Expansive Soils Stabilized with Recycled Polypropylene Fibers: An Assessment Based on Laboratory and Life Cycle Data for Mechanical and Environmental Performance †

Abstract

1. Introduction

2. Materials and Methodology

2.1. Soil

2.2. Propylene Fiber

2.3. Sample Preparation

2.4. Test Procedure

3. Results and Discussions

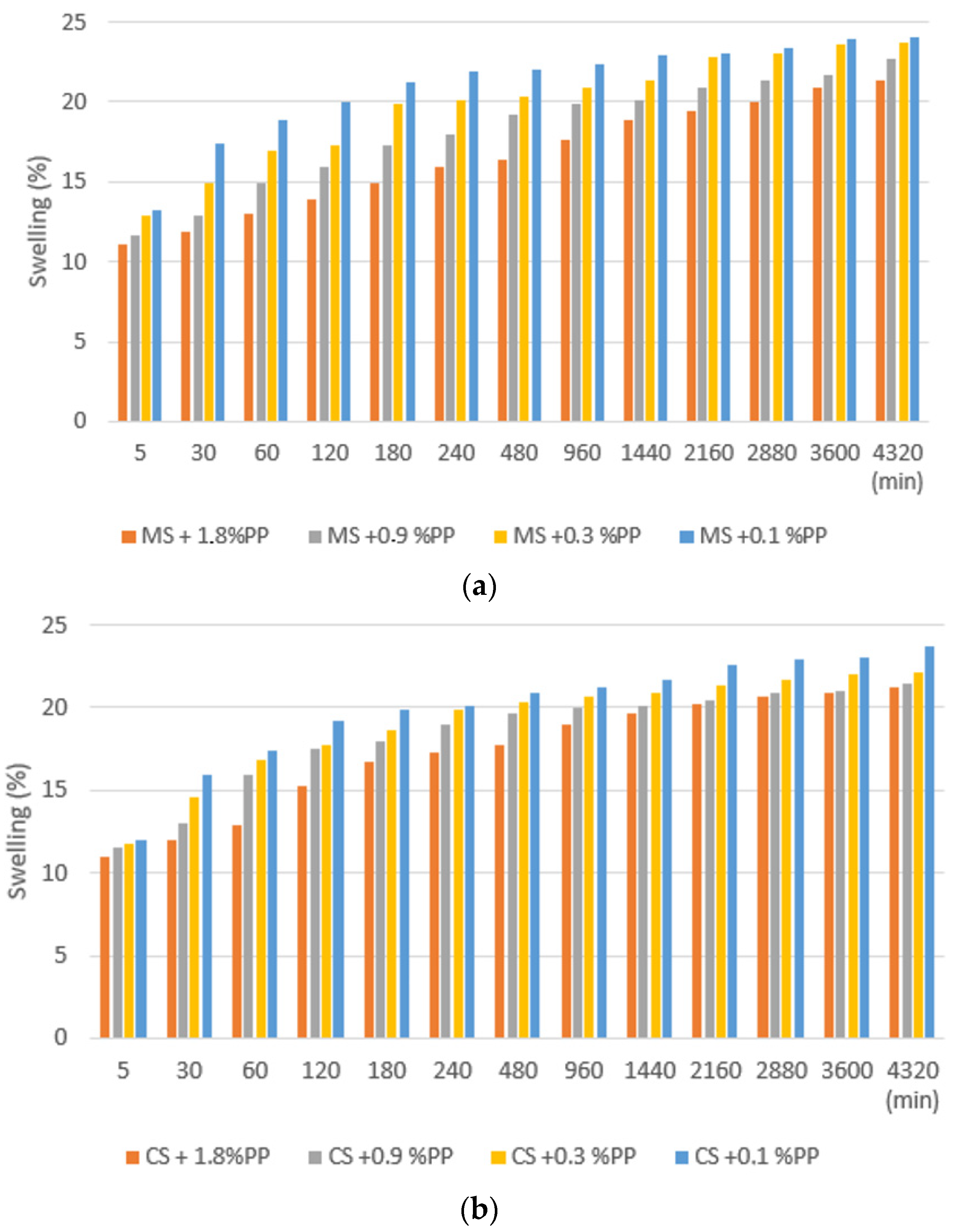

3.1. Effect of PP Sweepers’ Brush Filament on Swelling Soils

- Reduced Swelling Potential: Soil samples treated with PP filaments showed a 15–20% decrease in swelling relative to untreated soil.

- Improved Shear Strength: The addition of PP fibers increased soil shear strength by 12–18%, depending on fiber content.

- Optimum Fiber concentration: The best performance was found at 0.3–0.5% PP fiber concentration by weight, after which excessive fibers caused clumping and decreased efficacy.

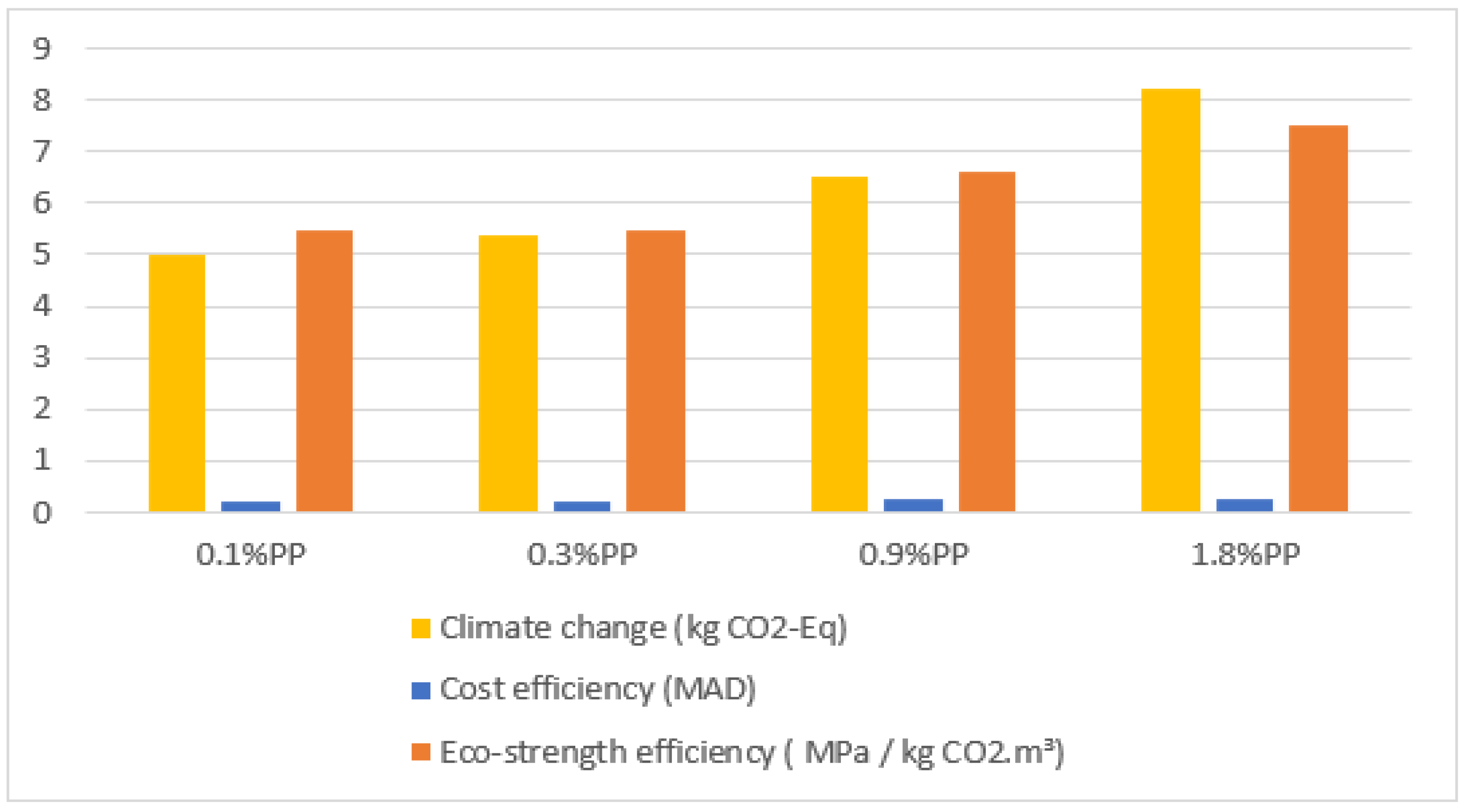

3.2. Life Cycle Assessment (LCA) Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jones, L.D.; Jefferson, I. Expansive Soils. In ICE Manual of Geotechnical Engineering Volume 1: Geotechnical Engineering Principles, Problematic Soils and Site Investigation; Brown, M., Burland, J., Chapman, T., Higgins, K., Skimmer, H., Toll, D., Eds.; ICE Publishing: London, UK, 2012; pp. 447–477. [Google Scholar]

- Nelson, J.D.; Chao, K.C.; Overton, D.D.; Nelson, E.J. Foundation Engineering for Expansive Soils; John Wiley & Sons: Hoboken, NJ, USA, 2015. [Google Scholar]

- Al-Rawas, A.A.; Goosen, M.F.A. Expansive Soils: Recent Advances in Characterization and Treatment; Taylor & Francis: Abingdon, UK, 2006. [Google Scholar]

- Al-Rawas, A.A.; Hago, A.W.; Al-Sarmi, H. Effect of Lime, Cement and Sarooj (Artificial Pozzolan) on the Swelling Potential of an Expansive Soil from Oman. Build. Environ. 2005, 40, 681–687. [Google Scholar] [CrossRef]

- Puppala, A.J.; Hoyos, L.R.; Potturi, A.K. Resilient Moduli Response of Moderately Cement-Treated Reclaimed Asphalt Pavement Aggregates. J. Mater. Civ. Eng. 2011, 23, 990–998. [Google Scholar] [CrossRef]

- Andrew, R.M. Global CO2 Emissions from Cement Production. Earth Syst. Sci. Data. 2018, 10, 195–217. [Google Scholar] [CrossRef]

- Tang, C.-S.; Shi, B.; Zhao, L.-Z. Interfacial Shear Strength of Fiber Reinforced Soil. Geotext. Geomembr. 2010, 28, 54–62. [Google Scholar] [CrossRef]

- Ahmad, F.; Bateni, F.; Azmi, M. Performance Evaluation of Silty Sand Reinforced with Fibres. Geotext. Geomembr. 2010, 28, 93–99. [Google Scholar] [CrossRef]

- Correia, A.A.; Oliveira, P.J.V.; Custódio, D.G. Effect of Polypropylene Fibres on the Compressive and Tensile Strength of a Soft Soil, Artificially Stabilised with Binders. Geotext. Geomembr. 2015, 43, 97–106. [Google Scholar] [CrossRef]

- Consoli, N.C.; Montardo, J.P.; Prietto, P.D.M.; Pasa, G.S. Engineering Behavior of a Sand Reinforced with Plastic Waste. J. Geotech. Geoenviron. Eng. 2002, 128, 462–472. [Google Scholar] [CrossRef]

- Yetimoglu, T.; Salbas, O. A Study on Shear Strength of Sands Reinforced with Randomly Distributed Discrete Fibers. Geotext. Geomembr. 2003, 21, 103–110. [Google Scholar] [CrossRef]

- Park, S.-S. Effect of Fiber Reinforcement and Distribution on Unconfined Compressive Strength of Fiber-Reinforced Cemented Sand. Geotext. Geomembr. 2009, 27, 162–166. [Google Scholar]

- Choudhary, A.K.; Jha, J.N.; Gill, K.S. A Study on CBR Behavior of Waste Plastic Strip Reinforced Soil. Emir. J. Eng. Res. 2010, 15, 51–57. [Google Scholar]

- Huntzinger, D.N.; Eatmon, T.D. A Life-Cycle Assessment of Portland Cement Manufacturing: Comparing the Traditional Process with Alternative Technologies. J. Clean. Prod. 2009, 17, 668–675. [Google Scholar] [CrossRef]

- Bläsing, M.; Amelung, W. Plastics in Soil: Analytical Methods and Possible Sources. Sci. Total Environ. 2018, 612, 422–435. [Google Scholar] [CrossRef]

- Maaitah, O.N. Soil Stabilization by Chemical Agent. Geotech. Geol. Eng. 2012, 30, 1345–1356. [Google Scholar] [CrossRef]

- Xie, L.; Xu, H.; Wang, Z.P.; Li, X.J.; Chen, J.B.; Zhang, Z.J.; Yin, H.M.; Zhong, G.J.; Lei, J.; Li, Z.M. Toward faster degradation for natural fiber reinforced poly(lactic acid) biocomposites by enhancing the hydrolysis-induced surface erosion. J. Polym. Res. 2014, 21, 357. [Google Scholar] [CrossRef]

- Cywar, R.M.; Rorrer, N.A.; Hoyt, C.B.; Beckham, G.T.; Chen, E.Y.X. Bio-based polymers with performance-advantaged properties. Nat. Rev. Mater. 2022, 7, 83–103. [Google Scholar] [CrossRef]

- Sorvari, J.; Wahlström, M. Industrial by-products. In Handbook of Recycling: State-of-the-Art for Practitioners, Analysts, and Scientists; Elsevier: Amsterdam, The Netherlands, 2024; pp. 259–285. [Google Scholar] [CrossRef]

- Vijayvergiya, V.N.; Ghazzaly, O.I. Prediction of Swelling Potential for Natural Clays. In Proceedings of the 3rd International Conference on Expansive Soils, Haifa, Israel, 30 July–1 August 1973; Volume 1, pp. 227–236. [Google Scholar]

- Bigot, G.; Zerhouni, M.I. Retrait, gonflement et tassement des sols fins. Bull.-Lab. Ponts Chaussées. 2000, 10, 105–114. [Google Scholar]

- Van Olphen, H. Clay Mineralogy. In An Introduction to Clay Colloid Chemistry; John Wiley & Sons: New York, NY, USA, 1963; Volume 27, pp. 69–71. [Google Scholar]

- Williams, A.; Donaldson, G. Building on Expansive Soils in South Africa: 1973–1980. In Expansive Soils; ASCE: Reston, VA, USA, 1980. [Google Scholar]

- Dakshanamurthy, V.; Raman, V. A Simple Method of Identifying an Expansive Soil. Soils Found. 1973, 13, 97–104. [Google Scholar] [CrossRef]

- Majid, A.; Baba, K. Assessing the Impact of Plant Fibers on Swelling Parameters of Two Varieties of Expansive Soil. Case Stud. Chem. Environ. Eng. 2023, 8, 100408. [Google Scholar] [CrossRef]

- Majid, A.; Baba, K.; Razzouk, Y. Mitigating Soil Swelling: Exploring the Efficacy of Polypropylene Fiber Reinforcement in Controlling Expansion of Expansive Soils. In The Scientific Conference on Geosciences and Environmental Management (GeoME); Springer Nature: Cham, Switzerland, 2023; pp. 183–192. [Google Scholar]

- Majid, A.; Baba, K.; Razzouk, Y. Comparative Analysis of Swelling Mitigation in Marl and Clay Soils: Natural Plant Fibers (Alfa, Jute, Sisal) vs. Polypropylene Fiber with Lime-Pozzolana Cement Utilizing Proctor Compaction. Bull. Tomsk. Polytech. Univ. Geo Assets Eng. 2024, 335, 52–63. [Google Scholar] [CrossRef]

- Garcia-Garcia, G.; Martín-Lara, M.Á.; Calero, M.; Ortega, F.; Blázquez, G. Life-Cycle Assessment of the Thermal and Catalytic Pyrolysis over Sepiolite of Face Masks. Sci. Total Environ. 2023, 895, 165063. [Google Scholar] [CrossRef]

- Chottemada, P.G.; Mishra, A.; Thomas, R.J.; Kar, A. Evaluation of Long-Term Properties and Life Cycle Assessment of Alkali-Activated Concrete with Varying Fiber Inclusions. Constr. Build. Mater. 2024, 431, 136437. [Google Scholar] [CrossRef]

- Zhou, X.; Zhai, Y.; Ren, K.; Cheng, Z.; Shen, X.; Zhang, T.; Bai, Y.; Jia, Y.; Hong, J. Life Cycle Assessment of Polycarbonate Production: Proposed Optimization Toward Sustainability. Resour. Conserv. Recycl. 2023, 189, 106765. [Google Scholar] [CrossRef]

| Reference | Lithological Section |

|---|---|

| CS | 0.00–0.50: Topsoil |

| 0.50–3.50: Brownish clay | |

| MS | 0.00–2.40: Brownish clay |

| 2.40–5.00: Greenish marl |

| Parameter | Clay Soil | Marl Soil |

|---|---|---|

| particle size analysis | ||

| % < 0.08 mm | 93.7 | 95.5 |

| % < 2 mm | 98.7 | 99.7 |

| % < 20 mm | 100 | 100 |

| WATER CONTENT w (%) | 16.6 | 19 |

| Atterberg limits | ||

| liquid limit LL (%) | 62 | 55 |

| plasticity index PI (%) | 38 | 37 |

| Classification | A3 | A3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

El Majid, A.; Baba, K.; Razzouk, Y. Expansive Soils Stabilized with Recycled Polypropylene Fibers: An Assessment Based on Laboratory and Life Cycle Data for Mechanical and Environmental Performance. Eng. Proc. 2025, 112, 28. https://doi.org/10.3390/engproc2025112028

El Majid A, Baba K, Razzouk Y. Expansive Soils Stabilized with Recycled Polypropylene Fibers: An Assessment Based on Laboratory and Life Cycle Data for Mechanical and Environmental Performance. Engineering Proceedings. 2025; 112(1):28. https://doi.org/10.3390/engproc2025112028

Chicago/Turabian StyleEl Majid, Ahlam, Khadija Baba, and Yassine Razzouk. 2025. "Expansive Soils Stabilized with Recycled Polypropylene Fibers: An Assessment Based on Laboratory and Life Cycle Data for Mechanical and Environmental Performance" Engineering Proceedings 112, no. 1: 28. https://doi.org/10.3390/engproc2025112028

APA StyleEl Majid, A., Baba, K., & Razzouk, Y. (2025). Expansive Soils Stabilized with Recycled Polypropylene Fibers: An Assessment Based on Laboratory and Life Cycle Data for Mechanical and Environmental Performance. Engineering Proceedings, 112(1), 28. https://doi.org/10.3390/engproc2025112028