed Deifalla. 2025. "A Review of Concrete Strengthening Methods Using Synthetic and Natural Composites" Engineering Proceedings 112, no. 1: 35. https://doi.org/10.3390/engproc2025112035

APA StyleEd-Dariy, Y., El Bhiri, B., & Deifalla, A. (2025). A Review of Concrete Strengthening Methods Using Synthetic and Natural Composites. Engineering Proceedings, 112(1), 35. https://doi.org/10.3390/engproc2025112035