Abstract

Water scarcity is one of the most major issues the world is facing at the moment. Solar still is one of the most economical and environment friendly technologies for desalinizing brackish and salty water. An experimental study on controllable parameters affecting the performance of a basin-type single-slope solar still was conducted in order to optimize them to achieve maximum productivity. The effects of three parameters, i.e., the basin water depth, the thickness of the glass cover, and glass cover cooling, on the distillate output of the solar still were studied. The effects of basin water depths of 2 cm, 3 cm, and 4 cm were tested experimentally, and the cumulative distillate output observed was 1.614, 1.444, and 1.386 L/day respectively. Glass cover thicknesses of 4 mm and 6 mm were used and the distillate output at these glass thickness was 1.587 and 1.078 L/day. In the comparative analysis of solar still performance with and without water showering, a distillate output of 2.022 L/day was found in the case of water showering, and an output of 1.587 L/day was observed in the case of no water showering on the glass cover.

1. Introduction

As the population of the world increases rapidly, the demand for fresh water is also increasing. The majority of water present in the form of lakes, seas, and oceans is saline and unfit for human consumption [1]. According to the UNO, 2.2 billion people across the globe lack access to fresh drinking water [2]. The desalination of water using solar energy is one of the most economical and feasible solutions to this problem, as solar energy is totally free and readily available. One of the simplest solar desalination technologies is the solar still [3].

A solar still separates salts and contaminants from water by heating it with solar energy. Polluted water is evaporated and the vapor formed is condensed on a clear sloping glass cover to yield distilled water [4]. One major issue with solar still technology is that it has a low distillate output and requires a large surface area for a reasonable distillate output [5]. Extensive research has been carried out in the past on different techniques to enhance the distillate output of solar stills, including glass cover cooling, electrical heater utilization to heat the basin water, external condensation, and the use of phase change materials [6].

Jam et.al conducted a study on the use of thermoelectric cooler modules to improve the productivity of a solar still, and a 570% yield enhancement was observed after connecting the hot side of the modules with the base plate and the cold side with the solar still’s glass cover [7]. AIKtranee et.al investigated the experimental effect of the Fresnel lens on solar still distillate enhancement, and an increase in output of up to 68.6% was observed after using the Fresnel lens on the solar still [8]. Attia et.al used different materials for the base plate in solar stills, and the solar still with a copper base plate produced the maximum distillate output compared to solar stills with base plates made of steel and zinc [9]. Muguran et.al investigated the effect of basin pressure on solar still productivity and found that a low basin pressure led to higher rates of water evaporation and condensation, and ultimately to a higher distillate output [10]. Nagaraju et.al found that the distillate output was increased by up to 71.4% by placing a sand trough in the basin water [11]. The external mirror effect of concentrating sunlight on the basin water was studied by Al-Mezeini el.al, and it was noted that with the external mirror, the distillate output of the solar still increased from 2.68 L/day to 3.075 L/day [12]. Kabeel et.al investigated the effect of red bricks coated with cement on solar still productivity, and found that the distillate output increased to 5.6 kg/day from 2.6 kg/day after using the cement-coated bricks [13]. In another study, Kabeel et.al used hollow circular-shaped copper fins and paraffin wax (PCM) in the tank below the absorber plate, and the distillate output observed was 8.1 L/m2/day, whereas the output of the conventional solar still was 4.02 L/m2/day [14]. Shoeibi et.al investigated the effect of thermoelectric heating and cooling on a solar still with a double slope glass cover, and observed a productivity enhancement of 2.32 times as compared to a conventional solar still [15]. Siddula et.al, through experimental investigation, found that the distillate output of a triangular-basin solar still was 3.67 kg/m2, a relative increase compared to that of a square-basin solar still, which was found to be 3.29 kg/m2 [16].

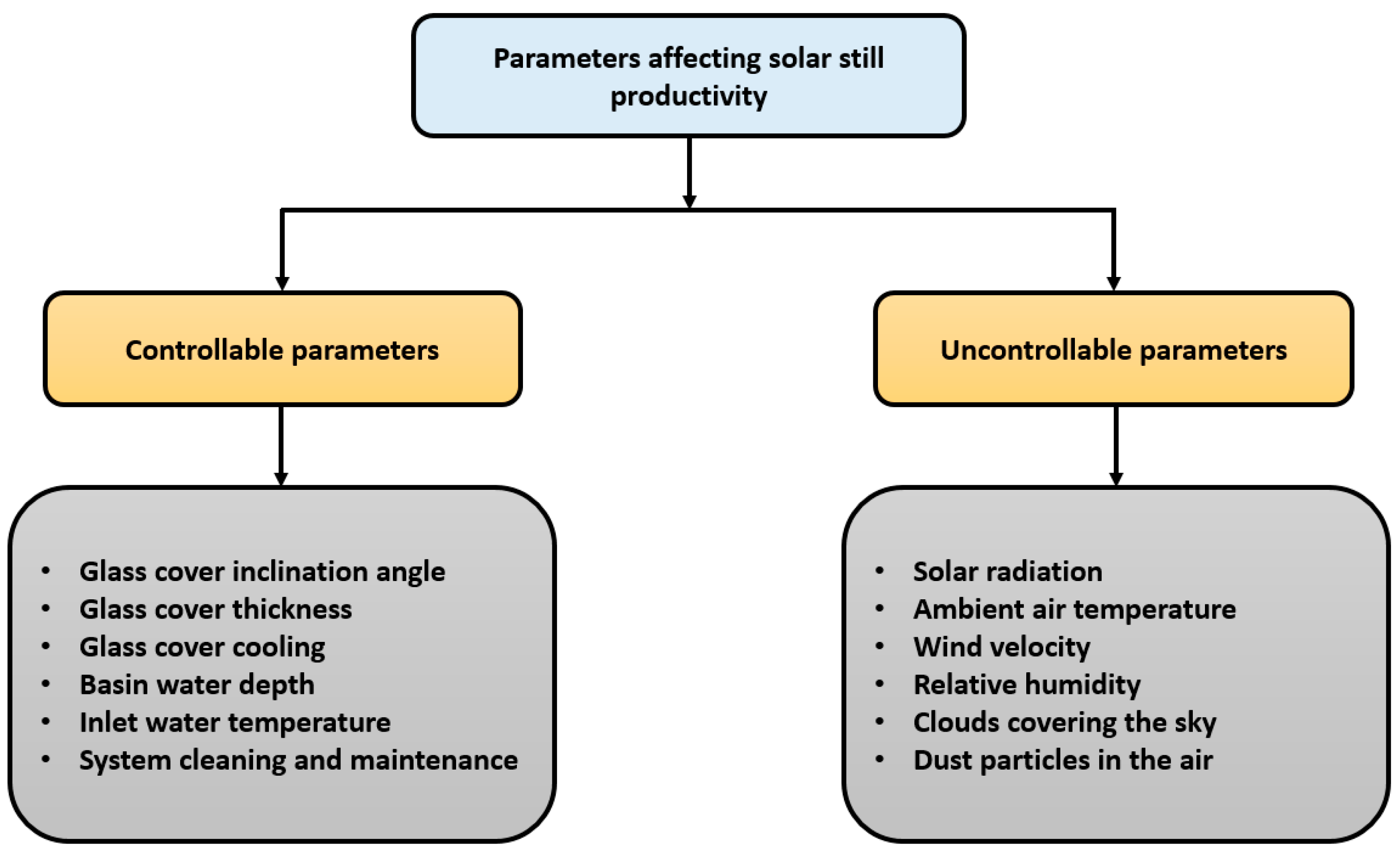

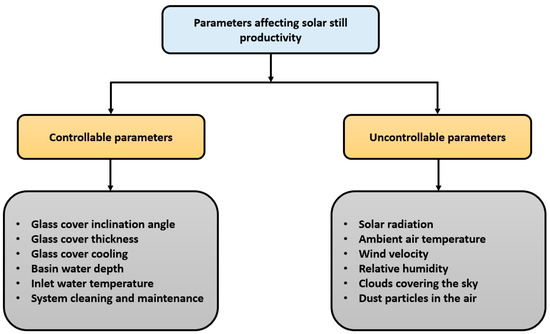

The parameters affecting solar still output can be categorized into two types: controllable parameters and uncontrollable parameters [17]. Details on these parameters are shown in Figure 1.

Figure 1.

Parameters affecting solar still productivity.

The objective of this research was to experimentally examine the effect of various controllable parameters, i.e., the basin water depth, the thickness of glass cover, and glass cover cooling, on the productivity of a basin-type single-slope solar still. Separate testing was performed for each parameter in order to find its optimized value for maximum solar still productivity.

2. Experimental Setup

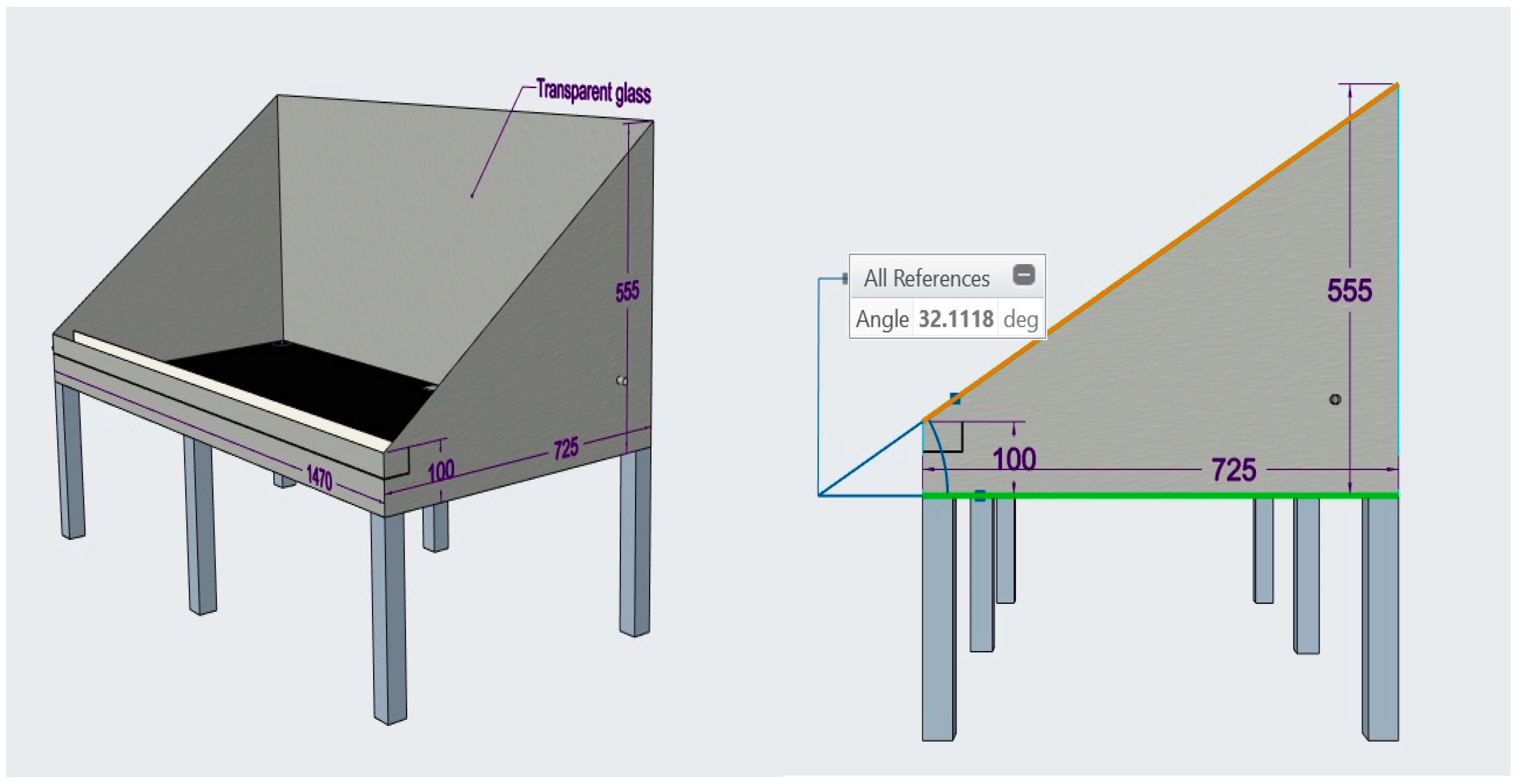

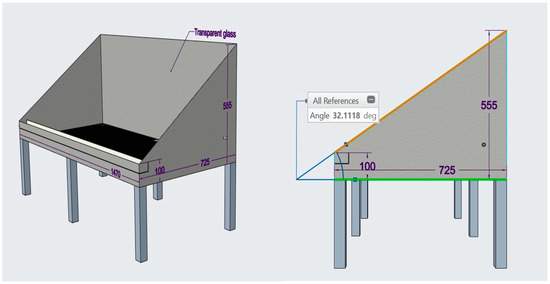

The experimental setup consisted of a passive basin-type solar still with a single-slope glass cover. The solar still was made of mild steel [18]. Transparent glass with thicknesses of 4 mm and 6 mm was used. The glass inclination angle was kept at 32° in relation to the latitude of the location in which the testing was performed (i.e., Sargodha) [19]. The dimensions of the solar still are shown in Table 1. The water level was maintained constant using a solenoid valve and a water level sensor. The temperature of the metal body, outside of the glass, inside of the glass, basin water, and basin was measured using five thermocouples (DS18B20). All the thermocouples were connected to a microcontroller (ESP32). The system was programmed to upload logged parameters such as the water temperature, glass cover temperature, and metal body temperature to the Thing Speak cloud each minute for remote analysis and monitoring. The microcontroller also regulated the solenoid valve. The specifications of the electrical components are shown in Table 2. Distilled water was collected using a graduated cylinder, and production was measured hourly. Showering of water droplets on the outside section of the glass was also performed manually. The experiments were carried out using glass with thicknesses of 4 mm and 6 mm. The effect of varying water depths on productivity was also analyzed. The solar still was airtight and sealed using silicone.

Table 1.

Dimensions of solar still.

Table 2.

Electrical component specifications.

A detailed schematic diagram of the single-slope solar still, with labeled dimensions, is shown in Figure 2.

Figure 2.

Solar still schematic diagram with labeled dimensions.

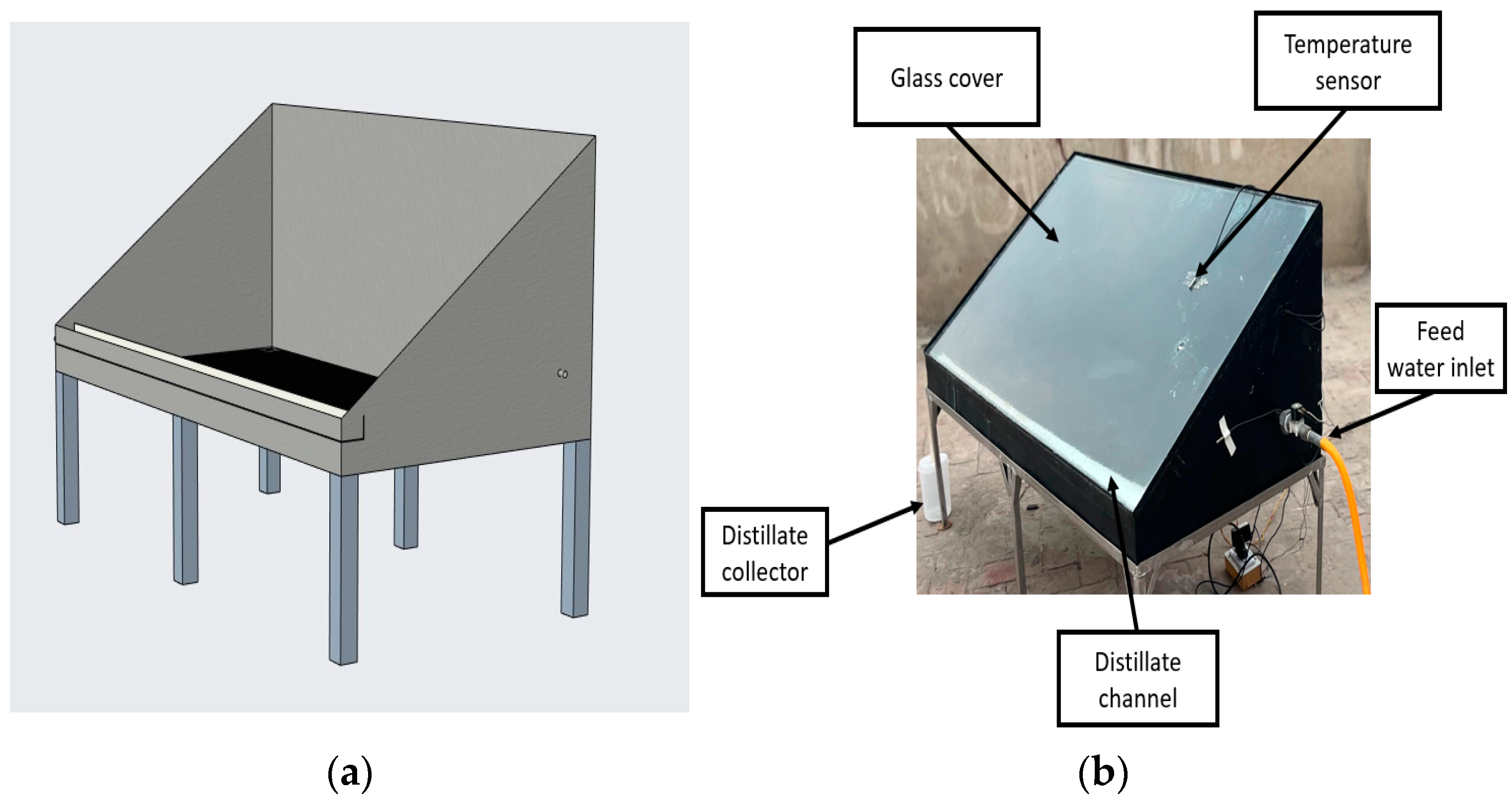

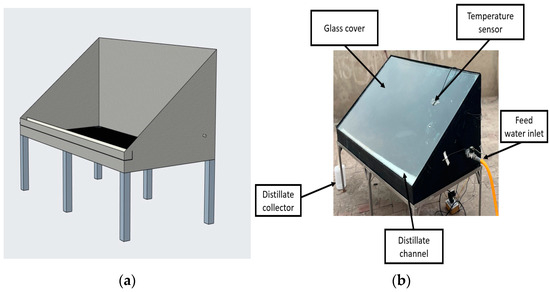

The solar still CAD model and experimental setup are shown in Figure 3.

Figure 3.

(a) Solar still CAD model; (b) solar still experimental setup.

3. Results and Discussion

This section explain the experimental effect of the three different parameters (basin water depth, glass cover thickness, and glass cover cooling) on the performance of the solar still. The experiments were conducted in Sargodha Punjab, Pakistan, in April, from 8:00 AM to 5:00 PM.

3.1. Effect of Basin Water Depth

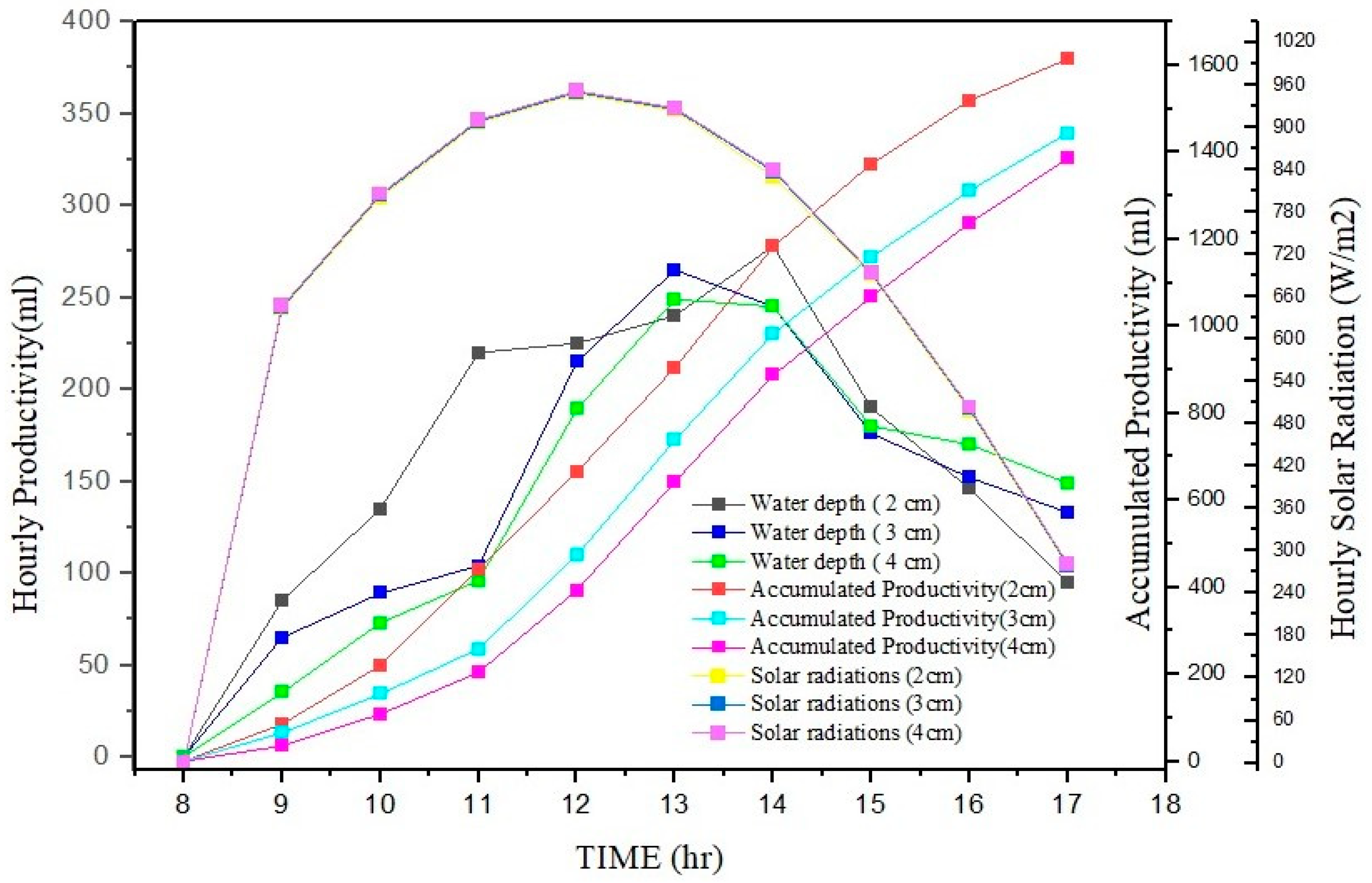

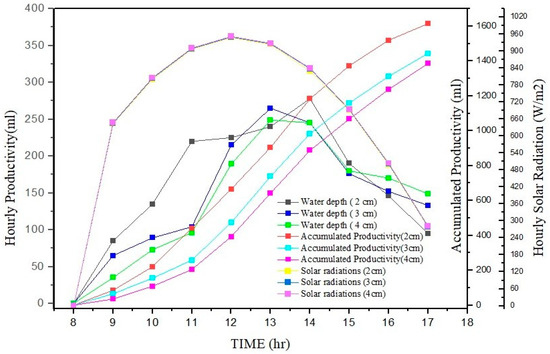

The basin water depth has a significant effect on the performance of the solar still. In this study, different experiments were performed with water depths of 2 cm, 3 cm, and 4 cm. The hourly and accumulated distillate output at these water depths is shown in Table 3.

Table 3.

Comparison of distillate output with different water depths.

This study shows an inverse relation between water depth and productivity. With an increase in the water depth, a decrease in solar still productivity was observed. Hourly readings of solar irradiance were recorded separately in each water depth case, and are shown in Table 4. It can be clearly seen that the values of solar irradiance are almost the same for these three cases, so a good comparative analysis can be drawn for the distillate output with varying basin water depths. The highest yield was recorded with the minimum water depth of 2 cm, while the lowest yield was recorded with maximum depth of 4 cm, as shown in Figure 4.

Table 4.

Comparison of solar irradiance in different water depth cases.

Figure 4.

Hourly and accumulated distilled water output of solar still (with water depths of 2 cm, 3 cm, and 4 cm).

The rate of evaporation increases with a decrease in water depth due to an increase in the basin water temperature. At a lower water depth level, the solar energy is more efficiently absorbed by the water as compared to with a large volume of water. The maximum productivity for each water depth was observed between 12 and 2 pm. It can be easily observed from Figure 4 that the solar radiation remained almost the same throughout the observation period in each case.

3.2. Effect of Glass Cover Thickness

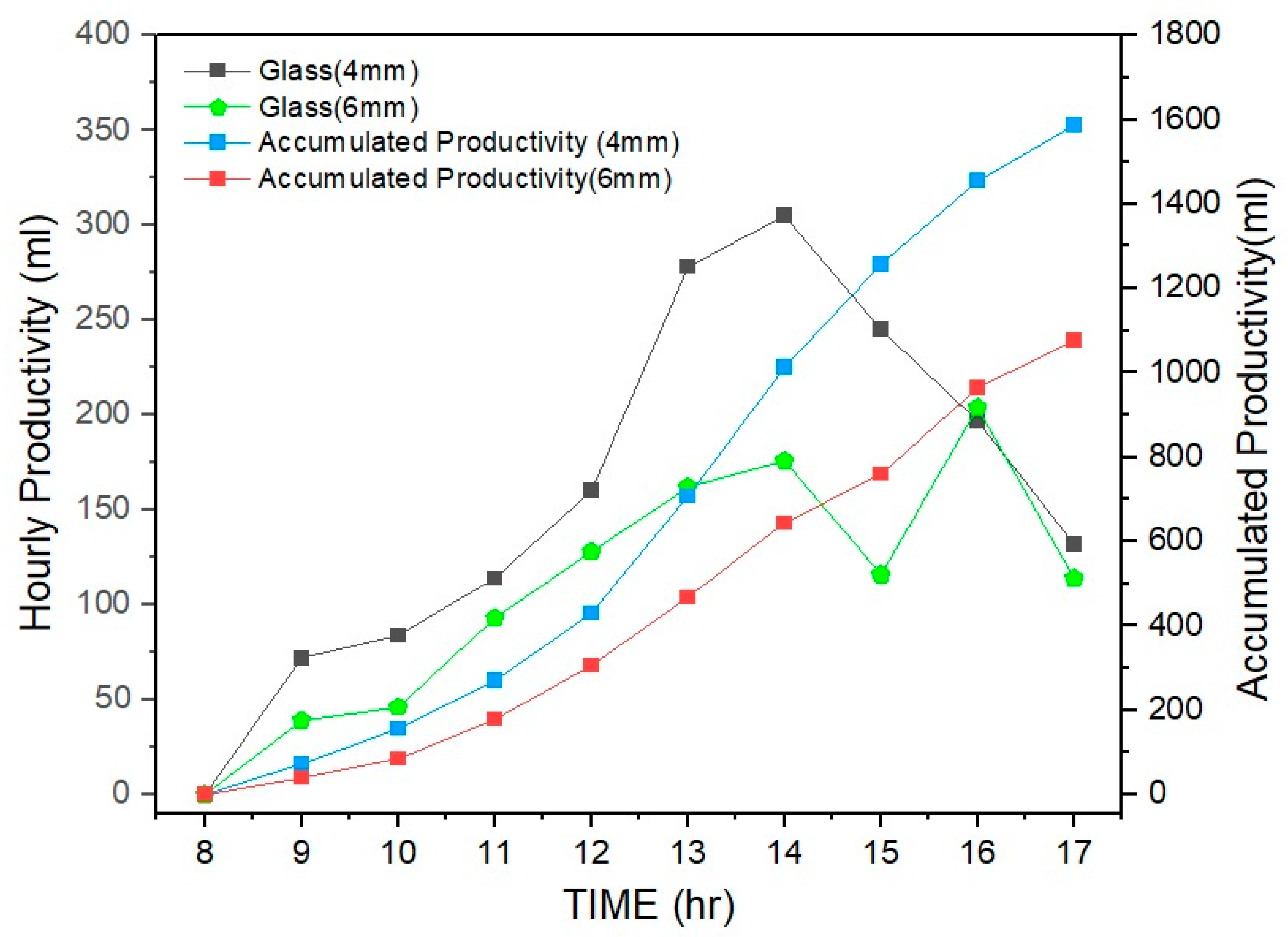

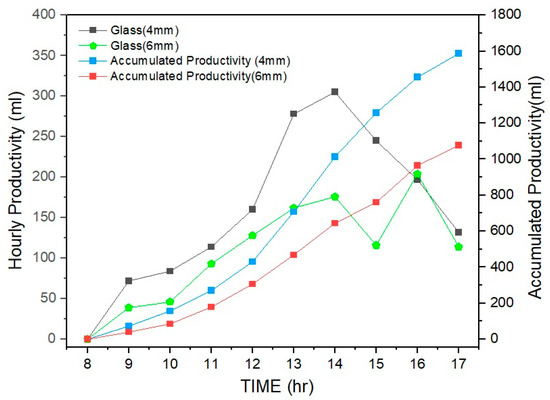

The impact of glass cover thickness on the productivity of the solar still was studied by comparing 4 mm and 6 mm glass thicknesses. The water depth was kept the same (i.e., 2 cm) in all cases. Hourly distillate outputs were recorded from 8:00 a.m. to 5:00 p.m., as shown in Table 5.

Table 5.

Comparison of distillate output with glass thicknesses of 4 mm and 6 mm.

The trend of hourly productivity can be seen in Figure 5. The total distillate output when using the 4 mm and the 6 mm glass cover was 1587 mL and 1078 mL. The productivity of the solar still with the 4 mm glass cover was 32% higher than that of the solar still with the 6 mm glass cover. The 4 mm glass has higher solar transmittance as compared to the 6 mm glass, which allows the more solar radiation to reach the water surface and consequently increases the rate of evaporation.

Figure 5.

Hourly and accumulated distilled water output of solar still with 4 mm and 6 mm glass covers.

The 6 mm glass is thicker, so it allows less solar radiation to reach the water. The temperatures of the basin water were marginally higher in the case of the 4 mm glass cover. Thinner glass warms up more rapidly and enables faster heat transfer.

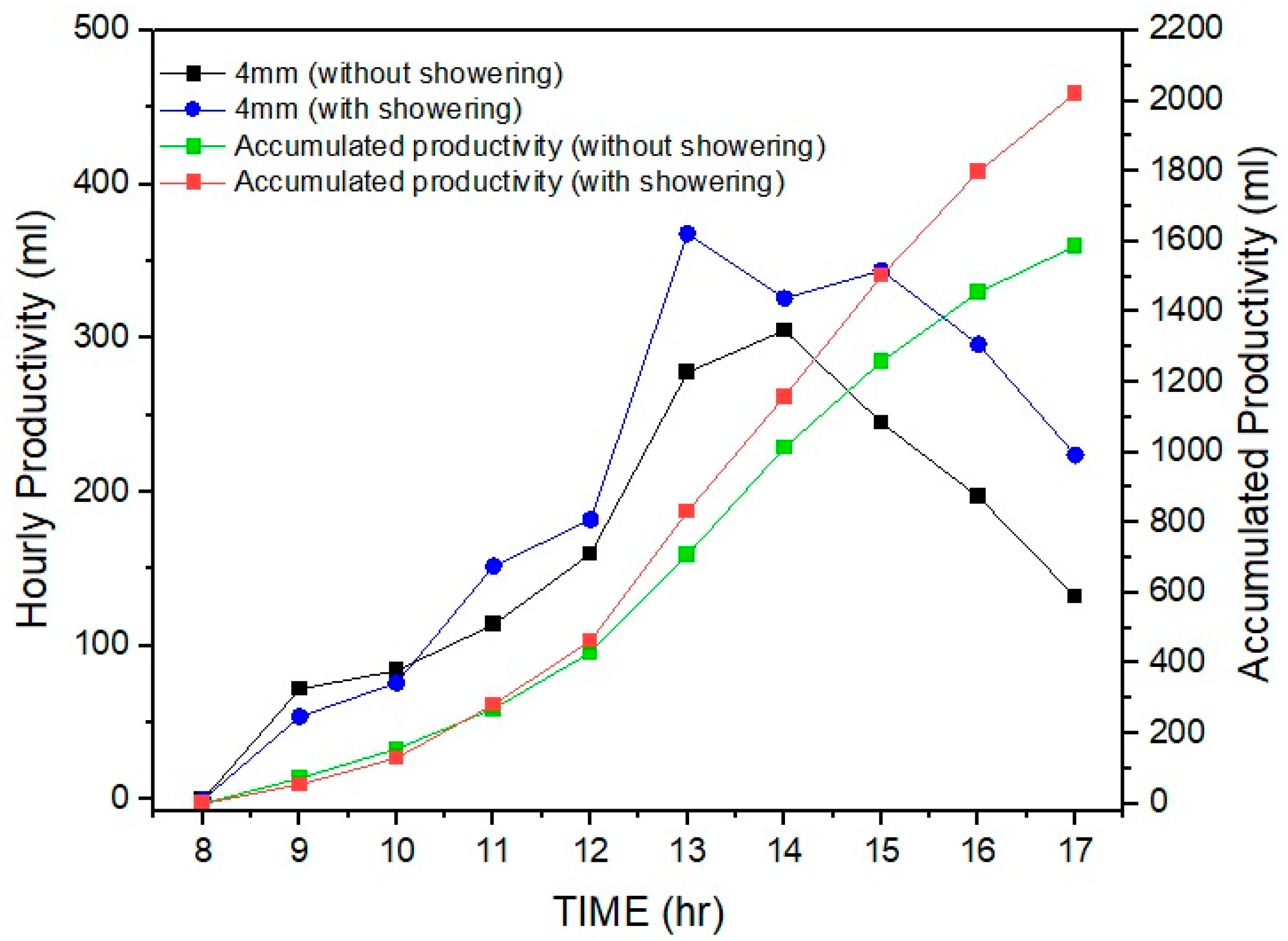

3.3. Effect of Glass Cover Cooling

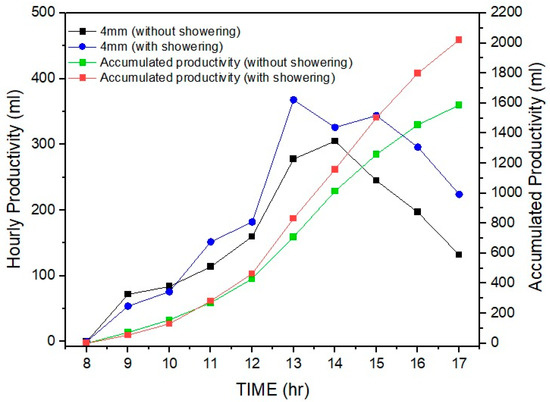

This section evaluates the performance of two configurations of the solar still: one with a glass thickness of 4 mm under standard conditions, and the other with 4 mm glass and manual showering of the glass cover to increase the condensation rate. The experiments were conducted from 8:00 AM to 5:00 PM and the hourly distillate output was recorded, as shown in Table 6. In the second configuration, the glass surface was cooled by manual showering every 30 min.

Table 6.

Comparison of distillate output of solar still with 4 mm glass with and without showering.

This experimental study revealed that cooling down the glass surface increases the condensation rate, and as a result, productivity is enhanced. The hourly and accumulated output of the solar still (with and without showering) is shown in Figure 6.

Figure 6.

Hourly and accumulated distilled water output of solar still with 4 mm glass cover (with and without showering).

The curve shows that from 9:00 a.m. to 12 p.m., both of the systems—with and without showering—show almost the same results. At 1:00 p.m., the setup yields the highest productivity of 368 mL (with glass cover cooling) and 278 mL at the same time (in the case of no glass cover cooling). Overall, the curve shows that productivity increases with enhanced solar radiation, reaching its maximum at 1:00 pm and then declining due to lower radiation intensity. The solar still performs much better with the glass cover cooling mechanism, due to there being a greater temperature difference between the basin water and glass cover [20]. In terms of accumulated productivity, the system with water showering on the glass cover shows higher performance (2022 mL) at the end of the day as compared to the setup with no glass cover cooling mechanism (1587 mL).

4. Conclusions

This study demonstrates the effect of three controllable parameters, i.e., basin water depth, glass cover thickness, and glass cover cooling, on the distillate output of a basin-type single-slope solar still. The optimized values of these parameters to achieve the maximum distillate output of the solar still were experimentally investigated. Separate experimental studies were conducted to observe the effect of each parameter independently. It was observed that with an increase in the water depth in the basin from 2 cm to 4 cm, the distillate output of the solar still decreased, so an inverse relation was found between the basin water depth and the distillate output of the solar still. The values of distillate output at 2, 3, and 4 cm were found to be 1.614, 1.444, and 1.386 L/day respectively, so the solar still performance was 10.5% better with a water depth of 2 cm than with a depth of 3 cm, and 14.1% better than with a 4 cm water depth, in terms of distillate output.

The relation between distillate output and glass cover thickness was also found to be inverse. The solar stills with glass cover thicknesses of 4 mm and 6 mm produced a distillate output of 1.587 L/day and 1.078 L/day respectively, so the solar still with the 4 mm glass cover thickness showed a 32% better output than the solar still with a 6 mm glass cover.

Glass cover cooling showed a positive effect on the distillate output of the solar still. The distillate output of the solar still was observed to be 2.022 L/day, which was 21.5% higher than that of the solar still without the glass cover cooling mechanism, at 1.587 L/day.

The performance of the solar still reached its maximum (2.022 L) with a water depth of 2 cm, glass cover thickness of 4 mm, and cooling mechanism for the glass cover.

Author Contributions

Conceptualization, N.M.M. and M.A.Z.; methodology, N.M.M.; software, M.S. (Muhammad Shahmeer) and M.S. (Mubeen Shehzad).; validation, M.S. (Muhammad Shahmeer) and M.S. (Mubeen Shehzad).; formal analysis, N.M.M.; investigation, N.M.M.; resources, M.S. (Muhammad Shahmeer).; data curation, M.A.Z.; writing—original draft preparation, N.M.M.; writing—review and editing, N.M.M. and M.A.Z.; visualization, M.S. (Mubeen Shehzad).; supervision, M.A.Z.; project administration, N.M.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Subramanian, K.; Meenakshisundaram, N.; Barmavatu, P.; Govindarajan, B. Experimental investigation on the effect of nano-enhanced phase change materials on the thermal performance of single slope solar still. Desalination Water Treat. 2024, 319, 100416. [Google Scholar] [CrossRef]

- Kumar, A.; Srishti; Paras. ANSYS Fluent-CFD analysis of a continuous single-slope single-basin type solar still. Green Technol. Sustain. 2024, 2, 100105. [Google Scholar]

- Katekar, V.P.; Deshmukh, S.S. A review on research trends in solar still designs for domestic and industrial applications. J. Clean. Prod. 2020, 257, 120544. [Google Scholar] [CrossRef]

- Uthappan, K.; Murugesan, S.; Karuppasamy, G.; Thangavel, K. Experimental investigation of single slope solar still for culinary wastewater treatment. Sol. Compass 2024, 12, 100095. [Google Scholar] [CrossRef]

- Mohaisen, H.S.; Alhusseny, A. Enhancing productivity and cost-effectiveness of single-slope solar stills using a multi-cavity built-in condenser: Experimental and performance analysis. Clean. Eng. Technol. 2025, 26, 100970. [Google Scholar] [CrossRef]

- Shoeibi, S.; Rahbar, N.; Esfahlani, A.A.; Kargarsharifabad, H. A review of techniques for simultaneous enhancement of evaporation and condensation rates in solar stills. Sol. Energy 2021, 225, 666–693. [Google Scholar] [CrossRef]

- Jam, R.F.; Gholizadeh, M.; Deymi-Dashtebayaz, M.; Khanjani, S.; Dartoomi, N. Experimental investigation of the thermoelectric and double-glazed glass effects on the performance of a solar still. Appl. Therm. Eng. 2024, 246, 122898. [Google Scholar] [CrossRef]

- AlKtranee, M.H.; Al-Yasiri, Q.; Kabeel, A.E. Improving the productivity of a single-slope solar still using Fresnel lenses under Iraq climatic conditions. Desalination Water Treat. 2020, 205, 22–30. [Google Scholar] [CrossRef]

- Attia, M.E.H.; Manokar, A.M.; Driss, Z.; Sathyamurthy, R.; Al-Kouz, W. Comparative study of a conventional solar still with different basin materials using exergy analysis. Desalination Water Treat. 2021, 224, 55–64. [Google Scholar] [CrossRef]

- Murugan, D.K.; Elumalai, N.; Subramani, S. Experimental investigation on the effect of basin pressure in a single basin solar still. Desalination Water Treat. 2021, 229, 10–16. [Google Scholar] [CrossRef]

- Nagaraju, V.; Murali, G.; Bewoor, A.K.; Kumar, R.; Sharifpur, M.; Assad, M.E.H.; Awad, M.M. Experimental study on performance of single slope solar still integrated with sand troughs. Sustain. Energy Technol. Assess. 2022, 50, 101884. [Google Scholar] [CrossRef]

- Al-Mezeini, S.S.S.; Siddiqui, M.A.; Shariq, M.; Althagafi, T.M.; Ahmed, I.A.; Asif, M.; Alsufyani, S.J.; Algarni, S.A.; Ahamed, M.B.N.; Elamin, K.M.A.; et al. Design and Experimental Studies on a Single Slope Solar Still for Water Desalination. Water 2023, 15, 704. [Google Scholar] [CrossRef]

- Kabeel, A.E.; El-Agouz, E.S.; Athikesavan, M.M.; Duraisamy Ramalingam, R.; Sathyamurthy, R.; Prakash, N.; Prasad, C. Comparative analysis on freshwater yield from conventional basin-type single slope solar still with cement-coated red bricks: An experimental approach. Environ. Sci. Pollut. Res. 2020, 27, 32218–32228. [Google Scholar] [CrossRef] [PubMed]

- Kabeel, A.E.; El-Maghlany, W.M.; Abdelgaied, M.; Abdel-Aziz, M.M. Performance enhancement of pyramid-shaped solar stills using hollow circular fins and phase change materials. J. Energy Storage 2020, 31, 101610. [Google Scholar] [CrossRef]

- Shoeibi, S.; Rahbar, N.; Esfahlani, A.A.; Kargarsharifabad, H. Application of simultaneous thermoelectric cooling and heating to improve the performance of a solar still: An experimental study and exergy analysis. Appl. Energy 2020, 263, 114581. [Google Scholar] [CrossRef]

- Siddula, S.; Stalin, N.; Mahesha, C.R.; Dattu, V.S.; Singh, D.P.; Mohanavel, V.; Sathyamurthy, R. Triangular and single slope solar stills: Performance and yield studies with different water mass. Energy Rep. 2022, 8, 480–488. [Google Scholar] [CrossRef]

- Malik, N.M.; Khalid, W.; Nasir, M.T.; Talha, M. Predicting the Performance of a Basin-Type Solar Still at Different Locations in Pakistan Using a Mathematical Model. Eng. Proc. 2024, 75, 33. [Google Scholar]

- Rajaseenivasan, T.; Murugavel, K.K.; Elango, T. Performance and exergy analysis of a double-basin solar still with different materials in basin. Desalination Water Treat. 2015, 55, 1786–1794. [Google Scholar] [CrossRef]

- Singh, S.K.; Kaushik, S.C.; Tyagi, V.V.; Tyagi, S.K. Comparative Performance and parametric study of solar still: A review. Sustain. Energy Technol. Assess. 2021, 47, 101541. [Google Scholar] [CrossRef]

- Muftah, A.F.; Alghoul, M.A.; Fudholi, A.; Abdul-Majeed, M.M.; Sopian, K. Factors affecting basin type solar still productivity: A detailed review. Renew. Sustain. Energy Rev. 2014, 32, 430–447. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).